Académique Documents

Professionnel Documents

Culture Documents

JSW Cement FZE Optimization Points Discussed and Agreed on 19th April '2018

Transféré par

abdullah amanullahDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

JSW Cement FZE Optimization Points Discussed and Agreed on 19th April '2018

Transféré par

abdullah amanullahDroits d'auteur :

Formats disponibles

JSW CEMENT FZE

Optimization Points Discussed and Agreed on 19th April '2018

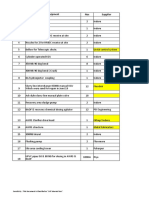

S No Item Description Sinoma reply

A General

1 System Capacities and Configuration to be as Per Enclosed Annex 1 Refer to Sinoma Reply in the same Annex

B Mechanical

1 OLBC width decreased to 1400 mm width and speed increased accordingly Agreed. OLBC price shall be optional separate

2 Plant internal belt conveyor speed to be increased to 1.5 m/s Agreed.

3 End crusher design for clinker cooler instead of intermediate crusher Agreed.

4 Coal Mill to be sized considering 17 tph capacity for Petcoke with HGI of 40 Agreed.

5 Standby dosing for fine coal to be Solid Flow Meter+phematic pump Agreed.

6 Cooling tower instead of chiller for water recirculation Agreed.

Baghouse to be of N+1 configuration with ACR of 1 to be maintained at N

7 Agreed.

condition

Cross Belt Analyser to be located on belt conveyor 111BC08 (ie the conveyor

8 Agreed.

before stacker yard conveyor)

Design capacity of 3450 is canceled only Capacity fo 3000 shall be guarantee. All

9 Agreed.

the Equipment including axilliary shall only be suitable for this concept.

10 Preheater fourth stage feeding only provision to be kept for future. Agreed.

Bed ash silo extraction system is not required now. Bed ash shall be dumped in

11 Agreed.

limestone stockpile and consumed in Raw Mix alsong with limestone.

Belt convyeors after Raw Mill Proportioing hoppers shall need not to be HR Belts

12 Agreed.

now.

Electric motor driven fire pumps shall have standy. No standby is required for

13 Agreed.

diesel pump and jockey pump.

The pit of Roller press bucket elevator is -3.500. & Deep pan conveyor shall not

14 Agreed

exceed -3.0mtr

15 Change KXT-Feeder to the Impact Flow Meter for Kiln Feeder Agreed

16 ID fan parameters will following the capacity of 3000TPD clinker. Agreed with desired margine of 15% on volume

17 Cancel the water spary system for cooler. Sinom to confirm

Heat Exchanger change the outlet temperature to 180°C. Adjust the bag filter and

18 Agreed

fan after heat exchanger.

19 Cancel Motorized valve for all fans with motor power less than 22 KW. Agreed

20 Rotary feeder undernearth the bag process bag filter shall be Single Agreed

Maximum degree of Belt conveyor is 16 degree for Lime stone only and 12

21 Agreed

degree for coal

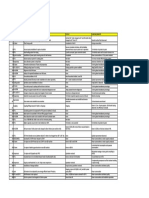

C E&I

1 Cables above 6 sq mm to be aluminum instead of copper (only cables) Agreed.

2 Busbars to be aluminium Agreed.

3 Earthing and Lightning to remain of copper construction Agreed.

4 All panels to be of Chinese Maker with core parts from ABB, Siemens or Scheider Agreed.

5 Main Panel can be located within the kiln load center itself. Hence separate room

Agreed.

for Main Sub-station to be deletd

6 4 nos feeder in main panel indicated as "Future"" can be deleted from scope. Only

Agreed.

space provision for addition in future to be provided

7 All MV panels to be provided with single incomer only Agreed.

8 Spare feeders to be restricted to 20% Agreed.

9 UPS to be provided for 120 min backup instead of 240 min Agreed.

10 SOx, NOx measurement for preheater outlet and fine coal bin gas analyser is not

Agreed.

