Académique Documents

Professionnel Documents

Culture Documents

Calibration Report For Digital Thermometer: Sample Customer S/N: XXXXXXX Report Number: W186693

Transféré par

Sandro ChiliquingaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Calibration Report For Digital Thermometer: Sample Customer S/N: XXXXXXX Report Number: W186693

Transféré par

Sandro ChiliquingaDroits d'auteur :

Formats disponibles

CALIBRATION REPORT FOR

DIGITAL THERMOMETER

SAMPLE CUSTOMER

S/N: XXXXXXX

Report Number: W186693

Page 1 of 4 Report No. W186693

ICL CALIBRATION LABORATORIES, INC.

Cert 526.01 Calibration

ISO/IEC 17025 and ANSI/NCSL Z540-1 accredited

The specialists in ASTM and laboratory thermometers & hydrometers 1501 SE Decker Avenue, Suite 118, Stuart, FL 34994 USA

Members: A2LA ASTM API NCSLI ASQ NCWM Tel: 772-286-7710 1-800-713-6647

Fax: 772-286-8737 email: sales@iclcalibration.com

Setting new standards in calibration excellence!

Internet: www.icllabs.com

CALIBRATION REPORT FOR DIGITAL THERMOMETER

The instrument or device identified below was examined and calibrated in ICL's metrology laboratory, using NIST traceable standards, following the

calibration procedure referenced below. This calibration fulfills the requirements of ISO/IEC 17025-2005, 'General Requirements for the Competence of

Testing and Calibration Laboratories' and ANSI/NCSL Z540-1-1994, 'Calibration Laboratories and Measuring and Test Equipment - 'General

Requirements'.

CLIENT

SAMPLE CUSTOMER

STREET ADDRESS

CITY, STATE ZIP

Purchase order number: NOT AVAILABLE

Submitted by: SAMPLE COMPANY

ICL internal reference (SO): 346605

DATES

Date received: 05-28-2015

Date report issued: 05-28-2015

Recalibration date specified by client: May 28, 2016

UUT (Unit Under Test) INFORMATION

Device information:

Manufacturer: MARTEL

Model No: 650.007.3208

Serial No: XXXXXXX

Description: BETA PROBE TI (18 INCH STEM)

Manufacturer's specified temperature range: -58/320 °F

Sensor immersion: APPROX. 10 INCHES

Readout resolution: 0.001 °F

Engineering units: °F

NOTE: The accuracy tolerance for this system calibration (sensor and readout) is either the root-sum-square of the accuracy tolerance of the sensor and

the accuracy tolerance of the readout device, (if separate, independent devices), or the manufacturer's specification for the sensor and readout

combination. Please see the 'Tolerance' column which appears in the 'Results of Calibration' table on the next page.

RESULTS OF PHYSICAL EXAMINATION

The condition of this device was satisfactory with no visually apparent defects, unless noted below. Minor cosmetic defects are generally not noted

unless they are judged to impact the usability of the device.

CALIBRATION PROCEDURE

ICL Procedure 04, which references relevent elements of ASTM E77, ASTM E220, ASTM E644 and ASTM E2593.

LABORATORY ENVIRONMENTAL CONDITIONS

Temperature: 23 °C +/- 5 °C, Relative humidity: between 30% and 80%

Page 2 of 4 Report No. W186693

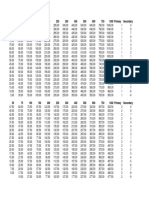

RESULTS OF CALIBRATION

AS FOUND

Nominal Temp Standard Rdg. UUT reading Correction Tolerance Accept Limit* P/F/Ind Uncertainty

32.000 °F 32.001 °F 31.975 °F 0.026 °F ± 0.1000 °F ± 0.0968 °F Pass ± 0.029 °F

110.000 °F 110.002 °F 110.003 °F -0.001 °F ± 0.1000 °F ± 0.0968 °F Pass ± 0.029 °F

212.000 °F 212.002 °F 211.990 °F 0.012 °F ± 0.1000 °F ± 0.0897 °F Pass ± 0.043 °F

300.000 °F 299.999 °F 299.980 °F 0.019 °F ± 0.1000 °F ± 0.0897 °F Pass ± 0.043 °F

The 'As Found' values were determined to be within tolerance, and no adjustment of this device was undertaken. Accordingly, the 'As Left' values are

the same as the 'As Found' values.

