Académique Documents

Professionnel Documents

Culture Documents

Milling Feeds and Speeds

Transféré par

Alfian KamilCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Milling Feeds and Speeds

Transféré par

Alfian KamilDroits d'auteur :

Formats disponibles

FEEDS & SPEEDS fOR MILLS & SAWS - CARBIDE TIPPED

Feeds & speeds are a starting recommendation only. Factors such as machine, fixture and tooling rigidity, horsepower available, coolant applica-

tion and others will affect the performance significantly. Please read machine operators instructions and use all safety shields and glasses before

performing these operations.

RPM=SFPM*3.82/CUTTER DIAMETER

IPM=IPT*RPM*#TEETH

IPT = Inches Per Tooth

IPM = Inches Per Minute

RPM = Rotations Per Minute

SFPM = Surface Feet Per Minute

Cutter Diameter = Diameter of the cutter in inches

APPLICATION - MILLS AND SAWS

CLASS OF SURFACE

MATERIAL INCHES PER

MATERIALS FEET PER

BRINELL TOOTH

MINUTE

(IPT)

(SFPM)

30-150*

ALUMINUM ALLOY - WROUGHT 1000-2000 .004-.008

(500kg)

MAGNESIUM ALLOY 50-90* 750-1500 .004-.008

NON-FERROUS (SOFT)

LEAD ALLOY 10-20* 300-1000 .004-.008

NON-METAL AND PLASTIC – 1500-3000 .004-.008

ZINC ALLOY - DIE CAST 80-100 750-1500 .005-.010

ALUMINUM BRONZE 40-175 200-600 .003-.006

BRASS ALLOY - LEADED AND

NON-FERROUS 10-100Rb 400-800 .004-.008

FREE CUTTING

(HARD)

NICKEL SILVER 10-100Rb 200-400 .003-.006

COPPER ALLOY - TOUGH 40-200* 200-500 .004-.008

DUCTILE CAST IRON - AUSTENITIC 120-275 75-150 .002-.004

DUCTILE CAST IRON - FERRITIC 140-270 250-400 .003-.006

DUCTILE CAST IRON - MARTENSITIC 270-400 200-300 .003-.006

CAST IRON GRAY - PEARLITIC 220-320 120-300 .002-.004

GRAY - FERRITIC 110-240 250-425 .003-.006

MALLEABLE CAST IRON -

200-320 130-225 .002-.004

MARTENSITIC

LOW AND MEDIUM CARBON STEEL -

100-240 250-500 .003-.006

LOW CARBON FREE MACHINING

STEELS LOW AND MEDIUM CARBON STEEL -

100-375 200-400 .002-.004

WROUGHT

LOW AND MEDIUM CARBON

100-275 200-400 .002-.004

ALLOY STEEL - FREE MACHINING

MEDIUM LOW AND MEDIUM CARBON

85-375 150-300 .002-.005

STRENGTH ALLOY STEEL

STEELS STAINLESS STEEL - 400 SERIES 135-325 200-400 .003-.006

STAINLESS STEEL - 400 SERIES

135-275 250-500 .003-.006

FREE MACHINING

HIGH STRENGTH HIGH STRENGTH STEEL -

175-400 75-150 .002-.004

STEELS WROUGHT & TOOL STEEL

HIGH TEMP ALLOYS

140-300 50-150 .002-.004

NICKEL & IRON BASE ALLOY

HIGH TEMP. STAINLESS STEEL - 300 SERIES 135-375 75-150 .002-.004

ALLOYS

STAINLESS STEEL - PH SERIES 150-440 75-150 .002-.004

TITANIUM ALLOY 110-380 100-200 .002-.004

www.supertoolinc.com – Phone 941-751-9677 – Fax 941-756-6480

Made in the USA *500kg

Vous aimerez peut-être aussi

- Jeopardy Powerpoint TemplateDocument31 pagesJeopardy Powerpoint TemplatetpsbellePas encore d'évaluation

- Bourbon The Rise Fall and Rebirth of An American Whiskey Fred MinnickDocument328 pagesBourbon The Rise Fall and Rebirth of An American Whiskey Fred Minnick孙艺博100% (1)

- Bomba de EspumaDocument16 pagesBomba de EspumaArmandoAndrePas encore d'évaluation

- Albinoni Adagio G-Minor Quartet SAMPLEDocument2 pagesAlbinoni Adagio G-Minor Quartet SAMPLEKylt Lestorn100% (1)

- Perfume Attars and Their HistoryDocument6 pagesPerfume Attars and Their Historykiez3b79ju100% (1)

- 100 Must-Read Fantasy Novels PDFDocument208 pages100 Must-Read Fantasy Novels PDFJoel100% (1)

