Académique Documents

Professionnel Documents

Culture Documents

62 017 Dowsil 890 SL Si Joint Sealant

Transféré par

Scott HendersonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

62 017 Dowsil 890 SL Si Joint Sealant

Transféré par

Scott HendersonDroits d'auteur :

Formats disponibles

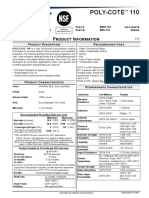

Technical Data Sheet

DOWSIL™ 890-SL Silicone Joint Sealant

Self-leveling silicone sealant for concrete and concrete to asphalt pavement joints.

Features & • Self-leveling, no tooling required.

Benefits • Can be extruded from -20 to 120°F.

• Flows into irregular joint widths and does not require tooling.

• Movement capability 100% extension and 50% compression.

• Ultra-low modulus.

• Weather and UV resistant.

• Fuel resistant-short term exposure. Refer to Dow form number 62-207 for more

information.

• Cold applied, ready-to-use as supplied. No heating or special preparation.

• Unprimed adhesion-primer is not required for Portland cement concrete and asphalt

which results in labor and material savings.

• Skin over- typically, the sealant will have a skin-over time of one hour or less at

standard conditions allowing roadways to quickly be opened to traffic.

Composition • One-part, cold applied, self-leveling silicone

Applications • DOWSIL™ 890-SL Silicone Joint Sealant can be used for concrete to concrete and

concrete to asphalt pavement joints.

• For use in new construction, repair or remedial applications. DOWSIL 890-SL Silicone

Joint Sealant can be used to seal irregularly shaped and spalled joints.

Typical Properties

Specification Writers: These values are not intended for use in preparing specifications.

Test1 Property Result D 5893 Requirement

As supplied

Color Dark gray

ASTM C 639 Flow Pass Smooth, level

ASTM C 1183 Extrusion rate, minimum 231 mL/min 20 mL/min

ASTM C 679 Tack free time Pass 5 hours max

1. ASTM: American Society for Testing and Materials

UNRESTRICTED – May be shared with anyone

®TM Trademarkof The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 890-SL Silicone Joint Sealant

Page 1 of 4 © 2017 The Dow Chemical Company. All rights reserved. Form No. 62-017-01 O

Typical Properties (Cont.)

Test Property Result D 5893 Requirement

ASTM C 792 Heat aging 0.97% 10% loss max

ASTM C 661 Durometer Shore 00 41 30 minimum

ASTM D 1475 Specific gravity 1.26–1.34

Cure time, ½” x ½” x 2” (73°F, 50% R.H.) Pass 21 day cure

As Cured – 21 days at 25°C (77°F) and 50% RH

Bond, non-immersed Pass No cracks or separation

Bond, water immersed Pass No cracks or separation

Bond, oven aged Pass No cracks or separation

ASTM D 412 Ultimate elongation 1400% 600% min

ASTM D 412 Tensile stress @ 150% 19 psi 45 psi max

ASTM C 793 Effects of accelerate weathering Pass 5,000 hours

Resilience 77% 75% min

ASTM C 719 Joint movement capability, +100/-50 percent, 10 cycles No failure

Figure 1: Good Joint Design

1Joint width wide enough to accommodate movement. (For additional information on joint width, see papers by Spells and

Klosowski, “Silicone Sealants for Use in Concrete Construction,” Vol. 1, No. 1, American Concrete Institute, SP-70, 1981; J.B.

Cook, “Construction Sealants and Adhesives,” Wiley-Interscience, 1970; and J.M. Klosowski, “Sealants in Construction,”

Marcel Dekker, 1989.).

2Joint sawed deep enough to allow backer rod/sealant placement and space for pumping of old sealant compounds. NOTE:

This applies to standard joints only; void space beneath backer rod in new construction is not needed.

3Proper backer rod placement to prevent three-sided adhesion.

4Sealant installed to proper depth and width.

5Sealant recessed a minimum of 3/8 inch to 1/2 inch (9.53 mm to 12.7 mm) below pavement surface.

6Depth of lowest slab determines the amount of recess required if grinding is anticipated; once grinding is complete, the

sealant will have proper recess below the pavement surface.

Description DOWSIL 890-SL Silicone Joint Sealant is a one-part, self-leveling silicone material that

cures to an ultra-low-modulus silicone rubber upon exposure to atmospheric moisture. The

cured silicone rubber remains flexible from -20 to 300°F.

