Académique Documents

Professionnel Documents

Culture Documents

3.2 Kabel

Transféré par

BoulHich BoulHichCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3.2 Kabel

Transféré par

BoulHich BoulHichDroits d'auteur :

Formats disponibles

Pipeline Technology Conference 2008

topic: Risk-weighted based integrity management

author: A.C. Kabel

presenter: A.C. Kabel

organisation: Pipeline Control

country: The Netherlands

contents

Abstract: ......................................................................................................................2

Presentation at the Hannover Messe 2008..................................................................3

Introduction..............................................................................................................3

Controlling pipelines ................................................................................................3

Initial process ..........................................................................................................4

Pipeline control........................................................................................................5

Risk management ...................................................................................................6

Risk-weighted integrity ............................................................................................7

Finishing ..................................................................................................................9

Figure 1 .................................................................................................................10

09/04/2008; AKA; Page 1 van 10

Pipeline Technology Conference 2008

Abstract:

The surveillance of the integrity of pipeline installations is the main task of the

pipeline manager. A pipeline installation has a shell function by which a medium can

be transported separated from the environment. The integrity is a value for safety,

usefulness and availability of a pipeline installation. The integrity also is the resultant

of a large number of influences coming from both the medium as well as the

environment of the pipeline installation. These influences are partly predictable and

therefore well controllable. Other influences however, have an unpredictable

character and for that reason are more difficult to control. This (un)predictable

controllability forms a certain degree of risk for the integrity.

It’s the pipeline managers task to control those risks for the pipeline integrity in an

effective way.

On the one hand this control happens by periodical surveillances and continuous

monitoring of processes and on the other hand by guarding activities near the

pipeline. A huge amount of all sorts of data proceeds from these control activities.

You can think of Cathodic Protection values, composition of the medium, third party

interferences, public authority plans, activities of landowners, ground composition,

condition of the pipeline coating and internal and external deterioration of the

pipeline. The surveillance of all these aspects usually takes place in different

departments and within these departments by different persons and in different ways

(by observation or acquisition of data). Because of the often vast length of a pipeline

the control is being done by several persons. Non of the persons involved has an

overall picture of the risks and surely not of the addition of risks, where risks

accumulate. Common control methods can therefore easily lead to inattention and

errors, consequently to a reduced integrity which can mean risks for safety,

usefulness and availability.

By (real-time) input of separate control data into a control system the addition of risks

can be executed continuously and automatically, the value of integrity of which can

be shown with a (warning)signal. This leads to an internal, external and total integrity

value which helps to take measures in a purposeful and efficient way. The application

also makes these risks visible on the pipeline itself which at the same time creates

understanding and insight of the causes of the risks, the locations with a higher risk

and the most efficient measures to be taken.

With this control system de management of risks is more purposeful and efficient and

less dependant from the attention of employees and therefore gives a strong pipeline

integrity prevention.

09/04/2008; AKA; Page 2 van 10

Pipeline Technology Conference 2008

Presentation at the Hannover Messe 2008

April 23th, 2008

Introduction

The control of a pipeline is a very serious and responsible task for a pipeline owner.

Pipelines run from and to industrial areas. At the time pipelines are constructed we

take care that they don’t run too near to cities and living areas. But a pipeline has a

long life-time, most of them longer than the life-time of a human and during that

period cities expand.

Pipelines are a very efficient and safe method of transporting gasses and liquids.

Pipelines are buried and only at specific places they have signals and objects that

make them visible above the surface. We know there is a pipeline, but after

construction we have never seen it again. That’s wonderful the landowners and town-

planning committees say and they try to use the land without any restriction. That’s

our problem we say as pipeline controllers and we try to build-in the necessary

restrictions for land using.

Pipeline Control has pipelines in areas with many cities. At the time the pipelines

were built they were constructed in a special pipeline area with small villages. The

nearest distance to a village was more than 100 meters. But the villages became

cities, cities go together, the special pipeline area is being used for houses and the

regular distance to the houses is now 9 meters. Rerouting the pipeline is not an

option because there is no space any more. Improving the safety of the pipeline isn’t

an option either, because a pipeline for dangerous goods is safe, otherwise we are

not allowed to operate it.