AS LEFT

Nominal Temp Standard Rdg. UUT reading Correction Tolerance Accept Limit* P/F/Ind Uncertainty

32.000 °F 32.001 °F 31.975 °F 0.026 °F ± 0.1000 °F ± 0.0968 °F Pass ± 0.029 °F

110.000 °F 110.002 °F 110.003 °F -0.001 °F ± 0.1000 °F ± 0.0968 °F Pass ± 0.029 °F

212.000 °F 212.002 °F 211.990 °F 0.012 °F ± 0.1000 °F ± 0.0897 °F Pass ± 0.043 °F

300.000 °F 299.999 °F 299.980 °F 0.019 °F ± 0.1000 °F ± 0.0897 °F Pass ± 0.043 °F

GUARD BANDING

ISO/IEC 17025:2005(E) requires, in Section 5.10.4.2., that, “When statements of compliance are made, the uncertainty of measurement shall be taken

into account.'' One valid way of complying with this requirement is applying a 'guard band' to the device's tolerance. The guard band is calculated as a

function of the test uncertainty ratio (TUR), the ratio of the tolerance of the UUT to the measurement uncertainty. Basically, the smaller the uncertainty is

relative to the tolerance, the smaller the guard band. A TUR of 5:1 or even 4:1 results in a guard band of zero, or very close to zero. A 3:1 TUR results

in a modest guard band. As TUR declines, the guard band becomes larger. The use of the guard band in the decision process is designed to reduce

the probability of a false acceptance (PFA), or a false failure, to 2% or less. The method and equations we use for calculation of the guard band comply

with the requirements of ANSI/NCSL Z540.3

The *Accept Limit(s) are calculated by subtracting the guard band from the tolerance. The Accept Limit is essentially a new tolerance, for this calibration

only, which we use to make a declaration of Pass, Fail, or Indeterminate, as explained below:

Pass The measured value falls within the interval described by the test point plus or minus the Accept Limit.

Fail The measured value falls outside the interval described by the test point plus or minus (the tolerance + the guard band).

Ind (Indeterminate) The measured value is indeterminate, falling in that grey area too close to permit a credible determination; it is statistically and

metrologically imprudent to declare that the instrument is definitively either 'in-tolerance' or 'out-of-tolerance'.

LIMITATIONS OF USE

This is a limited, or partial-range calibration, and accordingly, this instrument may be used with confidence only within the range bracketed by the test

points. If only a single test temperature was calibrated, the thermometer can be used with confidence only at and immediately around that test point.

MEASUREMENT UNCERTAINTY

The measurement uncertainty reported is the expanded uncertainty at 2 sigma (k=2), to provide a confidence level of approximately 95%.

The uncertainty is calculated considering both Type A and Type B contributors. Type A contributors include the standard deviation of the measurement

process from check standard control charts, the standard deviation of monthly Triple Point of Water calibrations of the standard, and UUT variability

observed during the calibration. Type B contributors include comparator uniformity, uncertainty of the calibration of the reference standard, stem

conduction and other immersion effects, the sensitivity and accuracy of the reference standard thermometer's readout, resolution of the reference

standard and resolution of the UUT.

The Type A and B contributors are combined using the root-sum-square method to obtain the standard uncertainty at 1 sigma. The standard uncertainty

is then multiplied by 2 to obtain the expanded uncertainty at 2 sigma (k=2). This uncertainty calculation is consistent with the requirements of the ISO

Guide to the Expression of Uncertainty in Measurement (the 'GUM') and NIST Technical Note 1297.

The expanded uncertainties (k=2) reported here do not contain estimates for (1) any effects that may be introduced by transportation of the instrument

between ICL and the user's facility, (2) drift of the instrument, (3) hysteresis of the instrument, or (4) any measurement uncertainties introduced by the

user.

NOTES AND SUPPLEMENTAL INFORMATION

All temperatures given in this report are those defined by the International Temperature Scale of 1990 (ITS-90).

