Académique Documents

Professionnel Documents

Culture Documents

(Am-15) Format For Pump Maint Report

Transféré par

ShashankKumar0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues2 pagesThis document is a pump maintenance report that details inspection and repair work. It lists information about the unit and job, reported problems, observations from dismantling, clearances maintained, remedial actions taken including replaced or salvaged parts, quality checks, and names of technicians. The pump was inspected, bearings and internal parts were replaced or repaired as needed, clearances were verified, and the pump was reassembled and tested before being returned to service.

Description originale:

AM-15 format for pump maintenance

Titre original

(Am-15) Format for Pump Maint Report

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document is a pump maintenance report that details inspection and repair work. It lists information about the unit and job, reported problems, observations from dismantling, clearances maintained, remedial actions taken including replaced or salvaged parts, quality checks, and names of technicians. The pump was inspected, bearings and internal parts were replaced or repaired as needed, clearances were verified, and the pump was reassembled and tested before being returned to service.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

22 vues2 pages(Am-15) Format For Pump Maint Report

Transféré par

ShashankKumarThis document is a pump maintenance report that details inspection and repair work. It lists information about the unit and job, reported problems, observations from dismantling, clearances maintained, remedial actions taken including replaced or salvaged parts, quality checks, and names of technicians. The pump was inspected, bearings and internal parts were replaced or repaired as needed, clearances were verified, and the pump was reassembled and tested before being returned to service.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

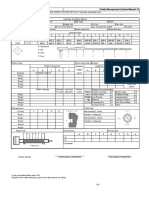

INDIAN OIL CORPORATION LIMITED Annexure -AM15

PUMP MAINTENANCE REPORT

UNIT DATE OF RECEIVING

EQUIPT. No. JOB START DATE

MODEL No. DATE OF COMPLETION

SERIAL No. SAP WO NO.

REPORTED PROBLEM

1) Seal failure 2) Bearing Housing Jammed 3) Poor Pumping 4) General overhaul

5) Vibration 6) Shaft failure 7) Bad 8) Any other problem

lubrication

o ANALYSED PROBLEM IN CONSULTATION WITH RELIABILITY CELL:

o OBSERVATION MADE DURING DISMANTLING:

1.0 BEARING

A) Damaged Bearing B) Damaged Bearing C) Damaged or loose

Housing deflector

D) Brg. loose on

E) Bearing loose in housing

shaft

2.0 SEAL (MECH. SEAL)

A) Rotary head damaged B) Mating ring damaged

C) Packings (RH, MR, Sleeve) Damaged D) Sleeve found damaged or seized

E) Gland plate condition F) Compression Unit damaged

G) Any other observation :

3.0 INTERNAL DAMAGE OF PUMP

A) Throat bush, specify stage B) Impeller W/R, specify stage

C) Casing W/R, specify stage D) Impeller (Near Hub portion)

E) Shaft-sheared out Fretting observed near bearing Key way

location damaged

F) Casing Damaged G) Stuffing Box jacket badly jammed

H) Coupling failure I) Any other damage

4.0 SPARES REQUIRED

S l. S AP Code Part De scri pti on Q ty C onsum ed

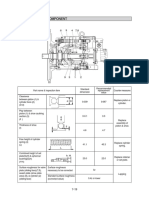

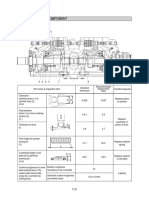

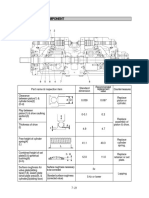

5.0 CLEARANCE MAINTAINED

PUM THROAT

CLEARAN IMP. BACK THROAT BUSH WITH GLAND INTERMEDIAT BUSH IN

CE P W/RING W/RING BUSH GLAND/ BUSH MULTISTAGE PUMP

TYPE

PACKING

COL 0.3 – 0.45 0.40 – 0.6 55 – 65 0.35 – 0.5 0.3 – 0.4 0.3 – 0.3 – 0.3 –

Standard

D 0.4 0.4 0.4

clearance

(mm) HOT 0.5 – 0.65 0.55 – 0.7 45 - 55 0.55 – 0.8 0.5 – 0.5 – 0.5 –

0.45 – 0.55

0.6 0.6 0.6

COL

Maintained

Clearance D

(mm) HOT

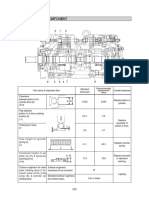

CLEARAN PUM BUSH UPPER LOWER SHAFT

P SPIDE R BUSH IN VERTICAL PUMP JOURNAL JOURNAL

CE BEARING RUN OUT

TYPE BEARING BEARING

COL

Standard 0.06 – 0.09 0.05 – 0.0 8 0.05 – 0.08 0.02mm

clearance D

(mm) HOT

COL

Maintained

Clearance D

(mm) HOT

Shaft Run out recording:

• Coupling P osition = _ _ _ _ _ _ _ _ _ _ _ _ _ ? Bearing P osition _ _ _ _ _ _ _ _ _ _ _ _ _

• Mech S eal L ocation = _ _ _ _ _ _ _ _ _ _ _ _ _ ? Impeller P osition _ _ _ _ _ _ _ _ _ _ _ _ _

REMEDIAL ACTION TAKEN

1. Bearings Fits Replaced I/B O/B

Recording of following after bearing assembly:

a. Shaft end play: c. Seal Chamber Squareness:

b. Radial Shaft movement: d. Concentricity:

2. Mech. Seal Assly:

A. Salvaged Parts: 1) Rotary Head 2) Mating

Ring

B. Replaced Parts: 1) RH 3) MR 3) RH Packing 4) MR Packing

5) Gland 6) Gland Packing 7) Sleeve 8) Sleeve Packing

c. Mech Seal Drg A.) Drg referred: B) Dimensions maintained as per drawing:

D.Seal Face flatness

checking thru opt. flat

Internal parts of Pump:

A. REPLACED: 1) Shaft, Key, Check Nut 2) Impeller W/Ring 3) Case W/Ring

4) Sleeve 5) Impeller 6) Pump Casing

7) Brg. Housing 8) Deflector 9) Throat Bush

10) Bearing Housing cover 11) Coupling 12) Impeller check nut

B. SALVAGED: Welding and Machine done for: -

1) Impeller W/Ring 2) Casing W/Ring 3) Bush 4) Deflector 5) Shaft

6) Sleeve 7) Any other parts per feasibility

C. Remarks for salvaged parts: Procurement action required for

1 2 3 4

5 6 7 8

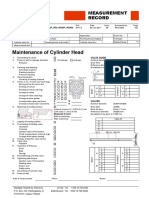

3. QUALITY CHECK

1) Seal Test Hydraulically : Yes No Pressure Kg/cm2

2) Pump Rotational Check : Free Not Free

3) Leak Test of housing : Yes No

2. OTHER DETAILS / OBSERVATIONS/ COMMENTS:

3. NAME OF TECHNICIANS

1. 2.

DMML MLE / SMLE Lead Technician

Vous aimerez peut-être aussi

- Group 2 Major ComponentDocument9 pagesGroup 2 Major ComponentTaha RdmanPas encore d'évaluation

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument7 pagesGroup 2 Major Component: 1. Main PumpHậu MinhPas encore d'évaluation

- PUMA M4.3 DHD 340 TD40 Maint June 2018Document1 pagePUMA M4.3 DHD 340 TD40 Maint June 2018Marco LeivaPas encore d'évaluation

- Group 2 Major ComponentDocument8 pagesGroup 2 Major ComponentDavidPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument8 pagesGroup 2 Major Component: 1. Main PumpRafał DworakPas encore d'évaluation

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpSergey MovchanPas encore d'évaluation

- Pump Assembly Inspection Plan Horizontal Split Case, Between Bearing PumpDocument2 pagesPump Assembly Inspection Plan Horizontal Split Case, Between Bearing Pumprafeekmek31Pas encore d'évaluation

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanPas encore d'évaluation

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentSergey MovchanPas encore d'évaluation

- Cylinder Condition ReportDocument5 pagesCylinder Condition ReportŞansal DikmenerPas encore d'évaluation

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiPas encore d'évaluation

- Cylinder Condition ReportDocument6 pagesCylinder Condition ReportValeriy DomashenkoPas encore d'évaluation

- R210LC-7 7-2Document10 pagesR210LC-7 7-2Krystian PalaciosPas encore d'évaluation

- ROUP 2 MAJOR COMPONENT HyundaiDocument9 pagesROUP 2 MAJOR COMPONENT Hyundaiعمروصالح كليسPas encore d'évaluation

- Shop Manual GD610, GD620, GD660, GD670 PDFDocument664 pagesShop Manual GD610, GD620, GD660, GD670 PDFAing LaingPas encore d'évaluation

- Measuring of Swing Bearing ClearanceDocument3 pagesMeasuring of Swing Bearing ClearanceSunil Singh100% (1)

- Type 6: Elastomer Bellows SealDocument4 pagesType 6: Elastomer Bellows SealTommy Tran NguyenPas encore d'évaluation

- F-A P-S: Global Carriers LTD Safety Management System Manual 10Document2 pagesF-A P-S: Global Carriers LTD Safety Management System Manual 10trobasPas encore d'évaluation

- Form2 Maintenance of Cylinder HeadDocument3 pagesForm2 Maintenance of Cylinder HeadmakinaPas encore d'évaluation

- QL5, DHD350: Disassembly Exploded ViewDocument1 pageQL5, DHD350: Disassembly Exploded ViewJORGE C. CHAO R.Pas encore d'évaluation