The point is that the risks have changed and are different. Where people are living

they can cause many influences to the pipeline during day and night. For example

they organise a local party, build a tent in the right of way (because there is space

and it is flat), using tent pegs of more than 2 meters long and telling everybody who

lives in the neighbourhood about it, but not us. And another one, horse riding with

carriages through poles placed in the right of way on a Saturday. To secure the poles

against falling they have been set 1,5 meter in the ground. Everyone was invited but

they forgot, or maybe they did not know they had to invite us.

Those influences can mean risks for the safety of the pipeline and therefore for the

safety of the people living in the proximity of the pipeline.

Controlling pipelines

It is therefore that the integrity of a pipeline has to be controlled seriously and in the

busy cities more than seriously.

We control the right of way, handle “One call” information, check the local building

plans, check the pipeline coating, carry out inline inspections and maintenance and

do a lot more. All these activities are grouped in the Pipeline Integrity Management.

But the moment we dig up a pipeline we see that it is damaged without knowing it.

Sometimes only the coating, sometimes bends or both. Sometimes we are able to

find out who caused the damage but many times we are not.

Does that mean that we have a narrow escape daily? May be.

09/04/2008; AKA; Page 3 van 10

Pipeline Technology Conference 2008

We conclude that everything we do to take care of the safety of the pipeline, is not

enough anymore. We have to do more. Because tomorrow or a day after an

unknown influence will cause a serious accident.

Today there are many products in the market to improve our control results. Every

month new products come and the existing products become better.

For instance leak detection systems, remote helicopter inspection, threat and impact

scans, camera guarding, coating and stress monitoring, very intelligent inspection

tools, combination tools and all kinds of software to use and implement the results of

these products.

A standard periodical inspection of the pipeline route is not enough anymore and can

easily lead to failures by the control employees and leaves the possibility that the

inspection is not done at the right time.

In our opinion we have to improve in two directions. Using the latest technology to

detect risks and implement an integral system that combines all the products to a

pipeline control solution.

Initial process

It is good to look back at first and go to the basis of pipeline controlling, the initial

process. The initial process goes from prevention to correction or risk management

to pipeline damage.

Basically the start of the prevention is the instructive initiative. At this moment we

inform the local authorities and do the regular control activities. We may have to

improve by informing and guiding people and house owner unions in the proximity of

the pipeline how they have to act. It may be necessary to place information plates in

the right of way.

Secondly, the regular surveillance stays in place and we have to check if the

instructive initiatives have their results and give more information if necessary. At this

moment we have to implement the results from a pipeline control solution. It is the

last chance in the prevention section. Later in the process it becomes a corrective

action and cannot prevent more risks or damages.

The corrective part is at first that we have to take more actions in supervising the

activities in and near by the right of way. We have to be more in the field and have to

install systems that detect not allowed activities and make rapid actions possible. We

also have to carry out more pipeline inspections. At this section we have to learn

from the necessary actions and implement them in the pipeline control solution for

improving the prevention.

Last but not least we have to improve our 24/7 system in case of an emergency. The

risk of harming humans in case of an emergency is higher than before, caused by the

location of the houses near the pipeline.

The initial process also gives costs separation. In the prevention part we are able to

regulate and plan our activities. In the correction part the outside world decides when

we have to act and where we have to be.

So there will be a breakeven point between the investments for prevention and the

costs for correction. At this moment it seems that the correction costs will become

more and more in the future, so we put our goals to the improvement of the

prevention.

09/04/2008; AKA; Page 4 van 10

Pipeline Technology Conference 2008

Part of this all will still be the Risk Based Inspection, which is: being at the right time

at the right place. But that is not so easy. Mostly the inspectors don’t have all the

necessary information in the field and it is very difficult to combine all the data from

the pipeline control system products to local information and to use it for the

prevention activities. That makes an integral control system solution necessary to

handle all the data and make it local information.

We indicate four major pipeline-control items:

- activities around

- natural influences around

- integrity of the pipeline and the state of its objects

- transported products

All these control items have their own origin and impact. They all need specific

preventive, analysing and corrective solutions. In our company we have specialist

task groups for all these control items. The results of their activities are available for

all groups. But a possible impact on the pipeline will only have local effect, handled

by one group, the survey-group. Therefore the survey-group needs all the fragmental

data presented as information that can be used in the prevention section of the initial

process.

It seems so easy. Just collect the data and make it accessable for the route

surveyors. Unfortunately it is not so simple. Each data item is different, has a

different dimension, is not aligned, has a different risk category and can be of more

or less influence on the pipeline integrity. And the data items can have impact on

each other and together can be of a stronger impact.

