Académique Documents

Professionnel Documents

Culture Documents

Leaching

Transféré par

Bren SisonDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Leaching

Transféré par

Bren SisonDroits d'auteur :

Formats disponibles

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

CHE 423: Separation Processes

LEACHING

Submitted by:

BSChE 4

SANTOS, Amabelle C.

SISON, Bren A.

YEPES, Anna Lyn G.

Submitted to:

Engr. Clydelle M. Rondaris

March 2018

LEACHING | Santos • Sison • Yepes 1

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

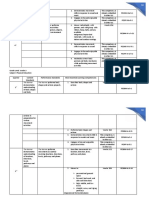

TABLE OF CONTENTS

Definition of Process ........................................................................................................... 3

Leaching Process for Biological Substances ................................................................. 5

Leaching Process for Inorganic and Organic Materials ............................................. 5

Preparation of Solids for Leaching .................................................................................. 6

Types of Equipment for Leaching .................................................................................... 7

Fixed-Bed Leaching ........................................................................................................ 7

Moving Bed Leaching .................................................................................................. 10

Agitated Solid Leaching .............................................................................................. 17

Selection or Design of a Leaching Process.................................................................. 22

References......................................................................................................................... 24

LEACHING | Santos • Sison • Yepes 2

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

DEFINITION OF PROCESS

Leaching is the process by which constituents of a solid material are

released into a contacting water phase. Although some species may be more of

an environmental concern than others, the leaching process is indiscriminant such

that all constituents (e.g., major or minor matrix components as well as inorganic,

organic and radionuclide contaminants) are released under a common set of

chemical phenomena which may include mineral dissolution, desorption and

complexation, and mass transport processes. In turn, these phenomena are

affected by certain factors that can alter the rate or extent of leaching. Among

these factors are:

• internal chemical and physical reactions

• external stresses from the surrounding environment

• physical degradation of the solid matrix due to erosion or cracking, and

• loss of matrix constituents due to the leaching process itself.

The process of leaching includes the partitioning of contaminants between

a solid and liquid phase (e.g., assuming local equilibrium) coupled with the mass

transport of aqueous or dissolved constituents. Mass transport is the summation of

diffusion, hindered diffusion, tortuosity effects, and effective surface area effects

through the pore structure of the material to the environment. Important

LEACHING | Santos • Sison • Yepes 3

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

chemical factors, those that influence the liquid-solid partitioning (LSP) of a

constituent, include solution pH, redox, the presence of dissolved organic matter,

and biological activity. Physical factors, such as relative hydraulic conductivity,

porosity and fill geometry, play an important role in determining the rate at which

constituents transport through a solid into a passing liquid phase.

The process itself is universal, as any material exposed to contact with water

will leach components from its surface or its interior depending on the porosity of

the material considered.

Leaching is the process of extracting substances from a solid by dissolving

them in a liquid, either in nature or through an industrial process. In the chemical

processing industry, leaching has a variety of commercial applications,

including separation of metal from ore using acid, and sugar from beets using

hot water.

Another term for this is lixiviation, or the extraction of a soluble particle from

its constituent parts. In a typical leaching operation, the solid mixture to be

separated consists of particles, inert insoluble carrier A and solute B.

The solvent, C, is added to the mixture to selectively dissolve B. The overflow from

the stage is free of solids and consists of only solvent C and dissolved B. The

underflow consists of slurry of liquid of similar composition in the liquid overflow

and solid carrier A. In an ideal leaching equilibrium stage, all the solute is dissolved

by the solvent; none of the carrier is dissolved. The mass ratio of the solid to liquid

in the underflow is dependent on the type of equipment used and properties of

the two phases.

LEACHING | Santos • Sison • Yepes 4

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Leaching is the process by which inorganic, organic contaminants or

radionuclides are released from the solid phase into the water phase under the

influence of mineral dissolution, desorption, complexation processes as affected

by pH, redox, dissolved organic matter and (micro)biological activity.

LEACHING PROCESS FOR BIOLOGICAL SUBSTANCES

In the biological and food processing industries,

many products re separated from their original natural

structure by liquid-solid leaching. An important process

is the leaching of sugar from sugar beets with hot water.

In the production of vegetable oils, organic solvents

such as hexane, acetone and ether are used to extract

the oil from peanuts, soybeans, flax seeds, castor

beans, sunflower seeds, cotton seeds, tung meal and

halibut livers. In the pharmaceutical industry, many different pharmaceutical

products are obtained by leaching plant roots, leaves, and stems. For the

production of soluble “instant” coffee, ground roasted coffee is leached with

fresh water. Soluble tea is produced by water leaching of tea leaves. Tannin is

removed from tree barks by leaching with water

LEACHING PROCESS FOR INORGANIC AND ORGANIC MATERIALS

Large uses of leaching processes occur in the metal processing industries.

The useful metals usually occur in mixtures with very large amounts of undesirable

constituents, and leaching is used to remove the metals as soluble salts. Copper

salts are dissolved or leached from ground ores containing other minerals by

sulfuric acid or ammoniacal solutions. Cobalt and nickel salts are leached from

their ores by sulfuric acid-ammonia-oxygen mixtures. Gold is leached from its ore

using an aqueous sodium cyanide hydroxide prepared by reacting Na 2CO3 with

Ca(OH)2.

LEACHING | Santos • Sison • Yepes 5

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

PREPARATION OF SOLIDS FOR LEACHING

Inorganic and Organic Materials

The method of preparation of the solid depends to a large extent upon the

proportion of the soluble constituent present, its distribution throughout the

original solid, the nature of solid – i.e., whether it is composed of plant cells or

whether the soluble material is completely surrounded by a matrix of insoluble

matter – and the original particle size.