UNRESTRICTED – May be shared with anyone

®TM Trademarkof The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 890-SL Silicone Joint Sealant

Page 2 of 4 © 2017 The Dow Chemical Company. All rights reserved. Form No. 62-017-01 O

Description (Cont.) Asphaltic paving materials have low tensile strengths. It is important to use an ultra-low

modulus material when sealing these substrates to ensure minimal strain is placed on the

asphaltic joint face.

Applicable • ASTM D 5893 Type SL

Standards • FAA P-605 for silicone joint sealants

• Meets SS-S-200E (section 4.4.12) Flame Test Requirements

• EN 14187-5 Hydrolysis Test

• EN 14188-2 Class B, C and D

How To Use Please refer to the Dow Silicone Pavement Sealants Installation Guide, form number 61-

507.

Handling PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN

Precautions THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS

AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD

INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE ON THE DOW WEBSITE AT

WWW.CONSUMER.DOW.COM, OR FROM YOUR DOW SALES APPLICATION

ENGINEER, OR DISTRIBUTOR, OR BY CALLING DOW CUSTOMER SERVICE.

Usable Life And Keep stored in original, unopened containers at or below 32°C (90°F). Refer to product

Storage packaging for “Use By” date. Keep containers tightly closed.

Packaging DOWSIL 890-SL Silicone Joint Sealant is supplied in 29 fl oz (857 mL) disposable plastic

Information cartridges, 4.5 gal (17 L) bulk pails, and 50 gal (189 L) bulk drums.

Limitations DOWSIL 890-SL Silicone Joint Sealant is not recommended for continuous water

immersion. It should not be applied in totally confined spaces where the sealant is not

exposed to atmospheric moisture.

The sealant should never be applied to wet or damp asphalt or concrete pavements or

installed during inclement weather.

Contact Dow prior to specifying for or installing in airfield runway applications.

Dow does not promote or warrant the use of DOWSIL™ sealants in applications associated

with spill containment areas of any kind.

This product is neither tested nor represented as suitable for medical or pharmaceutical

uses.

Shipping None.

Limitations

UNRESTRICTED – May be shared with anyone

®TM Trademarkof The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ 890-SL Silicone Joint Sealant

Page 3 of 4 © 2017 The Dow Chemical Company. All rights reserved. Form No. 62-017-01 O

Health And To support customers in their product safety needs, Dow has an extensive Product

Environmental Stewardship organization and a team of product safety and regulatory compliance

Information specialists available in each area.

For further information, please see our website, www.consumer.dow.com or consult your

local Dow representative.

Table 1: Recommended Backer Rod Installation (Shallow Cut)1

Measured in Inches

Joint Width 1/4 3/8 1/2 3/4 1 >1

Recessed Below Surface 3/8 3/8 3/8–1/2 3/8–1/2 1/2+ Contact Dow

Sealant Thickness 1/4 1/4 1/4 3/8 1/2

Backer Rod Diameter 3/8 1/2 5/8 7/8 1 1/4

Total Joint Depth 1–1 1/8 1 1/8–1 1/4 1 1/4–1 3/8 1 5/8–1 3/4 2 1/4–2 3/8

Measured in Millimeters

Joint Width 6 9 13 19 25

Recessed Below Surface 9 9 9–13 9–13 13+

Sealant Thickness 6 6 6 9 13

Backer Rod Diameter 9 13 16 22 32

Total Joint Depth 25–29 29–32 32–35 41–45 57–60

1. On road surfaces where grinding is planned at a later date, the sealant and backer rod should be installed so that

sealant is approximately 3/8 inch (9.35 mm) below the road surface after grinding is complete. An additional small

amount should be added to allow for surface imperfections on the bottom and to provide room for old sealant to pump

up from below during rehabilitation work in the summer months.

http://www.consumer.dow.com LIMITED WARRANTY INFORMATION – PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and

methods of use of our products are beyond our control, this information should not be used in substitution for customer’s tests

to ensure that our products are safe, effective, and fully satisfactory for the intended end use. Suggestions of use shall not be

taken as inducements to infringe any patent.

Dow’s sole warranty is that our products will meet the sales specifications in effect at the time of shipment.

Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown

to be other than as warranted.

TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW, DOW SPECIFICALLY DISCLAIMS ANY OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

DOW DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Page 4 of 4 ® Trademark of The Dow Chemical Company Form No. 62-017-01 O

Vous aimerez peut-être aussi

- DOWSIL™ 888 Silicone Joint Sealant: Features & BenefitsDocument3 pagesDOWSIL™ 888 Silicone Joint Sealant: Features & BenefitsTian NgPas encore d'évaluation

- DOWSIL™ 795 Structural Glazing Sealant Technical Data SheetDocument5 pagesDOWSIL™ 795 Structural Glazing Sealant Technical Data SheetTrung Nguyễn NgọcPas encore d'évaluation

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezPas encore d'évaluation

- Dowsil 790 Silicone Building SealantDocument4 pagesDowsil 790 Silicone Building SealantChris ChanonaPas encore d'évaluation

- PVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Document2 pagesPVDF Coated Galvalume Steel and Aluminum Architectural Flat Sheet & Coil Technical Data Bulletin (TDB)Jitendra PatelPas encore d'évaluation

- 62 586 Dowsil 1199 Silicone GlazingDocument3 pages62 586 Dowsil 1199 Silicone GlazingSaurav Negi EtherealPas encore d'évaluation

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Silicone Sealants: High Performance SealantDocument4 pagesSilicone Sealants: High Performance SealantParamdeep SinghPas encore d'évaluation

- Sample PVC Project SpecDocument8 pagesSample PVC Project SpecJULIOPas encore d'évaluation

- DOWSIL 791 Weatherproofing Sealant Product Data 1799967Document4 pagesDOWSIL 791 Weatherproofing Sealant Product Data 1799967Research DevelopmentPas encore d'évaluation

- 9765 Rubber Hydraulic Seals and WaterstopsDocument20 pages9765 Rubber Hydraulic Seals and WaterstopsStephenPas encore d'évaluation

- Technical Specification For Dow Corning 789Document2 pagesTechnical Specification For Dow Corning 789Akash SharmaPas encore d'évaluation

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraPas encore d'évaluation

- DOWSIL 999A Silicone Glazing Sealant Product Data 1799983Document3 pagesDOWSIL 999A Silicone Glazing Sealant Product Data 1799983bogzskiePas encore d'évaluation

- Silicone Compound Dm-3: Moisture Proofing Sealant & LubricantDocument1 pageSilicone Compound Dm-3: Moisture Proofing Sealant & LubricantvarunchPas encore d'évaluation

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- Dow Corning AllGuard Silicone Elastomeric CoatingDocument4 pagesDow Corning AllGuard Silicone Elastomeric Coatinggpax42Pas encore d'évaluation

- TEPA Rubber Hydraulic Seals and Waterstops Product BrochureDocument20 pagesTEPA Rubber Hydraulic Seals and Waterstops Product BrochureAnonymous 76B4vKPas encore d'évaluation

- Dowsil 789 Weatherproofing SealDocument3 pagesDowsil 789 Weatherproofing Sealsiju1974Pas encore d'évaluation

- Dow Corning 813C Construction and Concrete Silicone Sealant: Product InformationDocument4 pagesDow Corning 813C Construction and Concrete Silicone Sealant: Product InformationVRVPas encore d'évaluation

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.Pas encore d'évaluation

- DC 995Document3 pagesDC 995Andrea Nicola TurcatoPas encore d'évaluation

- Elastoseal EPDM Tanking SystemDocument8 pagesElastoseal EPDM Tanking SystemStephen100% (1)

- k10 SovacrylDocument2 pagesk10 Sovacryleqbalalam1984Pas encore d'évaluation

- Dow Corning 791 Silicone Weatherproofing Sealant: Product InformationDocument4 pagesDow Corning 791 Silicone Weatherproofing Sealant: Product InformationРоман СередаPas encore d'évaluation

- Sikawrap® Hex-230 C: Product Data SheetDocument4 pagesSikawrap® Hex-230 C: Product Data SheetArindam SarkarPas encore d'évaluation

- 3.7.11 PTS E-101sl - 170522 (Web)Document4 pages3.7.11 PTS E-101sl - 170522 (Web)betoaranoPas encore d'évaluation

