Académique Documents

Professionnel Documents

Culture Documents

PSM 1200535 PSM PDF

Transféré par

PaoloFregonaraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PSM 1200535 PSM PDF

Transféré par

PaoloFregonaraDroits d'auteur :

Formats disponibles

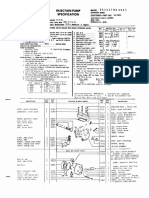

W.S. DARLEY & CO.

OPERATING INSTRUCTIONS - ELECTRIC PRIMING PUMP

The Darley electric primer will develop up to 25 in. Hg. in an air tight pumping system.

The Primer is activated by a combination spring return on-off valve and electric switch. Pulling the valve

out opens the valve and closes the electrical circuit to start the motor.

Before the pump can be primed, booster line valves, drain valves, cooling line valve, and all other

openings into the pump must be closed and absolutely air tight. The discharge side of the pump is

sealed by a check valve, therefore the main discharge valves need not be closed.

When operating from draft, suction hose connections must be tight and free of air leaks.

Make certain the suction hose strainer is properly submerged and free of foreign material.

The main pump drive should remain disengaged until priming is complete to prevent possible damage to

impeller seal rings by running “dry”.

Pull the primer shutoff valve all the way out to start priming and hold open until water discharges from

primer pump exhaust port. Push valve all the way in to shut off primer motor and seal tight.

CAUTION: FOR PRIMING UP TO 10’ OF LIFT:

If water does not discharge from the primer exhaust

within about 30 seconds (45 seconds with 2 – 20’

lengths of hose) stop the primer pump, check for air

leaks and make sure primer pump is receiving lubricant

from its reservoir, if one is present. MAX PRIMER

OPERATION TIME = 90 seconds every 5 minutes. DO

NOT EXCEED 90 SECONDS OF PRIMER OPERATION.

CAUTION: FOR PRIMING 10’ OF LIFT AND HIGHER:

If water does not discharge from the primer exhaust

within 90 seconds stop the primer pump, check for air

leaks and make sure primer pump is receiving lubricant

from its reservoir, if one is present. DO NOT EXCEED

90 SECONDS OF PRIMER OPERATION.

CAUTION: The primer pump and motor will begin to generate heat as

soon as operation begins. Extended run times (up to 90

seconds) and repeating priming cycles consecutively or

within short time periods may lead to premature failure

of the primer pump assembly: such failures include but

are not limited to: overheating of the motor, seizure of

the rotor, and cracking of primer vanes. To avoid this,

after your first priming attempt, thoroughly inspect the

pump system for air leaks, check that the primer is

Prepared by: EAP Rev. #: F

Revised by: TED Date: 12/1/08

Approved by: TED 1 1200512

Revision Date: 12/31/14

Vous aimerez peut-être aussi

- Vacuum - Condenser Presentasi 2Document17 pagesVacuum - Condenser Presentasi 2Neon PhoerbaPas encore d'évaluation

- NFPA 1521 Skill TestDocument31 pagesNFPA 1521 Skill TestPaoloFregonaraPas encore d'évaluation

- Gate Valve Inspection ChecklistDocument2 pagesGate Valve Inspection ChecklisternmrajaPas encore d'évaluation

- On-Vehicle Inspection: - RadiatorDocument2 pagesOn-Vehicle Inspection: - RadiatorsalusfrankPas encore d'évaluation

- On Vehicle Inspection: RadiatorDocument2 pagesOn Vehicle Inspection: RadiatorMiguel ruizPas encore d'évaluation

- Birla MEEP Op ManualDocument43 pagesBirla MEEP Op ManualAshok ChettiyarPas encore d'évaluation

- AC PROV OPERATION & MAINTENANCE-rev2.compressedDocument2 pagesAC PROV OPERATION & MAINTENANCE-rev2.compressedMuhammed RiazPas encore d'évaluation

- Robinson VacDocument10 pagesRobinson VacJajajaPas encore d'évaluation

- Cold Startup ProcedureDocument8 pagesCold Startup ProcedureRahul KurmiPas encore d'évaluation