In our opinion it is necessary to summarise weighted aligned data items to conclude

the possible local effect and implement it in the prevention section. For that result we

not only need products but also a control system solution.

Pipeline control

At fist I would like to tell you in a few words what Pipeline Control does in relation to

pipelines.

Pipeline Control has been set up to control and maintain pipelines for pipeline owners

with the aim of a safe and secure pipeline infrastructure that leads to a maximum

performance. “Your assets, our concern” is our statement. We will take care of the

pipeline installation and the pipeline owner can concentrate on the exploitation,

transporting products. We do our job according to a Service Level Agreement.

We control and inspect pipeline installations and manage all necessary actions to be

taken. And with all we mean all. We mention ordering and supervising mechanical

contractors and engineers, set up bid documents and procedures, public licenses

and private agreements, handling insurance matters, legal procedures and

recovering losses.

Our system allows us to work with and to handle all serious local partners. The result

is that we can keep the costs at a minimum with a maximum of availability and

performance.

09/04/2008; AKA; Page 5 van 10

Pipeline Technology Conference 2008

Risk management

A risk is a prospective item with an uncertain outcome. Risk is the product of a

probability and a potential impact. The aim of pipeline controlling is to manage the

risk exposure to an acceptable level in a cost-effective way.

The probability and the potential impact are different for each risk item. Risk items

can reinforce each other. A coating defect can at a moment be more serious when

the roots of a tree at that place have been growing in the coating and the tree dies.

The probability of external corrosion rises.

Risks have an owner. The pipeline controller is the risk owner and is responsible that

the risks are properly managed. Believe me, the pipeline controller does not damage

the pipeline, that is always an other one, the originator of the damage. It is not of any

importance and many times there is no known relationship between the risk owner

and the impact originator. The pipeline is buried and the originator has no idea that

he can harm a pipeline when he installs a tent peg. At that moment the relationship is

known. The originator is now accountable for the impact and the pipeline controller is

accountable for a proper risk management.

In the risk assessment a variety of aspects are important, for example: third party

interference, coating condition, Cathodic Protection, soil conditions, land exploitation,

public and governmental activities, maintenance, inline inspection, operations and

product influence and deflection.

All these aspects are risks for the integrity of a pipeline installation and have to be

incorporated in the inspection and control operations.

We are able to address an internal and external integrity. Summarised it makes a

total integrity of the pipeline system.

However big the impact may be, the normal risk responses are in place:

a. prevention, realising the impact can not happen by choosing an other option;

b. reduction, the probability and/or the impact is (very) low;

c. transfer, passing to a third party for rest risks;

d. acceptance, tolerate rest risks;

e. contingency, actions tot reduce the impact.

In other words a risk will always be and stay a risk and needs a sufficient preventive

action. Important is to act on the risk prevention as early as possible in the control

process. Later in the process there is less time, the costs are increasing and more

individuals are involved.

Risk management can only take place in the preventive section. In the corrective

section there is no risk probability less, the impact has taken place. It is not a risk any

more, contingency actions are in place.

Therefore we have to address pipeline control products in two sections, a preventive

and a corrective. Preventive products are installed to minimise the risks probability

and corrective products are installed to know that an impact has happened or to

reduce (the consequences of) an impact.

The preventive products are part of a control system solution, the corrective products

are part of the emergency organisation. Both are very important. The investment in

the preventive section improves the pipeline system and control management. The

investment in the corrective section cost money and does not improve the pipeline

system.

09/04/2008; AKA; Page 6 van 10

Pipeline Technology Conference 2008

Examples of preventive products are: One-call supervision, local information

initiatives, inline inspections, coating inspections, route survey, temperature, water

and stress detection and threat detection.

Examples of corrective products are: emergency organisation, camera guarding,

impact detection, leak detection and landslide detection.

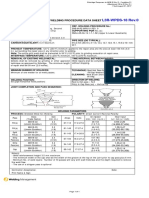

Risk-weighted integrity

We put the most of our investments and efforts in the preventive section based on

the risk assessment.

All the data we collect is stored in a database. The Pipeline Integrity application

retrieves the data, transfers it into weighted pipeline information and puts it for a

chosen selection pipeline section on the screen.