- Milling Speeds and Feeds PDFDocument1 pageMilling Speeds and Feeds PDFrobPas encore d'évaluation

- Drilling Speeds and FeedsDocument1 pageDrilling Speeds and FeedsLe Hoang HiepPas encore d'évaluation

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurPas encore d'évaluation

- Recommended Cutting Speeds For Dapra SBN CuttersDocument1 pageRecommended Cutting Speeds For Dapra SBN CuttersEduardo Aleman ReynaPas encore d'évaluation

- Keyseat Cutters Speeds and FeedsDocument1 pageKeyseat Cutters Speeds and FeedsdbaPas encore d'évaluation

- Fullerton 1835 Speeds FeedsDocument1 pageFullerton 1835 Speeds FeedsGilang RamadanPas encore d'évaluation

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsMahesh Deivasiga Mani DPas encore d'évaluation

- (Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingDocument2 pages(Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingSanjay KumarPas encore d'évaluation

- MechanicalsealDocument7 pagesMechanicalsealSidne SilvaPas encore d'évaluation

- Spring Materials Typical Properties 0001Document1 pageSpring Materials Typical Properties 0001OscarEdwardsPas encore d'évaluation

- Carbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, IncDocument2 pagesCarbide Tipped Reamers - Technical Information - Hannibal Carbide Tool, Incsemarasik_651536604Pas encore d'évaluation

- 09 GasketCharacteristicValues PDFDocument3 pages09 GasketCharacteristicValues PDFdraj1875977Pas encore d'évaluation

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsirinaPas encore d'évaluation

- Heat Losses - TECHDocument1 pageHeat Losses - TECHandre_silva_camposPas encore d'évaluation

- Recommendations For Thread Milling Cutters: Materials and Application RecommendationsDocument1 pageRecommendations For Thread Milling Cutters: Materials and Application RecommendationsHaizmeer BonziePas encore d'évaluation

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFGunnie PandherPas encore d'évaluation

- 82 2010 Irwin Metal DrillingDocument20 pages82 2010 Irwin Metal DrillingDonizetti ManutençãoPas encore d'évaluation

- 84 2010 Irwin Metal DrillingDocument20 pages84 2010 Irwin Metal DrillingDonizetti ManutençãoPas encore d'évaluation

- CONACO Elenco Materiali 01 - 21Document1 pageCONACO Elenco Materiali 01 - 21DonArmanPas encore d'évaluation

- Feeds & Speeds Chart For Drills, Reamers, Mills & Saws (Carbide Tipped)Document1 pageFeeds & Speeds Chart For Drills, Reamers, Mills & Saws (Carbide Tipped)Sunil KumarPas encore d'évaluation

- HSS & Cobalt Drill Speed - FeedDocument1 pageHSS & Cobalt Drill Speed - FeedPuneeth KumarPas encore d'évaluation

- Stal S700 - Porownanie - 10-Hillong-Milan-VeljkovicDocument30 pagesStal S700 - Porownanie - 10-Hillong-Milan-VeljkovicAdam WoźniakPas encore d'évaluation

- Chapter 2 - Price and Availability of Materials - 2019 - Engineering Materials 1Document14 pagesChapter 2 - Price and Availability of Materials - 2019 - Engineering Materials 1Juan Camilo AlarconPas encore d'évaluation

- Chemical Analysis of A Sample50X50X6Document2 pagesChemical Analysis of A Sample50X50X6Amit ChaitPas encore d'évaluation

- Stair Detail BDocument1 pageStair Detail BGRETCHEN SIYPas encore d'évaluation

- 009 Stainless PDFDocument34 pages009 Stainless PDFKamil MarszałekPas encore d'évaluation

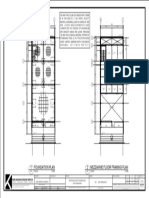

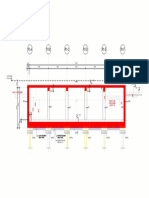

- Foundation Plan 1 Mezzanine Floor Framing Plan 2: Kabs Building Design ServiceDocument1 pageFoundation Plan 1 Mezzanine Floor Framing Plan 2: Kabs Building Design Servicefrancis sebastian lagamayoPas encore d'évaluation

- Whitney Suggested Cutting Speeds (SFM) : Feed and Speed ChartDocument1 pageWhitney Suggested Cutting Speeds (SFM) : Feed and Speed ChartCAT MINING SHOVELPas encore d'évaluation

- Typical Septic Tank DetailsDocument1 pageTypical Septic Tank DetailsBalaji GPas encore d'évaluation

- Rev Pre Desain Garasi Mobil (09012020)Document7 pagesRev Pre Desain Garasi Mobil (09012020)Agung SetiawanPas encore d'évaluation