If the soluble material is surrounded by a matrix of insoluble matter, the

solvent must diffuse inside to contact and dissolve the soluble material and then

diffuse out. This occurs in many hydrometallurgical processes where metal salts

are leached from mineral ores. In these cases, crushing and grinding of ores is

used to increase the rate of leaching since the soluble portions are made more

accessible to the solvent. If the soluble substance is in the solid solution in the solid

or is widely distributed throughout the whole solid, the solvent leaching action

could form small channels. The passage of additional solvent is then made easier,

and grinding to very small sizes may not be needed. Grinding of the particles is

not necessary if the soluble material is dissolved in solution adhering to the solid.

Then simple washing can be used as in washing of chemical precipitates.

Animal and Vegetable Materials

Biological materials are cellular in structure and the soluble constituents are

generally found inside the cells. The rate of leaching may be comparatively slow

because the cell walls provide another resistance to diffusion. However, to grind

biological materials sufficiently small to expose the contents of the individual cells

is impractical. Sugar beets are cut into thin wedge-shaped slices for leaching so

that the distance required for the water solvent to diffuse to reach individual cells

is reduced. The cells of the sugar beet are kept essentially intact so that sugar will

diffuse through the semipermeable cell walls, while the undesirable albuminous

and colloidal components cannot pass through the walls.

For the leaching of pharmaceutical products from leaves, stems, and roots,

drying of the material before extraction helps rupture the cell walls. Thus, the

solvent can directly dissolve the solute. The cell walls of soybeans and many

LEACHING | Santos • Sison • Yepes 6

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

vegetable seeds are largely ruptured when the original material are reduced in

size to about 0.1mm to 0.5mm by rolling or flaking. Cells are smaller in size, but the

walls are ruptured and the vegetable oil is easily accessible to the solvent.

TYPES OF EQUIPMENT FOR LEACHING

Fixed-Bed Leaching

Fixed bead leaching is used in the beet sugar industry and is also used for

the extraction of tanning extracts from tanbark, for the extraction of

pharmaceuticals from barks and seeds, and in other processes.

The figure shows a typical sugar beet diffuser or extractor is shown. The

cover is removable, so sugar beet slices called cossettes can be dumped into the

bed. Heated water at 344 K to 350 K flows into the bed to leach out the sugar.

The leached sugar solution flows out the bottom onto the next tank in series.

Countercurrent operation is used in the Shanks system. The top and bottom covers

are removable so that the leached beets can be removed and a fresh charge

added. About 95% of the sugar in the beets is leached to yield an outlet solution

from the system of about 12 wt%

DIFFUSION BATTERIES

Fixed bet extractors are often interconnected to form diffusion batteries.

The individual extractors may be completely enclosed columns that can operate

at elevated pressures and temperatures higher than the normal boiling point of

LEACHING | Santos • Sison • Yepes 7

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

the solvent. When operations are carried out at atmospheric pressure, open tanks

may be used. In such batteries, there is a continuous flow of extract usually in the

upward direction, in each active bed. Extract drawoff is obtained from the bed

containing the freshest solids and fresh solvent is fed into the bed containing the

most spent solids. After drawoff, extract flowing out of a bed is fed directly into

the opposite end of the next fresher bed. Spent solids are discharged periodically

from the system and fresh solids are loaded into the vessel vacated by the spent

solids. The drawoff and solvent feed locations are shifted in a corresponding

fashion. The solid unloading-loading and solvent feed and extract discharge

sequences, which are shown, are similar to those used in the Shank’s system.

LEACHING | Santos • Sison • Yepes 8

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Diffusion batteries are used for extracting soluble coffee, soluble tea, spices,

pickling salts and corn steep solids and formerly were used in very large numbers

for extracting beet sugar. Coffee or spice extraction batteries usually contain four

to eight columns, typically six; beet sugar batteries contained 10-16 cells, typically

14. Coffee extraction columns usually have diameters ranging between 0.25 and

0.75 m and are 4.5 – 6.0 m tall.

LEACHING | Santos • Sison • Yepes 9

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Moving Bed Leaching

There are a number of devices for stagewise countercurrent leaching

where the bed or stage moves instead of being stationary. These are used widely

in extracting oil from vegetable seeds such as cottonseeds, peanuts, and

soybeans. The seeds are usually dehulled first, sometimes precooked, often

partially dried, and rolled or flaked. Sometimes preliminary removal of oil is

accompanied by expressions. The solvents are usually petroleum products, such

as hexane. The final solvent – vegetable solution, called miscella, may contain

some finely divided solids.

Soybean Oil Production Process

The production of commercial soybean oil is complicated. Below are the

main steps of the soybean oil production process.

Soybean Flaking &

Extracting Refining

Cleaning Conditioning

Cleaning Section of Soybean Oil Production: The soybeans are first cleaned, dried

and dehulled prior to oil extraction. The soybean hulls need to be removed

because they absorb oil and give a lower yield. This de-hulling is done by cracking

the soybeans and a mechanical separation of the hulls and cracked soybeans.

Magnets are used to separate any iron from the soybeans.

The soybeans are also heated to about 75°C to coagulate the soy proteins to

make the oil extraction easier.