- LP301A LP600 4000 InstDocument1 pageLP301A LP600 4000 InstSERVICIOS ESPECIALIZADOS EN LUBRICACIÓNPas encore d'évaluation

- 0 Evv PQ0 M 8 Py 4 Laf R4 CPXWFOSXDocument4 pages0 Evv PQ0 M 8 Py 4 Laf R4 CPXWFOSXGjjddPas encore d'évaluation

- Penguin - Magnetic Drive Pump M SeiresDocument4 pagesPenguin - Magnetic Drive Pump M SeiresMiguel Angel LòpezPas encore d'évaluation

- Water Ace PumpDocument20 pagesWater Ace PumpDana Milner100% (1)

- Robinair Bombas de Vacío 15401 601Document32 pagesRobinair Bombas de Vacío 15401 601MarcWorld100% (1)

- Precommissioning Load TrialDocument47 pagesPrecommissioning Load Trialyinkaakins2001100% (3)

- Ball Valve BrochureDocument6 pagesBall Valve BrochureRohith GrandhiPas encore d'évaluation

- Drain ValveDocument1 pageDrain ValveJose MontielPas encore d'évaluation

- Vincke Gear Pumps CatDocument48 pagesVincke Gear Pumps CatVelibor KaranovicPas encore d'évaluation

- Installation Manual APSDocument14 pagesInstallation Manual APSTharaka MethsaraPas encore d'évaluation

- Udor Maintenance Trouble ShootingDocument4 pagesUdor Maintenance Trouble ShootingMONA100% (1)

- Udor Kappa 30Document6 pagesUdor Kappa 30DanutPas encore d'évaluation

- User Manual White PumpDocument14 pagesUser Manual White PumpbacabacabacaPas encore d'évaluation

- Mud Pumps Manual PDFDocument48 pagesMud Pumps Manual PDFMohamed Benlarbi100% (5)

- 2 - Troubleshooting Hydro Pumps - GB - 2008Document13 pages2 - Troubleshooting Hydro Pumps - GB - 2008Jorge Antonio DelgadoPas encore d'évaluation

- 22.5mw Siemens R On 16.11.09Document135 pages22.5mw Siemens R On 16.11.09Priyank Shukla100% (1)

- Bomba HydracellDocument9 pagesBomba HydracellHelison MendesPas encore d'évaluation

- 3.10 Ej 4396 SjaeDocument60 pages3.10 Ej 4396 SjaeCuong TranPas encore d'évaluation

- 23 KKK TurbineDocument1 page23 KKK Turbineshoaib705Pas encore d'évaluation

- HFM 15ppm Bilge Separator Operation ManualDocument24 pagesHFM 15ppm Bilge Separator Operation ManualNguyen Phuoc HoPas encore d'évaluation

- Manual Operación - Prensa P15 PMTDocument15 pagesManual Operación - Prensa P15 PMTMorales Pérez MarianaPas encore d'évaluation

- CONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)Document11 pagesCONTRACT No.14023 DATE 20.03.2014 Sirajganj 225Mw Combined Cycle Power Plant Project (2 Unit-Dual Fuel)VictorPas encore d'évaluation

- Rocker 400 Introduction Manual en - V2016.03 enDocument5 pagesRocker 400 Introduction Manual en - V2016.03 endayanara886Pas encore d'évaluation

- thermCA en Stand 2013 03 18Document56 pagesthermCA en Stand 2013 03 18mohamed ghareebPas encore d'évaluation

- PT 102662 Iom UsDocument5 pagesPT 102662 Iom UsMo ZeroPas encore d'évaluation

- D SeriesDocument20 pagesD SeriesJorge A VilalPas encore d'évaluation

- HFM 15ppm Bilge Separator - Operation ManualDocument24 pagesHFM 15ppm Bilge Separator - Operation ManualÖzgürMetin100% (5)