It looks like you see on the screen-print (figure 1)of the pipeline risk information, part

of our Pipeline Integrity Management system.

The screen is divided into three windows. At the top window the general pipeline

information is being presented. You can see a length of 100 meters with welds, wall

thickness and integrity results, internal, external en total. The integrity value is a

weighted summation of the pipeline control data and gives accurate information.

Green is sufficient, yellow says that it is time to analyse, red means that there is a

serious problem and action has to be taken immediately.

In the second window the internal en external metal loss is presented clockwise and

also the coating defects. The red and blue points are the results of the latest inline

inspection. The vertical lines present coating defects which have been detected

during a Close Interval Potential Survey.

The bottom window presents detailed information of the coating included values

about the coating condition, acidity of the soil, incidents with detailed information,

dimensions of the internal and external metal loss, Cathodic Protection remarks,

One-call-information, microbiological and material defects, research information,

maintenance remarks, local town-planning information, operations information and

route remarks.

The integrity lines at the top window are a result of the weighted risk summation. We

are well aware that the result is arbitrary, but in this way we combine the different

risks and make it available during the pipeline controlling.

The internal and external integrity lines are a maintenance marker and give a signal

of the location where we have to pay more attention. The external and total integrity

lines give information for the route surveyor about the local condition of the pipeline.

He can decide locally if certain activities are allowed.

All the data-items are related to a risk-item and to a risk factor. The risk factor is a

value of the influence of the risk-item to the integrity of the pipeline and the influence

on other risk-items.

Related to the example given before, if we detect a coating defect at the same

location as we detected the outside corrosion, the coating defect could have more

influence to the external corrosion. In the risk weighting the effect is bigger than only

09/04/2008; AKA; Page 7 van 10

Pipeline Technology Conference 2008

outside corrosion or only a coating defect. You will see the result in the external

integrity line as a notification to pay attention.

When we detect a dead tree at the same location the influence will be more and

visible in the external integrity line.

The moment the CP-protection falls, the external integrity line becomes yellow or

even red, depending on the depth of the corrosion and the value of the coating

defect.

The risk-weighted integrity is related to the values of the defects of the various

inspection and control systems on the pipeline. The integrity lines give information

based on history (inline and coating inspection) and real time data (CP, impact or

threat detection and route survey remarks).

During the control activities, the surveyors but also the specialist groups fill in their

findings and remarks by using a special form or download mass data.

During the route inspections the surveyors fill in their remarks and the system zooms

into the specific pipeline location.

The surveyor can check whether he filled in correctly and at the same time he sees

the local integrity and what has been remarked before.

It gives him all the relevant information there is. He may require more detailed

information, but he now knows it is available. He knows the risks and his further

actions will be risk based.

It costs energy and time to download all the information in the system. But that is only

once for the past and not for the future and only for relevant items. The benefit is that

it has to be done once and afterwards a document will never have to be searched

again without the risk that the information will be overlooked completely.

The pipeline integrity application makes the control task independent of the route

surveyor; they are able to act separately consistent to third parties and to the local

authorities.

Local authorities now a days ask more information for the external safety, which is

their responsibility. In the last years some major accidents within pipeline systems

happened world wide, causing many casualties. Pipelines that are near to or in cities

ask for more attention then the ones in the simple fields. In pipeline controlling we

have to provide the necessary information en reorganise our systems. Times are

changed, the authorities ask for information and expect it in a short time. With the

risk-weighted integrity management we can provide that information quickly.

By adding the data from pipeline control preventive products we are able to address

the locations where the most riskfull activities take place or where the pipeline is

exposed to earth movements or temperature influences. We are able to implement

the weighted data in the preventive program.

This results in more frequent route survey, special rules or precautions with the One-

call, local camera surveillance and local information sessions.

09/04/2008; AKA; Page 8 van 10

Pipeline Technology Conference 2008

Finishing

The benefits of the risk-weighted based integrity management is that the effort is

placed in the prevention of controlling pipeline installations and the survey activities

are independent of the route surveyor.

The weighted data of the involved control groups is presented as integrity information

for route survey and maintenance.

Pipeline Controlling becomes more and more extensive. Special tools and

technology are needed which is only cost-effective when controlling longer pipeline

lengths.

Cities ask for detailed information about the pipeline integrity of the many pipelines in

their proximity. And at the same time cities more and more develop activities that are

a risk for the pipeline integrity. Information conflicts and incidents are just around the

corner. We are able to quickly provide the necessary information with the risk-

weighted based integrity management.

