Académique Documents

Professionnel Documents

Culture Documents

NEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification Remarks

Transféré par

Srinivasa Rao Venkumahanthi0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues1 pagepump specifiaction

Titre original

Pump Secification

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentpump specifiaction

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

39 vues1 pageNEW 1 X 2100 M Induced Drfat Cooling Tower: Data For Pumps Sl. No Description UOM Specification Remarks

Transféré par

Srinivasa Rao Venkumahanthipump specifiaction

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

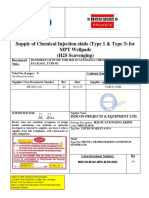

Doc. Ref.

: VSR/CT/ETDS/001

Doc. Rel. Date: 20th April 2018

Page no.: 1 of 1

NEW 1 x 2100 m3 INDUCED DRFAT COOLING TOWER

DATA FOR PUMPS

Sl. No Description UOM Specification Remarks

01 TAG NUMBER EVAP – CT – 001 & 002

COOLING TOWER WATER

02 PUMP NAME

TRANSFER PUMPS

HORIZONTAL NON-CLOG VENDOR CAN SPECIFY

03 PUMP TYPE

CENTRIFUGAL SUITABLE MODEL

04 OPERATING FLUID COOLING WATER

05 pH 8-9

06 CONCENTRATION % ds

07 SPECIFIC GRAVITY 1.05

08 VISCOSITY Cp ---

09 DESIGN PARAMETERS:

- CAPACITY m³ / hr 2300

- HEAD mtr 38

- TEMPERATURE °C 40

10 OPERATING PARAMETERS:

- CAPACITY m³ / hr 2200

- HEAD mtr 38

- TEMPERATURE °C 35

11 NPSH AVAILABLE mtr FLOODED

12 IMPELLER TYPE CLOSED

13 SHFAT SEALING TYPE GLAND PACKED

14 MOTOR POWER KW VENDOR TO SPECIFY

15 MOTOR SPEED RPM 1450

16 MOC

- CASING CS

- INTERNALS / IMPELLER SS 2333 / AISI 304L

- SHAFT SLEEVE SS 2333 / AISI 304L

17 OPERATION CONTINIOUS

18 QUANTITY Nos 2

Special Notes:

1) All pumps should be of well – proven design & from the normal range of production of supplier

2) Pump should be supplied along with its Base Frame, Foundation bolts, coupling with pilot bore

3) Coupling type: “TYRE “& Make – “FENNER”

4) Electrical motors shall be liberally sized with at least 15% over the pump rated & specified KW. While selecting

the motor base frame vendor has to consider one size higher than the motor size selected.

5) Motors will be supplied by others & do not form part of Inquiry.

6) Power supply: 415 V, 3 Phase, 50 Hz

7) During dispatch, discharge & suction nozzles should be covered with blind flanges to avoid foreign material

entering into the pump

8) Pumps to be supplied along with matting suction & discharge flanges

Prepared by Checked & Reviewed by Approved by

V Srinivasa Rao / Raghbir Singh / N C Ray /Tagore / Sanjay Singh /

Name / Dept.

Projects CRP - Mech CRP - Process GM – CRP

Signature

Date

Vous aimerez peut-être aussi

- Longwall Mining at Shallow Depth of Cover in IndiaD'EverandLongwall Mining at Shallow Depth of Cover in IndiaPas encore d'évaluation

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasPas encore d'évaluation

- ATFD PiparDocument10 pagesATFD Piparrajesh kothariPas encore d'évaluation

- ATFD Offer KBDocument10 pagesATFD Offer KBrajesh kothariPas encore d'évaluation

- 20kg-P&id (Sheet 3 of 3)Document1 page20kg-P&id (Sheet 3 of 3)naurizsultanov.fxPas encore d'évaluation

- AgitatorDocument3 pagesAgitatorMarcelo PerettiPas encore d'évaluation

- Karta Katalogowa Rexroth KFADocument20 pagesKarta Katalogowa Rexroth KFASebastianPas encore d'évaluation

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubPas encore d'évaluation

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubPas encore d'évaluation

- Manual Roof-Top Frio Calor Por Bomba RT-008-030Document45 pagesManual Roof-Top Frio Calor Por Bomba RT-008-030giulianogjPas encore d'évaluation

