Académique Documents

Professionnel Documents

Culture Documents

Operation Manual of UPS System

Transféré par

VisiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Operation Manual of UPS System

Transféré par

VisiDroits d'auteur :

Formats disponibles

Hi-Rel Electronics Pvt. Ltd.

I4 Operation Manual

Operation Manual

Uninterruptible Power Supply System

I4 UPS System

Hi-Rel Electronics Pvt. Ltd

B-1 1 7,1 1 8, GIDC Electronics Zone, Sector-25,

Gandhinagar -382 044, Gujarat - India

Ph : +91 -79-232871 80/81

Fax : +91 -79-232871 82

www .hirel.net

Version V.0 Page 1

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Model : I4

Version : V.0

COPYRIGHT © 2011 by Hi-Rel Electronics Pvt. Ltd.

All rights reserved

The information contained in this publication is intended solely for the

purposes indicated.

The present manual and any other documentation supplied with the UPS

system is not to be reproduced, either in part or in its entirety, without the

prior written permission of Hi-Rel Electronics Limited.

The illustrations and plans describing the equipment are intended as general

reference only and are not necessarily complete in every detail.

In the spirit of innovation, the contents of this manual are subject to

modification or change without notice.

Version V.0 Page 2

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Objective of this Manual:

The objective of this manual is to educate the user for proper installation

and the system to be use.

Scope Statement:

The scope of this manual covers only general operations of the DC UPS

system. How-ever, some information on primary maintenance can be found

in this manual.

Version V.0 Page 3

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Table of Contents:

Sr. No. Chapter Page #

1 Safety 5

2 Introduction 10

Components of the UPS System 11

Description of I4 UPS Module 13

Modes of Operation 17

3 Technical Specifications 20

4 Installation 22

Selecting the UPS Room 22

Lifting & shifting 23

Placing & Positioning 23

Wiring Connections 27

5 System Start-Up 30

Getting Acquainted With Your System 30

Electrical Start-Up & Shut down procedure 32

Energization 33

De-energization 34

Bypass 35

LED Mimic 37

LCD Screen 40

Dealing With Alarms 43

Parameter Adjustments 51

6 Maintenance 58

7 Contact Details 60

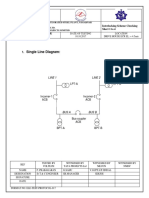

8 Drawing 62

Version V.0 Page 4

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

1. Safety

For the purpose of this manual and the product the following symbols are used.

SYMBOL DESCRIPTION

Alerts a person that high voltage is present which could result

in severe bodily injury or loss of life. Relevant instructions &

electrical safety measures must be adopted. DO NOT attempt

to bypass the instructions given in this manual. Always consult

DANGER HI-REL in case of doubt, BEFORE proceeding with other

actions not included in this manual.

Alerts a person that if procedures are not followed, damage

! to or destruction of the equipment could result.

CAUTION

Qualified person – who is formally trained by Hi-Rel

t Electronics Limited, to perform the specific job.

TRAINED

NOTE Calls for attention to the information that is especially

significant in understanding the operation.

Version V.0 Page 5

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Attention:

Please read the safety instructions contained in the following pages prior to

installing, starting up and maintaining the UPS system, the options and the

batteries.

Safety Regulations:

GENERAL:

• The equipment must be moved only in an upright position, in

the original packing to the final destination room.

• The equipment must be lifted only with a forklift or lifting

belts.

• Check for sufficient floor loading capacity.

• If you notice any visible damages to the packaging or the UPS,

do not install or start the system. Contact the nearest Hi-Rel

service center.

• WARNING! THERE IS RISK OF ELECTRICAL SHOCK: do not

remove the covers – there are no user serviceable parts

inside.

• THE UPS MUST NOT BE ENERGIZED UNLESS CONNECTED TO

EARTH

o The first connection to make is between the

grounding lead and the terminal indicated with the

symbol

o The field wiring outlets may be electrically alive even

when the UPS is disconnected from the mains.

o Dangerous voltages may be present during battery

operation.

o Disconnect batteries during maintenance or service

work.

Version V.0 Page 6

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

o Potentially hazardous voltages are present within the

UPS.

o BEWARE! The inverter can restart automatically,

when mains voltage is restored.

• Only Hi-Rel qualified personnel should carry out any

maintenance or service work

Version V.0 Page 7

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

INSTALLATION:

• The installation and connection of the UPS must be carried out

only by Hi-Rel trained personnel.

• During commissioning and maintenance, the following aspects

must be properly verified:

o Any damaged parts

o Squeezed wires and cables

o Improperly inserted plugs

• Ensure all earthing connections are properly attached.

• Switching off the UPS DOES NOT isolate the UPS from the

mains!

• The UPS system must not be installed in excessively humid

environment or near water.

• Install the unit in a sufficiently ventilated area; the ambient

outside temperature should not exceed 45˚C (113˚F)

o There should be free air circulation around and through

the unit. Air vents should not be blocked.

o Avoid direct sunlight or locations near heat sources.

• Ambient temperature should not exceed 25˚C (77˚F) in order

to derive optimum battery life.

STORAGE:

• The UPS and accessories must be stored in a dry location.

• Storage temperatures must be within -25˚C (-13˚F) to + 55˚C

(131˚F)

• If the unit is likely to be stored for a period exceeding three

months, the batteries must be recharged periodically – time

depending on storage temperature.

POSITIONING OF THE UPS:

• Provide for at least one meter in front of the machine to leave

plenty of room for maintenance operations.

• Space of minimum 60 cms must be left between the back of

the UPS and the wall to provide for flow of air from the fans

and for maintenance operation of the fans.

• No objects should be placed on top of the machine.

• The AC-DC INPUT / OUTPUT cables should enter from the

bottom of the UPS.

BATTERIES:

• Battery voltages are dangerous for a person’s safety.

• Batteries should never be short circuited.

• Remove all metal objects like watches, rings, etc from person

while working with the battery. Always use insulated tools.

• When replacing batteries, always use same numbers, voltage

(V) and capacity (Ah).

• Batteries should never be disposed off in a fire – they may

explode.

Version V.0 Page 8

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• The electrolyte contents of the battery are extremely toxic;

batteries should never be opened or mutilated.

• Batteries should never be charged in a sealed container.

• Protect the environment – dispose batteries safely in

accordance with local codes for safe disposal.

Safety instructions when working with batteries:

EXTERNAL BATTERIES MUST BE INSTALLED AND CONNECTED TO

THE UPS ONLY BY QUALIFIED SERVICE PERSONNEL.

BEFORE HANDLING THE UPS AND BATTERIES, THE

INSTALLATION PERSONNEL MUST READ THIS ENTIRE SECTION

DANGER VERY CAREFULLY.

• Battery terminals always carry full voltage current.

• The batteries used in this system carry extremely high currents

and provide dangerous voltages. There is always a risk of

electric shock.

• If the terminals are shorted together or grounded – they may

cause severe injury.

• Do not touch un-insulated battery terminals.

• Exercise extreme caution to avoid electric shock and burns that

are caused when battery terminals are contacted or shorting

terminals during battery installation.

All qualified operating personnel should adhere to the following

precautions:

• Always use protective gear such as rubber gloves, boots and

protective eye shades.

o If mishandled, caustic acids and toxic materials from the

batteries can rupture or leak.

o Before handling batteries, ensure removal of rings, metal

wristwatches, key chains and other metal objects, including

jewelry.

o Carrying metal objects, especially in the top pockets runs risks

of them falling into the battery cabinet.

• Ensure that tools have insulated handles and are insulated so that

they will not short the battery terminals.

• Do not lay tools or metal parts on top of the battery and do not place

them where they are likely to fall on the battery or into the cabinet.

• Install batteries only as per the Battery Installation Manual of the

battery manufacturer.

• When connecting terminals, never allow a cable to short across a

battery’s terminals, the string of a battery, the cabinet or the rack.

• Cable lugs must be so aligned on the battery terminals, such that the

cable lug will not come in contact with any part of the cabinet or

rack, even if the battery is moved.

• Cables must be kept away from sharp metal edges.