required

11 DCS with redundent CPU will be used only for Pyro system, others are single CPU. Agreed.

D Civil and Structural

1 Change of superstructure construction of Raw mill, Coal mill and Raw mill hopper

Agreed.

to concrete from steel

2 Boundary wall on the front side and chain link fencing on other sides Agreed.

3 Sales / Dispatch office deleted from scope Agreed.

4 Clinic to be deleted from scope Agreed.

5 Fire Station to be deleted from scope Agreed.

6 Canteen area reduced from 1200 sqm to 750 sqm Agreed.

7 Main store area reduced from 2300 sqm to 1200 sqm Agreed.

8 Workshop area reduced from 4200 sqm to 2500 sqm Agreed.

9 Truck parking area to be of interlocking tile construction instead of concrete Agreed.

10 Bitumen construction of roads instead of concrete Agreed.

11 Road for line 2 shall be Constructed in future. Agreed.

12 Roof cover for open nuisance bag filter, Raw meal silo top shall be removed. Agreed.

13 Bore well and its pump is removed from Sinoma Scope Agreed.

E Special Remarks

1 Due to process requirement, roller press drives to be supplied with VFD panel Agreed.

Annex 7.1 Optimization List 1/2 Contract

F Sub-Supplier

Sinoma/Beijing power equipment group(to be

1 Coal Mill

decided)

Bags shall be as per agreed sub-supplier list and

2 Process baghouse

casing and hopper by Sinoma

3 Corrective / Coal Crusher and Apron Feeder for Crusher Sinoma

4 Stacker Reclaimer for Limestone and Coal Sinoma

5 Roller press Sinoma

6 Baoding Tianwei Transformer/Shandong

Transformer Dachi/China Electric Equipment/ Shenyang

Haocen

7 Sinoma (ShangRao) Machinery Co., Ltd/Beijing

Surface Feeder Farthest Technology Co.,Ltd./Tangshan Ruiyiju

machinery equipment Co., Ltd.

8 Sanghai East pump group,/ Sandong Boshan

Pump Science and Technology/ Shandong

Water pumps other than Fire hydrant pumps shall be as per approved vendors list

Shuanglun Group/ Shanghai Liancheng Group/

Shanghai Kaiquan Pump Group

Annex 7.1 Optimization List 2/2 Contract

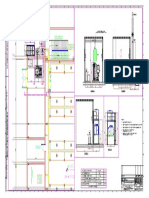

Annex1 OPTIMIZED PLANT DESIGN CONFIGURATION

RATED Sinoma

DEPARTMENT / EQUIPMENT REMARKS

CAPACITY Reply

Belt Conveyor from Mines to Agreed

2000 TPH

Plant Premises

Agreed.

Base offer

with 2 x

15,000 MT

Limestone Stockpile 2x15000T

Linear

longitudinal

Stockpile.

Limestone Stacker 600 TPH Agreed

Limestone Re-claimer 350 TPH Agreed

Bulk Receiving Unit for Agreed

400 TPH

Correctives and Coal / Petcoke

Bypass for Agreed

Corrective and Coal / Petcoke

275 TPH Crusher to be

Crusher (Assuming 30% fines)

Provided

1 x 2250 T Agreed

Bauxite, 1 x

Combined Corrective and Coal 2250 T Iron Ore,

/ Petcoke Stockpile 1 x 10000 T

Shale, 2 x 5000

T Coal / Petcoke

Corrective and Coal / Petcoke Agreed

Stacker (Luffing and Slewing 400 TPH

Type)

Corrective and Coal / Petcoke Agreed

200 TPH

Re-claimer

Raw Mill Hopper 1 x 400 t for LS, With Agreed

1 x 150 T for provision for

Annex 7.1 Optimization List 1/3 Contract

RATED Sinoma

DEPARTMENT / EQUIPMENT REMARKS

CAPACITY Reply

Shale, 1 x 100 T addition of 1

for Bauxite and x 400 T for LS

1 x 100 T for in future

Iron Ore

Agreed and

extraction

Fly ash and Bed ash bins

system for

extraction system to be

bed ash silo

included in scope

not

required.

