Académique Documents

Professionnel Documents

Culture Documents

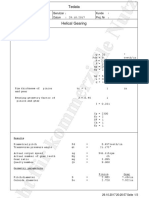

Tedata: Program User Date Customer Proj. NR: Mdesign: 1.1.2:: 10.04.2019

Transféré par

Juanjo Torrez VDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tedata: Program User Date Customer Proj. NR: Mdesign: 1.1.2:: 10.04.2019

Transféré par

Juanjo Torrez VDroits d'auteur :

Formats disponibles

Tedata

Program : MDESIGN User : Customer :

Version : 1.1.2 Date : 10.04.2019 Proj. Nr :

Spur Gearing

Input data:

Spur Gearing

Pressure angle 20°

Diametral pitch Pd = 4 teeth/in

Face width F = 1 in

Transmitted power P = 0.47 hp

Rotational speed of pinion np = 100 rpm

Number of pinion teeth Np = 19

Desired output speed ng = 100 rpm

Design life L = 25000 h

Number of load applications per q = 1

revolution

Rim thickness of pinion tr = 1 1 in

and gear

Gear application Commercial enclosed gear

units

Elastic coefficient Cp = 2300

Overload factor Ko = 2

Factor of safety SF = 1

Hardness ratio factor Ch = 1

Reliability factor Kr = 1.5

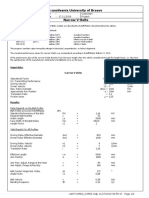

Results

Actual output speed ng = 100.000 rpm

Actual number of gear teeth Ng = 19

Gear ratio mg = 1.000

Qualty number Qv = 7.000

Geometry parameters

Pinion Gear

Pitch diameter D = 4.750 4.750 in

Outside diameter Do = 5.250 5.250 in

Root diameters Dr = 4.125 4.125 in

Base circle diameter Db = 4.464 4.464 in

Addendum a = 0.250 in

Dedendum b = 0.313 in

Clearance c = 0.063 in

Circular pitch p = 0.785 in

Whole depth ht = 0.563 in

Working depth hk = 0.500 in

Tooth thickness t = 0.393 in

04/10/2019 10:36:49 Page 1/3

Tedata

Program : MDESIGN User : Customer :

Version : 1.1.2 Date : 10.04.2019 Proj. Nr :

Spur Gearing

Center distance C = 4.750 in

Fillet radius in basic rack rf = 0.075 in

Pinion Gear

Bending geometry factor J = 0.316 0.316

Pitting geometry factor I = 0.079

Force and speed factors

Pitch line speed vt = 124.355 ft/min

Tangential force Wt = 124.674 lbf

Normal force Wn = 132.675 lbf

Radial force Wr = 45.378 lbf

Size factor Ks = 1.050

Load distribution factor Km = 1.139

Dynamic factor Kv = 1.123

Note

Face width F = 1.00 in

0

Recommended range of Face width F = 2.000 -

4.000

Face width/Pinion diameter ratio F/Dp = 0.21

1

Recommended range of ratio F/Dp = 0.500 -

2.000

Pinion Gear

Rim thickness factor Kb = 1.000 1.000

Number of load cycle Nc = 1.5e+008 1.5e+008

Bending stress cycle factor Yn = 0.970 0.970

Pitting stress cycle factor Zn = 0.940 0.940

Expected bending stress St = 4241.779 4241.779 psi

Expected contact stress Sc = 68562.919 68562.919 psi

Allowable bending stress number Sat = 6561.122 6561.122 psi

Allowable contact stress number Sac = 1.095e+005 1.095e+005 psi

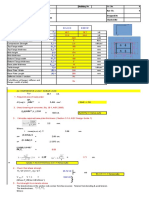

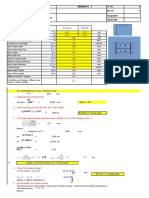

Note

After computing the values for allowable bending stress number and for

allowable

contact stress number, you should go to the data in AGMA Standard 2001-C95,

to

select a suitable material. Consider first whether the material should be

steel,

cast iron, bronze, or plastic. Then consult the related tables of data.