• Battery cables must be so installed that the UPS or battery cabinet

doors do not pinch them.

• Battery terminals must never be connected to ground.

Version V.0 Page 9

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• If battery terminal is inadvertently grounded, remove the source of

ground. Contacting any part of the grounded battery can cause the

risk of an electrical shock.

• Batteries must be installed in a temperature and humidity controlled

indoor area, free of contaminants, to reduce risk of fire or electric

shock.

• The battery system chassis ground must be connected to UPS chassis

ground.

o If a conduit is used, the ground conductor must be routed in

the same conduit as the battery conductor.

• When replacing the batteries or repairing the battery connections,

SHUT OFF the UPS and remove the battery fuses / breakers.

Version V.0 Page 10

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

2. Introduction

Uninterruptible Power Supply or UPS is normally regarded as the ultimate

solution to electrical power problems. It protects the critical AC load, which

needs a reliable, continuous power from AC Utility supply interruptions. The

various utility (Mains) supply problems are as listed below.

• Temporary Interruption

• Long-Term Interruption

• Momentary Interruption

• Sag or Under-Voltage

• Swell or Over-Voltage

• Transient, Impulse or Spike

• Notch

• Noise

• Harmonic Distortion

These disturbances have different effect on loads such as:

1) Reduced personnel safety

2) Equipment/machine failures

3) Reduction in the operating life of the machines

4) Increase the general costs and losses in economical terms.

5) Decrease in lifespan the equipment.

The UPS not only protects the load against above power hazards but also

provides continuous regulated pure AC power to the load.

The I4 UPS are an On-line UPS, also sometimes called Double Conversion

UPS. In the UPS the AC electrical power from the utility (Mains) supply is fed

into the charger to be converted in to DC. This DC will maintain the charge

on the battery and at the same time supply DC power to the inverter. The

inverter will then invert the DC source to become an AC supply for the

critical load.

During a power failure, the DC power for the inverter will be drawn from

the battery bank for uninterruptible supply to load. When AC power is

restored, the charger will then charge the battery and continue to supply

energy for the inverter, which powers the load.

Typical Applications include: -

• Process control and Monitoring systems

• Security systems

• Telecommunication systems

• Health care systems

• Data Centers. Server farms &Computers

• Pharmaceuticals & lab equipment’s/analyzers etc

• And many more---

Key Features of I4 UPS:

Version V.0 Page 11

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• High efficiency resulting from the combination of latest generation

IGBT and DSP based control circuitry.

• High branch fuse clearing ability in the event of short circuit at the

load end.

• Front and back access oriented layout affording ease of handling and

maintenance.

• Extremely flexible – offering tailor made options like parallel or hot

standby redundancy, input harmonic filters, galvanic isolation

transformers, bypass line regulator and additional connectivity

features like Modbus, Profibus, SNMP and potential free contacts.

(For details of more options, contact factory)

Components of an UPS System:

Auxiliary

Module

Mains Output L

UPS

Distribution Distribution

Module

Unit Module O

A

Battery

Module D

• = Items available from Hi-Rel, depending on the purchase

contract.

Refer to your purchase contract / drawings for specific details.

Version V.0 Page 12

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Mains Distribution Unit

This unit is already a part of your installation. It distributes the Mains

(utility) and / or Generator power to your facility and will also supply input

power to your UPS system. The safety “earth” connection for the UPS

system is also considered to be a part of the Mains distribution unit.

Auxiliary Module

An Auxiliary module generally comprises a Voltage stabilizer (Static type or

Servo type) to provide a stable Alternate supply to the UPS.

UPS module

It consists of the UPS (without battery). Depending upon the configuration

selected one or more UPS modules can be employed.

Battery module

This module comprises the battery pack for supplying power to the UPS

module in the event of a mains failure. There are various types of batteries

- SMFB, LATB, Ni-Cad, etc. Battery module may either be in the form of an

enclosure or may be supplied as a rack. Vented batteries such as LATB can

emit acidic fumes & require a special room.

Output Distribution Module

Output of the UPS system needs to be distributed to various loads. Such a

module generally comprises switches, fuses, etc for each load. The co-

ordination of fuses is important to avoid faults in a particular load from

affecting the other loads supported by the UPS.

The scope of this manual is limited to UPS MODULE only

Version V.0 Page 13

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Description of I4 UPS Module

(A) Block diagram with 6 Pulse UPS

Version V.0 Page 14

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

(B) Block diagram with 12 Pulse UPS

I4 UPS Module Description

Version V.0 Page 15

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Charger -

- Converts the AC mains to regulated DC power.

- Charges the Battery when mains are present.

Inverter

- Converts DC into Frequency & Voltage controlled AC supply

Battery (separate module)

- Stores energy while mains supply is present.

- Delivers energy (DC supply) to the Inverter when mains supply is absent.

Static Switch (A bi-directional solid state transfer switch)

- Normally connects the Inverter output to the load

- Automatically transfers the load to an Alternate supply if Inverter fails or

overloads.

- Automatically re-transfers the load from the Alternate supply to the

Inverter, once the Inverter is healthy or the overload condition has ceased.

In case of parallel system when all inverter fails or trips on overload then

only it will transfer automatically to static bypass.

MBS (Maintenance Bypass Switch)

The maintenance bypass switch is a special make before break switch, in

normal position connects the inverter output to load, when changed to

Bypass position connects bypass ac power to load without interruption,

leaving the UPS available for maintenance.

(Caution! please refer operating procedure before operating this switch)

Version V.0 Page 16

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Major power components of the I4 UPS Module

Component Description

CBI Mains input circuit breaker

CBA Alternate input circuit breaker

CBB Battery isolating circuit breaker

MIS Module isolator switch

MBS Maintenance Bypass Switch

FC Charger input fuse

FD DC link fuse

FA Alternate static switch fuse

FB Battery circuit fuse.

LD DC link filter choke

CD DC link filter capacitors – multiple units

CO Output AC filter capacitors – multiple units

LO Output filter choke

T2 Inverter output isolation transformer

Control section

Charger

I4 charger module uses three thyristor-thyristor modules. The charger

control generates the required firing angles so as to maintain a regulated DC

o/p. Charger performs the function of battery charging as well as providing

dc supply to the inverter. The Battery charging current is monitored by the

charger control & will operate the charger so as to limit the charging

current of the battery to a preset value.

SMPS

A Switch Mode Power supply generates the control power supplies for the

Control of I4 UPS module (Inverter, Static switch, etc). This power supply

receives input from the DC link as well as the Alternate supply lines,

enabling it to operate under all eventualities.

System control.

The system control card is the heart of the I4 UPS module. It employs an

advanced, digital signal processor based, control for the Inverter & the

Static switch. It monitors the performance of the UPS module &

communicates the status to the user interface card. It also receives

operational commands from the user interface & controls the UPS module

accordingly.

Gate Drivers

The main function of the gate driver is to drive the Inverter IGBT power

devices. The gate driver employs a sophisticated hybrid circuit in order to

drive as well as protect the IGBT. It acts on the PWM signals generated by

the system control.

System F/B (Feedback).

The system f/b (feedback) assembly taps all the required information

(voltages, currents, etc) from various parts of the I4 UPS module as provides

the feedback to the system control.

Version V.0 Page 17

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

User Interface

It employs a powerful micro controller based circuitry along with a non-

volatile memory. It controls the LCD-Keypad as well as the LED mimic for

status reporting as well as programming the parameters of the UPS module.

Modes of operation:

Normal Mode

MBS

Bypass Static switch

(Alternate) source

Load

Input utility Static switch

Charger Inverter

source (Mains)

Battery

In normal mode the input utility (Mains) power is converted in to DC power

by charger, this DC power is converted into AC Power by Inverter. This ac

power generated by inverter passes through static switch to the load. Also

this power is used to charger battery.

Version V.0 Page 18

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Battery Mode

MBS

Bypass

(Alternate) source Static switch Load

Input utility Inverter Static switch

Charger

source (Mains)

Battery

In an event of mains (utility) power failure or out of tolerance, the charger

turns off, the dc power required by inverter to generate AC power is drawn

from battery source and through static switch it reaches to the load.

