Académique Documents

Professionnel Documents

Culture Documents

Flowrox PC-pump D-Series Datasheet ENG

Transféré par

Alberto DiazDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flowrox PC-pump D-Series Datasheet ENG

Transféré par

Alberto DiazDroits d'auteur :

Formats disponibles

01/13

Progressive Cavity Pump, D-series TECHNICAL DATA SHEET

The Flowrox progressive cavity (PC) pumps’ D-series is designed Benefits and Features

for the most demanding industrial dosing applications. Due to its

• Low life cycle costs (TCO)

technical features and design high efficiency and high pressure [EUR/m3]

are achieved with a short construction. It is easy to install and • High efficiency

requires less energy and maintenance resulting in very low Total • High pressure (12 bar)

Cost of Ownership (TCO). • Easy and quick installation

- Over 180º stepless

adjustment of the suction

flange direction

GENERAL • User-friendly and easy

maintenance

- Long service interval

The Flowrox D-series progressing cavity pumps were conceived by utilizing - Quick replacement of the

Flowrox’s extensive experience in progressing cavity pump service and mechanical shaft seal

spare parts production as well as the knowledge gained from our

innovative peristaltic pump range. Flowrox is the industry benchmark for

abrasive, corrosive and other demanding shut-off, control and pumping Applications

applications. • All demanding and accurate

dosing applications in various

industries

BENEFITS

The precise ½-lobe rotor and stator technology allows a rigid and tighter

pumping unit, which enables 12 bar pressure per stage and excellent

efficiency. With optimized compression of rotor and stator friction,

spillover and wearing is minimized.

Easy installation, usage and maintenance have been taken into account in

pump’s structure, e.g. the direction of pump’s suction connection can be

adjusted stepless and change of main seal is quick and easy.

With Flowrox PC pump’s built-in advantages the customer’s actual savings

both in energy consumption as well as installation and maintenance costs

result in the total cost of ownership decreasing and higher plant

availability.

½-lobe round rotor

enables accurate

dosing

Product specification

Material alternatives: Drive: Shaft sealing:

Frame: • Electric motor with • Single Mechanical Shaft Seal

• Tubular beam or without

integrated VFD

Suction Pipe:

• Stainless steel

Rotor:

• Stainless steel hard coated

• Stainless steel

• Carbon steel hard coated

Stator

• NBR

MAIN DIMENSIONS

Weight

Model A B C D E F* G* H I J D1, D2 ØD3 D4

(kg)

D004/12 215 85 80 100 364 569 218 125 160 120 14 R1” 10 M8

D01/12 265 135 80 100 414 619 218 125 160 120 14 R1” 10 M8

D025/12 255 125 80 100 404 609 218 125 160 120 15 R1” 10 M8

D075/12 345 215 90 100 580 904 240 140 174 130 17 R1” 10 M8

* = Normative dimensions. Dimensions are in mm.

Information without engagement. All rights to changes without prior notice

reserved.

Flowrox Oy P.O. Box 338 Tel. +358 (0)201 113 311 info@flowrox.com

FI-53101 Fax +358 (0)201 113 300 www.flowrox.com

Lappeenranta

Finland

Vous aimerez peut-être aussi

- Flowrox PC-pump E-Series Datasheet ENGDocument2 pagesFlowrox PC-pump E-Series Datasheet ENGAlberto DiazPas encore d'évaluation

- Flowrox PC-pump EL-series Datasheet ENGDocument2 pagesFlowrox PC-pump EL-series Datasheet ENGAlberto Diaz100% (1)

- Butterfly ValveDocument5 pagesButterfly ValveSathishkumar DhamodaranPas encore d'évaluation

- KAT A 1331 W Wafer CEREX300 W Stainless Steel Water Edition10 17.12.2018 enDocument3 pagesKAT A 1331 W Wafer CEREX300 W Stainless Steel Water Edition10 17.12.2018 enSathishkumar DhamodaranPas encore d'évaluation