- Pump DatasheetDocument4 pagesPump Datasheetbmanojkumar16Pas encore d'évaluation

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariPas encore d'évaluation

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoPas encore d'évaluation

- Pressurization UnitDocument16 pagesPressurization UnitsheetalnathPas encore d'évaluation

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocument4 pagesIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoPas encore d'évaluation

- Basf Mechanical Euipmen: 08-01-20 R3.1 d0 IFB ST PV AL HS RMDocument9 pagesBasf Mechanical Euipmen: 08-01-20 R3.1 d0 IFB ST PV AL HS RMbecpavanPas encore d'évaluation

- Espicificaciones Mecanicos de Bombas de Impulsion Datasheet 54-P01A/B/CDocument3 pagesEspicificaciones Mecanicos de Bombas de Impulsion Datasheet 54-P01A/B/Cmauro.vergaraPas encore d'évaluation

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalPas encore d'évaluation

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaPas encore d'évaluation

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaPas encore d'évaluation

- FACOR - TS 5.1 - Pumps - R1Document9 pagesFACOR - TS 5.1 - Pumps - R1Amit TiwariPas encore d'évaluation

- Magnetic Drive Pump Hot Oil UnitDocument1 pageMagnetic Drive Pump Hot Oil Unitarun manchekarPas encore d'évaluation

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaPas encore d'évaluation

- Annexure To Be AttachedDocument12 pagesAnnexure To Be AttachedAnonymous vspGaH8Pas encore d'évaluation

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalPas encore d'évaluation

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengPas encore d'évaluation

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaPas encore d'évaluation

- Data Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.Document4 pagesData Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.zvlcar nainPas encore d'évaluation

- Eth - 7000024824 - Hvac BoqDocument28 pagesEth - 7000024824 - Hvac Boqmohammedansin1Pas encore d'évaluation

- CCV 308Document8 pagesCCV 308francisco abarcaPas encore d'évaluation

- 6695 (ElChecklist)Document21 pages6695 (ElChecklist)aungsan ooPas encore d'évaluation

- BLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFDocument6 pagesBLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFEdy AlamPas encore d'évaluation

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaPas encore d'évaluation

- Cam 200-390-110kwDocument4 pagesCam 200-390-110kwbocahjeblogPas encore d'évaluation

- Data Sheet 65 DS 51.5Document4 pagesData Sheet 65 DS 51.5Gokula Krishnan CPas encore d'évaluation

- Operation & DataDocument506 pagesOperation & DataАндрей АндреевPas encore d'évaluation

- Pump SpecsDocument5 pagesPump SpecsNitin KurupPas encore d'évaluation

- Centrifugal Pump Data Sheet: Doc. No.Document6 pagesCentrifugal Pump Data Sheet: Doc. No.Mahdi KazemiPas encore d'évaluation

- R2 - RevADocument12 pagesR2 - RevAChirag ShahPas encore d'évaluation

- 9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankDocument3 pages9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankFikri MakhlufPas encore d'évaluation

- Data Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1Document1 pageData Sheet - Rotary Gas Meter: RRPL-OGD-DOC-NO:-GGL-RPD-150-003 Sheet 1 of 1akshay bahalPas encore d'évaluation

- DTS Sme 39163 Pro 1022C - 01Document2 pagesDTS Sme 39163 Pro 1022C - 01Jairo Andres Romero QuirogaPas encore d'évaluation

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalPas encore d'évaluation

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalPas encore d'évaluation

- New Profile PEWDocument14 pagesNew Profile PEWChrill DsilvaPas encore d'évaluation

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodPas encore d'évaluation

- L&T Document Number:: 0 1 ARN DDU ARN DDUDocument56 pagesL&T Document Number:: 0 1 ARN DDU ARN DDUFayaz AhammedPas encore d'évaluation

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Document5 pagesSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarPas encore d'évaluation

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcPas encore d'évaluation

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuPas encore d'évaluation

- Pompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM BatulicinDocument124 pagesPompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM Batulicinmuh_akbar2451Pas encore d'évaluation

- Fitvma - DBGF 633 - LDP: Icatalog NO:: 00-3843Document2 pagesFitvma - DBGF 633 - LDP: Icatalog NO:: 00-3843johnny sabinPas encore d'évaluation