Static bypass Mode

MBS

Bypass

(Alternate) source Static switch Load

Input utility Static switch

Charger Inverter

source (Mains)

Battery

In this mode , in an event of inverter voltage going out of tolerance , due to

inverter failure or due to any other reason , the load will transfer to static

bypass as shown in fig. with a transfer time less than 4 ms. If input utility

supply is available and in range, the battery charging will continue as

normal through charger .

Version V.0 Page 19

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Maintenance bypass Mode

MBS

Bypass

(Alternate) source Static switch Load

Input utility

source (Mains) Charger Inverter Static switch

Battery

The maintenance bypass switch (MBS) is provided for taking the system for

maintenance without disturbing the load. During this mode the load is

served by Bypass (Alternate source) .The MBS switch is a special make

before brake switch .It has two positions, a NORMAL and BYPASS. In Normal

mode of switch the inverter output is connected to the load. Where as in

later Bypass (Alternate) source feeds the load.

COUTION: please refer operating procedure of this switch, wrong operating

procedure may affect the load and UPS system.

Version V.0 Page 20

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

3. Technical Specification for I4

Input voltage 415V +10% , - 15% 3 Phase 3 Wire

Input

Input frequency range 50Hz ± 6 %

Alternate input Voltage 230V ± 10% single phase two wire

Bypass/Alternate

Alternate input Frequency 50Hz ± 6%

Charger walk in time 35 seconds

Charger type Full bridge Full controlled converter

Charger output voltage 405V ± 1% Nominal

Full discharge battery within 6-8

Charger Charger capable of charging hours. Max. backup time envisaged

on UPS will be 2 hours

10 to 25 % of AH of battery.

Battery charging current limit (Adjustable). Max. limit is 25% of

rated power capacity of the UPS

Inverter output voltage 230V single phase two wire (110 V

available as option)

Inverter output Frequency 50Hz

±1% static load (No load to full load

Voltage Regulation

at nominal DC)

± 5% transient load , recovery time

Voltage Transient Response

to 98% in less than 20 milliseconds

Inverter output voltage 5% of the nominal voltage

adjustability

Inverter Max. 5% RMS THD with non-linear

Harmonic distortion loads (Crest factor 3:1)

Max 3 % for linear loads

Inverter frequency stability ± 0.1 % free-running

1) 125% of rated output power (kW)

for 10 minute.

Overload capacity ( on Inverter) 2) 150% of rated output power (kW)

for 1 minute,

At 45deg.C and minimum DC bus

Output Load Crest Factor 3:1

Frequency range for ± 6% of 50Hz (± 1% to ± 6% field

synchronization to alternate line programmable)

Static Switch

Overload capacity (on static

800% of FLA for one cycle

Bypass(alternate) )

Output Rated power @ 0.8 lagging power factor

Frequency slew rate 1.0 Hz/second

Efficiency AC to AC of the UPS at 85% minimum from 25% to 100% full

nominal AC input and floating rated load

battery

Version V.0 Page 21

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Meters –digital-LCD: Metering

Voltage meters Mains Power Meter Total KVA

Bypass(Alternate) Total kW

Battery/ Charger Total Power Factor

Inverter UPS KVA

Load UPS kW

UPS Power Factor

Frequency Meters Mains Current Meter Mains

Bypass(Alternate) Battery

Inverter

Load

Version V.0 Page 22

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

4. Installation

Selecting the UPS Room:

The UPS being complex equipment meant to support mission critical

application, the selection of the right location / room, assumes very

significant importance to ensure best performance of the system.

NOTE

• Ensure that the room / location selected is clean and free from

conductive & corrosive dust and is freely ventilated.

• If it is not possible to ensure freely ventilated environment, the room

has to be adequately air-conditioned.

• The recommended ambient temperature for the UPS room is 45˚C

(113˚F)

• Before placing the UPS system at the designated location, ensure

sufficient floor load capacity. If additional / optional cabinets or

cubicles are planned to be installed in the same location, floor

loading for these should also be taken into consideration.

• While selecting the location / room for the UPS, take into account

the dimensions of the UPS modules as well as any optional /

additional cubicles (if any) to be located in the designated area. For

dimensions of the UPS modules for various ratings – refer Technical

Specifications.

• Provide for at least one meter in front of the machine to leave plenty

of room for maintenance operations.

• Space of minimum 60 cms must be left between the back of the UPS

and the wall to provide for flow of air from the fans and for

maintenance operation.

• It is recommended that a minimum of 400mm (16 inches) clearing

should be provided for between the top of the UPS and ceiling, to

ensure proper ventilation and heat dissipation.

• The AC-DC INPUT / OUTPUT cables should enter from the bottom of

the UPS.

• The UPS module is not free standing and requires bolting to the floor.

Ensure that proper foundation and eyelets have been provided as per

footprint drawing provided with the system.

Version V.0 Page 23

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• Normally, Ni-Cad and LATB batteries are not installed in the same

room as the UPS modules. How-ever SMFB batteries may be installed

in the same room. In this case, ensure that the dimension of the

battery bank as well as floor loading and operating temperature

requirements for batteries are taken into consideration.

Lifting and Shifting:

• The UPS module must be moved only in an upright position and in the

original packing, along with the pallet, to the designated location of

placement.

• It is recommended to use a forklift to move the UPS module. In case a

crane has to be used, ensure to use suitable lifting straps and

spreader bars. The center of gravity should be taken into

consideration while moving the package.

• In case of additional / optional cubicles, exercise the same care and

caution as applicable to lifting and shifting of the UPS module.

Placing and Positioning:

Place the UPS module at the planned location, unpack the top and sides of

the packing case and remove the pallet while keeping the package gently

raised.

• Unpack additional / optional cubicles in the same manner as the UPS.

• Before lowering the UPS module on to the foundation, ensure that

the UPS bolting holes are aligned with the foundation eyelets and

bolted to the foundation. Ensure same procedure for optional

cubicles.

• The additional / optional cubicles must be lined up and as per the GA

(General Arrangement) diagram, and coupled to the UPS module with

the baying kit provided with the system.

Version V.0 Page 24

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Panel Baying Diagram

Version V.0 Page 25

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Wiring Connections:

!

CAUTION

• Before connecting the power cables of the various inputs and outputs

of the UPS, verify that the mains voltage and frequency, bypass

voltage and frequency, output load voltage and frequency and

battery bank (number of cells, float / boost voltage, AH capacity)

conform to the information given in Technical Specifications.

• Select the proper rating of fuses / breakers and cables for the input,

bypass and battery source feeders.

• The first connection to be made is the earthing to all cubicles

including the UPS module.

• The earthing cable is to be terminated at the designated position

located on the UPS module.

• In case flexible earthing cable is used, the cable size should be same

as the cable used for input mains.

• In case additional / optional cubicles are used, their earth must be

terminated at the UPS main earth.

Version V.0 Page 26

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

UPS Earthing

Location

Auxiliary Panel Earthing Location

• Before proceeding with connecting of cables for UPS input, bypass,

battery and output, ensure that all source feeders are switched off

and fuses / battery isolators are removed.

Version V.0 Page 27

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Input / Output Cable Termination Location:

1 2 3 4 5 6 7 8 9 10 11 12 13

Version V.0 Page 28

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Terminal No. Description

1 Utility(Mains) Input R-Phase( Line-1)

2 Utility(Mains) Input Y-Phase( Line-2)

3 Utility(Mains) Input B-Phase( Line-3)

4 From Battery bank final +ve of battery bank

5 From Battery bank final -ve of battery bank

6 For Common Battery application. Applicable for only parallel/dual redundant

UPS.

NOT USED FOR STANDALONE UPS SYSTEM

7 For Common Battery application. Applicable for only parallel/dual redundant

UPS.

NOT USED FOR STANDALONE UPS SYSTEM

8 Bypass (Alternate) source input Phase

9 Bypass (Alternate) source input Neutral

10 UPS output Phase for paralleling 2 ups output. Applicable for only parallel

system.