Raw Mill 275 TPH Agreed

Blending Silo 1 x 10000 T Agreed

Bag House for Raw Mill & Kiln Agreed

To Suit

(Pulse Jet type)

Kiln Feed 250 TPH Agreed

Coal / Petcoke Mill (VRM) 17 TPH Coal Output Agreed

(Petcoke) with same

mill to be

indicated and

guaranteed

Coal / Petcoke Conveying – Agreed

11 TPH

Kiln Burner

Coal / Petcoke Conveying – Agreed

11 TPH No design

Pre-calciner Burner

margin

5-Stage, Single String Pre- required Agreed

heater with In line Pre-calciner 3000 TPD

and low NOx Burners

Rotary Kiln with three supports 3000 TPD Agreed

Grate area > 72 Agreed with

High efficiency Grate Cooler

m2 73 m 2

Bag House for Cooler To Suit Agreed

Annex 7.1 Optimization List 2/3 Contract

RATED Sinoma

DEPARTMENT / EQUIPMENT REMARKS

CAPACITY Reply

Clinker Transport to Clinker Agreed

250 TPH

Silo Top

Clinker Silo 1 x 30000 T Agreed

Clinker Bulk Loading System Agreed

2 x 300 TPH

(Outside Clinker Silo)

Unburnt Clinker Silo 1 x 500 T Agreed

Clinker Bulk Loading System Agreed

(Below Off Spec. / Reject 1 x 300 TPH

Clinker Silo)

Only RO unit Agreed

to be

standby.

Filtration

Water Treatment Plant 1 x 750 m3 units need

not be

standby. All

pumps will

have standby

Capacity of Agreed

all other

Raw Water Tank 1 x 2000 m3 tanks to

remain

unchanged

Sewage Treatment Plant 30 m3/day Agreed

Annex 7.1 Optimization List 3/3 Contract

Vous aimerez peut-être aussi

- Idle and Dedicated Mode ThresholdDocument5 pagesIdle and Dedicated Mode ThresholdatitPas encore d'évaluation

- F43-Obajana Line 3-PM-04 - Clinker ProductionDocument109 pagesF43-Obajana Line 3-PM-04 - Clinker ProductionYhane Hermann BackPas encore d'évaluation

- PSP 42 Operation ManualDocument21 pagesPSP 42 Operation ManualGeorge RobinsonPas encore d'évaluation

- 5 B 1 GSM To UMTS Training Series 15 WCDMA RF Optimization Process V1 0Document68 pages5 B 1 GSM To UMTS Training Series 15 WCDMA RF Optimization Process V1 0Nguyen Son Tung100% (1)

- Sinoma International Engineering Co. 2013 Annual ReportDocument52 pagesSinoma International Engineering Co. 2013 Annual Reportnsprasad88Pas encore d'évaluation

- AC DC kilns compared for cement applicationsDocument10 pagesAC DC kilns compared for cement applicationsPrateek SinghPas encore d'évaluation

- PDF Created With Pdffactory Trial VersionDocument8 pagesPDF Created With Pdffactory Trial VersionVisnu SankarPas encore d'évaluation

- Asphalt Batch Mix Plant CABP-80 (80 TPH)Document12 pagesAsphalt Batch Mix Plant CABP-80 (80 TPH)ys710924Pas encore d'évaluation

- Peb DesignDocument1 pagePeb DesignVishal TiwariPas encore d'évaluation

- 1.clarifications Required From Sinoma - OLD PENDING POINTSDocument9 pages1.clarifications Required From Sinoma - OLD PENDING POINTSabdullah amanullahPas encore d'évaluation

- API 11P Vs API 618Document2 pagesAPI 11P Vs API 618luis100% (3)

- Safety Valve's Noise LevelDocument2 pagesSafety Valve's Noise Levelaravind grandhiPas encore d'évaluation

- Comments Reply SheetDocument1 pageComments Reply SheetAfsal JhPas encore d'évaluation