- Feuilles de Donnees Transmetteur de NiveauDocument5 pagesFeuilles de Donnees Transmetteur de NiveauAHMED AMIRA100% (1)

- Instrument Data Sheets: Revision HistoryDocument9 pagesInstrument Data Sheets: Revision Historyerik masongPas encore d'évaluation

- Air Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ADocument4 pagesAir Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ASouvik DaluiPas encore d'évaluation

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisPas encore d'évaluation

- C128.2.230210-Effwa InfraDocument13 pagesC128.2.230210-Effwa InfraMahesh MPas encore d'évaluation

- Pump Data SheetDocument3 pagesPump Data Sheetkaustav100% (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineD'EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineÉvaluation : 5 sur 5 étoiles5/5 (1)

- Benitez Cap9Document44 pagesBenitez Cap9Srinivasa Rao VenkumahanthiPas encore d'évaluation

- NP - AewDocument3 pagesNP - AewSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Steam Trap Selection: Understanding SpecificationsDocument5 pagesSteam Trap Selection: Understanding SpecificationsSrinivasa Rao VenkumahanthiPas encore d'évaluation

- NP - MasterDocument3 pagesNP - MasterSrinivasa Rao VenkumahanthiPas encore d'évaluation

- PMT-HelponExceltool Demo LockedDocument253 pagesPMT-HelponExceltool Demo LockedSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Oh I Ou 1173374043Document54 pagesOh I Ou 1173374043Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Project (Mechanical) Department - Attendance Sheet For The Month of September - 2017Document3 pagesProject (Mechanical) Department - Attendance Sheet For The Month of September - 2017Srinivasa Rao VenkumahanthiPas encore d'évaluation

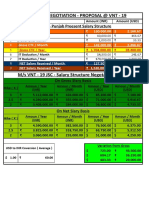

- VNT - 19Document1 pageVNT - 19Srinivasa Rao VenkumahanthiPas encore d'évaluation

- SS R1Document2 pagesSS R1Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhPas encore d'évaluation

- To, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaDocument1 pageTo, Income Tax Department - CPC, Post Bag No - 1, Electronic City Post Office, BENGALURU - 560 100, Karnataka - IndiaSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Tectyl 506 OilDocument1 pageTectyl 506 OilSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Employee Certification LetterDocument1 pageEmployee Certification LetterSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Group Erw Seamless Product BrochureDocument6 pagesGroup Erw Seamless Product BrochureSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Appendix C - Energy Savings Analysis: The User Should Input Project Specific Data Into The Yellow Shaded CellsDocument1 pageAppendix C - Energy Savings Analysis: The User Should Input Project Specific Data Into The Yellow Shaded CellsamronkpjbPas encore d'évaluation

- 1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Document1 page1 X 650 Tds Chemical Recovery Boiler - Pressure Parts Manufacuring Discrepancies (Tirchy)Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Jindal Steel SpecificationsDocument76 pagesJindal Steel SpecificationsVignesh Chellappan NatarajanPas encore d'évaluation

- Flow But FabDocument8 pagesFlow But FabSrinivasa Rao VenkumahanthiPas encore d'évaluation

- VNT - 19Document1 pageVNT - 19Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Tectyl 506 PDFDocument4 pagesTectyl 506 PDFjaskaran singhPas encore d'évaluation

- Black Liquor and Recovery Boilers 2016Document25 pagesBlack Liquor and Recovery Boilers 2016Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Nilar - CostingDocument3 pagesNilar - CostingSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Commissioning Schedule 01Document30 pagesCommissioning Schedule 01Srinivasa Rao VenkumahanthiPas encore d'évaluation

- Kirana Items ListDocument10 pagesKirana Items ListSrinivasa Rao Venkumahanthi100% (1)

- Aew - 003Document3 pagesAew - 003Srinivasa Rao VenkumahanthiPas encore d'évaluation

- ATM Tank Calc (Converted)Document5 pagesATM Tank Calc (Converted)rahul84803Pas encore d'évaluation

- Bfs Deaerator RFQDocument2 pagesBfs Deaerator RFQSrinivasa Rao VenkumahanthiPas encore d'évaluation

- Scheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsDocument1 pageScheduel For 1 X 400 Tds Upgradtion To 1 X 600 TdsSrinivasa Rao VenkumahanthiPas encore d'évaluation

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadPas encore d'évaluation

- Intel Stratix 10 Avalon - MM Interface For PCI Express Solutions User GuideDocument173 pagesIntel Stratix 10 Avalon - MM Interface For PCI Express Solutions User Guideenoch richardPas encore d'évaluation

- Moses ManualDocument455 pagesMoses ManualDadypeesPas encore d'évaluation

- SAT Biochar Ethylene Poster 10 - 10b PDFDocument1 pageSAT Biochar Ethylene Poster 10 - 10b PDFsherifalharamPas encore d'évaluation

- LPG GasDocument39 pagesLPG Gasv prasanthPas encore d'évaluation

- ME 352 Design of Machine Elements: Lab ReportDocument5 pagesME 352 Design of Machine Elements: Lab ReportKeshav VermaPas encore d'évaluation

- Eating With Chloe Lets EatDocument150 pagesEating With Chloe Lets Eatemily.jarrodPas encore d'évaluation

- Egt Margen From The Best ArticalDocument6 pagesEgt Margen From The Best ArticalakeelPas encore d'évaluation

- E-OLSS: Electronic ControlDocument12 pagesE-OLSS: Electronic ControlSamidiPas encore d'évaluation

- Poems Prescribed For 2012-2014 English B CSEC ExamsDocument24 pagesPoems Prescribed For 2012-2014 English B CSEC ExamsJorge Martinez Sr.100% (2)

- 9701 w09 QP 21Document12 pages9701 w09 QP 21Hubbak KhanPas encore d'évaluation

- MATLAB Fundamentals Quick ReferenceDocument43 pagesMATLAB Fundamentals Quick ReferenceCarlos Manuel Cardoza EspitiaPas encore d'évaluation

- Mini Project 1 - 1Document9 pagesMini Project 1 - 1Sameer BaraPas encore d'évaluation

- HMT RM65 Radial DrillDocument2 pagesHMT RM65 Radial Drillsomnath213Pas encore d'évaluation

- LighthouseDocument4 pagesLighthousejaneborn5345Pas encore d'évaluation

- The Wild T1 TheodoliteDocument61 pagesThe Wild T1 TheodoliteCJLara100% (1)

- Ventricular Septal DefectDocument9 pagesVentricular Septal DefectpepotchPas encore d'évaluation

- The Variable Resistor Has Been AdjustedDocument3 pagesThe Variable Resistor Has Been AdjustedPank O RamaPas encore d'évaluation

- Lc420euf Sda1 LGDocument41 pagesLc420euf Sda1 LGjavierPas encore d'évaluation

- History and Philo of ScienceDocument5 pagesHistory and Philo of ScienceJan Oliver YaresPas encore d'évaluation

- Astm 2017-F2059Document5 pagesAstm 2017-F2059laythPas encore d'évaluation

- 7 +Royal+Court+Affairs,+Sultanate+of+OmanDocument12 pages7 +Royal+Court+Affairs,+Sultanate+of+OmanElencheliyan PandeeyanPas encore d'évaluation

- Analysis of LaminatedDocument31 pagesAnalysis of LaminatedKaustubh JadhavPas encore d'évaluation

- Sketchup-Rhino Cheat SheetDocument1 pageSketchup-Rhino Cheat Sheetxanext7Pas encore d'évaluation

- FAJASDocument891 pagesFAJASCecilia GilPas encore d'évaluation

- Furuno CA 400Document345 pagesFuruno CA 400Димон100% (3)

- BTK Implant Guide SurgeryDocument48 pagesBTK Implant Guide SurgeryMaria VolvinaPas encore d'évaluation

- Southwest Airlines Final ReportDocument16 pagesSouthwest Airlines Final Reportapi-427311067Pas encore d'évaluation

- Serving North Central Idaho & Southeastern WashingtonDocument12 pagesServing North Central Idaho & Southeastern WashingtonDavid Arndt100% (3)

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Document2 pagesNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelPas encore d'évaluation

- Assignment 4 SolutionsDocument9 pagesAssignment 4 SolutionsNengke Lin100% (2)