For instance use through-hardened steel with hardness, HB

Pinion Gear

Grade 1 249.539 249.539

04/10/2019 10:36:49 Page 2/3

Tedata

Program : MDESIGN User : Customer :

Version : 1.1.2 Date : 10.04.2019 Proj. Nr :

Spur Gearing

Grade 2 215.334 215.334

04/10/2019 10:36:49 Page 3/3

Vous aimerez peut-être aussi

- Outrigger Pad Design CalculationDocument2 pagesOutrigger Pad Design Calculationfcesar19860% (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsD'EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsPas encore d'évaluation

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiPas encore d'évaluation

- Slab Design Excel SheetDocument8 pagesSlab Design Excel SheetRajat GargPas encore d'évaluation

- Leica CME ManualDocument24 pagesLeica CME ManualMaria DapkeviciusPas encore d'évaluation

- Not For Commercial Use: TedataDocument3 pagesNot For Commercial Use: TedataMayber DelgadoPas encore d'évaluation

- Helical Gearing Design Calculations and Stress AnalysisDocument3 pagesHelical Gearing Design Calculations and Stress AnalysisJason CanoPas encore d'évaluation

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocument3 pagesTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoPas encore d'évaluation

- Caja Reductora 2da EtapaDocument2 pagesCaja Reductora 2da EtapaEdwin Paco PovedaPas encore d'évaluation

- Not For Commercial Use: TedataDocument2 pagesNot For Commercial Use: Tedatawilly rojas zeballosPas encore d'évaluation

- Astorga Entrada ConicosDocument3 pagesAstorga Entrada ConicosGadiel BalderasPas encore d'évaluation

- Machine DesignDocument15 pagesMachine DesignYaPas encore d'évaluation

- Involute Spur Gear Geometry Calculations: Input DataDocument11 pagesInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVPas encore d'évaluation

- Perhitungan Stern TubeDocument8 pagesPerhitungan Stern TubechaktimewpPas encore d'évaluation

- Segunda ChavetaDocument1 pageSegunda ChavetaAntonio MoscosoPas encore d'évaluation

- Priner ChaveteroDocument1 pagePriner ChaveteroAntonio MoscosoPas encore d'évaluation

- Chabeta Con MDESIGNDocument1 pageChabeta Con MDESIGNEbanderPas encore d'évaluation

- Nozzle Load Total GSDocument3 pagesNozzle Load Total GSdidik_wahyudiPas encore d'évaluation

- Design of Agitator 8 Batch Volume PDFDocument3 pagesDesign of Agitator 8 Batch Volume PDFakash kumarPas encore d'évaluation

- Steel Silos DesignDocument5 pagesSteel Silos Designhgag selimPas encore d'évaluation

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorRodrigo NavarretePas encore d'évaluation

- Input Data MijaDocument3 pagesInput Data MijaMijael Tarqui PortilloPas encore d'évaluation

- Pier Cap Corbel 30m SGDocument3 pagesPier Cap Corbel 30m SGSM ConsultantsPas encore d'évaluation

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JanePas encore d'évaluation

- Project:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed byDocument1 pageProject:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed bySantosh BapuPas encore d'évaluation

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Single Plate Connection - Sheet1 - 2Document3 pagesSingle Plate Connection - Sheet1 - 2AbdullahibnfulanPas encore d'évaluation

- Slab DesignDocument4 pagesSlab DesignRubina HannurePas encore d'évaluation

- Calculation and Design of Critical Speed and Power AgitatorDocument4 pagesCalculation and Design of Critical Speed and Power AgitatorFrendy RianPas encore d'évaluation

- 3) Corbel DesignDocument10 pages3) Corbel Designp_ignatiusPas encore d'évaluation

- Differentialtestreport: Test ParametersDocument2 pagesDifferentialtestreport: Test Parametersmuhammad ahsanPas encore d'évaluation

- Horizontal Vessel Foundation Design FounDocument22 pagesHorizontal Vessel Foundation Design FounAllanPas encore d'évaluation