- NALCO: AN OVERVIEW OF KEY OPERATIONSDocument36 pagesNALCO: AN OVERVIEW OF KEY OPERATIONSPrasant Kumar100% (1)

- Maleic Anhydride Expansion ProjectDocument2 pagesMaleic Anhydride Expansion Projectthaneiro100% (1)

- DC Motor CatalogueDocument12 pagesDC Motor CatalogueAbhishek KumarPas encore d'évaluation

- Meeting/Project Name: Date of Meeting: Project No. Meeting Facilitator: Document No. Venue Subject. 1. Meeting ObjectiveDocument2 pagesMeeting/Project Name: Date of Meeting: Project No. Meeting Facilitator: Document No. Venue Subject. 1. Meeting ObjectiveBagadi AvinashPas encore d'évaluation

- Comments On Existing PFRDocument1 pageComments On Existing PFRDeepak SharmaPas encore d'évaluation

- Revamping of Cooling Tower CellsDocument5 pagesRevamping of Cooling Tower CellsAbhinav PradhanPas encore d'évaluation

- Compliance & Response Sheet: Sensitivity: LNT Construction Internal UseDocument1 pageCompliance & Response Sheet: Sensitivity: LNT Construction Internal Useirshad khanPas encore d'évaluation

- SEZ Coker 184KBPSD Revamp Project Executive SummaryDocument12 pagesSEZ Coker 184KBPSD Revamp Project Executive SummarySubhojit AdhikaryPas encore d'évaluation

- Equipment and supplier detailsDocument2 pagesEquipment and supplier detailsarkaprava paulPas encore d'évaluation

- Best Practices in Energy Efficiency in Cement SectorDocument32 pagesBest Practices in Energy Efficiency in Cement SectorChandra SekarPas encore d'évaluation

- Brosur NKDocument8 pagesBrosur NKHeroe PoernomoPas encore d'évaluation

- Tech Details For Semi Mobile Crushing SystemDocument6 pagesTech Details For Semi Mobile Crushing SystemSukalyan BasuPas encore d'évaluation

- Traveling Grate Boiler 50 TPH 95 KGCM 450CDocument52 pagesTraveling Grate Boiler 50 TPH 95 KGCM 450CMajid KhanPas encore d'évaluation

- Monthly ReportDocument3 pagesMonthly ReportvijayPas encore d'évaluation

- Ammonia Absorption Refrigeration Technology GuideDocument24 pagesAmmonia Absorption Refrigeration Technology GuidePUSHKARKHANNAPas encore d'évaluation

- Brief Introduction: Satyakam Mohapatra Engineer (Mechanical)Document73 pagesBrief Introduction: Satyakam Mohapatra Engineer (Mechanical)Rajneesh VachaspatiPas encore d'évaluation

- Energy Saving and Quality Improvement MeasuresDocument1 pageEnergy Saving and Quality Improvement MeasuresRahul PareraoPas encore d'évaluation

- Loading Considerations for Structural DesignDocument4 pagesLoading Considerations for Structural DesignVishal TiwariPas encore d'évaluation

- BC01C1-Soot Blower Spec - R0Document6 pagesBC01C1-Soot Blower Spec - R0JKKPas encore d'évaluation

- 190 TPH Start Up ProcedureDocument19 pages190 TPH Start Up ProcedurepothanPas encore d'évaluation

- Daikin-McQuay 210.8 TR water cooled chiller technical detailsDocument5 pagesDaikin-McQuay 210.8 TR water cooled chiller technical detailsDHAVALESH AMPas encore d'évaluation

- Instruction Book October 15 White BookDocument20 pagesInstruction Book October 15 White BookSinan PravadaliogluPas encore d'évaluation

- Construction and Working of Coal Handling PlantDocument30 pagesConstruction and Working of Coal Handling PlantArvind ShuklaPas encore d'évaluation

