Académique Documents

Professionnel Documents

Culture Documents

Tabla END Intercambiadores

Transféré par

DarioCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tabla END Intercambiadores

Transféré par

DarioDroits d'auteur :

Formats disponibles

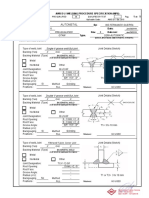

Application Description ECT RFT MFL IRIS Comments

Nonferromagnetic

material Generally, thin - ECT is the recommended

Condensers tubes made of brass, X choice for its speed and its

aluminum brass, accuracy.

cupronickel, or titanium.

Copper with low profile - ECT inspection with special

OD finsTypical problem probes to detect circumferential

Air Conditioners X

iscircumferential cracking cracks. These probes are

and wear in the land area. normally called AC probes.

- ECT is the recommended

Nonferromagnetic choice for its speed and

material Stainless steel, X X accuracy.- IRIS can sometimes

Cu/Ali be used to confirm the sizing of

ID defects.

- ECT is used only for thin tubes

(<1.6 mm) with saturation

Heat Mildly ferromagnetic

probes.- For thicker walls, it is

Exchangers material Duplex steel, X X X X

better to use RFT or MFL.- IRIS

SS439, Seacure, Monel

can sometimes be used to

confirm the sizing of defects.

Ferromagnetic material

- RFT, MFL, and IRIS are good,

Carbon steel, nickel.

X X X and most of the time

Typicaldefects are pitting

complementary.

and corrosion.

- RFT is not effective because

Carbon steel tube

the fins disturb the remote field.-

withaluminum fins

MFL is quick and sensitive but

Air Coolers Typical defects are ID X X

does not allow sizing.- IRIS is

pitting and OD wear close

often used to back up MFL, but

to the water box.

has difficulty with OD flaws.

- RFT is good for wear detection

Carbon steel tube and can easily pass the bend.-

Typical defects are MFL is good only on straight

Boilers X X X

pitting, wear, and boiler tubes without swages.-

cracking at the tubesheet. IRIS is good for wear and pits but

has no sensitivity in the bend.

- RFT is the only effective

Carbon steel or cast

technique because it does not

iron pipes Typical

Buried Pipes X require cleaning, and it can easily

defects are pitting and

negotiate elbows. However,

general corrosion.

sensitivity to pitting is limited.

Vous aimerez peut-être aussi

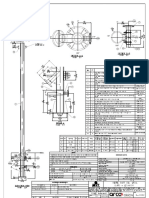

- PV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020Document6 pagesPV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020DarioPas encore d'évaluation

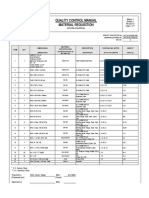

- AUT-GMAW-2 Rev.0 PDFDocument5 pagesAUT-GMAW-2 Rev.0 PDFDarioPas encore d'évaluation

- Intsallation of Hot Tap fittingsSAEP0311Document24 pagesIntsallation of Hot Tap fittingsSAEP0311DarioPas encore d'évaluation

- Tried & True Technology: Tank Heating CoilsDocument2 pagesTried & True Technology: Tank Heating CoilsDarioPas encore d'évaluation

- Welding Symbol Guide (ISO 2553Document32 pagesWelding Symbol Guide (ISO 2553Marcelo CunhaPas encore d'évaluation

- Modco Brochure (Figure 500) - Customer Version (3MG) PDFDocument8 pagesModco Brochure (Figure 500) - Customer Version (3MG) PDFTrinh DungPas encore d'évaluation

- AWS D1.1 PQR form guideDocument4 pagesAWS D1.1 PQR form guideDarioPas encore d'évaluation

- Annex Form J2 D1.1 D1.1M 2020 PDFDocument3 pagesAnnex Form J2 D1.1 D1.1M 2020 PDFDarioPas encore d'évaluation

- Annex Form J2 D1.1 D1.1M 2020 PDFDocument3 pagesAnnex Form J2 D1.1 D1.1M 2020 PDFDarioPas encore d'évaluation

- American Bureau of Shipping: Application For Certification of Container Corner CastingsDocument3 pagesAmerican Bureau of Shipping: Application For Certification of Container Corner CastingsDarioPas encore d'évaluation

- TWM - Total Welding Management - Barckhoff 2005Document197 pagesTWM - Total Welding Management - Barckhoff 2005lazaroccs100% (5)

- O0176A-M-V41562-01 Sheet 1 Rev.0Document1 pageO0176A-M-V41562-01 Sheet 1 Rev.0DarioPas encore d'évaluation

- Simufact Welding: Simulations Software For Welding ProcessesDocument8 pagesSimufact Welding: Simulations Software For Welding ProcessesDarioPas encore d'évaluation

- Duratruss Catalog 2017 PDFDocument72 pagesDuratruss Catalog 2017 PDFDario100% (1)

- Flare Stack Mechanical Design Calculations by Abdel Halim GalalaDocument24 pagesFlare Stack Mechanical Design Calculations by Abdel Halim Galalamarkfgt100% (2)

- Duratruss Catalog 2017 PDFDocument72 pagesDuratruss Catalog 2017 PDFDario100% (1)

- O0176A-M-K-41582-01-1 Rev.0 PDFDocument1 pageO0176A-M-K-41582-01-1 Rev.0 PDFDarioPas encore d'évaluation