- Tinplate and Chromium Coated Products-08.06.2006Document2 pagesTinplate and Chromium Coated Products-08.06.2006Talha DikenPas encore d'évaluation

- Westinghouse Lighting Roadway Lighting Product Brochure 3-78Document24 pagesWestinghouse Lighting Roadway Lighting Product Brochure 3-78Alan MastersPas encore d'évaluation

- Grounding BarDocument1 pageGrounding BarDean AnggaraPas encore d'évaluation

- Drilling Speeds and FeedsDocument2 pagesDrilling Speeds and FeedsHoeruman oenPas encore d'évaluation

- Chapter 2 - The Price and Availability of Materia - 2012 - Engineering MaterialsDocument12 pagesChapter 2 - The Price and Availability of Materia - 2012 - Engineering MaterialsDavidPas encore d'évaluation

- F C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CDocument1 pageF C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CAshok RajPas encore d'évaluation

- Aluminum Selection ChartDocument1 pageAluminum Selection ChartFahri Risfa ZulfiPas encore d'évaluation

- Bolts - ASTM F3125Document4 pagesBolts - ASTM F3125rahuljoagPas encore d'évaluation

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaPas encore d'évaluation

- Material GradeDocument2 pagesMaterial GradeS. Veeravel100% (1)

- Low-Carbon Steel WireDocument6 pagesLow-Carbon Steel WireHans GoethePas encore d'évaluation

- Steel Preheating ChartDocument1 pageSteel Preheating ChartKhuram ShahzadPas encore d'évaluation

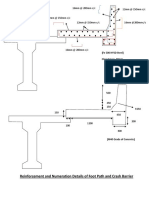

- Crash Barrier and Footpath Details ModifiedDocument1 pageCrash Barrier and Footpath Details ModifiedcometPas encore d'évaluation

- Grajfer NechiDocument1 pageGrajfer Nechimaxdan111Pas encore d'évaluation

- Sec RWTDocument1 pageSec RWTMuriyanto MuriPas encore d'évaluation

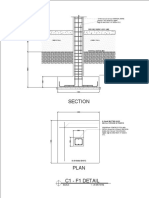

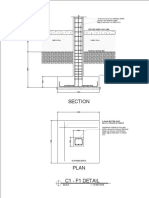

- C1-F1 Detail PDFDocument1 pageC1-F1 Detail PDFBien JulianPas encore d'évaluation

- Catalog PCBN enDocument2 pagesCatalog PCBN enXavierPas encore d'évaluation

- C1-F1 Detail PDFDocument1 pageC1-F1 Detail PDFBien JulianPas encore d'évaluation

- Section: Ground Finish Floor LineDocument1 pageSection: Ground Finish Floor LineBien JulianPas encore d'évaluation

- Chemical Properties of RMDocument8 pagesChemical Properties of RMDINESH SHARMAPas encore d'évaluation

- Annular Cutter Feeds and SpeedsDocument1 pageAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErPas encore d'évaluation

- 30MT Pole DesignDocument2 pages30MT Pole DesignbereketPas encore d'évaluation

- Materijal Klasa DUŽINA (MM) ŠIRINA (MM) Debljina (MM) : ParketDocument1 pageMaterijal Klasa DUŽINA (MM) ŠIRINA (MM) Debljina (MM) : Parketnova011Pas encore d'évaluation

- MonelDocument3 pagesMonelnurarifiantoPas encore d'évaluation

- Galvanic ChartDocument2 pagesGalvanic ChartJason WilliamPas encore d'évaluation

- O6 Tool Steel: Chemical AnalysisDocument3 pagesO6 Tool Steel: Chemical AnalysischandraPas encore d'évaluation

- Electrode Booklet F Web 110Document1 pageElectrode Booklet F Web 110satnamPas encore d'évaluation

- Detail C: 4.5 0.2 Thickness Hot - Dip GalvanizedDocument2 pagesDetail C: 4.5 0.2 Thickness Hot - Dip GalvanizedKAMAL DASPas encore d'évaluation

- Force Platform: Instruction ManualDocument9 pagesForce Platform: Instruction ManualAlfian KamilPas encore d'évaluation

- Sparkvue 3.0 SoftwareDocument1 pageSparkvue 3.0 SoftwareAlfian KamilPas encore d'évaluation

- PS 3200Document2 pagesPS 3200Alfian KamilPas encore d'évaluation

- 2-Axis Force Platform Force Platform: Typical ApplicationsDocument1 page2-Axis Force Platform Force Platform: Typical ApplicationsAlfian KamilPas encore d'évaluation

- 1934 Pembunuhan Di Orient ExpressDocument4 pages1934 Pembunuhan Di Orient ExpressAlfian KamilPas encore d'évaluation