- Gtl-Main ImageDocument23 pagesGtl-Main Imagedeepak diliPas encore d'évaluation

- Heaters For Bitumen (Tar) and Emulsion - Specification: Indian StandardDocument6 pagesHeaters For Bitumen (Tar) and Emulsion - Specification: Indian StandardAmanulla KhanPas encore d'évaluation

- Annex 7-2 Deviation ListDocument3 pagesAnnex 7-2 Deviation Listabdullah amanullahPas encore d'évaluation

- Maintaining a 40-Year-Old Steam ReformerDocument14 pagesMaintaining a 40-Year-Old Steam Reformervaratharajan g rPas encore d'évaluation

- Layout and Site SelectionDocument17 pagesLayout and Site Selectionjojo pantherPas encore d'évaluation

- Revised Deviation Sheet 08.12.2022Document2 pagesRevised Deviation Sheet 08.12.2022Swarup NayakPas encore d'évaluation

- Turbine Issues ResolutionDocument34 pagesTurbine Issues Resolutionraj3850% (2)

- Tilting Rotary FurnaceDocument8 pagesTilting Rotary FurnaceErnane MagalhãesPas encore d'évaluation

- Condensador en Aplicaciones de RefrigeracionDocument24 pagesCondensador en Aplicaciones de Refrigeracionnibble1974Pas encore d'évaluation

- Hvac Boq-07082014Document18 pagesHvac Boq-07082014farshan296015Pas encore d'évaluation

- Startup Plan Sulphuric AcidDocument1 pageStartup Plan Sulphuric AcidFahd AliPas encore d'évaluation

- 19DV - GUIDE SPECS - CopyDocument6 pages19DV - GUIDE SPECS - CopyVijay BaskaranPas encore d'évaluation

- Spray-type Deaerators: Highly Efficient Oxygen RemovalDocument4 pagesSpray-type Deaerators: Highly Efficient Oxygen RemovalVahed MoradiPas encore d'évaluation

- 82P21 Detail Sent 51 CDocument5 pages82P21 Detail Sent 51 CRakesh PatelPas encore d'évaluation

- Engineering Requests SL - No. Item Description Conformance CommentsDocument2 pagesEngineering Requests SL - No. Item Description Conformance Commentsshameer_sanju1049Pas encore d'évaluation

- Comments Resolution SheetDocument6 pagesComments Resolution SheetPrasadPas encore d'évaluation

- BOQ Sample For A Civil Work of Mechanical LabDocument54 pagesBOQ Sample For A Civil Work of Mechanical LabSelvakumar SPas encore d'évaluation

- High Pressure Gear Pumps KP 1Document24 pagesHigh Pressure Gear Pumps KP 1Gaurav ChovatiyaPas encore d'évaluation

- List of ActivitiesDocument5 pagesList of Activitiesnaim indahiPas encore d'évaluation

- Galvanize Galvanize Business Unit: Trust Us To GalvanizeDocument6 pagesGalvanize Galvanize Business Unit: Trust Us To GalvanizeAdet WildanPas encore d'évaluation

- MP Projects AheadDocument8 pagesMP Projects AheadJPas encore d'évaluation

- Annexure N ERI BMS YP contract Revised SOW - incl LN comments 16 April 2017Document17 pagesAnnexure N ERI BMS YP contract Revised SOW - incl LN comments 16 April 2017Liberty MunyatiPas encore d'évaluation

- Water Efficiency in Thermal Power SectorDocument27 pagesWater Efficiency in Thermal Power Sectorhari reddyPas encore d'évaluation

- 1 00 561 U4089 - Rev 04 PDFDocument15 pages1 00 561 U4089 - Rev 04 PDFSandip SurPas encore d'évaluation

- Sabb-Gray Water WsfuDocument22 pagesSabb-Gray Water Wsfuabdullah amanullahPas encore d'évaluation

- Mohamed Anas.S: Job ObjectiveDocument3 pagesMohamed Anas.S: Job Objectiveabdullah amanullahPas encore d'évaluation

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionDocument1 pageNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahPas encore d'évaluation