IMPORTANT NOTE: The correct operation of digital electronic thermometers is dependent upon all components functioning properly. Correct

temperature indication may be impeded by physical damage to the sensor or cable assembly, contamination of electrical contacts or components by

water, oil or other contaminants, or by other, less obvious causes such as low battery level or failure of internal components. Accordingly, ICL

Calibration Laboratories, Inc. represents that the calibration data provided in this report were those values observed during the performance of this

calibration, however cannot be responsible for inaccurate readings which may be experienced in future uses due to conditions which are beyond our

control.

TRACEABILITY INFORMATION

This calibration is traceable to NIST through an unbroken chain of comparisons. Our primary reference standard, a NIST calibrated SPRT, is used only

to calibrate our transfer standards, which in turn are used to calibrate our clients' instruments. Measurement uncertainty has been calculated at each

step in the chain and is fully documented.

Page 3 of 4 Report No. W186693

ICL maintains three Rosemount model 162CE 25.5 Ohm SPRTs, for redundancy and to permit sequential rotation to NIST for calibration. As of this

date, traceability is conveyed through S/N 5058, our MTE-262, calibrated by NIST on August 17, 2012. NIST GMP-11 recommends a 36 month

calibration cycle for SPRTs. PRT transfer standards are calibrated annually against this SPRT, per NIST GMP-11 recommendations, and are monitored

continually using measurement assurance strategies including check standards, control charts and monthly triple point of water checks.

The comparators and transfer standards used in the performance of this calibration are indicated below, organized by test point.

Nominal Temp Comparator Serial No MTE# Manufacturer

32.000 °F 7341 Glycol bath B21419 353 Hart Scientific

110.000 °F 6020 Water bath B09334 340 Hart Scientific

212.000 °F 6020 Oil bath B09333 338 Hart Scientific

300.000 °F 6020 Oil bath B09335 337 Hart Scientific

Nominal Temp Standard Serial No. MTE# Manufacturer Next Due Position

32.000 °F 5614 PRT 722680 298 Hart Scientific 09/09/15 Standard

110.000 °F 5614 PRT 731860 250 Hart Scientific 09/09/15 Standard

212.000 °F 5614 PRT 554325 067 Hart Scientific 10/07/15 Standard

300.000 °F 5614 PRT 590752 070 Hart Scientific 09/09/15 Standard

TECHNICIAN: PEDRO ORTIZ

ICL CALIBRATION LABORATORIES, INC.

An ISO/IEC 17025 & ANSI/NCSL Z-540-1 accredited laboratory - American Association for Laboratory Accreditation Certificate #526.01

Approved by: ________________________________________ Reviewed by: ________________________________________

J. Jeff Kelly, Technical Director

Deborah M. Weber, Quality Deputy This report document was prepared by Lori J. Parr

Date report issued: 05-28-2015 Recalibration date specified by client: May 28, 2016

NIST GMP-11 (September 2014), 'Good Measurement Practice for Assignment and Adjustment of Calibration Intervals for Standards' cautions that,

'Temperature standards are dynamic with use. Shock, contamination and other factors can cause drift from accepted values'. GMP-11 recommends an

initial calibration interval of 12 months for digital thermometers, standard thermistors and PRTs.

The user should be aware that any number of factors may cause this instrument to drift out of calibration before the specified calibration interval has

expired.

This calibration report may not be reproduced except in full without the express written permission of ICL Calibration Laboratories, Inc.

This report applies only to the item calibrated. This calibration report shall not be used to claim product endorsement by the A2LA.

End of Report No.W186693

Page 4 of 4 Report No. W186693

Vous aimerez peut-être aussi

- Calibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Document4 pagesCalibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Sherwin John NavarroPas encore d'évaluation

- Sample Thermohydrometer Y205188Document5 pagesSample Thermohydrometer Y205188houssPas encore d'évaluation

- CR1000X 46301Document2 pagesCR1000X 46301mitziPas encore d'évaluation

- 9190A Ultra-Cool Field Metrology Well: Ultra-Cool Dry-Block Calibrator With Best-In-Class StabilityDocument5 pages9190A Ultra-Cool Field Metrology Well: Ultra-Cool Dry-Block Calibrator With Best-In-Class StabilityAnonymous IXswcnWPas encore d'évaluation

- 085 9800 Manual Rev BDocument18 pages085 9800 Manual Rev BRolandoIgorLeivaPas encore d'évaluation