NOT USED FOR STANDALONE UPS SYSTEM

11 UPS output Neutral for paralleling 2 ups output. Applicable for only parallel

system.

NOT USED FOR STANDALONE UPS SYSTEM

12 UPS output Phase

13 UPS output Neutral

t

TRAINED

• Unlock the door of the UPS panel and remove the protection plate

mounted on the terminals.

• Terminate the cables at the designated terminals as per Input /

output cable termination location.

• Wiring of the battery bank must be done by referring to the manual

of the battery manufacturer and final positive and negative terminals

of the battery bank must be terminated at the UPS end on to the

designated terminal. In case battery junction box / battery isolator is

used externally, this must be located as close as possible to the

battery bank.

• The UPS to battery bank cable should be selected in such a manner

that the voltage drop is not more than 5% of the nominal DC. The

lesser the voltage drop than 5% is better.

• After all the input / output connections are made, ensure that they

are tightly screwed on to the terminals in such a way that they do not

come in contact with nearby terminals, which may create a short

circuit.

• Ensure that all the fuse holders inside the UPS have a fuse of the

proper rating, inserted and are in closed position.

Version V.0 Page 29

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• Once the power wiring is complete, control wiring for customer

interface board may be taken up. For details, refer Table No: 6

Customer Interface Board.

Customer Interface Cable Routing Diagram

Version V.0 Page 30

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Customer Interface Connections:

Version V.0 Page 31

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

5. System Start-up

Getting Acquainted With Your System:

Power Switches:

• I4 UPS has been provided with four main breakers:

o CBI - Circuit Breaker Input

o CBA - Circuit Breaker Alternate

o CBB - Circuit Breaker Battery

o MIS - Module isolation Switch

Circuit Breaker Input (CBI)

• This breaker is used to connect / disconnect input utility source to

charger section of the UPS.

Circuit Breaker Alternate (CBA)

• This breaker is used to connect / disconnect alternate source of

supply to static switch section of the UPS.

Circuit Breaker Battery (CBB)

• This breaker is used to connect / disconnect charger output to

battery bank.

Manual Isolation Switch (MIS)

• This breaker is used to connect / disconnect static switch output of

the UPS to load.

CBA

CBI

MIS

CBB

Version V.0 Page 32

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Front Panel Keypad

Left Navigation Key

Right Navigation Key

Up Scroll Key

Down Scroll Key

Enter Key

Activate the metering menu

Activate the alarm menu

Activate the parameter menu

Activation performs self test of all front panel

LEDs, all LEDs will be blinking automatically.

Activation will shut OFF the audio buzzer, if

active.

When kept pressed for 3 seconds will turn ON

the INVERTER.

When kept pressed for 5 seconds will turn OFF

the INVERTER, if it is ON.

Version V.0 Page 33

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Electrical Start-up and Shutdown Procedure

Once you have acquainted yourself with the various switches and system

components, you are ready for electrical start-up of the system.

Before electrical startup, make sure that all the input / output terminals

are tightly screwed, all fuse holders have fuses inserted and are in closed

position, the input / output terminal protection is in place and the UPS is

properly grounded.

Turn on the input feeder of the UPS from the utility source and then follow

the steps detailed here below:

Start / Stop.

The UPS inverter can be started using the ON key. The UPS inverter can be

stopped using the OFF/Reset key.

ON OFF/

ON Reset

NOTE The ON / OFF key must be kept depressed for approximately 5

seconds in order to initiate the action.

(This is incorporated to allow intentional operations only)

NOTE The UPS inverter is designed for continuous operation as such

start / stop operation may not be required.

It is recommended that the UPS be left ON as far as possible.

Stopping the UPS inverter may cause a transfer to the Alternate

!

supply (if available & synchronized). High voltage supply will

still be available at the terminals & at the LOAD.

CAUTION

Version V.0 Page 34

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Energization

Follow the Energization procedure in steps & in the

!

sequence mentioned in the procedure.

Non compliance to the procedure can result in serious

injury to the personnel as well as damage to the

CAUTION equipment.

DO NOT switch ON the battery isolator CBB, in case the

! Input mains power supply is not available and charger

voltage is not fully developed otherwise it may result in

failure of “FB” fuse and damage the system.

CAUTION

The UPS module has High voltage supplies connected.

Don’t touch metallic parts, wires, PC cards, etc. When

the front door is open.

DANGER

Energization to be performed by qualified personnel

t ONLY. Who have specifically practiced the above

procedure during training

TRAINED

Energization of a module shall be done after the

NOTE necessary installation checks.

This is not a routine operation. It is recommended that

the UPS system remain in ON condition ALWAYS and

should NOT be switched OFF in the evenings or during

holidays, unless absolutely necessary.

Preconditions required for Energization

Mains, Alt & Batt supply at terminals - Available

Input (Mains) supply CBI OFF

Alternate (Bypass) supply CBA OFF

Battery isolator CBB OFF

Module Isolator Switch MIS OFF

Maintenance bypass switch MBS Normal

Energization Procedure

1. Open the Front door.

2. Switch CBA to ON position.

3. Switch CBI to ON position and wait for one minute till DC voltage of charger develops.

Check the voltage of charger in 'Metering' on LCD.

4. Switch CBB to ON position.

5. Switch MIS to ON position. Supply will be available to load through alternate supply.

Check the status of static switch on Mimic.

6. Give start command to the Inverter through ON push button (press pushbutton for

approx. 5 seconds). The load will now be transferred to the inverter. Check the status of

static switch on Mimic.

7. Close the front door. Energization completes!

Version V.0 Page 35

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

De – Energization

Follow the de-energization procedure in steps & in the

! sequence mentioned in the procedure.

Non compliance to the procedure can result in serious

injury to the personnel as well as damage to the

CAUTION equipment.

DO NOT switch the Maintenance bypass switch MBS till de-

! energization is complete.

CAUTION

The UPS module has High voltage supplies connected.

Don’t touch metallic parts, wires, PC cards, etc. when

the front door is open.

Capacitors inside the UPS module can store charge for a

DANGER long time. Before touching such parts ensure that these

have completely discharged and NO harmful voltage

present

De-energization to be performed by qualified personnel

t ONLY. Who have specifically practiced the above

procedure during training.

TRAINED

NOTE De - Energization is required only for major repairs /

replacement of the components of the UPS module or for

disconnecting the unit from service.

For routine STOP operation - refer to the START /STOP

procedure.

Procedure for De-energization

1. Open the Front door.

2. Give stop command to the Inverter through OFF/RESET push button (press pushbutton for

approx. 5 seconds).

3. Switch MIS to OFF position.

4. Switch CBB to OFF position.

5. Switch CBI to OFF position.

6. Switch CBA to OFF position.

7. Wait for 5 minutes.

8. Close the front door. – UPS Shutdown complete!

Version V.0 Page 36

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Bypass

Follow the procedure in steps & in the sequence

!

mentioned.

Non compliance to the procedure can result in serious

injury to the personnel as well as damage to the

CAUTION equipment

The UPS module has High voltage supplies connected.

Don’t touch metallic parts, wires, PC cards, etc. when

the front door is open.

DANGER

This operation should be performed by qualified

personnel ONLY. Who have specifically practiced the

t above procedure during training.

TRAINED

Bypass is a maintenance procedure to carry out

repairs / maintenance on the UPS by transferring the

NOTE load to the Alt supply.

This is not a routine operation.

Preconditions required for transfer to Bypass

Manual bypass switch position (MBS) NORMAL

Static switch position on INV

Inverter supply ON & healthy

Inverter output to Alternate supply Synchronized

Procedure for transfer to Bypass

1. Go in to CONTROL menu, and change “MANUAL BYPASS TO YES” in LCD display.

2. Give ENTER command.

3. Load will be transferred to alternate through static switch.

4. Confirm the status of static switch to bypass on Mimic card.

5. Change over the position of MBS switch from NORMAL to BYPASS.

6. Shutdown the UPS system as per the de-Energization procedure.

Version V.0 Page 37

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Return from Bypass

Follow the procedure in steps & in the sequence

! mentioned.