- Tamil (Second Language) Summer Break - Holiday Assignment 2019 - 20Document2 pagesTamil (Second Language) Summer Break - Holiday Assignment 2019 - 20abdullah amanullahPas encore d'évaluation

- Aurora Fire PumpDocument8 pagesAurora Fire Pumpabdullah amanullahPas encore d'évaluation

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Document2 pagesUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahPas encore d'évaluation

- English Summer Break - Holiday Assignment 2019 - 20Document2 pagesEnglish Summer Break - Holiday Assignment 2019 - 20abdullah amanullahPas encore d'évaluation

- Nonmetal Ducts - Guide Specification - Updated 6-2019Document17 pagesNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahPas encore d'évaluation

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Document5 pagesCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahPas encore d'évaluation

- Science Summer Break - Holiday Assignment 2019 - 20Document2 pagesScience Summer Break - Holiday Assignment 2019 - 20abdullah amanullahPas encore d'évaluation

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Document2 pagesUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahPas encore d'évaluation

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionDocument1 pageNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahPas encore d'évaluation

- 15730-DX Cooling Units Rev 01Document10 pages15730-DX Cooling Units Rev 01abdullah amanullahPas encore d'évaluation

- Learn Hindi Letters and NumbersDocument3 pagesLearn Hindi Letters and Numbersabdullah amanullahPas encore d'évaluation

- Revision SSTDocument2 pagesRevision SSTabdullah amanullahPas encore d'évaluation

- Kairos ScheduleDocument1 pageKairos Scheduleabdullah amanullahPas encore d'évaluation

- Our Body is a Wonderful MachineDocument2 pagesOur Body is a Wonderful Machineabdullah amanullahPas encore d'évaluation

- PT2 Revision Worksheet EnglishDocument3 pagesPT2 Revision Worksheet Englishabdullah amanullahPas encore d'évaluation

- Worksheet - WaterDocument2 pagesWorksheet - Waterabdullah amanullah100% (2)

- Indian Social Studies Class 3 EnvironmentDocument2 pagesIndian Social Studies Class 3 Environmentabdullah amanullahPas encore d'évaluation

- Compressed UCDM EnglishDocument176 pagesCompressed UCDM EnglishAnonymous zmYUcSPPas encore d'évaluation

- Ga Layout For Stem GeneratorDocument1 pageGa Layout For Stem Generatorabdullah amanullahPas encore d'évaluation

- Infrastructure Charges Notice CalculatorDocument1 pageInfrastructure Charges Notice Calculatorabdullah amanullahPas encore d'évaluation

- 0.list of Drawing - Lower LevelDocument1 page0.list of Drawing - Lower Levelabdullah amanullahPas encore d'évaluation

- New Indian Model School, SharjahDocument2 pagesNew Indian Model School, Sharjahabdullah amanullahPas encore d'évaluation

- The King's Condition worksheet for Grade 3Document2 pagesThe King's Condition worksheet for Grade 3abdullah amanullahPas encore d'évaluation

- Automatedmeterreadingtechnology PDFDocument5 pagesAutomatedmeterreadingtechnology PDFabdullah amanullahPas encore d'évaluation

- Infrastructure Charges Notice CalculatorDocument1 pageInfrastructure Charges Notice Calculatorabdullah amanullahPas encore d'évaluation

- Acoustic Performance Goals for Doha Oasis Theme ParkDocument43 pagesAcoustic Performance Goals for Doha Oasis Theme Parkabdullah amanullahPas encore d'évaluation

- Qatar Fire Safety Guidelines for Residential ApartmentsDocument122 pagesQatar Fire Safety Guidelines for Residential ApartmentsAbdul Jamal100% (1)

- Develop Diesel Fuel AdditivesDocument9 pagesDevelop Diesel Fuel AdditivesidownloadbooksforstuPas encore d'évaluation

- The Pipeline and The Paradigm Sample ChapterDocument25 pagesThe Pipeline and The Paradigm Sample ChapterDaniel KohanPas encore d'évaluation