09/04/2008; AKA; Page 9 van 10

Pipeline Technology Conference 2008

Figure 1

09/04/2008; AKA; Page 10 van 10

Vous aimerez peut-être aussi

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesD'EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesPas encore d'évaluation

- Technical Report (Submission)Document16 pagesTechnical Report (Submission)Mamirul channelPas encore d'évaluation

- Operative Procedures For Road Safety Inspections: January 2005Document13 pagesOperative Procedures For Road Safety Inspections: January 2005ramadan1978Pas encore d'évaluation

- Corrosion Solutions For Gas Transmission Pipelines: Solution NoteDocument2 pagesCorrosion Solutions For Gas Transmission Pipelines: Solution NotePencari CahayaPas encore d'évaluation

- Pipeline Leak Detection TechniquesDocument10 pagesPipeline Leak Detection TechniquesMohamed Alaa100% (1)

- Integrity Lessons LearntDocument27 pagesIntegrity Lessons LearntRene ParedeschaconPas encore d'évaluation

- Multi Drone Collaboration Gas Pipeline Monitoring QoS Safety and SecurityDocument13 pagesMulti Drone Collaboration Gas Pipeline Monitoring QoS Safety and SecurityHatem AlDoisPas encore d'évaluation

- Advance Safety SeminarDocument34 pagesAdvance Safety Seminarpp3986Pas encore d'évaluation

- Pipeline Leak Detection Study - OTH94Document58 pagesPipeline Leak Detection Study - OTH94ElcioDiasJrPas encore d'évaluation

- Project ProposalDocument9 pagesProject ProposalAMER, ASNAR M.Pas encore d'évaluation

- FNL 1Document7 pagesFNL 1Sabbir Ahmed 1721669Pas encore d'évaluation

- ProposalDocument20 pagesProposalmalcomPas encore d'évaluation

- Occasional Guidance Note Pipe Crossings and Pipe Bridges Risk AssessmentDocument16 pagesOccasional Guidance Note Pipe Crossings and Pipe Bridges Risk Assessmentpenyuka tembalangPas encore d'évaluation

- Valverde2012 WSN TypeDocument19 pagesValverde2012 WSN Typehhakim32Pas encore d'évaluation

- Automatic Drainage Control System Using ArduinoDocument18 pagesAutomatic Drainage Control System Using ArduinoJnaneshwari SPas encore d'évaluation

- Measurement and Control of SpillageDocument5 pagesMeasurement and Control of SpillageDelton ParcidesPas encore d'évaluation

- 2K24 - Mrep - Gas Leakage Detection SytsemDocument23 pages2K24 - Mrep - Gas Leakage Detection SytsemRaju'K HalgyePas encore d'évaluation

- Pgjonline-Com-MagaDocument13 pagesPgjonline-Com-MagaJagdish mogaPas encore d'évaluation

- Condition Monitoring of Pump (Vibration)Document5 pagesCondition Monitoring of Pump (Vibration)Zaki Rizqi FadhlurrahmanPas encore d'évaluation

- Army Institute of Technology, Pune Department of Electronics & TelecommunicationDocument14 pagesArmy Institute of Technology, Pune Department of Electronics & TelecommunicationAmbuj TripathiPas encore d'évaluation

- Practical Solution For Continuous Monitoring of Critical ParametersDocument1 pagePractical Solution For Continuous Monitoring of Critical ParametersRohanPas encore d'évaluation

- Ipc2012 90730Document8 pagesIpc2012 90730Marcelo Varejão CasarinPas encore d'évaluation

- Drone-Based Bridge InspectionDocument19 pagesDrone-Based Bridge InspectionTuba ArshadPas encore d'évaluation

- Extend Life Aging PipelinesDocument20 pagesExtend Life Aging PipelinesPar MadPas encore d'évaluation

- Air PrognosticatorDocument43 pagesAir Prognosticatorsce21cs079Pas encore d'évaluation

- Fundamentals of Bridge Maintenance and InspectionDocument74 pagesFundamentals of Bridge Maintenance and InspectionArkarPas encore d'évaluation

- Keywords:: Bhopal Gas Tragedy and Maxcred IIDocument2 pagesKeywords:: Bhopal Gas Tragedy and Maxcred IIAaditi guptaPas encore d'évaluation