- PURIFIERSDocument7 pagesPURIFIERSjames dogelioPas encore d'évaluation

- Turbine Shaft Sealing System FINALDocument18 pagesTurbine Shaft Sealing System FINALMuhammad luqmanPas encore d'évaluation

- MM-18 - Bilge Separator - OPERATION MANUALDocument24 pagesMM-18 - Bilge Separator - OPERATION MANUALKyaw Swar Latt100% (2)

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1Pas encore d'évaluation

- Model BX: Industrial PumpsDocument8 pagesModel BX: Industrial PumpsF81Pas encore d'évaluation

- CPP 3000 BDocument2 pagesCPP 3000 BMarco NucciarelliPas encore d'évaluation

- LYX100 ManualDocument12 pagesLYX100 ManualEMMAPas encore d'évaluation

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfPas encore d'évaluation

- TURBIN (Operating Instruction)Document3 pagesTURBIN (Operating Instruction)AriefSh JuniorPas encore d'évaluation

- FH3 EL FHT ManualDocument2 pagesFH3 EL FHT ManualRubi WantoPas encore d'évaluation

- Cyclone CompressorDocument4 pagesCyclone CompressorElton HodgesPas encore d'évaluation

- 1 5-EnDocument14 pages1 5-EnThong Kin MunPas encore d'évaluation

- User S Guide KDDocument22 pagesUser S Guide KDEmil KochanekPas encore d'évaluation

- Boiler Sop RevDocument17 pagesBoiler Sop RevDhilip AnPas encore d'évaluation

- Rocker 300 Introduction Manual en - V2016.03 ENDocument4 pagesRocker 300 Introduction Manual en - V2016.03 ENAdnan AtefPas encore d'évaluation

- Super Max 12800 ManualDocument12 pagesSuper Max 12800 ManualFranz MonsantoPas encore d'évaluation

- Power Team PE30 ManualDocument6 pagesPower Team PE30 ManualTitanplyPas encore d'évaluation

- Manufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)Document2 pagesManufacturer'S Operating Instructions TEST PUMP MODEL DP-Series (3/4/6/8/56-250)babjihanumanthuPas encore d'évaluation

- 3300 Series Installation ManualDocument2 pages3300 Series Installation ManualMarceloGonçalvesPas encore d'évaluation

- Erection and Commissioning of Power TransformerDocument24 pagesErection and Commissioning of Power TransformerAnonymous wl7fgzivP0% (1)

- 001 Final Presentation - Size4-3 DAY 1Document97 pages001 Final Presentation - Size4-3 DAY 1AlWaleed KhalidPas encore d'évaluation

- Maintenance Mstruction: DescriptionDocument11 pagesMaintenance Mstruction: Descriptionamir barekatiPas encore d'évaluation

- Pressure Washer Operations ManualDocument16 pagesPressure Washer Operations ManualkhalidcosmosPas encore d'évaluation

- Conexiones Control de Lubricación Lincoln Model 84050 (Series "F")Document8 pagesConexiones Control de Lubricación Lincoln Model 84050 (Series "F")MERCH 06Pas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Safety at The Medical or Rescue EmergencyDocument13 pagesSafety at The Medical or Rescue EmergencyPaoloFregonaraPas encore d'évaluation

- East Courtenay Fire Dept Project Final 13 May 2014 PDFDocument46 pagesEast Courtenay Fire Dept Project Final 13 May 2014 PDFPaoloFregonaraPas encore d'évaluation

- Press - Release - Osaka - University - Japan - OZONO - COVID19Document2 pagesPress - Release - Osaka - University - Japan - OZONO - COVID19PaoloFregonaraPas encore d'évaluation

- East Courtenay Fire Dept Project Final 13 May 2014 PDFDocument46 pagesEast Courtenay Fire Dept Project Final 13 May 2014 PDFPaoloFregonaraPas encore d'évaluation

- Safety at The Medical or Rescue EmergencyDocument13 pagesSafety at The Medical or Rescue EmergencyPaoloFregonaraPas encore d'évaluation