Extraction Section of Soybean Oil Production: First the soybeans are cut in flakes

which are put in a percolation extractor and immerged with a solvent, normally

hexane. Counterflow is used as extraction system because it gives the highest

yield. After removing the hexane, the extracted flakes only contain about 1% of

soybean oil and is used as livestock meal or to produce food products such as

soy protein. The hexane is separated from the soybean oil in evaporators. The

LEACHING | Santos • Sison • Yepes 10

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

evaporated hexane is recovered and returned to the extraction process. The

hexane free crude soybean oil is then further purified.

Solvent Extraction Workshop View:

Purification Section of Soybean Oil Production: The crude soybean oil still contains

many oil-insoluble and oil-soluble impurities that needs to be removed. The oil-

insoluble material are removed with filtration and the soluble materials is removed

with different processes including degumming (removing of phosphatides), oil

refining (washing with alkaline solution to remove free fatty acids, colorants,

insoluble matter and gums) and bleaching (with activated earth or activated

carbon to remove color and other impurities.

Hydrogenation Section of Soybean Oil Production (optional): This process will

increase the stability of the soybean oil and will make it less liquid. However, this

process will create more saturated fats and will reduce the favorable unsaturated

fats. In addition, transfats are produced which can cause heart problems.

Hydrogenated soybean oil is used in foods that require more solid fat such as

margarines.

LEACHING | Santos • Sison • Yepes 11

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Horizontal Continuous Extractor

Horizontal continuous extractor is a typical workhorse of solvent extraction

type vegetable oil processing units. It can be adopted for steviol glycoside

extraction with very little modification. In this system, the leaves are to be loaded

in chain of baskets with perforated bottom, which moves in continuous circle

carried by a chain drive. As the baskets move through the system, progressively

dilute extractant is sprinkled on the baskets. The extractant percolates through

the leaves in the basket and collects in different sumps. Extract from one sump is

used as extractant for another stage. After repeated extraction with progressively

dilute extracts and ultimately with fresh water, the baskets are tipped

mechanically and the leaves are discharged through a chute. In this system the

leaves and the extractant flows in opposite (counter-current) direction.

Advantages and Disadvantages of Horizontal Continuous Extractor

Advantages Disadvantages

• Can be integrated into continuous • Cost of equipment is high

process • Large equipment, so maintaining

• Extraction efficiency is high stable optimal thermal profile is

• Final extract is fairly concentrated difficult

LEACHING | Santos • Sison • Yepes 12

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

• Hydraulic conductivity of soaked

leaves is low and it impairs

percolation

Bollman Extractor

In the figure, an enclosed moving-bed bucket elevator is shown. This is

called the Bollman extractor. It is a bucket-elevator unit designed to handle

about 2000 to 20,000 kg/h (50 to 500 U.S. tons/day) of flaky solids (e.g., soybeans).

Buckets with perforated bottoms are held on an endless moving belt. Dry flakes,

fed into the descending buckets, are sprayed with partially enriched solvent

(“half miscella”) pumped from the bottom of the column of ascending buckets.

As the buckets rise on the other side of the unit, the solids are sprayed with a

countercurrent stream of pure solvent. Exhausted flakes are dumped from the

buckets at the top of the unit into a paddle conveyor; enriched solvent, the “full

miscella,” is pumped from the bottom of the casing. Because the solids are

unagitated and because the final miscella moves cocurrently, the Bollman

LEACHING | Santos • Sison • Yepes 13

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

extractor permits the use of thin flakes while producing extract of good clarity. It

is only partially a countercurrent device, however, and it sometimes permits

channeling and consequent low stage efficiency. Perhaps for this reason, it is

being displaced in the oil extraction industry by horizontal basket, pan, or belt

percolators.

Advantages and Disadvantages of Bollman Extractor

Advantages Disadvantages

• Can be integrated into continuous • Cost of equipment is high

process • Large equipment, so maintaining

• Extraction efficiency is high stable optimal thermal profile is

• Final extract is fairly concentrated difficult

• Hydraulic conductivity of soaked

leaves is low and it impairs

percolation. Sometimes channeling

through leaf matrix also occurs

which also have adverse effect on

extraction efficiency.

Hildebrandt Extractor

The Hildebrandt total-immersion extractor is shown in the figures. The helix

surface is perforated so that solvent can pass through countercurrently. It consists

of three screw conveyors arranged in a U shape. The screws are so designed to

compact the solids during their passage through the unit. The design offers the

LEACHING | Santos • Sison • Yepes 14

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

obvious advantages of countercurrent action and continuous solids compaction,

but there are possibilities of some solvent loss and feed overflow, and successful

operation is limited to light, permeable solids. The solids are charged at the top

right, conveyed downward, across the bottom, and then up the other leg. The

solvent flows countercurrently.

A somewhat similar but simpler design uses a horizontal screw section for

leaching and a second screw in an inclined section for washing, draining, and

discharging the extracted solids.

Advantages and Disadvantages of Hildebrandt Extractor

Advantages Disadvantages

• Precision process control • Hydraulic conductivity may be an

• Extraction is through immersion issue in the draining stage

method, so hydraulic conductivity • Precision mechanical parts need

is not an issue in extraction stage high maintenance

• High thermal efficiency

• High concentration of the product

in the extract due to

countercurrent extraction

Rotocel Extractor

In the horizontal-basket

design, illustrated by the Rotocel

extractor, walled compartments in

the form of annular sectors with

liquid-permeable floors revolve

about a central axis. The

compartments successively pass a

feed point, a number of solvent

sprays, a drainage section, and a

discharge station (where the floor

opens to discharge the extracted

solids). The discharge station is

circumferentially contiguous to the feed point. Countercurrent extraction is

achieved by feeding fresh solvent only to the last compartment before dumping

LEACHING | Santos • Sison • Yepes 15

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

occurs and by washing the solids in each preceding compartment with the

effluent from the succeeding one. The Rotocel is simple and inexpensive, and it

requires little headroom. This type of equipment is made by a number of

manufacturers. Horizontal table and tilting-pan vacuum filters, of which it is the

gravity counterpart, are used as extractors for leaching processes involving

difficult solution-residue separation.