- F-A P-S: Global Carriers LTD Safety Management System Manual 10Document2 pagesF-A P-S: Global Carriers LTD Safety Management System Manual 10trobasPas encore d'évaluation

- Cylinder Condition ReportDocument7 pagesCylinder Condition ReportThusitha Dalpathadu100% (2)

- Group 2 Major ComponentDocument8 pagesGroup 2 Major Componentdeniden2013Pas encore d'évaluation

- Maintenance of Reciprocating CompressorDocument21 pagesMaintenance of Reciprocating CompressorAyub BashaPas encore d'évaluation

- EXHVALVEDocument1 pageEXHVALVESemih AçmazPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpMustofa TofaPas encore d'évaluation

- PRP Product CatalogulDocument236 pagesPRP Product CatalogulAmit Chopra AmitPas encore d'évaluation

- Removal & Assembly: 1. Guide Roller UnitDocument5 pagesRemoval & Assembly: 1. Guide Roller UnitRheana DomingoPas encore d'évaluation

- 2. المكونات الرئيسيهDocument8 pages2. المكونات الرئيسيهالمهندسوليدالطويلPas encore d'évaluation

- 7-2 Major ComponentDocument9 pages7-2 Major ComponentkrisnantoPas encore d'évaluation

- WS09TZ200029Document14 pagesWS09TZ200029sudeepPas encore d'évaluation

- Cylinder ConditionDocument5 pagesCylinder ConditionMykola TvarovskyPas encore d'évaluation

- Hyd Cylinder Details Jyo MakeDocument4 pagesHyd Cylinder Details Jyo MakeAnna BhosadikePas encore d'évaluation

- Kymco Vitality Cilindro Pistón PDFDocument19 pagesKymco Vitality Cilindro Pistón PDFFlanagan MatusPas encore d'évaluation

- TM 9-1245 37-MM Gun, M3, and Carriage, M4-1941Document54 pagesTM 9-1245 37-MM Gun, M3, and Carriage, M4-1941ferdockmPas encore d'évaluation

- Elastomer Bellows Seal: Performance Capabilities Product DescriptionDocument4 pagesElastomer Bellows Seal: Performance Capabilities Product DescriptionKaarthicNatarajanPas encore d'évaluation

- Machine StructureDocument68 pagesMachine StructureVictor HemzPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument9 pagesGroup 2 Major Component: 1. Main PumpMauricio CalixtoPas encore d'évaluation

- ED - Engine Hood DoorDocument57 pagesED - Engine Hood DoorCarlos MafudPas encore d'évaluation

- International Harvester Front End Loader Service ManualDocument8 pagesInternational Harvester Front End Loader Service ManualDiegoPas encore d'évaluation

- Group 2 Major Component: 1. Main PumpDocument11 pagesGroup 2 Major Component: 1. Main PumpHậu MinhPas encore d'évaluation

- SECTION 3.05: Crankcase Component OverhaulDocument36 pagesSECTION 3.05: Crankcase Component OverhaulLUISA FERNANDA TORRES MANOSALVAPas encore d'évaluation

- Adjustment: Centering Bolt Standard BoltDocument2 pagesAdjustment: Centering Bolt Standard Boltjeremih alhegnPas encore d'évaluation

- Drive Shaft and Front AxleDocument28 pagesDrive Shaft and Front AxleRamon AcostaPas encore d'évaluation

- Engine Repair - Adjustment ParametersDocument20 pagesEngine Repair - Adjustment Parameterssarvagya.tftPas encore d'évaluation

- Reassembly: (A) Check Bearing PositionDocument21 pagesReassembly: (A) Check Bearing PositionRonfermPas encore d'évaluation

- LMV Operation Parts Manual 230918 132746Document84 pagesLMV Operation Parts Manual 230918 132746jvargasPas encore d'évaluation

- A5hf1 Intro Part1Document41 pagesA5hf1 Intro Part1Huỳnh Minh ĐứcPas encore d'évaluation

- Test Vehicle Information/Test Specifications FMVSS 135: FORM 135 05/16/02Document8 pagesTest Vehicle Information/Test Specifications FMVSS 135: FORM 135 05/16/02fghdPas encore d'évaluation

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringPas encore d'évaluation

- Koyo Failures Causes and CountermeasuressDocument20 pagesKoyo Failures Causes and CountermeasuressbederinadmlPas encore d'évaluation

- Blower k430 Snh60 Overhaul ProcedureDocument39 pagesBlower k430 Snh60 Overhaul ProcedurejamiekuangPas encore d'évaluation