- KAT-A 1360 EKN-H Edition3 05.02.2021 ENDocument6 pagesKAT-A 1360 EKN-H Edition3 05.02.2021 ENkad-7Pas encore d'évaluation

- Rotary Power C Range 1221705 02 1021Document16 pagesRotary Power C Range 1221705 02 1021MIGUEL ÂNGELO DUTRA BUENOPas encore d'évaluation

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Sonny LuuPas encore d'évaluation

- KAT-A 1030 EKOplusWater en 07-11Document20 pagesKAT-A 1030 EKOplusWater en 07-11Jeffrey Calinao ManaloPas encore d'évaluation

- Gate Valve VAGDocument5 pagesGate Valve VAGrosiPas encore d'évaluation

- Kat A 1331 Lug Cerex300 L Wasser en 03 12Document6 pagesKat A 1331 Lug Cerex300 L Wasser en 03 12Sathishkumar DhamodaranPas encore d'évaluation

- Paco LC, LF, LCV BrochureDocument8 pagesPaco LC, LF, LCV BrochureMas PramPas encore d'évaluation

- Product Bulletin - Doen DJ142 eDocument8 pagesProduct Bulletin - Doen DJ142 eeePas encore d'évaluation

- Goulds 3910 BulletinDocument12 pagesGoulds 3910 BulletinLuevandresPas encore d'évaluation

- Vanco - Broshur PDFDocument5 pagesVanco - Broshur PDFFrido FaizalPas encore d'évaluation

- Frame Mounted End Suction Pump: Key Features and BenefitsDocument2 pagesFrame Mounted End Suction Pump: Key Features and BenefitsTim100% (1)

- Couplings and Mechanical Soft Starts: CatalogDocument52 pagesCouplings and Mechanical Soft Starts: Catalogashumishra007Pas encore d'évaluation

- Kat A 1331wafer Cerex300 W Wasser en 03 12Document6 pagesKat A 1331wafer Cerex300 W Wasser en 03 12Sathishkumar DhamodaranPas encore d'évaluation

- Series SDocument4 pagesSeries SMario VidićPas encore d'évaluation

- Ps 10 6 Ea4 PDFDocument4 pagesPs 10 6 Ea4 PDFYeisson Beltran AquinoPas encore d'évaluation

- DYNATORQUE CAMERON Gear and AccesoriesDocument12 pagesDYNATORQUE CAMERON Gear and Accesoriesemperor_vamsi100% (1)

- Multitec 200 / 250 - High-Pressure Pump in Ring-Section DesignDocument2 pagesMultitec 200 / 250 - High-Pressure Pump in Ring-Section Design47x996691523Pas encore d'évaluation

- Spec MD Series QuickcleanDocument2 pagesSpec MD Series QuickcleanThanh XuanPas encore d'évaluation

- KAT-A 1130-IL KOS-Internal Edition7 31.07.2018 enDocument4 pagesKAT-A 1130-IL KOS-Internal Edition7 31.07.2018 enSathishkumar DhamodaranPas encore d'évaluation

- Armstrong PumpDocument8 pagesArmstrong PumpRohith RavindranathPas encore d'évaluation

- Ebara 1-8-1-DWO - Techdata - SS - V14Document18 pagesEbara 1-8-1-DWO - Techdata - SS - V14Citramanda ServicesPas encore d'évaluation

- TESCO Hydro-Form CentralizersDocument2 pagesTESCO Hydro-Form CentralizersAdrien OfthestonePas encore d'évaluation

- Sustaining Our Environment: Eaton® Introduces GH109 Hose and Connectors To Support EPA Emission ReductionsDocument2 pagesSustaining Our Environment: Eaton® Introduces GH109 Hose and Connectors To Support EPA Emission Reductionszahar222Pas encore d'évaluation

- Aurora Pump 6-491-12aDocument28 pagesAurora Pump 6-491-12ajuan yenquePas encore d'évaluation

- Submersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDocument20 pagesSubmersible Pumps: For Dewatering, Sewage, Marine and Rental MarketsDebora MaryantiPas encore d'évaluation