Rotocel extractors have all the advantages and disadvantages associated

with basket type extractors. They have an added advantage of compact size,

high throughput and better energy efficiency.

LEACHING | Santos • Sison • Yepes 16

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Agitated Solid Leaching

When the solid can be ground fine to about 200 mesh (0.074mm), it can be

kept in suspension by small amounts of agitation. Continuous countercurrent

leaching can be kept in suspension by small amounts of agitation. Continuous

countercurrent leaching can be accomplished by placing a number of agitators

in series, with settling tanks or thickeners between each agitator.

In this countercurrent-stage system, fresh solvent enters the first stage

thickener. The clear, settled liquid leaves and flows from stage to stage. The feed

solids enter the last stage, where they are contacted with solvent from the

previous stage and then enter the settler. The slowly rotating rake moves the solids

to the bottom discharge. The solids together with some liquid are pumped as a

slurry to the next tank. If the contact is insufficient, a mixer can be installed

between the settlers.

Advantages Disadvantages

• Rapid recovery of desired solids • Higher capital and operating

• Relatively high extraction costs

It is also assumed that the solid is insoluble, and no adsorption will happen

for the solute in the solid, meaning that the solution in the liquid phase leaving a

stage is the same as the solution remaining with the solid matrix in the settled slurry

leaving the same stage. The settled solid leaving a stage always contains some

liquid. This solid-liquid stream is called the underflow or slurry stream. The liquid is

LEACHING | Santos • Sison • Yepes 17

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

called the overflow stream. The concentration of oil or solute in the overflow

stream is equal to that in the liquid solution accompanying the slurry or underflow

stream.

Example Application in the industry is Cyanide Leaching for Gold

In the industry of metal processing, cyanide leaching is performed on ores

to remove metal impurities and preserve desirable products, such as gold.

Cyanide leaching is a desirable technique due to the final product being

leached (ihome). The final product, gold, is desirable because of its high demand

and high profitability.

Cyanide is used because it is a naturally occurring chemical that is found

in nuts, plants, insects, and fruits. Cyanide is very beneficial because it is not

harmful to the environment. The process of gold leaching demands the use of

cyanide because it escalates the separation process of extracting the gold from

the ore.

One of the main reasons cyanide leaching is performed as an alternative

method to separating gold from an ore is because it is much safer than using

liquid mercury for the extraction. Due to the low concentrations of cyanide

needed for separation, there is little to no harm to the environment, minimal

amounts of cyanide needed for preserving natural resources, and very safe for

miners to perform with.

LEACHING | Santos • Sison • Yepes 18

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

Kennedy Extractor

The extractor, named after its inventor, Angus B. Kennedy and currently

manufactured by the Vulcan Copper and Supply CO. (U.S.A.).

The plant appears to be quite versatile, as it is possible to treat in the

extractor, materials such as cottonseed, ground nut, castor bean flakes, tungnuts,

flaxseed and sunflowerseed in addition to soyabeans. Further, no requirement

seems to exist for the oil-bearing material to be in the conventional flake form,

since extraction has been accomplished successfully on material that was either

granular, powdery, gelatinous, fibrous, stringy or pulpy in nature. A variety of

solvents including petroleum fractions, acetone, alcohol, trichloroethylene and

mixed solvents have been used successfully.

"The continuous extractor consists of a series of enclosed extraction

chambers or sections. Into each of these is fitted an impeller wheel assembly

consisting of an enclosed hub (the lower portion of the hub is partially submerged

in the liquid), four curved blades of perforated metal, and a shaft extending

through bearings in the sides of the extractor walls. The impeller wheel assemblies

are driven from the outside by a common drive shaft through a worm and gear

arrangement.

"The controlled quantities of the material are fed at a constant rate by a

feed screw conveyor into the first extraction section of the extractor. The material

then is carried through the extractor in counter-current flow to the solvent.

"Each portion of immersed solid material in a section is collected by an

impeller blade and carried through the liquid in that section. As the solids are

carried up the curved wall of that section, they are slightly compressed between

the wall and the curved blade to form a wedge, which is lifted above the liquid

level and sloughs off the blade into the next section. This slight compression and

draining through lifting the solids above the liquid level reduce the amount of

entrained liquid carried over to the succeeding section.

"On striking the liquid surface in the succeeding section, the wedge readily

breaks up and disperses. The solids immersed in the liquid of this section as distinct

particles are again collected by an impeller blade and moved through the liquid.

"The extracted solids are gravity drained of a good part of the entrained

solvent, while being carried up the drag chain conveyor, and then are dropped

LEACHING | Santos • Sison • Yepes 19

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

into a collecting can with a perforated false bottom for separating additional

liquid drainings."

The Kennedy extractor, also requiring little headroom, operates

substantially as a percolator that moves the bed of solids through the solvent

rather than the conventional opposite. It comprises a nearly horizontal line of

chambers through each of which in succession the solids being leached are

moved by a slow impeller enclosed in that section. There is an opportunity for

drainage between stages when the impeller lifts solids above the liquid level

before dumping them into the next chamber. Solvent flows counter-currently from

chamber to chamber. Because the solids are subjected to mechanical action

somewhat more intense than in other types of continuous percolator, the

Kennedy extractor is now little used for fragile materials such as flaked oil seeds.