- WS09TZ200052Document11 pagesWS09TZ200052sudeepPas encore d'évaluation

- Kbu KBZ4Document5 pagesKbu KBZ4Andrew VPas encore d'évaluation

- Triveni Turbine Limited: Customer Care Cell Site ReportDocument6 pagesTriveni Turbine Limited: Customer Care Cell Site ReportRahulChaturvediPas encore d'évaluation

- WS09TZ200054Document11 pagesWS09TZ200054sudeepPas encore d'évaluation

- NewwDocument7 pagesNewwIrfanmaulana ardiansyahPas encore d'évaluation

- Journeyman Millwright TestDocument53 pagesJourneyman Millwright TestGary Casteel87% (15)

- Almost Everthing For MEPDocument55 pagesAlmost Everthing For MEPdkpushp100% (4)

- Chapter 4 - Energy Analysis For A Control Volume PDFDocument11 pagesChapter 4 - Energy Analysis For A Control Volume PDFHectorCabzPas encore d'évaluation

- Bombas CentrifugasDocument12 pagesBombas CentrifugasIsaac Deusdedit Salazar EhuanPas encore d'évaluation

- Naval AprilDocument3 pagesNaval AprilSameerFernandezPas encore d'évaluation

- BHEL Erection ManualDocument127 pagesBHEL Erection Manualsv100% (3)

- 000 0 AXIAL PUMP DESIGN 36hamza-Khan-FinalDocument6 pages000 0 AXIAL PUMP DESIGN 36hamza-Khan-FinalRabei RomulusPas encore d'évaluation

- MEYCO SA 160 v5 PDFDocument2 pagesMEYCO SA 160 v5 PDFSushil DhunganaPas encore d'évaluation

- Megaroyal - 20200713 v0Document38 pagesMegaroyal - 20200713 v0Balinderjit SinghPas encore d'évaluation

- CAT Engine Specifications: 3512B Offshore Emergency Generator SetDocument6 pagesCAT Engine Specifications: 3512B Offshore Emergency Generator SetHussain ShahPas encore d'évaluation

- V G I S: On Variable-Primary FlowDocument5 pagesV G I S: On Variable-Primary FlowSantiago J. ramos jrPas encore d'évaluation

- Estimation of The Effevtive Power Without Indicatir DiagramsDocument2 pagesEstimation of The Effevtive Power Without Indicatir DiagramsSriram KumarPas encore d'évaluation

- Section A.6 Steam and Water Cycle EquipmentDocument19 pagesSection A.6 Steam and Water Cycle EquipmentChava TejaPas encore d'évaluation

- Free Surface Flow Simulation With ACUSIM in The Water IndustryDocument8 pagesFree Surface Flow Simulation With ACUSIM in The Water IndustryKhiladi PujariPas encore d'évaluation

- F Mint 08 Preventive, Maintenance Check SheetDocument10 pagesF Mint 08 Preventive, Maintenance Check SheetBangali SinghPas encore d'évaluation

- Our Declared Goal Is Your Complete Satisfaction. See For Yourself!Document2 pagesOur Declared Goal Is Your Complete Satisfaction. See For Yourself!Shark1971Pas encore d'évaluation

- Engine Fuel Sys ShowDocument63 pagesEngine Fuel Sys ShowInterogator5100% (2)

- DPFG Wellhead Valves Leak Off Test Procedure RevCDocument6 pagesDPFG Wellhead Valves Leak Off Test Procedure RevCHossein100% (1)

- WastewaterOperatorStudyManual PDFDocument242 pagesWastewaterOperatorStudyManual PDFAnggaPas encore d'évaluation

- 123Document4 pages123Hasni ChawiPas encore d'évaluation

- PED Ch1Document17 pagesPED Ch1dpatel 2310Pas encore d'évaluation

- Rozdzielacze Hydrauliczne Danfoss PVG 120Document48 pagesRozdzielacze Hydrauliczne Danfoss PVG 120Jose Manuel Barroso PantojaPas encore d'évaluation

- Rexroth Hydrostatic Fan Drives - Ra98065 - 1006Document20 pagesRexroth Hydrostatic Fan Drives - Ra98065 - 1006MattH3Pas encore d'évaluation

- QXR 1320 Specification Completed March 26 2010Document3 pagesQXR 1320 Specification Completed March 26 2010death666dark100% (1)

- Critical Tau.... Arulanandan 1980 PDFDocument107 pagesCritical Tau.... Arulanandan 1980 PDFAsad HafudhPas encore d'évaluation

- B-191 Operationmanual en A LowresDocument28 pagesB-191 Operationmanual en A LowresDinhtrung TruongPas encore d'évaluation

- A4VGDocument68 pagesA4VGAgus YulfizarPas encore d'évaluation

- SAR Surface AeratorDocument8 pagesSAR Surface Aeratorqoreysoe19Pas encore d'évaluation

- 412 MM CH28 Fuel SystemDocument208 pages412 MM CH28 Fuel SystemMuhammad VALA100% (1)