- Ian Rosewarne A320 Edp-Acmp h205Document34 pagesIan Rosewarne A320 Edp-Acmp h205Gdchavez326 ChavezPas encore d'évaluation

- Innomag BrochureDocument8 pagesInnomag BrochureHENDRIK2011Pas encore d'évaluation

- ATKat 2004 eDocument103 pagesATKat 2004 eSaulius ŽilinskasPas encore d'évaluation

- cp1210 SpecsDocument2 pagescp1210 Specsyoucef alimPas encore d'évaluation

- Rotex Pneumatic Cylinder CatalogueDocument4 pagesRotex Pneumatic Cylinder Cataloguekumar ambujPas encore d'évaluation

- DbsDocument9 pagesDbsibharPas encore d'évaluation

- Roto JetDocument0 pageRoto JetHernan GirautPas encore d'évaluation

- Kobelt Tabla de EspecificacionesDocument43 pagesKobelt Tabla de EspecificacionesWilson CendalesPas encore d'évaluation

- Product Bulletin - Doen DJ172 eDocument8 pagesProduct Bulletin - Doen DJ172 eeePas encore d'évaluation

- Hydraulic Pumps, Motors & Filters: Replaces: DOC 02 R E Edition: 03/05.2010Document32 pagesHydraulic Pumps, Motors & Filters: Replaces: DOC 02 R E Edition: 03/05.2010Juan Carlos Bermudez Cardenas100% (1)

- M Orbitales A PDFDocument20 pagesM Orbitales A PDFAcu TomeiPas encore d'évaluation

- Kent Kf19 HammerDocument2 pagesKent Kf19 HammerEduardoPas encore d'évaluation

- Alfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsDocument2 pagesAlfa Laval M6: Gasketed Plate Heat Exchanger For A Wide Range of ApplicationsCyrilDepalomaPas encore d'évaluation

- JRS Series TablasDocument4 pagesJRS Series TablascarlosPas encore d'évaluation

- Catalogo JUMBO InglesDocument8 pagesCatalogo JUMBO InglesDarko BogdanovicPas encore d'évaluation

- Sturdy Bearing Assembly and Axial Heat Expansion: PumpsDocument8 pagesSturdy Bearing Assembly and Axial Heat Expansion: PumpsTejas MahadikPas encore d'évaluation

- 2 VAG EKO Plus F4Document3 pages2 VAG EKO Plus F4Baris BoskanPas encore d'évaluation

- BB1Document8 pagesBB1Roozbeh PPas encore d'évaluation

- Aurora PumpsDocument12 pagesAurora PumpsM Alim Ur RahmanPas encore d'évaluation

- HPS LowProSeries Feb2010Document2 pagesHPS LowProSeries Feb2010maleta roja6Pas encore d'évaluation

- Model 008 Cartridge Circulator: Water Circulation Pumps & CirculatorsDocument2 pagesModel 008 Cartridge Circulator: Water Circulation Pumps & CirculatorsFernando BarbosaPas encore d'évaluation

- Bloomfoss Hydraulic Actuatos Product-Manual - BT-SeriesDocument7 pagesBloomfoss Hydraulic Actuatos Product-Manual - BT-SeriesSady KanettiPas encore d'évaluation

- Zenit Uniqa Series Electric Submersible Pumps Catalogue enDocument28 pagesZenit Uniqa Series Electric Submersible Pumps Catalogue enFERNANDO PARRA ARCEPas encore d'évaluation

- Steel Wheel Roller: Bw5AsDocument4 pagesSteel Wheel Roller: Bw5AsArman Seorang MelankolisPas encore d'évaluation

- Description: M0300 Strap-On Saddle Flow MeterDocument5 pagesDescription: M0300 Strap-On Saddle Flow MeterJamesh BabuPas encore d'évaluation

- Tarby TitanDocument4 pagesTarby TitanAlberto HerreraPas encore d'évaluation

- N1100 Spec SheetDocument2 pagesN1100 Spec SheetJavier GarciaPas encore d'évaluation

- Fan Vanco CatalogueDocument24 pagesFan Vanco CatalogueYizhar Bechamel MestokoPas encore d'évaluation