- O0176A-M-K-41582-01-1 Rev.0Document1 pageO0176A-M-K-41582-01-1 Rev.0DarioPas encore d'évaluation

- Exhibit 3 - V-41562-BomDocument2 pagesExhibit 3 - V-41562-BomDarioPas encore d'évaluation

- 1191R-DWG Sheet 4 Rev.ADocument1 page1191R-DWG Sheet 4 Rev.ADarioPas encore d'évaluation

- Aeim04 DWG Me 01 0Document1 pageAeim04 DWG Me 01 0DarioPas encore d'évaluation

- 1811482-A-P01-A 1-2Document1 page1811482-A-P01-A 1-2DarioPas encore d'évaluation

- O0176A-M-K-41582-01-1 Rev.CDocument1 pageO0176A-M-K-41582-01-1 Rev.CDarioPas encore d'évaluation

- Calculation ReportDocument229 pagesCalculation ReportDarioPas encore d'évaluation

- Curriculum Vitae Replace With First Name(s) Surname(s)Document2 pagesCurriculum Vitae Replace With First Name(s) Surname(s)Valentina100% (1)

- 1191R-MC-001 - Rev. 0Document178 pages1191R-MC-001 - Rev. 0DarioPas encore d'évaluation

- Idv 103 BT M TQ DWG 001 CDocument1 pageIdv 103 BT M TQ DWG 001 CDarioPas encore d'évaluation

- Example E4.3.1Document6 pagesExample E4.3.1Dario100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Pipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationDocument13 pagesPipe Welding and How To Pass A SMAW 6G (Open Root) Pipe Welding CertificationMichael TayactacPas encore d'évaluation

- PISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesDocument2 pagesPISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesViajante_santosPas encore d'évaluation

- Building Systems Classification DocumentDocument48 pagesBuilding Systems Classification Documentabdullah sahibPas encore d'évaluation

- Ut Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sDocument1 pageUt Velocity Table: Material L-Wave Velocity M/s S-Wave Velocity In/ms S-Wave Velocity M/sprakashPas encore d'évaluation

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan MuhammadPas encore d'évaluation

- Industrial Training ReportDocument66 pagesIndustrial Training Reportapi-373020854Pas encore d'évaluation

- #### # ## E232 0010 Qba - 0Document9 pages#### # ## E232 0010 Qba - 0MARCOPas encore d'évaluation

- Ethacure 300Document12 pagesEthacure 300scorpionbadshahPas encore d'évaluation

- How To Line The Burner Pipe PDFDocument19 pagesHow To Line The Burner Pipe PDFMustafa Ramadan100% (2)

- Besser concrete block parts catalogDocument18 pagesBesser concrete block parts catalogkuzemdooPas encore d'évaluation

- Aircraft RivetsDocument50 pagesAircraft RivetsPranjal DograPas encore d'évaluation

- Ceilcote Secondary Containment July 2013Document51 pagesCeilcote Secondary Containment July 2013Jaime Andres Perez Alvarado100% (1)

- Woodtech Pu ExteriorDocument2 pagesWoodtech Pu ExteriorSathish SathishPas encore d'évaluation

- Lincolnweld 761Document2 pagesLincolnweld 761Huascar Rafael Robles CaceresPas encore d'évaluation

- Market Survey FlooringDocument12 pagesMarket Survey FlooringSAURABH KUMAR SINGHPas encore d'évaluation

- AMS-2406 - Plating, Chromium Hard DepositDocument9 pagesAMS-2406 - Plating, Chromium Hard Depositnaveed100% (1)

- Item 311Document64 pagesItem 311Jansen WongPas encore d'évaluation

- Bristle Blaster CatalogoDocument6 pagesBristle Blaster CatalogoAlécio de OliveiraPas encore d'évaluation

- API 520 Sizing & Selection GuideDocument31 pagesAPI 520 Sizing & Selection Guidesimitzu0% (1)

- LEDE CodosDocument2 pagesLEDE CodosFIRE RL SYSTEMSPas encore d'évaluation

- Concrete Manufacturers Association Membership ListDocument37 pagesConcrete Manufacturers Association Membership ListForbes KambaPas encore d'évaluation

- Comparing Quality & Yield Performance in January 2019Document7 pagesComparing Quality & Yield Performance in January 2019Aris SusantoPas encore d'évaluation

- Firemaster Industry BrochureDocument24 pagesFiremaster Industry BrochureAlina NastasaPas encore d'évaluation

- Arup CampusDocument3 pagesArup Campusnono04050% (1)

- Ciclo Di Verniciatura: Painting CycleDocument1 pageCiclo Di Verniciatura: Painting CycleMaffone NumerounoPas encore d'évaluation

- SSH KPKNL 2021Document12 pagesSSH KPKNL 2021Taufik GeodetikPas encore d'évaluation

- An Overview of Changes in The ACI 318-19 Building Code, and Looking Ahead To ACI 318-25 - Andrew W. TaylorDocument72 pagesAn Overview of Changes in The ACI 318-19 Building Code, and Looking Ahead To ACI 318-25 - Andrew W. TaylorAjong DdpPas encore d'évaluation

- 7010 - Data - Sheet - USDocument19 pages7010 - Data - Sheet - USDaniela MendozaPas encore d'évaluation

- 70Document41 pages70masoud132Pas encore d'évaluation

- AashtoDocument2 pagesAashtophanna100% (1)