Stationary Basket Extractor

The French Stationary Basket Extractor extracts percolates through beds of

solids contained in a circular array of sector-shaped compartments with

perforated bottoms and drains into sumps positioned below the beds. Solids do

not move. Instead, the solid feed spout and solids discharge zone rotate about

the circle and the extract feed and discharge connections are switched

periodically. These extractors are like automated diffusion batteries in which

downflow is used; but because extract backmixes in each sump, the extract

concentration leaving a stage is somewhat different from that entering the next

stage.

LEACHING | Santos • Sison • Yepes 20

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

"In the vertical type of extractor, the flakes are conveyed carefully to the

filling column on the top of the extractor, which consists of a two compartment

device that maintains a seal against the escape of vapour. The basket extraction

system requires an overfeed of flakes so that a small overflow is always returned

to an over-flow bin, usually located in the preparation building. Miscella is applied

with the flakes into the basket so that uniform filling is obtained. The baskets travel

down on this first side of the extractor and the miscella filters through the material

in the baskets, passing downwards in the same direction as the flakes. This

concurrent flow has, strangely enough, proved to be as efficient in the early

stages of extraction as countercurrent flow. This concurrent flow allows repeated

filtration of miscella. The resulting final miscella is of such a clarity that cannot be

attained by the most elaborate filtration systems.

Advantages Disadvantages

• Yields very clean miscella • Possibility of channeling solvent

• Flakes are not subjected to flow through the seeds

mechanical disturbance • Some oil seeds tend to pack in

the basket, hence, extraction

becomes slower.

LEACHING | Santos • Sison • Yepes 21

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

SELECTION OR DESIGN OF A LEACHING PROCESS

At the heart of a leaching plant design at any level—conceptual,

preliminary, firm engineering, or whatever—is unit-operations and process design

of the extraction unit or line. The major aspects that are particular for the leaching

operation are the selection of process and operating conditions and the sizing of

the extraction equipment.

Process and Operating Conditions

The major parameters that must be fixed or identified are the solvent to be

used, the temperature, the terminal stream compositions and quantities, leaching

cycle (batch or continuous), contact method, and specific extractor choice.

A. Choice of Solvent

The solvent selected will offer the best balance of a number of desirable

characteristics: high saturation limit and selectivity for the solute to be extracted,

capability to produce extracted material of quality unimpaired by the solvent,

chemical stability under process conditions, low viscosity, low vapor pressure, low

toxicity and flammability, low density, low surface tension, ease and economy of

recovery from the extract stream, and price. These factors are listed in an

approximate order of decreasing importance, but the specifics of each

application determine their interaction and relative significance, and any one

can control the decision under the right combination of process conditions.

B. Temperature

The temperature of the extraction should be chosen for the best balance

of solubility, solvent-vapor pressure, solute diffusivity, solvent selectivity, and

sensitivity of product. In some cases, temperature sensitivity of materials of

construction to corrosion or erosion attack may be significant.

LEACHING | Santos • Sison • Yepes 22

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

C. Terminal Stream Compositions and Quantities

These are basically linked to an arbitrary given: the production capacity of

the leaching plant (rate of extract production or rate of raw-material purification

by extraction). When options are permitted, the degree of solute removal and

the concentration of the extract stream chosen are those that maximize process

economy while sustaining conformance to regulatory standards.

D. Leaching Cycle and Contact Method

As is true generally, the choice between continuous and intermittent

operation is largely a matter of the size and nature of the process of which the

extraction is a part. The choice of a percolation or solids-dispersion technique

depends principally on the amenability of the extraction to effective, sufficiently

rapid percolation.

E. Type of Reactor

The specific type of reactor that is most compatible (or least incompatible)

with the chosen combination of the preceding parameters seldom is clearly and

unequivocally perceived without difficulty, if at all. In the end, however, that

remains the objective. As is always true, the ultimate criteria are reliability and

profitability.

LEACHING | Santos • Sison • Yepes 23

PAMANTASAN NG LUNGSOD NG MAYNILA

University of the City of Manila

College of Engineering and Technology

Department of Chemical Engineering

REFERENCES

Board, N. (2013). Modern Technology of Oils, Fats & Its Derivatives (2nd Revised

Edition). India: Asia Pacific Business Press, Inc.

CHE 433: Modern Separations, Leaching. (2018, March 20). Retrieved from

https://sites.google.com/site/che433nielsen/industrial-applications

Erickson, D. R. (1990). Edible Fats and Oils Processing: Basic Principles and Modern

Practices. Champaign, Illinois: American Oil Chemists' Society.

Geankoplis, Transport Processes and Unit Operations

Leaching: Definition and Process Retrieved 19 March 2017 from

https://study.com/academy/lesson/leaching-definition-process.html

Leaching Process Retrieved 19 March 2017 from

https://www.vanderbilt.edu/leaching/leaching-process/

Liquid-Solid Leaching Process Retrieved 19 March 2017 from

http://portal.unimap.edu.my/portal/page/portal30/Lecturer%20Notes/KEJURUTE

RAAN_BIOPROSES/Semester%202%20Sidang%20Akademik%2020132014/BIOPRO

CESS%20ENGINEERING%20PROGRAMME/Third%20Year/ERT%20320%20-

%20BIOSEPARATION%20ENGINEERING/LIQUID-SOLID%20Leaching.pdf

Rousseau, R. W. (1987). Handbook of Separation Process Technology. Canada:

John Wiley & Sons.