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideD'EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideÉvaluation : 4.5 sur 5 étoiles4.5/5 (8)

- Subsea Rigid Pipelines – Methods of InstallationD'EverandSubsea Rigid Pipelines – Methods of InstallationÉvaluation : 5 sur 5 étoiles5/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineD'EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineÉvaluation : 5 sur 5 étoiles5/5 (1)

- Flowrox ValveDimensions ENGDocument32 pagesFlowrox ValveDimensions ENGAlberto DiazPas encore d'évaluation

- Anodo de SacrificioDocument1 pageAnodo de SacrificioAlberto DiazPas encore d'évaluation

- Flowrox LPP-T Hose DatasheetDocument2 pagesFlowrox LPP-T Hose DatasheetAlberto DiazPas encore d'évaluation

- Ceram C0+CTDocument1 pageCeram C0+CTAlberto DiazPas encore d'évaluation

- Englisch WerkstoffberichtDocument10 pagesEnglisch WerkstoffberichtAlberto DiazPas encore d'évaluation

- Flowrox LPP D Hose DatasheetDocument2 pagesFlowrox LPP D Hose DatasheetAlberto DiazPas encore d'évaluation

- B7 GB AZ Boerger Sugar 0513Document4 pagesB7 GB AZ Boerger Sugar 0513Alberto DiazPas encore d'évaluation

- Recubrimiento CeramicoDocument6 pagesRecubrimiento CeramicoAlberto DiazPas encore d'évaluation

- Blog Projectmaterials Com Pipes Pipe Size Chart Asme b36 10Document18 pagesBlog Projectmaterials Com Pipes Pipe Size Chart Asme b36 10Alberto DiazPas encore d'évaluation

- Curso de Ingles Nivel MedioDocument4 pagesCurso de Ingles Nivel MedioAlberto DiazPas encore d'évaluation

- Englisch WerkstoffberichtDocument2 pagesEnglisch WerkstoffberichtAlberto DiazPas encore d'évaluation

- Balmoral Bunded Tank InstallationDocument4 pagesBalmoral Bunded Tank InstallationAlberto DiazPas encore d'évaluation

- A134 PDFDocument4 pagesA134 PDFAlberto DiazPas encore d'évaluation

- REDO - Product Information 05.05-Engl PDFDocument22 pagesREDO - Product Information 05.05-Engl PDFAlberto DiazPas encore d'évaluation

- Calidad Del Agua Decreto-UruDocument16 pagesCalidad Del Agua Decreto-UruAlberto DiazPas encore d'évaluation

- Energy Recovery VentilationDocument16 pagesEnergy Recovery VentilationAlberto DiazPas encore d'évaluation

- Vs Instrumentation ValvesDocument2 pagesVs Instrumentation ValvesAlberto DiazPas encore d'évaluation

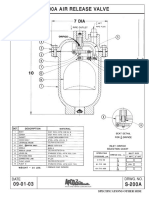

- Purgadoras de AireDocument15 pagesPurgadoras de AireAlberto DiazPas encore d'évaluation

- APCO. S-200a Air Release ValveDocument2 pagesAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Mitigeur Watt PDFDocument2 pagesMitigeur Watt PDFAlberto DiazPas encore d'évaluation

- Granta Note Installation GuidelinesDocument11 pagesGranta Note Installation GuidelinesAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)Pas encore d'évaluation

- Transportation SystemDocument6 pagesTransportation SystemMawi CrovempirePas encore d'évaluation

- TSPC Logic A Circuit For All SeasonsDocument4 pagesTSPC Logic A Circuit For All SeasonsJaya Chandra ManchalaPas encore d'évaluation

- Video StandardDocument3 pagesVideo StandardVarsha SathePas encore d'évaluation

- Overview of The OMG Data Distribution Service: Douglas C. Schmidt & Jeff ParsonsDocument58 pagesOverview of The OMG Data Distribution Service: Douglas C. Schmidt & Jeff ParsonsLongphi GamePas encore d'évaluation