Non compliance to the procedure can result in serious

injury to the personnel as well as damage to the

CAUTION

equipment.

The UPS module has High voltage supplies connected.

Don’t touch metallic parts, wires, PC cards, etc. when the

front door is open.

DANGER

Bypass is a maintenance procedure to carry out repairs /

maintenance on the UPS by transferring the load to the Alt

NOTE supply.

This is not a routine operation.

Preconditions for return from Bypass

BYPASS Manual bypass switch position (MBS)

Procedure for return from Bypass

1. Open the Front door.

2. Switch CBA to ON position of both UPS and monitor the Alternate voltage in

manager card.

3. Switch ON the MIS one by one in both UPS. The output of UPS will be available

through the Bypass. Check the MIMIC indication of Load on bypass LED in both UPS.

4. Switch the MBS to Normal condition. The output load will be transferred to UPS.

5. Switch CBI to ON position and wait for one minute till DC voltage of charger

develops. Check the voltage of charger in 'Metering' on LCD.

6. Switch CBB to ON position of both UPS.

7. Give start command to the Inverter through ON push button in both UPS one by

one. Monitor the inverter voltage in the manager card of the both UPS.

8. Load will be transferred to the inverter through the static switch.

9. Confirm the status of static switch to Inverter in both UPS.

Version V.0 Page 38

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

LED Mimic

Version V.0 Page 39

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Sr. No. Indication Condition Status

1 Bypass Input Absent Red

Within range Green

Out of Range Red

2 Mains Input Absent OFF

Within range Green

Out of Range Blinking Green

3 Charger Operation ON Green

OFF Red

Trip Blinking red

4 Battery Discharge Red

5 Battery Operation Boost charge Red

Float Charge Green

Discharge Off

6 Battery MCCB ON Green

OFF/TRIP Blinking Red

7 Inverter Operation ON Green

OFF Red

Trip Blinking red

8 Load on Inverter Inverter SSW ON Green

Inverter SSW OFF OFF

9 Load on Bypass Bypass SSW ON Red

Bypass SSW OFF OFF

10 Synchronization Sync Steady yellow

No sync Blinking yellow

No alarms and

previous alarms are

Common Alarm acknowledged by

11 Indication user. OFF

No alarms and no

acknowledgement

provided by user for

previous alarms. Red

Any alarm present Blinking red

LCD SCREEN

This user interface consists in a permanent back lit LCD screen having:

• 2 lines with 16 characters (standard version for English characters)

• And 12 keys (the function is described for each operating mode).

The operation is extremely simple and is structured on three important

main menus related to the UPS operation, as follows:

Version V.0 Page 40

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Metering

UPS must offer some metering information for the user to be able to

examine the operating status at any time of electric parameters and

information screen.

Alarms

In the event of mains failures or abnormal functioning, the UPS must

keep a history of what has happened as a series of events.

Parameters

The user must be able to program certain functions of the UPS (user

parameters, accessible with password) to his needs.

Version V.0 Page 41

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

LCD screen standard version:

The 3 keys existing on the left side of the screen are used to activate the

operating modes, while the buttons on the right side are used to carry out

functions inside these operating modes.

METERING METERING SUBMENU

ALARMS ALARM SUBMENU

PARAMETER PARAMETER SUBMENU

METERING MODE: The metering mode is entered any time the [Metering]

button is pressed.

After Pressing of the [Metering] button auto scroll will be activated

which will scroll the metering parameters without pressing [Up] or

[Down] button. This auto scroll will be deactivated when [Up] or [Down]

button will pressed.

While in this mode the LCD will display a series of screens containing

metering information.

In this mode the keys perform the following functions:

• [Metering] - Enter into the metering menu;

• [Up] - Scrolls the backward to the next screen;

• [Down] - Scrolls the forward to the next screen;

There is no function of Left, Right and Enter key.

NOTE The meter readings displayed are for general indicative

purposes only. For more precise measurements, dedicated

instruments are recommended.

Version V.0 Page 42

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Metering menu navigation

METERING

IN R XXX V

XXX A XX.XX Hz

IN Y XXX V

XXX A XX.XX Hz

IN B XXX V

XXX A XX.XX Hz

Display example (Input YB line)

IN Y 415 V

22 A 48. 08 Hz

Similarly for other.

This menu allows, when the keypad metering is pressed, to show on the

LCD panel a series of screens containing metering information about system

parameters. There is no submenu so use only up and down key see the

information.

Input R Phase

IN-R XXX V The Input R Phase Voltage

XXXX A XX.XX HZ The Input R Phase Current

The Input R Phase Frequency

Input Y Phase

IN-Y XXX V

XXXX A XX.XX Hz The Input Y Phase Voltage

The Input Y Phase Current

The Input Y Phase Frequency

Input B Phase

IN-B XXX V

The Input B Phase Voltage

XXXX A XX.XX Hz

The Input B Phase Current

The Input B Phase Frequency

Output

OUT XXX V The Output Voltage

XXXX A XX.XX Hz The Output Current

The Output Frequency

Alternate

ALT XXX V The Alternate Voltage

XXXX A XX.XX Hz

Version V.0 Page 43

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

The Alternate Current

The Alternate Frequency

Load

LOAD XXX.XKVA The Total Load in KVA

XXX.X KW X.XX PF The Total Load in KW

Load Power Factor

UPS

UPS

UPS XXX.X

XX.XX KVA

KVA The UPS Module Load in KVA

XXX.X KW XX.X

XX.XX KW X.XXPF

PF The UPS Module Load in KW

UPS Module Power Factor

Load Percentage (With Respect to UPS Rating in

TOT LD XXX.X % KVA)

UPS LD XXX.X %

The Total Load

The Ups Load

BATT_V

BATT_V XXX V The Charger / Battery Voltage

XXX.X A CHG/DISCHG

The Battery Current (charging or

discharging)

Inverter Voltage

INV_V XXXV

UPS_I XXXXA The Inverter Voltage

Inverter Current

OUT_PEAK_CURRENT

Output Peak Current

XXXX A The Output Peak Current

CLOCK DATE Date

XX/XX/XX The Current Time

Time

CLOCK TIME The Current Date

XX:XX:XX

Version V.0 Page 44

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Dealing With Alarms:

Alarms are messages indicating an abnormal functioning of the UPS. These

messages are displayed on the front panel LCD screen both visually and with

an audio buzzer. These alarms are alerted to the user in the following three

modes, simultaneously:

• Text readout on the front panel LCD screen

• By a red flashing visual LED

• By an audio buzzer (which has an auto reset of 10 SECONDS)

Following is the list of alarms along with the cause that has triggered the

alarm:

ALARMS LIST

Sr. Alarm Name Probable Cause Action

No.

1 SC SUPPLY FAIL 1. SC Power supply failed 1. Call for service support if problem

2. SC Power supply output persist

shorted/overloaded

3. SC Power supply input is not

present

4. SC Power supply fuse is blown

2 INV OVER LD T SC 1. Inverter tripped due to overload1. Remove excess load.

2. After 20 minutes inverter will start

automatically if unsuccessful – Call

for service support.

3 INV CL ACTIVE 1. The inverter output is 1. Remove excess load IMMEDIATELY

overloaded by 150% of nominal or the inverter may trip.

full load current.

4 INV SAT TRIP 1. The inverter output was 1. Check load side for overload

severely overloaded. /short circuit – Remove fault.

2. SMPS for gate drive is faulty or 2. Press Reset Key to clear the SAT

fail. TRIP alarm. After clearing the SAT

3. Cooling FAN failure TRIP alarm, try to start inverter.

3. Try starting the inverter & if

unsuccessful – Call for service

support.

5 LOW BATTERY 1. Reserve (battery) power has 1. You only have few minutes of

been nearly exhausted. battery backup left.

LOW BATTERY TRIP 1. Reserve (battery) power has 1. Wait till mains resume and

been exhausted 2. Battery to charge.