Schwartzberg, Henry G., Leaching Organic Materials (n.d.)

Separations Retrieved 19 March 2017 from

http://encyclopedia.che.engin.umich.edu/Pages/SeparationsChemical/IonExc

hangeColumns/IonExchangeColumns.html

UK Essays. (2018, March 20). Retrieved from Agitation Leaching Theory And

Practice Biology Essay: https://www.ukessays.com/essays/biology/agitation-

leaching-theory-and-practice-biology-essay.php

LEACHING | Santos • Sison • Yepes 24

Vous aimerez peut-être aussi

- Leaching TheoryDocument12 pagesLeaching TheoryJérôme Kyabu0% (1)

- Hydrometallurgy NotesDocument96 pagesHydrometallurgy NotesTatenda SibandaPas encore d'évaluation

- Hyorometallurgy: Liont To byDocument31 pagesHyorometallurgy: Liont To byMichael Vincent Mirafuentes0% (1)

- Introduction To Pyro MetallurgyDocument76 pagesIntroduction To Pyro MetallurgyDrTrinath Talapaneni75% (4)

- Leaching Equipment - Pharm Eng I - 2nd YrDocument28 pagesLeaching Equipment - Pharm Eng I - 2nd YrRutens NdreaPas encore d'évaluation

- Hydro MetallurgyDocument51 pagesHydro MetallurgyMamamamajPas encore d'évaluation

- LeachingDocument23 pagesLeachingIram Tahira100% (4)

- MT Unit 4 LeachingDocument72 pagesMT Unit 4 Leachinglavanya thanigaiPas encore d'évaluation

- Sedimentation PDFDocument33 pagesSedimentation PDFniezajanepatnaPas encore d'évaluation

- Leaching: Diagram 1: Example of Making Green Tea To Illustrate LeachingDocument4 pagesLeaching: Diagram 1: Example of Making Green Tea To Illustrate LeachingMiracle Chibuike OdiPas encore d'évaluation

- Chapter One - Mecanical Unit OperationDocument17 pagesChapter One - Mecanical Unit OperationBizuayehu GeroPas encore d'évaluation

- Filtration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBDocument48 pagesFiltration: Nur Istianah, ST, MT, M.Eng - KP2 - THP UBNoer FaizinPas encore d'évaluation

- Leaching 1 2Document32 pagesLeaching 1 2hartatiprasetyoPas encore d'évaluation

- New Hydrometallurgical Process For Gold RecoveryDocument6 pagesNew Hydrometallurgical Process For Gold RecoveryWaskito BudiawanPas encore d'évaluation

- SedimentationDocument38 pagesSedimentationMilind BhaskarPas encore d'évaluation

- Leaching - Solid - Liquid Extraction Lecture 1Document40 pagesLeaching - Solid - Liquid Extraction Lecture 1Tumisang Seodigeng100% (1)

- SedimentationDocument39 pagesSedimentationIsaiah Paul G. SacramentoPas encore d'évaluation

- The Differences Between Adsorption, Ion Exchange & SolventDocument17 pagesThe Differences Between Adsorption, Ion Exchange & SolventAditya Haryadi100% (4)

- LeachingDocument10 pagesLeachingnhalieza1067Pas encore d'évaluation

- Makanza Flotation (2008)Document23 pagesMakanza Flotation (2008)Richard CookPas encore d'évaluation

- Written ReportDocument16 pagesWritten ReportJamel Cayabyab50% (2)

- Mineral Engineering & Fuel Technology: Person Involved Name Designation and Email .Id DepartmentDocument125 pagesMineral Engineering & Fuel Technology: Person Involved Name Designation and Email .Id DepartmentSandeep KumarPas encore d'évaluation

- Week 1 Introduction To Mass TransferDocument30 pagesWeek 1 Introduction To Mass TransferKagendren AyanPas encore d'évaluation

- Leaching PPT 2022Document20 pagesLeaching PPT 2022gautham GAUTHAMPas encore d'évaluation

- MINE292-Coal Processing-2013 PDFDocument8 pagesMINE292-Coal Processing-2013 PDFdonnypsPas encore d'évaluation

- Lab LleDocument20 pagesLab LleMuhamad Baihakhi Shamsudin100% (1)

- Mineral Processing Laboratory ManualDocument43 pagesMineral Processing Laboratory Manualalnemangi100% (1)

- Flotation 21Document62 pagesFlotation 21Jamel CayabyabPas encore d'évaluation

- 6.0 SedimentationDocument43 pages6.0 Sedimentationmythili100% (1)

- Centrifugal Separation and SievingDocument5 pagesCentrifugal Separation and SievingVincent NguyenPas encore d'évaluation

- Copper HydrometallurgyDocument11 pagesCopper HydrometallurgyRonald QuilangPas encore d'évaluation

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Final Plant ReportDocument61 pagesFinal Plant ReportEDSON CHENJERAIPas encore d'évaluation

- Why Electrowinning Hates IronDocument7 pagesWhy Electrowinning Hates IronJOSE MACASSIPas encore d'évaluation

- Settling and SedimentationDocument28 pagesSettling and SedimentationPratiksha GorePas encore d'évaluation

- LeachingDocument32 pagesLeachingaaaPas encore d'évaluation

- FlotationDocument39 pagesFlotationMuhammad Zubair SharifPas encore d'évaluation