- Davit Design and Support CalculationDocument22 pagesDavit Design and Support CalculationJagdish KotadiyaPas encore d'évaluation

- Transilvania University Designs Narrow V-BeltsDocument2 pagesTransilvania University Designs Narrow V-BeltsDiana Maria CozmaPas encore d'évaluation

- Davit Design Calculation: L 1 D V H V H V DDocument2 pagesDavit Design Calculation: L 1 D V H V H V DSiva baalanPas encore d'évaluation

- Mod10 1ToothBendingDocument4 pagesMod10 1ToothBendingMario AndradePas encore d'évaluation

- Spur Gears Component Generator ReportDocument4 pagesSpur Gears Component Generator ReportStefan MilojevicPas encore d'évaluation

- Spur Gears Component Generator Strength AnalysisDocument4 pagesSpur Gears Component Generator Strength AnalysisStefan MilojevicPas encore d'évaluation

- Spur Gears Component GeneratorDocument4 pagesSpur Gears Component GeneratorEngineering ProductionPas encore d'évaluation

- V-Belt, US StandardsDocument1 pageV-Belt, US StandardsErick SalmonesPas encore d'évaluation

- Chain Drive Calculation - 12-Jul-2017: Chain: ANSI 60 (ISO 606) Simplex Renold Synergy Serial Number: GY60A1Document1 pageChain Drive Calculation - 12-Jul-2017: Chain: ANSI 60 (ISO 606) Simplex Renold Synergy Serial Number: GY60A1Kathy Rocío GallardoPas encore d'évaluation

- Spur GearDocument5 pagesSpur GearMelindaPas encore d'évaluation

- Rectangular Expansion Joint: Description Section PDF Symbol NotesDocument3 pagesRectangular Expansion Joint: Description Section PDF Symbol NotesRufus D SPas encore d'évaluation

- Seismic and wind load calculations for vessel support structureDocument3 pagesSeismic and wind load calculations for vessel support structurecordajohnPas encore d'évaluation

- Anchor Bolt As Per BS CodeDocument16 pagesAnchor Bolt As Per BS Codesuvodip khanPas encore d'évaluation

- Anchor Bolt and Circular Base Plate Design As Per BS 5950Document16 pagesAnchor Bolt and Circular Base Plate Design As Per BS 5950Shamim Ahsan ZuberyPas encore d'évaluation

- Corbel DesignDocument5 pagesCorbel DesignHari prasad GaddamPas encore d'évaluation

- TRUNNION CHECK CN-0xxDocument2 pagesTRUNNION CHECK CN-0xxAkashPas encore d'évaluation

- Padeye Calculation Design AssumptionsDocument7 pagesPadeye Calculation Design AssumptionsRajat KatyalPas encore d'évaluation

- Check For Tension: TF TDF: MF m1 M MWDocument4 pagesCheck For Tension: TF TDF: MF m1 M MWkeerthivasan_mrvPas encore d'évaluation

- 참고자료 12. Lifting Lug AnalysisDocument3 pages참고자료 12. Lifting Lug Analysisaoaaoa1122Pas encore d'évaluation

- Langston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFDocument9 pagesLangston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFeacondePas encore d'évaluation

- Design of Cantilever Slab As Per IS 456 2000Document2 pagesDesign of Cantilever Slab As Per IS 456 2000Ram LanghePas encore d'évaluation

- Crack Width Calculation: MaterialsDocument2 pagesCrack Width Calculation: MaterialsIrfan AliPas encore d'évaluation

- Appendix CDocument6 pagesAppendix CPat SulaimanPas encore d'évaluation

- Hot-rolled steel beam section properties and classificationDocument19 pagesHot-rolled steel beam section properties and classificationken koemhongPas encore d'évaluation

- Base Plate Design for Column Base ConnectionDocument6 pagesBase Plate Design for Column Base ConnectionThuyTranPas encore d'évaluation

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranPas encore d'évaluation

- Mechanical Engineering Handbook 96 105Document10 pagesMechanical Engineering Handbook 96 105basaricaPas encore d'évaluation