- Yamaha CLP 170 Service ManualDocument122 pagesYamaha CLP 170 Service ManualicaroheartPas encore d'évaluation

- CA-AM Amplifier ManualDocument2 pagesCA-AM Amplifier ManualDewey AndersonPas encore d'évaluation

- 1.5 3.8t XE Series Electric Forklift With Li Ion TechnologyDocument6 pages1.5 3.8t XE Series Electric Forklift With Li Ion TechnologyScottJacksonPas encore d'évaluation

- Catalogue - Sundez Brine To Water Heat Pump 3 9kwDocument4 pagesCatalogue - Sundez Brine To Water Heat Pump 3 9kwMarko PetricPas encore d'évaluation

- Media and Information Literacy: Quarter 4 - Lesson 3: Massive Open Online CourseDocument9 pagesMedia and Information Literacy: Quarter 4 - Lesson 3: Massive Open Online CourseCatherine BotardoPas encore d'évaluation

- Grameenphone ReportDocument122 pagesGrameenphone ReportNayamotPas encore d'évaluation

- Waterfall Model - DesignDocument7 pagesWaterfall Model - DesignDibyendu Das100% (1)

- Lab 3Document2 pagesLab 3SamerFouadZakharyPas encore d'évaluation

- MGC1101FOUDocument35 pagesMGC1101FOUThomas HultstedtPas encore d'évaluation

- Online Car Rental Management System PresentationDocument14 pagesOnline Car Rental Management System PresentationRaja Bilal JanjuaPas encore d'évaluation

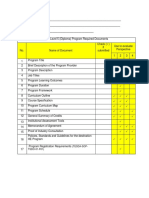

- Template of KRADocument4 pagesTemplate of KRA1qwfegfhngPas encore d'évaluation

- Database Management System - Ch07Document25 pagesDatabase Management System - Ch07Osei BanningPas encore d'évaluation

- APSA-370 Operation Manual eDocument109 pagesAPSA-370 Operation Manual eKano MolapisiPas encore d'évaluation

- Reset GuideDocument2 pagesReset GuideRuzhen DimitrovPas encore d'évaluation

- An Introduction To Programming in VHDL: Marios S. PattichisDocument24 pagesAn Introduction To Programming in VHDL: Marios S. Pattichisrakesh1091Pas encore d'évaluation

- Program Evaluation Documents (Table 1 To 16)Document14 pagesProgram Evaluation Documents (Table 1 To 16)Cristina CarpioPas encore d'évaluation

- 2023 11 15 18 44 49 ORDENADOR-PC LogDocument404 pages2023 11 15 18 44 49 ORDENADOR-PC LogTriust XDPas encore d'évaluation

- CEM Presentation - Nov 2020 3Document45 pagesCEM Presentation - Nov 2020 3betifeleke1Pas encore d'évaluation

- Sample Questions For CBAP Certifications 1611302275Document7 pagesSample Questions For CBAP Certifications 1611302275cruzamanPas encore d'évaluation

- BS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Document30 pagesBS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Michael Camit EsoPas encore d'évaluation

- Women SafetyDocument6 pagesWomen Safetyanon_318625233Pas encore d'évaluation

- Practical No.: 2: A) Exploring and Managing Raster Data: Adding Raster Layers, Raster Styling and AnalysisDocument11 pagesPractical No.: 2: A) Exploring and Managing Raster Data: Adding Raster Layers, Raster Styling and AnalysisAkshata PardulePas encore d'évaluation

- FEA Engineer - JDDocument1 pageFEA Engineer - JDManjunath AithalPas encore d'évaluation

- Capstone Project Proposal COMP 10076 Capstone Prep: ApprovedDocument7 pagesCapstone Project Proposal COMP 10076 Capstone Prep: ApprovedJohanthan SputkaovPas encore d'évaluation

- Modbus/TCP Client Support: Additional Important Product Information For Release 3.83Document11 pagesModbus/TCP Client Support: Additional Important Product Information For Release 3.83Sudipto MajumderPas encore d'évaluation