- Abdulla Samin MV 14449: Lab Report Froth FlotationDocument4 pagesAbdulla Samin MV 14449: Lab Report Froth FlotationKevin100% (1)

- Extraction and Leaching PPT Notes PDFDocument15 pagesExtraction and Leaching PPT Notes PDFJeaz JeazePas encore d'évaluation

- Size ReductionDocument12 pagesSize ReductionJohn Paul RodriguezPas encore d'évaluation

- LeachingDocument8 pagesLeachingRodolfoSottoJr.Pas encore d'évaluation

- MO UNIT - I PPT NotesDocument81 pagesMO UNIT - I PPT NotesKrishnan DhanasekaranPas encore d'évaluation

- Problem Set - Particle Fluid Separation2012Document3 pagesProblem Set - Particle Fluid Separation2012John Kevin San Jose50% (2)

- Crystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerDocument5 pagesCrystallization Equipment (Crystallizers) : Swenson-Walker CrystallizerJustin Paul CongePas encore d'évaluation

- Designing Flotation Circuits For High Fines RecoveryDocument10 pagesDesigning Flotation Circuits For High Fines RecoveryClaudio Galleguillos BeniPas encore d'évaluation

- Leaching EquipmentsDocument32 pagesLeaching EquipmentsArun Kumar80% (5)

- Chemical Engineering Lab Ii (CDB 3052) Experiment 2: Activated Carbon Adsorption Isotherm & KineticsDocument23 pagesChemical Engineering Lab Ii (CDB 3052) Experiment 2: Activated Carbon Adsorption Isotherm & Kineticskang1995Pas encore d'évaluation

- Elution and Carbon Reactivation BasicsDocument19 pagesElution and Carbon Reactivation BasicsdiegovergaraPas encore d'évaluation

- FlotationDocument40 pagesFlotationAhmed Mohamed RedaPas encore d'évaluation

- LeachingDocument21 pagesLeachingBon Bon100% (1)

- Alta2009continuous Vat Leaching - First Copper Pilot TrialsDocument9 pagesAlta2009continuous Vat Leaching - First Copper Pilot TrialsGeorgi SavovPas encore d'évaluation

- Wastewater TreatmentDocument61 pagesWastewater TreatmentGoutham R100% (1)

- Microbial Aspects in Waste Water Treatment A TechnicalDocument11 pagesMicrobial Aspects in Waste Water Treatment A TechnicalHarshit YadavPas encore d'évaluation

- Environmental I AssDocument15 pagesEnvironmental I AssAbel TayePas encore d'évaluation

- Water Treatment System-Iit NoteDocument14 pagesWater Treatment System-Iit NoteBhaswar MajumderPas encore d'évaluation

- Microbial Aspects in Wastewater Treatment - A Technical ReviewDocument11 pagesMicrobial Aspects in Wastewater Treatment - A Technical Reviewxyz 123Pas encore d'évaluation

- Chapter 3 - Water TreatmentDocument21 pagesChapter 3 - Water TreatmentSri SundragomathyvenkateshPas encore d'évaluation

- V2i4 1160Document8 pagesV2i4 1160Ajay Kumar GantiPas encore d'évaluation

- WW Treatment Objectives, Methods & ImplementationDocument40 pagesWW Treatment Objectives, Methods & ImplementationBren SisonPas encore d'évaluation

- The Field of Engineering ManagementDocument27 pagesThe Field of Engineering ManagementBren SisonPas encore d'évaluation

- Mathcad PDFDocument14 pagesMathcad PDFBren SisonPas encore d'évaluation

- Laws and Contracts For Chemical Engineers: Origin, Nature, and Development of Law and ContractDocument1 pageLaws and Contracts For Chemical Engineers: Origin, Nature, and Development of Law and ContractBren SisonPas encore d'évaluation

- Basic Concepts Of: MicrobiologyDocument29 pagesBasic Concepts Of: MicrobiologyBren SisonPas encore d'évaluation

- Particleboard Based On Rice Husk: Effect of Binder Content and Processing ConditionsDocument6 pagesParticleboard Based On Rice Husk: Effect of Binder Content and Processing ConditionsBren SisonPas encore d'évaluation

- Process Engineering Center: Job DescriptionDocument1 pageProcess Engineering Center: Job DescriptionBren SisonPas encore d'évaluation

- Emergencies Emergency Escape Route Assignments Employees EmployeesDocument1 pageEmergencies Emergency Escape Route Assignments Employees EmployeesBren SisonPas encore d'évaluation

- Methodology: Pamantasan NG Lungsod NG MaynilaDocument3 pagesMethodology: Pamantasan NG Lungsod NG MaynilaBren SisonPas encore d'évaluation

- 92135-233797-1-PBDocument9 pages92135-233797-1-PBBren SisonPas encore d'évaluation

- TG No. 4 Kiln Drying of RattanDocument20 pagesTG No. 4 Kiln Drying of RattanBren SisonPas encore d'évaluation

- Religions: Catholic Social Teaching On Building A Just Society: The Need For A Ceiling and A FloorDocument11 pagesReligions: Catholic Social Teaching On Building A Just Society: The Need For A Ceiling and A FloorBren SisonPas encore d'évaluation

- CPI Topic OutlineDocument2 pagesCPI Topic OutlineBren SisonPas encore d'évaluation

- TestingDocument1 pageTestingBren SisonPas encore d'évaluation

- Expt 9Document17 pagesExpt 9Bren SisonPas encore d'évaluation

- Air Conditioning EquipmentDocument28 pagesAir Conditioning EquipmentBren SisonPas encore d'évaluation