- DOWSIL 995 Silicone Structural Sealant Product Data 1799968Document4 pagesDOWSIL 995 Silicone Structural Sealant Product Data 1799968bogzskiePas encore d'évaluation

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiPas encore d'évaluation

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelPas encore d'évaluation

- Non-Heat Sealable Cellophane Films for PackagingDocument2 pagesNon-Heat Sealable Cellophane Films for PackagingImawan WastPas encore d'évaluation

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cPas encore d'évaluation

- N730FS 000090aDocument3 pagesN730FS 000090aabdellah.farah.daherPas encore d'évaluation

- Sika Carbodur SDocument4 pagesSika Carbodur SMohamed alhaj EmadPas encore d'évaluation

- Aquashield Cool Roof - TDSDocument2 pagesAquashield Cool Roof - TDSAnoop ShankarPas encore d'évaluation

- Dow Corning 730Document3 pagesDow Corning 730Mahdi abanPas encore d'évaluation

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderPas encore d'évaluation

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomPas encore d'évaluation

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanPas encore d'évaluation

- Sika Hydrotite CJDocument3 pagesSika Hydrotite CJGB career CouncilPas encore d'évaluation

- DOWSIL™ 732 Multi-Purpose Sealant: Features & BenefitsDocument4 pagesDOWSIL™ 732 Multi-Purpose Sealant: Features & BenefitsRJ VIDEOSPas encore d'évaluation

- Fabrication of Large GRP Storage TanksDocument60 pagesFabrication of Large GRP Storage TanksjoekaledaPas encore d'évaluation

- Dovetail Deck Coating SolutionsDocument2 pagesDovetail Deck Coating SolutionsDan SmithPas encore d'évaluation

- pds-cpd-SikaWrap Hex100G-us PDFDocument2 pagespds-cpd-SikaWrap Hex100G-us PDFjohanes b mudaPas encore d'évaluation

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnPas encore d'évaluation

- 226NDocument2 pages226NUmaibalanPas encore d'évaluation

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisPas encore d'évaluation

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraPas encore d'évaluation

- Dow Corning: 795 Silicone Building SealantDocument2 pagesDow Corning: 795 Silicone Building SealantParamdeep SinghPas encore d'évaluation

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarPas encore d'évaluation

- HYDROTITE & PVC WATERSTOP SPECDocument4 pagesHYDROTITE & PVC WATERSTOP SPECMichael VillaluzPas encore d'évaluation

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazPas encore d'évaluation

- Description: Hybrid Façade SealantDocument2 pagesDescription: Hybrid Façade SealantTung ThanhPas encore d'évaluation

- Technical Data Sheet: Lasteek Rwe500Document2 pagesTechnical Data Sheet: Lasteek Rwe500Engr KamalPas encore d'évaluation

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUPageduesca RouelPas encore d'évaluation

- DOWSIL™ 995 Silicone Structural Sealant Technical Data SheetDocument5 pagesDOWSIL™ 995 Silicone Structural Sealant Technical Data SheetKharisma Utomo GroupPas encore d'évaluation

- CCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0Document4 pagesCCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0amanraza.canPas encore d'évaluation

- Sikalastic®-632: Product Data SheetDocument5 pagesSikalastic®-632: Product Data SheetShanaei MiskinPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Astm C635Document8 pagesAstm C635Buildcraft InteriorsPas encore d'évaluation

- Guide To Design Criteria For Bolts and Riveted JointsDocument352 pagesGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- Ccsi We FormDocument5 pagesCcsi We FormScott HendersonPas encore d'évaluation

- ACI Concrete Inspector Certification JTADocument17 pagesACI Concrete Inspector Certification JTAScott HendersonPas encore d'évaluation

- Conc Mix DesDocument16 pagesConc Mix Destomp23hotmailcomPas encore d'évaluation

- Catalogue Lagon Viton enDocument20 pagesCatalogue Lagon Viton enhiren_mistry55Pas encore d'évaluation

- Aerospace Fuel Tank SealantDocument4 pagesAerospace Fuel Tank SealantAznil aznilPas encore d'évaluation

- Rockwool Firepro: Comprehensive Range of Passive Fire Protection Products and SolutionsDocument109 pagesRockwool Firepro: Comprehensive Range of Passive Fire Protection Products and Solutionsewqeq100% (1)

- Dow Coring Asia ManualDocument69 pagesDow Coring Asia ManualGULJAR SINGHPas encore d'évaluation