- Increase Availability, Reduce Maintenance Cost: Based On Failure Analysis Must Answer 7 Basic QuestionsDocument13 pagesIncrease Availability, Reduce Maintenance Cost: Based On Failure Analysis Must Answer 7 Basic QuestionsAlfian KamilPas encore d'évaluation

- PR 1 The Nature of Failure - 3Document19 pagesPR 1 The Nature of Failure - 3Alfian KamilPas encore d'évaluation

- Sori Bikinnya Buru2. Penjelasan Simpelnya Ada Di:: Duction-Motor - HTMLDocument9 pagesSori Bikinnya Buru2. Penjelasan Simpelnya Ada Di:: Duction-Motor - HTMLAlfian KamilPas encore d'évaluation

- Unit 8: Focus On Time Analysis: - Before You ReadDocument5 pagesUnit 8: Focus On Time Analysis: - Before You ReadScribd0ProfilePas encore d'évaluation

- one-day-dLL COT 2nd QuarterDocument5 pagesone-day-dLL COT 2nd Quarterwilbert giuseppe de guzmanPas encore d'évaluation

- Contoh Format Final Paper (Technique)Document7 pagesContoh Format Final Paper (Technique)Nini Nurani RakhmatullahPas encore d'évaluation

- Plywood ScooterDocument7 pagesPlywood ScooterJim100% (4)

- DPI Vs PPI - What Is The Difference - Photography LifeDocument90 pagesDPI Vs PPI - What Is The Difference - Photography LifePavan KumarPas encore d'évaluation

- Weldkart Brochure PDFDocument2 pagesWeldkart Brochure PDFNiharika DubeyPas encore d'évaluation

- Voz Pasiva: ProfesorDocument3 pagesVoz Pasiva: ProfesorAnderson CamposPas encore d'évaluation

- Fees To Be Submitted by The Candidate: Rs. 8065/-Provisional Admission List of M.A. Geography 1 Semester For The Session 2020-21Document6 pagesFees To Be Submitted by The Candidate: Rs. 8065/-Provisional Admission List of M.A. Geography 1 Semester For The Session 2020-21Aequitas RegistrationPas encore d'évaluation

- 7 Ways To Improve Your Oratory SkillsDocument3 pages7 Ways To Improve Your Oratory SkillsManzPas encore d'évaluation

- Lacoue-Labarthe, Philippe - Introduction To Walter Benjamin's 'The Concept of Art Criticism in The German Romantics'Document25 pagesLacoue-Labarthe, Philippe - Introduction To Walter Benjamin's 'The Concept of Art Criticism in The German Romantics'carlosarayamPas encore d'évaluation

- Nutrition Month Celebration PRES TalksDocument2 pagesNutrition Month Celebration PRES Talksjessica bacaniPas encore d'évaluation

- J.S. BachDocument1 pageJ.S. BachJose FloresPas encore d'évaluation

- Chapter 8 Test and ReviewDocument5 pagesChapter 8 Test and Reviewapi-232613595Pas encore d'évaluation

- Nissan Maxima - Brake Light Switch ReplacementDocument15 pagesNissan Maxima - Brake Light Switch Replacementap00Pas encore d'évaluation

- The Man Who Sold The WorldDocument9 pagesThe Man Who Sold The WorldJoell Rojas MendezPas encore d'évaluation

- LTY400HM01Document28 pagesLTY400HM01plasma plasmaPas encore d'évaluation

- Design of StaircaseDocument16 pagesDesign of StaircaseOscarKonzultPas encore d'évaluation

- Work of ArchDocument5 pagesWork of ArchMadhu SekarPas encore d'évaluation

- Barbeau, Maurius. Totem Poles (Vol. 2)Document25 pagesBarbeau, Maurius. Totem Poles (Vol. 2)IrvinPas encore d'évaluation

- Buehler Summet, Sample Prep and AnalysisDocument136 pagesBuehler Summet, Sample Prep and AnalysisSebastian RiañoPas encore d'évaluation

- Partimento-Fugue - The Neapolitan Angle PDFDocument43 pagesPartimento-Fugue - The Neapolitan Angle PDFPaul100% (1)

- Suraj Kund MelaDocument11 pagesSuraj Kund MelaAayushee BajoriaPas encore d'évaluation

- Heavenly Home: 1. HallelujahDocument1 pageHeavenly Home: 1. Hallelujahnuokehun123456Pas encore d'évaluation

- Speech For English CarnivalDocument5 pagesSpeech For English CarnivalshammalabsreetharanPas encore d'évaluation

- The Main Tudor Style Decoration Was The Fine Carving, Sometimes With Sycamore InlayDocument8 pagesThe Main Tudor Style Decoration Was The Fine Carving, Sometimes With Sycamore InlayMj OhPas encore d'évaluation