7 INV OVER TEMP 1. Cooling fan failure. 1. Reduce load & try to start the unit

2. Excess load. – if unsuccessful – Call for service

3. Ambient temperature above support.

specified limits. 2. Measure the ambient temperature

at approximately 1mt from the

unit – if found in excess of

specified limits – take actions to

Version V.0 Page 45

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

reduce it (room ventilation, a/c,

etc.) – wait for approximately 20

min. to allow cooling & try to start

the unit – if unsuccessful – Call for

service support.

8 PRC SUPPLY FAIL 1. PRC Power supply failed 1. Call for service support if problem

2. PRC Power supply output persist

shorted/overloaded

3. PRC Power supply input is not

present

4. PRC Power supply fuse is blown

9 SC CAN1 FAIL 1. CAN communication between 1. Call for service support if problem

SC-PRC is fail persist

10 STOP COMMAND 1. Stop command is Activated to ***

inverter

11 INV LOW 1. Inverter is stop or trip 1. Check the trip conditions if

2. Adjustment/Calibration Error inverter is trip.

2. Check the adjustment for Inverter

low & inverter voltage reference.

3. Call for service support if

condition persists.

12 INV HIGH 1. Inverter control problem 1. Check the adjustment for Inverter

2. Adjustment/Calibration Error high & inverter voltage reference.

2. Call for service support if

condition persists.

13 ALT LOW 1. Alternate supply low/absent. 1. Check the Alt low adjustment

2. Adjustment/Calibration Error 2. Measure actual value with a

MULTIMETER & if found to be in

specified limits – Call for service

support.

14 ALT HIGH 1. Alternate supply High. 1. 1. Check the Alt high adjustment

2. Adjustment/Calibration Error. 2. Measure actual value with a

MULTIMETER & if found to be in

specified limits – Call for service

support

15 ALT FO 1. Alternate supply problem. 1. Check the alternate supply.

2. Adjustment error 2. Check the adjustment for the

frequency tolerance if alternate

supply is found OK.

3. Call for the service support if

problem persists.

16 MIS OFF 1. MIS switch is Off 1. Check the MIS contact connections

2. MIS contact not sensed by the if alarm is present even after MIS

SC/PRC card. is ON.

2. Call for the service support if

problem persists.

17 MANUAL TRANSFER 1. Manual transfer command is ON.1. When it is not required make it

OFF otherwise if bypass source is

not present or unhealthy there will

be no output supply available.

Version V.0 Page 46

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

18 NO SYNC 1. Inverter o/p is not synchronized 1. If bypass is present then after

with alternate or bypass source some time this alarm will be

removed.

9 SC SUPPLY FAIL 1. SC Power supply failed 1. Call for service support if problem

2. SC Power supply output persist

shorted/overloaded

3. SC Power supply input is not

present

4. SC Power supply fuse is blown

20 OUTPUT UNDER V 1. Static switch i1.11. 1. Check the trip conditions for

Inverter/Alternate supply inverter.

not available 2. Check the adjustment value for

2. Fault in static switch Output Low.

3. Adjustment/ Calibration error 3. Call for service supports. If

condition persist.

21 OUTPUT OVER V 1. Inverter/Alterna11. 1. Check the trip conditions for

Inverter/Alternate problem inverter.

output high voltage 2. Check the adjustment value for

2. Adjustment/ Calibration error Output Low.

3. Call for service supports. If

condition persist.

22 OVER LOAD 1. The inverter output is 1. Remove excess load IMMEDIATELY.

overloaded. If Alt source is not healthy and

load is on inverter then inverter

will trip after predefine time and

output will also trip.

22 INV OVER LD TRIP 1. The inverter tripped due to 1. Remove excess load.

overload. 2. After 20 minutes inverter will start

automatically if unsuccessful – Call

for service support.

23 LOAD ON BYPASS 1. Inverter is stopped or tripped. 1. Check the conditions for inverter

2. Manual transfer to bypass. trip.

2. Call for the service support if

problem persists.

24 ALT SSW ERROR 1. Alternate static switch is faulty. 1. If problem persist call for service

support

25 INV SSW ERROR 1. Inverter static switch is faulty. 1. If problem persist call for service

support

26 PRC SUPPLY FAIL 1. PRC Power supply failed 1. Call for service support if problem

2. PRC Power supply output persist

shorted/overloaded

3. PRC Power supply input is not

present

4. PRC Power supply fuse is blown

27 MAINS HIGH 1. Mains supply problem 1. Measure actual value of mains

2. Adjustment /Calibration input supply with a multi-meter &

parameter error if found to be in specified limits.

2. Check the mains high adjustment.

3. Call for service support if both of

Version V.0 Page 47

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

above points found OK.

28 MAINS LOW 1. Mains supply problem 1. Measure actual value of mains

2. Adjustment /Calibration input supply with a multi-meter &

parameter error if found to be in specified limits.

2. Check the mains high adjustment.

3. Call for service support if both of

above points found OK.

29 MANUAL BOOST 1. Manual boost mode is present. ***

30 HIGH DC 1. Charger control problem. 1. If condition persist call for service

SHUTDOWN support.

2.

31 BAT MCCB OFF 1. Battery MCCB is OFF. 1. Check the Battery MCCB contact

CHG 2. Failure in sensing the contact of connections to charger control

Battery MCCB by the charger card if alarm is present even after

control card. Battery MCCB is ON.

2. Call for service support if problem

persists.

32 CHG OVER TEMP 1. Cooling fan failure. 1. Call for service support.

2. Excess load. 2. Reduce load & try to start the unit

3. Ambient temperature above – if unsuccessful – Call for service

specified limits support.

3. Measure the ambient temperature

at approx 1mt from the unit – if

found in excess of specified limits

– take actions to reduce it (room

ventilation, a/c, etc.) – wait for

approximately 20 min. to allow

cooling & try to start the unit – if

unsuccessful – Call for service

support.

33 SC COMM FAIL 1. Serial communication between 1. Check the RS485 bus Connections

UI & SC is failed. 2. Call for the service support if

2. Loose connections in RS485 problem persists.

communication bus.

34 PRC COM M FAIL 1. Serial communication between 1. Check the RS485 bus Connections

UI & PRC is failed. 2. Call for the service support if

2. Loose connections in RS485 problem persists.

communication bus.

35 CHG COMM FAIL 1. Serial communication between 1. Check the RS485 bus Connections

UI & Charger is failed. 2. Call for the service support if

2. Loose connections in RS485 problem persists.

communication bus.

36 MAINS FAIL 1. Mains input supply is not 1. Check mains input supply.

present 2. If alarm is present even after

2. Failure of Logic supply of UI mains supply is present check logic

supply of UI.

37 BAT DISCHARGE 1. Battery is discharging due to 1. Check mains input supply.

absence of mains input supply 2. Check the charger trip condition if

or charger trip. mains input supply is available.

Version V.0 Page 48

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

38 DC GROUND 1. Earth fault on DC BUS 1. Call for the service support if

Problem persists.

39 BATT MCCB OFF UI 1. Battery MCCB is OFF. 1. Check the Battery MCCB contact

2. Failure in sensing the contact of connections to UI card if alarm is

Battery MCCB by the UI card. present even after Battery MCCB is

ON.

2. Call for service support if problem

persists.

40 INV HIGH DC 1. Inverter trip due to inverter 1. Monitor the charger DC voltage in

input DC voltage > Predefined LCD. Try to restart the inverter

reference. through RESET and ON keys if DC

Voltage < Predefined reference.

2. Call for the service support if

problem persists.

41 STANDBY UPS FO 1. Reference frequency from the 1. Check the fiber connections

SC/PRC card of another UPS is between SC/PRC cards of two UPS.

not received in PR mode. 2. Call for the service support if

problem persists.

42 OUTPUT FO 1. Output frequency out of 1. Check the bypass frequency is

tolerance band. within tolerance band or not.

2. Call for the service support if

bypass frequency is within range.

43 UPS IS 1. Failure in receiving the PMI 1. Check the PMI connections

STANDALONE signal from the SC/PRC card of between SC/PRC cards of two UPS.

another UPS in PR mode. 2. Call for the service support if

problem persists.