- Coronavirus-Leaflet EN 2901Document2 pagesCoronavirus-Leaflet EN 2901PaoloFregonaraPas encore d'évaluation

- PSM 1200535 PSM PDFDocument1 pagePSM 1200535 PSM PDFPaoloFregonaraPas encore d'évaluation

- Safety Program Development and ManagementDocument18 pagesSafety Program Development and ManagementPaoloFregonaraPas encore d'évaluation

- Application Checklist: Staffing For Adequate Fire and Emergency Response (SAFER)Document6 pagesApplication Checklist: Staffing For Adequate Fire and Emergency Response (SAFER)PaoloFregonaraPas encore d'évaluation

- NFPA 1521 Descriptor CursoDocument3 pagesNFPA 1521 Descriptor CursoPaoloFregonaraPas encore d'évaluation

- Nims Training ProgramDocument85 pagesNims Training Programravikumar19834853Pas encore d'évaluation

- Files MGMT217NTGSMF PDFDocument322 pagesFiles MGMT217NTGSMF PDFPaoloFregonaraPas encore d'évaluation

- East Courtenay Fire Dept Project Final 13 May 2014 PDFDocument46 pagesEast Courtenay Fire Dept Project Final 13 May 2014 PDFPaoloFregonaraPas encore d'évaluation

- ISO Manual Del EstudianteDocument190 pagesISO Manual Del EstudiantePaoloFregonaraPas encore d'évaluation

- CORRECTED IAP 10-14-19 To 10-18-19Document26 pagesCORRECTED IAP 10-14-19 To 10-18-19PaoloFregonaraPas encore d'évaluation

- Basic SCBA: Self-Contained Breathing ApparatusDocument51 pagesBasic SCBA: Self-Contained Breathing ApparatusPaoloFregonaraPas encore d'évaluation

- PSM 1200535 PSM PDFDocument1 pagePSM 1200535 PSM PDFPaoloFregonaraPas encore d'évaluation

- Application Checklist: Staffing For Adequate Fire and Emergency Response (SAFER)Document6 pagesApplication Checklist: Staffing For Adequate Fire and Emergency Response (SAFER)PaoloFregonaraPas encore d'évaluation

- Basic Pump Operations Instructor Manual (Rev 7 29 13) PDFDocument53 pagesBasic Pump Operations Instructor Manual (Rev 7 29 13) PDFPaoloFregonaraPas encore d'évaluation

- Fqs Guide 2012decDocument28 pagesFqs Guide 2012decPaoloFregonaraPas encore d'évaluation

- Nims Training ProgramDocument67 pagesNims Training ProgramPaoloFregonaraPas encore d'évaluation

- ISO-Student Manual August 2013Document194 pagesISO-Student Manual August 2013PaoloFregonaraPas encore d'évaluation

- Nims Training ProgramDocument67 pagesNims Training ProgramPaoloFregonaraPas encore d'évaluation

- RRM pgs323 324Document2 pagesRRM pgs323 324PaoloFregonaraPas encore d'évaluation

- Poli Past OsDocument9 pagesPoli Past OsPaoloFregonaraPas encore d'évaluation

- Tactical Command SheetDocument1 pageTactical Command SheetPaoloFregonaraPas encore d'évaluation

- NFPA10 ExtintoresDocument0 pageNFPA10 Extintoresomatiaspe2328Pas encore d'évaluation

- Tactical Command SheetDocument1 pageTactical Command SheetPaoloFregonaraPas encore d'évaluation

- Working Principle of Hydraulic LiftDocument3 pagesWorking Principle of Hydraulic LiftNoaman Mehmood0% (1)

- Chapter 6Document1 pageChapter 6Vala PratikPas encore d'évaluation

- Ross Pump Control Valves BrochureDocument6 pagesRoss Pump Control Valves BrochureHassan HaiderPas encore d'évaluation

- Working Principle of Rotary PumpsDocument2 pagesWorking Principle of Rotary Pumpscyril john100% (1)