- Drilling Operations: Dr. Shilpa Patil Sinhgad College of Science, Pune 41Document13 pagesDrilling Operations: Dr. Shilpa Patil Sinhgad College of Science, Pune 41Shilpa Patil0% (1)

- Atos Fuel SDocument133 pagesAtos Fuel Singenieriaelectronic100% (1)

- Product Details: The Protective Coatings Professionals™Document2 pagesProduct Details: The Protective Coatings Professionals™JKLimPas encore d'évaluation

- Anfo Vs EmulsionDocument38 pagesAnfo Vs EmulsionRitesh TiwariPas encore d'évaluation

- Road Speed Limiter AUSTDocument5 pagesRoad Speed Limiter AUSTRiki KrisnaldiPas encore d'évaluation

- CVS - Company Profile PDFDocument31 pagesCVS - Company Profile PDFMuhammad RidwanPas encore d'évaluation

- Wikiepdia - Cracking Chemistry)Document6 pagesWikiepdia - Cracking Chemistry)Azrul NizamPas encore d'évaluation

- Energy Value ChainDocument2 pagesEnergy Value ChainSatyam AgarwalPas encore d'évaluation

- CDU II Operating ManualDocument562 pagesCDU II Operating ManualRajeshwar Telang91% (11)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument9 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsAbdo MajidPas encore d'évaluation

- Medium Capacity Air Separation Plants for Oxygen Nitrogen and Argon ProductionDocument8 pagesMedium Capacity Air Separation Plants for Oxygen Nitrogen and Argon Productionkalyanm203515100% (1)

- Fischer TropschDocument19 pagesFischer TropschConnor SailorPas encore d'évaluation

- I C Engine TestingDocument87 pagesI C Engine TestingLove Reloaded100% (1)

- ST2D PDFDocument4 pagesST2D PDFMelvin CotradoPas encore d'évaluation

- Operating Manual OISDocument9 pagesOperating Manual OISdoumtPas encore d'évaluation

- Range Rover Classic Manual 1995Document767 pagesRange Rover Classic Manual 1995Vargas DP100% (1)

- CPC PDFDocument2 pagesCPC PDFQichiix Kici100% (1)

- SM Si50-402A CompressorDocument61 pagesSM Si50-402A Compressorttt44967% (3)

- Xp13000Eh Generator: User ManualDocument66 pagesXp13000Eh Generator: User ManualANGEL MALAVERPas encore d'évaluation

- Mepc.2-Circ.22 (E)Document86 pagesMepc.2-Circ.22 (E)tomislav_darlic100% (1)

- Main Engine Fuel Injection Valve Damage: ReturnDocument5 pagesMain Engine Fuel Injection Valve Damage: ReturnKupujem HNPas encore d'évaluation

- Liquid Biofuel - A Viable Choice For Power Generation PDFDocument2 pagesLiquid Biofuel - A Viable Choice For Power Generation PDFRussell CarterPas encore d'évaluation

- Hydrogen Fuel CellsDocument17 pagesHydrogen Fuel CellsChaithz LuciPas encore d'évaluation

- 50FA14B1-4C69-4B24-8E63-8FB2FCEA6231Document1 page50FA14B1-4C69-4B24-8E63-8FB2FCEA6231Tomislav CvarPas encore d'évaluation

- Petrotrin: A Valued Partner in Trinidad and Tobago's Energy IndustryDocument10 pagesPetrotrin: A Valued Partner in Trinidad and Tobago's Energy IndustryAnthony BasantaPas encore d'évaluation

- Fluid Mechanic1Document4 pagesFluid Mechanic1Major Singh Sidhu0% (1)

- Fuel from plastic waste: Converting waste plastics into liquid fuelsDocument56 pagesFuel from plastic waste: Converting waste plastics into liquid fuelssumit potdarPas encore d'évaluation

- 25-Fuel SystemDocument21 pages25-Fuel SystemПавелPas encore d'évaluation