44 PRC CAN FAIL 1. Failure in receiving data on CAN 1. Check the CAN connections

bus from PRC section of SC/PRC between SC/PRC cards of two UPS.

card of another UPS in PR 2. Call for the service support if

mode. problem persists.

45 I/P PHASE OUT 1. Failure of input phase. 1. Check the mains supply.

2. Failure of input sensing control 2. Call for the service support if

fuse. problem persists.

46 CHG PMI FAIL 1. Failure in receiving the PMI 1. Check the PMI connections

signal from the charger card of between charger cards of two UPS.

another UPS in PR mode only. 2. Call for the service support if

problem persists.

47 MAINS FREQ O TOL 1. Mains frequency is out of 1. Check the mains supply.

tolerance. 2. Call for the service support if

problem persists.

48 SC CAN2 FAIL 1. CAN communication failure 1. Call for the service support if

generated during PR mode. problem persists.

49 SSW OT 1. Cooling fan failure. 1. Reduce load & try to start the unit

2. Excess load. – if unsuccessful – Call for service

3. Ambient temperature above support.

specified limits. 2. Measure the ambient temperature

at approximately 1mt from the

unit – if found in excess of

specified limits – take actions to

Version V.0 Page 49

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

reduce it (room ventilation, a/c,

etc.) – wait for approximately 20

min. to allow cooling & try to start

the unit – if unsuccessful – Call for

service support.

50 MBS ON 1. Manual Bypass Switch operated ***

51 CHG CAN FAIL 1. CAN communication failure 1. Call for the service support if

between charger control cards, problem persists.

generated in PR mode only.

52 SYS ON BATT 1. Battery in discharging mode 1. Battery discharging due to charger

off

53 POWER DEMAND

54 BAT LIQ LOW LEVL

55 ABNORM ROOM

TEMP

56 EQUALIZE CHG DIS

57 ABNOR BAT TEMP

58 GENERATOR OP

59 DISABLE

60 REMOTE START

61 REMOTE STOP

62 REMOTE MUTE

63 ASYNC COMMAND

64 RETRANSFER

Version V.0 Page 50

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Alarm Log

• All alarms (currently pending as well as those that have been cleared)

are logged.

• The log stores a max of 999 alarms along with the date-time stamp of

occurrence.

• The log works on a FIFO (First In First Out) basis, as such will display the

last 999 alarms that have occurred.

• Date and Time of occurrence of alarm is display on the screen

Alarm Log submenu navigation

SUBMENU

<ALARM LOG> ALARM NAME

LOG #1 dd:mm:yy / hh:mm:ss

Return to ALARM LOG ALARM NAME

LOG #2 dd:mm:yy / hh:mm:ss

.........

.........

.........

Return to ALARM LOG ALARM NAME

LOG#999 dd:mm:yy / hh:mm:ss

Display example (Inverter Under voltage)

INV UV

LOG #10 19:05:00

INV UV

LOG #10 10/01/10

Similarly for others.

• An alarm once generated and then released will be displayed with a * at

beginning.

Version V.0 Page 51

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Alarm Assign submenu navigation

Hear you can select the Relay to assign

SUBMENU

<ALARM ASSIGN> RELAY 1

<ALARM NAME>

<ALARM ASSIGN> RELAY 2

<ALARM NAME>

.............

.............

.............

<ALARM ASSIGN> RELAY 8

<ALARM NAME>

Display example (Inverter Under voltage)

RELAY 1

OVERLOAD

Similarly for others.

There are 8 Relays in the UPS, which can be assigned for any alarm

condition.

So when that particular alarm will be generated you can get changeover in

relay output which has been assigned for that particular alarm.

You can assign the Alarms to Relay navigate the menu of alarms like below,

If you want to assign Alarm to that Relay then press Enter key.

Version V.0 Page 52

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Parameter Adjustments:

PARAMETER ADJUSTMENT PARAMETER

CALIBRATION PARAMETER

CONTROL PARAMETER

In Parameter mode three submenus are there.

1. Adjustment Parameter

All reference parameters are included in this submenu. This menu is

password protected.

In this menu if you simply press right button you can enter in

Adjustment Parameter and see the parameter value but you cannot

modify the parameters value. There is a method to enter in

Adjustment of Parameters.

• You have to press Parameter button for 5 seconds continuously

then on LCD screen one message display.

ENTER PASSWORD

XXXXX

There is 5-digit password you can enter password by setting of up and

down key press.

Procedure To Enter the Password

1. Press Parameter button for 5 Sec.

2. Use Up and Down key to enter the correct password.

3. Use RIGHT key to move on next character flashing cursor

to the next parameter.

4. Repeat steps 2 & 3 to set new value.

5. If whole password set then Press ENTER key. If password match

then you can see the screen 1.ADJUSTMENT, you can set those

parameters.

Procedure for changing the Adjustment Parameter.

Procedure To change the Adjustment Parameter

1. Press the Right Button to activate the flashing cursor.

2. Use Up and Down key to increase or to decrease the

value and set the data.

3. Use ENTER key to store the value.

4. Now you can navigate into Adjustment Parameter through UP

and DOWN key and if you want to change the other parameter

the Repeat steps 1,2 & 3 to set new value.

Version V.0 Page 53

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Sr No Parameter Name Description

Version V.0 Page 54

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

1 INV VOLTAGE REF. To set inverter voltage

2 INV I. LIMIT REF. To set Inverter Current Limit Reference

3 LOW BATTERY REF. To set Low battery Alarm reference Voltage

4 DC VOLT LOW REF. To set Low Battery Trip reference Voltage

5 DC VOLT HIGH REF. To set the threshold for inverter trip due to high DC

bus voltage

6 INV LOW V REF. To set Inverter low voltage limit

7 INV HIGH V REF. To set Inverter high voltage limit

8 ALT LOW V REF. To set Alt low voltage limit

9 ALT HIGH V REF. To set Alt high voltage limit

10 FREQ BAND To set Frequency tolerance band

11 OUT LOW V REF. To set output low voltage limit

12 OUT HIGH V REF. To set output high voltage limit

13 MAINS LOW V REF. To set Mains low voltage limit

14 MAINS HIGH V REF. To set Mains high voltage limit

15 I BAT CHG REF To set the battery charging current limit in %

16 V DC FLOAT REF To set charger float voltage

17 V DC BOOST REF. To set charger boost voltage

18 CHG. HIGH REF. To set the charger high dc reference

19 OVERLOAD REF. To set the overload limits of the ups in KVA.

20 INVERTER FREQ To set the switching frequency of Inverter in KHz

21 CL FLOAT BOOST To set the float to boost change over limit in Ampere

22 CL BOOST FLOAT To set the boost to float change over limit in Ampere

23 BOOST TIMER REF To set he boost timing in minutes

24 IR COMPENSATION To set the IR compensation in Voltage for charger

25 125% OL-TRIP To set time for 125% overload in minutes

26 150% OL-TRIP To set time for 150% overload in minutes

27 OUT IR COMP To set the IR compensation in Voltage for inverter

28 SYS ON BATT REF To set system on battery reference Voltage

29 O/P PF FOR OL To set PF(power factor) for overload

Version V.0 Page 55

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

2. Calibration Parameter

All metering parameters are included in this submenu. This menu is also

password protected. In this menu if you simply press Parameter button

then you enter into Parameter submenu and by pressing DOWN key you can

see Calibration Parameter and by pressing RIGHT key you can see the

calibration parameter data. There is a method to enter in password, which

is same as above procedure for Adjustment Parameter.

Procedure to change the Parameter value is same as the Adjustment

Parameter. But the password is different than the Adjustment and Control

Parameter.