- Cylindrical Compression Helix Springs For Suspension SystemsD'EverandCylindrical Compression Helix Springs For Suspension SystemsPas encore d'évaluation

- Laminar Flow Reactor ProblemDocument6 pagesLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- NeurophysiologyDocument364 pagesNeurophysiologyTaimoor Ul HassanPas encore d'évaluation

- LP Galvo Scanner LaserphotoDocument16 pagesLP Galvo Scanner LaserphotoCostin DinamaxPas encore d'évaluation

- Queries With TableDocument14 pagesQueries With TableAkhileshPas encore d'évaluation

- MT Slides Logistics (14 NovDocument24 pagesMT Slides Logistics (14 NovRyan Tw ChoumingPas encore d'évaluation

- Bombers and SeagullsDocument8 pagesBombers and SeagullshpgeraldPas encore d'évaluation

- Digital-To-Analog Converter ICs SB Vol11 Issue5Document12 pagesDigital-To-Analog Converter ICs SB Vol11 Issue5Hooman KaabiPas encore d'évaluation

- Yokogawa 2015 Centum VP For Batch ControlDocument9 pagesYokogawa 2015 Centum VP For Batch ControlArzymanPas encore d'évaluation

- Maa 2.8 ExponentsDocument12 pagesMaa 2.8 ExponentsMuborakPas encore d'évaluation

- Adverb Clause of Time (Adverbial Cause of Time)Document9 pagesAdverb Clause of Time (Adverbial Cause of Time)Toh Choon HongPas encore d'évaluation

- QST HamClockDocument3 pagesQST HamClockCPC PHCPas encore d'évaluation

- LRFD Design ExampleDocument698 pagesLRFD Design ExampleCesar RomeroPas encore d'évaluation

- Tehandler KatoDocument15 pagesTehandler KatoWalterPas encore d'évaluation

- Rational Expectation TheoryDocument7 pagesRational Expectation TheoryIsmith PokhrelPas encore d'évaluation

- ParkerDocument106 pagesParkerJoseJSanchezPas encore d'évaluation

- ICM User GuideDocument84 pagesICM User Guidewords2zhigang_612545Pas encore d'évaluation

- GR/KWH, KG/HR or Tons/Month.: ScopeDocument5 pagesGR/KWH, KG/HR or Tons/Month.: ScopeThaigroup CementPas encore d'évaluation

- Stresses in Deep Beams Analyzed Using Finite Difference MethodDocument122 pagesStresses in Deep Beams Analyzed Using Finite Difference Methodakash kumarPas encore d'évaluation

- Power-Electronics-News December-2022 HIGHDocument37 pagesPower-Electronics-News December-2022 HIGHtrival001Pas encore d'évaluation

- Rex - O. Ed. Wagner - W-Waves - BiocommDocument13 pagesRex - O. Ed. Wagner - W-Waves - BiocommLeon BlažinovićPas encore d'évaluation

- Basic use of datum planes in Creo ParametricDocument8 pagesBasic use of datum planes in Creo ParametricKartik BhararaPas encore d'évaluation

- Bus Network Topology GuideDocument8 pagesBus Network Topology GuideMjjames Manalo100% (1)

- Structural Design of Penstock - Criteria: Indian StandardDocument21 pagesStructural Design of Penstock - Criteria: Indian StandardAlok KumarPas encore d'évaluation

- Johannes KeplerDocument25 pagesJohannes KeplersigitPas encore d'évaluation

- Control Yokogawa PDFDocument59 pagesControl Yokogawa PDFmiraPas encore d'évaluation

- Flight Planning For ATTDocument106 pagesFlight Planning For ATTTienek Lee100% (1)

- MBA (Travel & Tourism) 1st Year Sylabus 2020-21 - 28th SeptDocument34 pagesMBA (Travel & Tourism) 1st Year Sylabus 2020-21 - 28th SeptHimanshuPas encore d'évaluation

- Manulife VRV System Selection for Philippines OfficeDocument7 pagesManulife VRV System Selection for Philippines Officelucio ruiz jrPas encore d'évaluation