- Pumps, Fans, Blowers, and CompressorsDocument68 pagesPumps, Fans, Blowers, and CompressorsBren SisonPas encore d'évaluation

- How To Write Chapter 3 & 4Document35 pagesHow To Write Chapter 3 & 4Bren SisonPas encore d'évaluation

- Pharmaceutical IndustryDocument67 pagesPharmaceutical IndustryBren SisonPas encore d'évaluation

- Related Literature and Studies 1Document22 pagesRelated Literature and Studies 1Bren SisonPas encore d'évaluation

- Strengthening MechanismsDocument21 pagesStrengthening MechanismsBren SisonPas encore d'évaluation

- Pulp and Paper Industry PDFDocument56 pagesPulp and Paper Industry PDFBren SisonPas encore d'évaluation

- Formal Lab ReportDocument4 pagesFormal Lab ReportBren SisonPas encore d'évaluation

- Formal Lab Report 2Document4 pagesFormal Lab Report 2Bren SisonPas encore d'évaluation

- Ceramic IndustryDocument54 pagesCeramic IndustryBren SisonPas encore d'évaluation

- Starch and Flour IndustryDocument39 pagesStarch and Flour IndustryBren SisonPas encore d'évaluation

- Understanding PTS Security PDFDocument37 pagesUnderstanding PTS Security PDFNeon LogicPas encore d'évaluation

- PP Master Data Version 002Document34 pagesPP Master Data Version 002pranitPas encore d'évaluation

- Previous Year Questions - Macro Economics - XIIDocument16 pagesPrevious Year Questions - Macro Economics - XIIRituraj VermaPas encore d'évaluation

- HepaDocument1 pageHepasenthilarasu5100% (1)

- ResumeDocument3 pagesResumeapi-280300136Pas encore d'évaluation

- Not A Toy Sample PDFDocument37 pagesNot A Toy Sample PDFMartha Paola CorralesPas encore d'évaluation

- Contoh Discussion Text Tentang HomeworkDocument8 pagesContoh Discussion Text Tentang Homeworkg3p35rs6100% (1)

- E-Versuri Ro - Rihana - UmbrelaDocument2 pagesE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- Random Variables Random Variables - A Random Variable Is A Process, Which When FollowedDocument2 pagesRandom Variables Random Variables - A Random Variable Is A Process, Which When FollowedsdlfPas encore d'évaluation

- 10 Killer Tips For Transcribing Jazz Solos - Jazz AdviceDocument21 pages10 Killer Tips For Transcribing Jazz Solos - Jazz Advicecdmb100% (2)

- A Review of Service Quality ModelsDocument8 pagesA Review of Service Quality ModelsJimmiJini100% (1)

- Who Trs 993 Web FinalDocument284 pagesWho Trs 993 Web FinalAnonymous 6OPLC9UPas encore d'évaluation

- Analytical Chem Lab #3Document4 pagesAnalytical Chem Lab #3kent galangPas encore d'évaluation

- Hand Out Fire SurpressDocument69 pagesHand Out Fire SurpressSeptiawanWandaPas encore d'évaluation

- Owners Manual Air Bike Unlimited Mag 402013Document28 pagesOwners Manual Air Bike Unlimited Mag 402013David ChanPas encore d'évaluation

- HFE0106 TraskPart2Document5 pagesHFE0106 TraskPart2arunkr1Pas encore d'évaluation

- 928 Diagnostics Manual v2.7Document67 pages928 Diagnostics Manual v2.7Roger Sego100% (2)

- Dec JanDocument6 pagesDec Janmadhujayan100% (1)

- Switching Simulation in GNS3 - GNS3Document3 pagesSwitching Simulation in GNS3 - GNS3Jerry Fourier KemePas encore d'évaluation

- PE MELCs Grade 3Document4 pagesPE MELCs Grade 3MARISSA BERNALDOPas encore d'évaluation

- COURTESY Reception Good MannersDocument1 pageCOURTESY Reception Good MannersGulzina ZhumashevaPas encore d'évaluation

- HRMDocument118 pagesHRMKarthic KasiliaPas encore d'évaluation

- TraceDocument5 pagesTraceNorma TellezPas encore d'évaluation

- Futures Volume 1 Issue 3 1969 (Doi 10.1016/0016-3287 (69) 90026-3) Dennis Livingston - Science Fiction As A Source of Forecast MaterialDocument7 pagesFutures Volume 1 Issue 3 1969 (Doi 10.1016/0016-3287 (69) 90026-3) Dennis Livingston - Science Fiction As A Source of Forecast MaterialManticora VenerabilisPas encore d'évaluation

- Syllabus: What Is Artificial Intelligence? ProblemsDocument66 pagesSyllabus: What Is Artificial Intelligence? ProblemsUdupiSri groupPas encore d'évaluation

- Stentofon Pulse: IP Based Intercom SystemDocument22 pagesStentofon Pulse: IP Based Intercom SystemCraigPas encore d'évaluation

- Draft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Document13 pagesDraft JV Agreement (La Mesa Gardens Condominiums - Amparo Property)Patrick PenachosPas encore d'évaluation

- EVOM ManualDocument2 pagesEVOM ManualHouston WhitePas encore d'évaluation

- Elpodereso Case AnalysisDocument3 pagesElpodereso Case AnalysisUsama17100% (2)

- 2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesDocument1 page2 To 20 Years - Girls Stature-For-Age and Weight-For-Age PercentilesRajalakshmi Vengadasamy0% (1)