- Prefill Valve: RE 20478, Edition: 2017-12, Bosch Rexroth AGDocument20 pagesPrefill Valve: RE 20478, Edition: 2017-12, Bosch Rexroth AGBademianPas encore d'évaluation

- (KENR8398) Interactive Schematic - 793F OHT Hydraulic SystemDocument17 pages(KENR8398) Interactive Schematic - 793F OHT Hydraulic SystemLuisLazoPas encore d'évaluation

- Equation 1Document5 pagesEquation 1andam.abdulahPas encore d'évaluation

- Price List - Audco - 2011 - 12Document3 pagesPrice List - Audco - 2011 - 12samvendan100% (1)

- Well HydraulicsDocument25 pagesWell HydraulicsFArzand E Gul100% (1)

- C823 3 DOC MAT MEC 044 00 CRS Reply To Comments 8. 31 22Document259 pagesC823 3 DOC MAT MEC 044 00 CRS Reply To Comments 8. 31 22721917114 47Pas encore d'évaluation

- Theory of Pressure Relief, 1Document6 pagesTheory of Pressure Relief, 1petrochemPas encore d'évaluation

- SERIES 3000: Angle Surge Relief ValveDocument6 pagesSERIES 3000: Angle Surge Relief ValveMd Aamir AnsariPas encore d'évaluation

- Noxon ClipsDocument12 pagesNoxon ClipsZoran DanilovPas encore d'évaluation

- Installation, Testing, and Maintenance of Fire Hydrants: FieldDocument85 pagesInstallation, Testing, and Maintenance of Fire Hydrants: FieldCristiam MondragónPas encore d'évaluation

- Daily Report Piping Dept. 08-09Document3 pagesDaily Report Piping Dept. 08-09Rizky SkrillexPas encore d'évaluation

- 1 - Hydro Power PlantsDocument54 pages1 - Hydro Power Plantsraghurmi100% (1)

- Khanna's Qbjective Type QuestionsDocument878 pagesKhanna's Qbjective Type Questionsmohit guptaPas encore d'évaluation

- Fire and Safety Certification Training ChennaiDocument9 pagesFire and Safety Certification Training ChennaiConserve AcademyPas encore d'évaluation

- I I P P: Proinert Discharge Valve AssemblyDocument2 pagesI I P P: Proinert Discharge Valve AssemblyMohammed SbeitanPas encore d'évaluation

- AC DownloadDocument5 pagesAC DownloadJason RogersPas encore d'évaluation

- Cylinder Head 15614Document2 pagesCylinder Head 15614Guyue bePas encore d'évaluation

- Curva de Funcionamiento Bomba 2 Estacion 1 - Diametro de Impulsor 8,3 In, para Mayor EficienciaDocument4 pagesCurva de Funcionamiento Bomba 2 Estacion 1 - Diametro de Impulsor 8,3 In, para Mayor EficienciaOscar Vicente MartinezPas encore d'évaluation

- FLS BROCHURE Cameron Style FLS Gate Valve Rev 2Document4 pagesFLS BROCHURE Cameron Style FLS Gate Valve Rev 2Alex100% (1)

- Ball Valves - FITOKDocument53 pagesBall Valves - FITOKВалентин СелищевPas encore d'évaluation

- Darcys LawDocument44 pagesDarcys LawRoman Lazarescu100% (1)

- Module 3.1 Ppt3.1 PumpsDocument26 pagesModule 3.1 Ppt3.1 Pumpsjithin jacobPas encore d'évaluation

- Effect of Design and Operational Parameters On Jet Pump PerformanceDocument8 pagesEffect of Design and Operational Parameters On Jet Pump PerformancegffPas encore d'évaluation

- Calculation of Pipe Friction LossDocument33 pagesCalculation of Pipe Friction LossEyob AdPas encore d'évaluation

- Injection Pump Specification Modei.: Licet - . - . - . - . .F.%Document2 pagesInjection Pump Specification Modei.: Licet - . - . - . - . .F.%johnny sabinPas encore d'évaluation