- Sigma Procedure - RTDDocument15 pagesSigma Procedure - RTDFarhan IftakharPas encore d'évaluation

- Calibration Report For Laboratory Weights: Sample Company S/N: XXXXXX Report Number: W210065Document6 pagesCalibration Report For Laboratory Weights: Sample Company S/N: XXXXXX Report Number: W210065t williePas encore d'évaluation

- DC80Document13 pagesDC80Rier AssistenciaPas encore d'évaluation

- 5 Temperature Measurement Mistakes With RtdsDocument17 pages5 Temperature Measurement Mistakes With RtdsrahulPas encore d'évaluation

- Type RN73 Series: Key FeaturesDocument5 pagesType RN73 Series: Key FeaturesdannnirPas encore d'évaluation

- Tweeners Models 1502A, 1503, and 1504Document3 pagesTweeners Models 1502A, 1503, and 1504Anonymous IXswcnWPas encore d'évaluation

- Temperature Instrument RangesDocument5 pagesTemperature Instrument RangesE.C.MADHUDUDHANA REDDYPas encore d'évaluation

- Cert. No.: 6530-12141206 Traceable® Certifícate of Calibration For Digital BarometerDocument1 pageCert. No.: 6530-12141206 Traceable® Certifícate of Calibration For Digital BarometerHenry GuatoPas encore d'évaluation

- Calibration ManualDocument21 pagesCalibration Manualjosealvaro073391Pas encore d'évaluation

- Certificado TermohigrometroDocument1 pageCertificado Termohigrometroconsuelo alarcon ramosPas encore d'évaluation

- Calibration Techniques and Process: Abdul Latif, Pe H (NI)Document69 pagesCalibration Techniques and Process: Abdul Latif, Pe H (NI)Engr Umair AzizPas encore d'évaluation

- CEPs Course Work 1 (1) IsDocument6 pagesCEPs Course Work 1 (1) Iszayyanraajpoot456Pas encore d'évaluation

- Ver5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 ReportDocument23 pagesVer5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 Reporttata kaisserliPas encore d'évaluation

- Positector Calibration ProcedureDocument6 pagesPositector Calibration ProcedureluigimasterPas encore d'évaluation

- Acelerometro ADXL103-ADXL203Document12 pagesAcelerometro ADXL103-ADXL203cukey13Pas encore d'évaluation

- Adxrs610 Yaw Rate GyroDocument12 pagesAdxrs610 Yaw Rate GyroTarek Car MillaPas encore d'évaluation

- Calibration Certificate: Metrological CentreDocument2 pagesCalibration Certificate: Metrological CentrenduenasPas encore d'évaluation

- DS13200C 23200C PDFDocument2 pagesDS13200C 23200C PDFSEONCITEFAPas encore d'évaluation

- Certificado de Calibração - Validador 2023Document2 pagesCertificado de Calibração - Validador 2023Edson RamosPas encore d'évaluation

- RTD Spec2Document5 pagesRTD Spec2vijay.victorysolutions01Pas encore d'évaluation

- A Basic Guide To RTD Measurements: Application ReportDocument42 pagesA Basic Guide To RTD Measurements: Application ReportSyfPas encore d'évaluation

- Sbaa 275Document42 pagesSbaa 275Salman AlparisiPas encore d'évaluation

- CAT CP 1 (T) Calibration of RTDDocument4 pagesCAT CP 1 (T) Calibration of RTDAmar Singh100% (1)

- Manual Book DS - CT4132 - en - Co - 20053Document4 pagesManual Book DS - CT4132 - en - Co - 20053M. Hadi SuwitoPas encore d'évaluation

- Getting Back To The Basics of Electrical MeasurementsDocument12 pagesGetting Back To The Basics of Electrical MeasurementsAvinash RaghooPas encore d'évaluation

- Overcome Your Test Challenges With Truevolt Series Digital MultimetersDocument42 pagesOvercome Your Test Challenges With Truevolt Series Digital MultimetersAntonovici Dorin AndreiPas encore d'évaluation

- 75عDocument3 pages75عFikry FaradinnaPas encore d'évaluation

- Cal Cert FormatDocument6 pagesCal Cert FormatINSTRUCAL CALIBRATION SERVICESPas encore d'évaluation