Sr No Parameter Name Description

1 IN_R Input R Phase voltage

XXX Volts

2 IN_R Input R Phase current

XXXX Amp

3 IN_Y Input Y Phase voltage

XXX Volts

4 IN_Y Input Y Phase current

XXXX Amp

5 IN_B Input B Phase voltage

XXX Volts

6 IN_B Input B Phase current

XXXX Amp

7 OUT Output voltage

XXX Volts

8 OUT Total Output current of PRC

XXXX Amp

9 ALT Alternate Voltage

XXX Volts

10 DC_V DC Bus voltage

XXX Volts

11 DC_I DISCHARGE Battery Discharge Current

XXX.X Amp

12 DC_I CHARGE Battery Charging Current

XXX.X Amp

13 INV_V Inverter Voltage of system control

XXX Volts

14 BATT_V Charger voltage

XXX V

15 INV V RMS PRC Inverter Voltage of PRC

XXX Volts

16 OUT I RMS SC Total Output current System control

XXXX Amp

17 UPS I RMS UPS current

XXXX Amp

18 SET SECOND To set the second of RTC clock

XX:XX:XX

Version V.0 Page 56

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

19 SET MINUTE To set the minute of RTC clock

XX:XX:XX

20 SET HOUR To set the hour of RTC clock

XX:XX:XX

21 SET DATE To set the date of RTC clock

XX/XX/XX

22 SET MONTH To set the month of RTC clock

XX/XX/XX

23 SET YEAR To set the year of RTC clock

XX/XX/XX

24 NODE ADDRESS To set the node address for

XXX communication

24 UPS NO To set the Node address of ups

XXX

Version V.0 Page 57

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

3. Control Parameter

All Control parameters are included in this submenu. This menu is not

password protected. In this menu if you simply press Parameter button

then you enter into Parameter submenu and by pressing DOWN key you

can see Control Parameter and by pressing RIGHT key you can see the

Control parameter data.

Procedure to change the Parameter value is same as the Adjustment

Parameter.

CONTROL PARAMETER NAVIGATION

CONTROL TRANSFER MODE

MANUAL TRANSFER

MANUAL BOOST

INV. CONFIG.

CHG. CONFIG.

Transfer mode submenu navigation

TRANSFER MODE

1. SYNC-1

TRANSFER MODE

2. SYNC-2

TRANSFER MODE

3. ASYNC-1

TRANSFER MODE

4. ASYNC-2

Version V.0 Page 58

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Manual Transfer submenu navigation

MANUAL TRANSFER

NO

MANUAL TRANSFER

YES

Manual Boost submenu navigation

MANUAL BOOST

NO

MANUAL BOOST

YES

After pressing the ENTER key, we can enter the following submenu.

BOOST TIMER

001 MIN

. . .

. . .

. . .

BOOST TIMER

999 MIN

Inverter Configuration submenu navigation

INV. CONFIG.

STAND-ALONE

INV. CONFIG.

PARALLEL

Charger Configuration submenu navigation

CHG. CONFIG.

STAND-ALONE

CHG. CONFIG.

PARALLEL

After selecting yes or no press ENTER key to assign selected data.

Version V.0 Page 59

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

Input Assign submenu navigation

Here you can select the Input parameters

SUBMENU

<INPUT ASSIGN> INPUT 1

<INPUT NAME>

<INPUT ASSIGN> INPUT 2

<INPUT NAME>

.............

.............

.............

<INPUT ASSIGN> INPUT 8

<INPUT NAME>

Display example (Power Demand)

INPUT 1

POWER DEMAND

Similarly for other Inputs & There are 8 Input in the UPS.

You can assign any input data to Input navigate the menu of Input data like

below, If you want to assign Input data to that Input parameters then press

Enter key. Here you can select the Input data for the particular relay as per

following list.

Sr No Parameter Name Description

1 DISABLE No Action

2 POWER DEMAND Reserved

3 BAT LIQ LOW LEVEL Battery Liquid low level alarm

4 ABNORM ROOM TEMP. Abnormal room temp alarm

5 REMOTE START Inverter start command

6 REMOTE STOP Inverter stop command

7 EQUALIZE CHG/DISCHARGE Reserved

8 ABNORMAL BAT TEMP. Abnormal battery temp alarm

9 REMOTE MUTE Alarm mute command

10 ASYNC COMMAND Reserved

11 GENERATOR OPERATION Generator operation status

12 RETRANSFER Reserved

ON KEY: Press ON key for 2 sec to start the Inverter. In case of Sat trip reset

the Sat trip and then try to start the inverter.

OFF/RESET KEY: Press OFF key for 5 sec to stop the Inverter. In case of Sat

trip this key will work as a RESET key: pressing this key for one sec

will reset Sat trip.

MUTE KEY: Press MUTE key to stop the buzzer.

TEST KEY: Press TEST key to test the LEDs on key pad.

Version V.0 Page 60

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

6. Maintenance

As any other electrical equipment, the UPS system also needs periodic

preventive maintenance to ensure higher reliability and trouble free

performance.

It is highly recommended that the preventive maintenance of the UPS be

carried out by either company trained service personnel or by qualified

trained service technician. We therefore recommend that you sign a

Maintenance & Service contract with the local service center organization.

The following tips will guide the user in proper maintenance during the life

of the system:

• The UPS system should be serviced once a year by qualified service

personnel. The necessary shutdown / de-energization should be

planned accordingly.

• Always follow startup and shutdown procedures as mentioned in the

operation manual.

• Keep the UPS clean and dust free externally and internally.

• Clean the UPS system using only a soft and slightly dampened cotton

cloth.

DO NOT use corrosive chemicals or soap to clean the

! panels.

DO NOT open the front door or side covers while

cleaning.

CAUTION DO NOT attempt cleaning the UPS module from inside.

This requires De-Energization and will be done during

scheduled maintenance visits by authorized service

• As high temperature of the UPS and / battery room affects the

lifespan of several components inside the Ups system, it is required

to maintain the UPS / battery room temperature well within the

specified limits and free from dust.

• It is recommended that periodic cleaning of ventilation channels and

grids should be carried out in order to ensure proper air circulation.

• It is recommended that the fans be replaced in the units, every

20,000 hours.

• Components such as power filter capacitors and lithium batteries (for

backup of data on the control board) should be replaced every 50,000

hours.

• Ensuring health of the batteries is of utmost importance as without

healthy batteries, the UPS will not deliver the desired performance.

For this periodic checking of the battery health is a must. For battery

maintenance, refer the battery manufacturer’s manual.

• Manual battery mode test should be performed at least once a

month, especially if the batteries are not sufficiently discharged

during the normal operations. Discharge time you use should be at

least half of the battery run time.

Version V.0 Page 61

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

• In case some of the cells of the battery bank are found to be weak,

immediate replacement of those cells with new cells of same rating,

make and capacity should be carried out.

• In the event the UPS is kept under shutdown for longer durations, the

battery needs to be charged minimum once in three months, for

duration of 12 hours.

• During maintenance shutdown, visual and mechanical inspection of

the UPS must be carried out.

• Never use wire links in place of fuses.

• Always use the recommended rating / make / type of fuses as per

this operations manual.

• Check the calibration of all the parameters like input voltage,

current, output voltage, current, frequency, etc and recalibrate if

required as per the procedure given in this manual.

• Carry out functional checks of thyristors, diodes, transformers, filter

components etc to ensure that they are operating within the

specified design parameters.

• All functional tests like mains failure simulation, load transfer on

static bypass simulation, load transfer on maintenance bypass

simulation should be carried out at least once a year.

• Monitoring battery operation in discharge and recharge mode

including any boost charge should be carried out at least once a year.

Version V.0 Page 62

Hi-Rel Electronics Pvt. Ltd. I4 Operation Manual

7. Contact Details

BRANCH ADDRESS

Works: Customer Support:

HI-REL ELECTRONICS LTD.,

B-117,118, GIDC ELECTRONICS ZONE, Mr.Aniruddh Brahmbhatt

SECTOR - 25,

GANDHINAGAR - 382 044. HI-REL ELECTRONICS LTD.,

GUJARAT (INDIA). B-161, GIDC ELECTRONICS ZONE,

PH. NO. : 079 232 87180 / SECTOR - 25,

232 87181 GANDHINAGAR - 382 044.

FAX NO. : 079 232 87182 GUJARAT (INDIA).

EMAIL : contact@hirel.net PH. NO. : 079 232 87190 /

232 87189

FAX NO. : 079 232 87182/ 89 / 90

EMAIL : aniruddh_brahmbhatt@hirel.net

Mumbai Bangalore