- NIH Design Requirements Manual Ver 5-13 PDFDocument919 pagesNIH Design Requirements Manual Ver 5-13 PDFEmmanuel WinfulPas encore d'évaluation

- Product FolioDocument6 pagesProduct FolioVishnu DuttaPas encore d'évaluation

- Tile Ins Tile - Installation - Tile - Care - Guide - Pdftallation Tile Care GuideDocument20 pagesTile Ins Tile - Installation - Tile - Care - Guide - Pdftallation Tile Care GuideUstun OzgurPas encore d'évaluation

- Kingspan Kooltherm k106 90mm Standard Details Brochure en GB v04Document80 pagesKingspan Kooltherm k106 90mm Standard Details Brochure en GB v04Alexandru VasilePas encore d'évaluation

- World Emulsion Polymers: Industry Study With Forecasts ForDocument8 pagesWorld Emulsion Polymers: Industry Study With Forecasts ForUmer MurtazaPas encore d'évaluation

- FP200 FR Expanding Foam: AbescoDocument2 pagesFP200 FR Expanding Foam: AbescoIrfan AliPas encore d'évaluation

- 12V140 Seris Engine Shop ManualDocument471 pages12V140 Seris Engine Shop ManualRaed Mahyoub100% (4)

- Asia Sealant Application Guide Final Version 9-29-04Document61 pagesAsia Sealant Application Guide Final Version 9-29-04surajit7gupta100% (2)

- 7.insulation SeminarDocument55 pages7.insulation SeminarvgPas encore d'évaluation

- NPQS A2-10 Metal Roof SpecificationDocument19 pagesNPQS A2-10 Metal Roof Specificationlwin_oo2435Pas encore d'évaluation

- Igas B NewDocument2 pagesIgas B NewvnunezPas encore d'évaluation

- Fosroc Nukote JF80Document3 pagesFosroc Nukote JF80Balasubramanian AnanthPas encore d'évaluation

- Kpo 00 Pip SPC 00019 eDocument24 pagesKpo 00 Pip SPC 00019 erameshqcPas encore d'évaluation

- SIKA Product Information ChartDocument32 pagesSIKA Product Information ChartPrateek ModyPas encore d'évaluation

- Automotive TVET ProgramDocument70 pagesAutomotive TVET Programlucky javellanaPas encore d'évaluation

- THE RAPID Sealing System: Rise Multi-Cable TransitsDocument44 pagesTHE RAPID Sealing System: Rise Multi-Cable Transitsbakien-canPas encore d'évaluation

- Sikaflex® Construction+: Product Data SheetDocument4 pagesSikaflex® Construction+: Product Data SheetQuality JamPas encore d'évaluation

- Polysulphide SealantDocument2 pagesPolysulphide SealantMr. Ashok DwivediPas encore d'évaluation

- Manual D41e-P-6 PDFDocument607 pagesManual D41e-P-6 PDFLENIN75% (4)

- Product Data Sheet for Multiseal 2000 Liquid Waterproofing SystemDocument4 pagesProduct Data Sheet for Multiseal 2000 Liquid Waterproofing SystemYohanes DitoPas encore d'évaluation

- Dichtungsband k434 de 0216 Eng ScreenDocument2 pagesDichtungsband k434 de 0216 Eng ScreenAlexandru IonescuPas encore d'évaluation

- Structural Silicone Sealants: Standard Specification ForDocument4 pagesStructural Silicone Sealants: Standard Specification ForAzmi BazazouPas encore d'évaluation

- Data Sheet SSG4000AC UltraGlazeDocument8 pagesData Sheet SSG4000AC UltraGlazeÉdmilson OliveiraPas encore d'évaluation

- EquipmentFolder 2007Document6 pagesEquipmentFolder 2007Fernando FerrettiPas encore d'évaluation

- Komatsu D155ax 3 Super Dozer Bulldozer Service Repair Manual SN 60001 and Up 1590145474Document38 pagesKomatsu D155ax 3 Super Dozer Bulldozer Service Repair Manual SN 60001 and Up 1590145474rachidaccPas encore d'évaluation

- Sikaflex-1a-Purform Es enDocument5 pagesSikaflex-1a-Purform Es enArturo Aguilar SantesPas encore d'évaluation