- Thermocouple Simulators: Model 520/521Document2 pagesThermocouple Simulators: Model 520/521Abraham BejarPas encore d'évaluation

- CP No.401-IPRT CalibrationDocument20 pagesCP No.401-IPRT Calibrationsirsa11Pas encore d'évaluation

- Operation Manual: JencoDocument13 pagesOperation Manual: JencotadilakshmikiranPas encore d'évaluation

- User and Service Manual: Qa-PtDocument43 pagesUser and Service Manual: Qa-PtRaul PerezPas encore d'évaluation

- ICS 3022 Accelerometer DatasheetDocument4 pagesICS 3022 Accelerometer DatasheetsergiojgsPas encore d'évaluation

- Ideal Industries, Inc. Technical Manual Models: 61-773 61-775Document11 pagesIdeal Industries, Inc. Technical Manual Models: 61-773 61-775Alexandre LiraPas encore d'évaluation

- Yokogawa Temperature Transmitergs01c50b01-00eDocument9 pagesYokogawa Temperature Transmitergs01c50b01-00eLuis Eduardo Díaz LópezPas encore d'évaluation

- Typical Sources of Uncertainty in Materials TestingDocument3 pagesTypical Sources of Uncertainty in Materials TestingSonja KostićPas encore d'évaluation

- Some Guide Lines For Obtaining The Best Performance From RTD'S and Pt100'S ParticularlyDocument12 pagesSome Guide Lines For Obtaining The Best Performance From RTD'S and Pt100'S ParticularlyghrairiPas encore d'évaluation

- WALTER KIDDE Aerospace Abbreviated Component Maintenance Manual (Acm)Document7 pagesWALTER KIDDE Aerospace Abbreviated Component Maintenance Manual (Acm)jordiPas encore d'évaluation

- AccreditationDocument40 pagesAccreditationWalid BdeirPas encore d'évaluation

- VDM 300 ThermoDocument4 pagesVDM 300 ThermoAmr KonswaPas encore d'évaluation

- Control Company Thermometer CatologDocument36 pagesControl Company Thermometer CatologgrahambeastPas encore d'évaluation

- Pressure ProcedureDocument4 pagesPressure ProcedureCitco IdfcPas encore d'évaluation

- Specifications 2. Handling Instructions: See Attachment) Illustrates The Fundamental Design of TheDocument10 pagesSpecifications 2. Handling Instructions: See Attachment) Illustrates The Fundamental Design of TheMitra AsayeshPas encore d'évaluation

- Work Sheet: Page 1 of 2Document11 pagesWork Sheet: Page 1 of 2kevin joseyPas encore d'évaluation

- PRO6000 ServiceManual 100355REV9 r9 28JAN16Document12 pagesPRO6000 ServiceManual 100355REV9 r9 28JAN16Osires FerreiraPas encore d'évaluation

- Making The Right Choice For Your Temperature ReadoutDocument2 pagesMaking The Right Choice For Your Temperature Readoutjuncar25Pas encore d'évaluation

- Nabl 174Document34 pagesNabl 174Ashish DubeyPas encore d'évaluation

- Heat Flux SenserDocument35 pagesHeat Flux Senserسامح الجاسمPas encore d'évaluation

- SHT3x Datasheet AnalogDocument13 pagesSHT3x Datasheet AnalogAaronPas encore d'évaluation

- Calibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24Document17 pagesCalibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24luroguitaPas encore d'évaluation

- Example of Measurement Uncertainty EstimationDocument7 pagesExample of Measurement Uncertainty EstimationCristiano PernichelliPas encore d'évaluation

- Calibration Procedure For Digital Multimeter An - Usm-486a - Tb-9-6625-2350-24Document23 pagesCalibration Procedure For Digital Multimeter An - Usm-486a - Tb-9-6625-2350-24luroguitaPas encore d'évaluation

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Advanced Temperature Measurement and Control, Second EditionD'EverandAdvanced Temperature Measurement and Control, Second EditionPas encore d'évaluation

- Wide-Vue Analog Panel Meters: Ordering InformationDocument10 pagesWide-Vue Analog Panel Meters: Ordering InformationSandro ChiliquingaPas encore d'évaluation

- Secondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Document5 pagesSecondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Sandro ChiliquingaPas encore d'évaluation

- Consumable and Accessory Warranty StatementDocument2 pagesConsumable and Accessory Warranty StatementSandro ChiliquingaPas encore d'évaluation

- English Pedagogical Module 1: Back To School!Document24 pagesEnglish Pedagogical Module 1: Back To School!Sandro ChiliquingaPas encore d'évaluation

- Oil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetDocument4 pagesOil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetSandro ChiliquingaPas encore d'évaluation

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocument2 pages#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaPas encore d'évaluation

- 14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionDocument3 pages14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionSandro ChiliquingaPas encore d'évaluation

- Lower Explosive Limits of Combustible GasesDocument1 pageLower Explosive Limits of Combustible GasesSandro ChiliquingaPas encore d'évaluation

- Megohmmeter/IR TesterDocument2 pagesMegohmmeter/IR TesterSandro ChiliquingaPas encore d'évaluation

- 2800 Series Digital Panel Meters: Inputs SpecificationsDocument2 pages2800 Series Digital Panel Meters: Inputs SpecificationsSandro ChiliquingaPas encore d'évaluation

- Multiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderDocument1 pageMultiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderSandro ChiliquingaPas encore d'évaluation

- Fluorescent Magnetic Particle Premix: Product Data SheetDocument3 pagesFluorescent Magnetic Particle Premix: Product Data SheetSandro ChiliquingaPas encore d'évaluation

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaPas encore d'évaluation

- 8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsDocument12 pages8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsSandro ChiliquingaPas encore d'évaluation

- Series 1500/2500 Safety Relief ValvesDocument12 pagesSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaPas encore d'évaluation

- Addendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFDocument1 pageAddendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFSandro ChiliquingaPas encore d'évaluation

- User Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Document48 pagesUser Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Sandro ChiliquingaPas encore d'évaluation

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosPas encore d'évaluation

- Data Sheet of The Machine.Document4 pagesData Sheet of The Machine.Sandro ChiliquingaPas encore d'évaluation

- Datasheet Inductance Sensor 8 MMDocument2 pagesDatasheet Inductance Sensor 8 MMSandro ChiliquingaPas encore d'évaluation

- Basic Examinations ExamDocument2 pagesBasic Examinations ExamSandro ChiliquingaPas encore d'évaluation

- Smart Senso AS8900Document12 pagesSmart Senso AS8900Sandro ChiliquingaPas encore d'évaluation

- Complete Two Metering Skids For Custody Transfer With Coriolis Flow Meters, Provers &complete Sampling System (Auto Sampler) With Analysis System ForDocument23 pagesComplete Two Metering Skids For Custody Transfer With Coriolis Flow Meters, Provers &complete Sampling System (Auto Sampler) With Analysis System ForMOSES EDWINPas encore d'évaluation

- Iso TR 16476 2016Document11 pagesIso TR 16476 2016Milan DamjanovicPas encore d'évaluation

- Deutscher Kalibrierdienst: Guideline DKD-R 6-2 Calibration of Measuring Devices For VacuumDocument16 pagesDeutscher Kalibrierdienst: Guideline DKD-R 6-2 Calibration of Measuring Devices For VacuumDragan Ilic100% (1)

- Certificado Del Estandar de Referencia para IrDocument7 pagesCertificado Del Estandar de Referencia para IrVERONICAPas encore d'évaluation

- Uncertainty in Measurement - J.V. Nicholas and D.R. White PDFDocument58 pagesUncertainty in Measurement - J.V. Nicholas and D.R. White PDFsujudPas encore d'évaluation

- MCL-QSD-CP-PG-001 - Profile GaugeDocument3 pagesMCL-QSD-CP-PG-001 - Profile Gaugevg869030Pas encore d'évaluation

- Uncertainty Assessment For DC Power Supply: SKC Compliance LabDocument18 pagesUncertainty Assessment For DC Power Supply: SKC Compliance LabRAVIRAJ DATTATRAYA PADOLPas encore d'évaluation

- Physics Unit 6 Source BookDocument50 pagesPhysics Unit 6 Source BookÅzmâñ Khäñ100% (1)

- IncertidumbreDocument7 pagesIncertidumbreLaura GuarguatiPas encore d'évaluation

- Calibration in Pharmaceutical IndustryDocument82 pagesCalibration in Pharmaceutical Industryosama kamel100% (2)

- M3003 The Expression of Uncertainty and Confidence in MeasurementDocument81 pagesM3003 The Expression of Uncertainty and Confidence in MeasurementpostgradoengerenciaPas encore d'évaluation

- Calibration of Pressure Gauges PDFDocument43 pagesCalibration of Pressure Gauges PDFMiroslav ProdanaPas encore d'évaluation

- Sample Calibration ProceduresDocument37 pagesSample Calibration ProceduresGabriel Dediu100% (1)

- Confidential Singapore Accreditation Council Singapore Laboratory Accreditation Scheme (Sac-Singlas) Laboratory Assessment ChecklistDocument30 pagesConfidential Singapore Accreditation Council Singapore Laboratory Accreditation Scheme (Sac-Singlas) Laboratory Assessment ChecklistYusranPas encore d'évaluation

- Typical Pressure Measurement Uncertainty Defined by An FPG8601 Force Balanced Piston GaugeDocument10 pagesTypical Pressure Measurement Uncertainty Defined by An FPG8601 Force Balanced Piston GaugeSiphosethu SikhakhanePas encore d'évaluation

- Calibration Services Purchase Order Criteria: CAB/ILAC-TP/092/INF 2008-10-17Document1 pageCalibration Services Purchase Order Criteria: CAB/ILAC-TP/092/INF 2008-10-17Fernando RomeroPas encore d'évaluation

- High-Voltage and High Current Testing Standards: Past, Present and Future of IEC and IEEEDocument4 pagesHigh-Voltage and High Current Testing Standards: Past, Present and Future of IEC and IEEERomany AllamPas encore d'évaluation

- Sop 29 Assignment of Uncertainty 20180131Document11 pagesSop 29 Assignment of Uncertainty 20180131Misael NavarroPas encore d'évaluation

- Quality by DesignAnalyticalDocument127 pagesQuality by DesignAnalyticalSunil Murkikar (GM - PMI Quality Operations)Pas encore d'évaluation

- Reporting Uncertainty of Test Results and Use of The Term Measurement Uncertainty in ASTM Test MethodsDocument7 pagesReporting Uncertainty of Test Results and Use of The Term Measurement Uncertainty in ASTM Test MethodsCJPATAGANPas encore d'évaluation

- Journals PerataaDocument21 pagesJournals PerataaAnung 'Hidayat Panuntun'Pas encore d'évaluation

- Uncertainty of Measurement in Spectrometric Analysis: A Case StudyDocument10 pagesUncertainty of Measurement in Spectrometric Analysis: A Case StudyLaura VrabiePas encore d'évaluation

- Sop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationDocument10 pagesSop 1 Recommended Standard Operating Procedure For Calibration Certificate PreparationEileen OngPas encore d'évaluation

- KIRKUP, Les - Data Analysis For Physical Scientists - Featuring Excel®-Cambridge University Press (2012) - 221Document11 pagesKIRKUP, Les - Data Analysis For Physical Scientists - Featuring Excel®-Cambridge University Press (2012) - 221Gautham S NairPas encore d'évaluation

- Oiv Oeno 418 2013 - enDocument68 pagesOiv Oeno 418 2013 - enΠερσα ΒολάνηPas encore d'évaluation

- ISO 8655-6 2022 (En)Document24 pagesISO 8655-6 2022 (En)tania100% (8)

- A Measurement Infrastructure For Sustainable ManufacturingDocument18 pagesA Measurement Infrastructure For Sustainable ManufacturingbthiepPas encore d'évaluation

- Eurachem For Decision Rule PDFDocument2 pagesEurachem For Decision Rule PDFsonnu151Pas encore d'évaluation

- Limitations of The Application of The Horwitz Equation: Trac Trends in Analytical Chemistry December 2006Document12 pagesLimitations of The Application of The Horwitz Equation: Trac Trends in Analytical Chemistry December 2006ImmerPas encore d'évaluation

- Jis C 1604 - 2013 PDFDocument50 pagesJis C 1604 - 2013 PDFfitrianaPas encore d'évaluation