- Health & Safety AssignmentDocument10 pagesHealth & Safety AssignmentLeo SerasinghePas encore d'évaluation

- Project & Environmental Review: Guidelines - Environmental Noise AssessmentDocument22 pagesProject & Environmental Review: Guidelines - Environmental Noise AssessmentlomaPas encore d'évaluation

- SAMWEL - Charles - FYP - Progressive ReportDocument13 pagesSAMWEL - Charles - FYP - Progressive Reportnas alawiPas encore d'évaluation

- A Low-Cost Continuous Turbidity MonitorDocument18 pagesA Low-Cost Continuous Turbidity MonitorpinoPas encore d'évaluation

- Safe Manhole First Report IOT NewDocument12 pagesSafe Manhole First Report IOT NewOshin DcunhaPas encore d'évaluation

- Incidents Triggered by Failures of Level Sensors: Chemical EngineeringDocument6 pagesIncidents Triggered by Failures of Level Sensors: Chemical EngineeringJuan Pablo Villazon RichterPas encore d'évaluation

- Real-Time Traffic Management SystemDocument8 pagesReal-Time Traffic Management SystemIJRASETPublicationsPas encore d'évaluation

- Paper 83 - Spe 117121-Pp Total Well Integrity - Column FormatDocument9 pagesPaper 83 - Spe 117121-Pp Total Well Integrity - Column FormatalizareiforoushPas encore d'évaluation

- Routine Construction Site InspectionDocument11 pagesRoutine Construction Site InspectionMylz MendozaPas encore d'évaluation

- Wireless Sensor Network-Based Air Quality Monitoring SystemDocument6 pagesWireless Sensor Network-Based Air Quality Monitoring SystemAkhil AroraPas encore d'évaluation

- BorealisDocument6 pagesBorealisbqdianzPas encore d'évaluation

- Modeling and Monitoring of Pipelines and NetworksDocument267 pagesModeling and Monitoring of Pipelines and Networksjoseamh69062247100% (2)

- Statistical Method in Civil EnginerngDocument80 pagesStatistical Method in Civil EnginerngBakhtiyar Q.KhawajaPas encore d'évaluation

- Pipeline Inspection SystemDocument12 pagesPipeline Inspection SystemYuvraj Singh RanaPas encore d'évaluation

- Road Safety Training DocumentsDocument25 pagesRoad Safety Training DocumentsAbdullah Al BakyPas encore d'évaluation

- Delivery of The Complete ProjectDocument16 pagesDelivery of The Complete ProjectMarcialPas encore d'évaluation

- Document Cover Page TemplateDocument5 pagesDocument Cover Page TemplateDan Jenniel CedeñoPas encore d'évaluation

- BFB 0030473Document4 pagesBFB 0030473tikaPas encore d'évaluation

- Integrity Management of Subsea PipelineDocument12 pagesIntegrity Management of Subsea PipelineAnkush VarshneyPas encore d'évaluation

- O-M of Water Supply and Sewerage ProjectDocument2 pagesO-M of Water Supply and Sewerage ProjectDilawarJuttPas encore d'évaluation

- IOT Based Manhole Detection and Monitoring SystemDocument8 pagesIOT Based Manhole Detection and Monitoring SystemIJRASETPublicationsPas encore d'évaluation

- Report 1 Version 1.gammon Final ReportDocument35 pagesReport 1 Version 1.gammon Final ReportArun KumarPas encore d'évaluation

- Operative Procedures For Road Safety InsDocument12 pagesOperative Procedures For Road Safety InsAkalu TemesgenPas encore d'évaluation

- Synopsis of Iot 3Document6 pagesSynopsis of Iot 3shwetasharma23Pas encore d'évaluation

- Case Histories of Life Cycle Well Integrity Management Using iWIT Software PDFDocument9 pagesCase Histories of Life Cycle Well Integrity Management Using iWIT Software PDFhamadahutpPas encore d'évaluation

- 1.1. Statistics in Engineering: 1.1.1. General IntroductionDocument6 pages1.1. Statistics in Engineering: 1.1.1. General IntroductionEnes LenkPas encore d'évaluation

- Tunnel SafetyDocument77 pagesTunnel SafetyTobin Don0% (1)

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentHanyuGuoPas encore d'évaluation

- Sensors 19 00369Document14 pagesSensors 19 00369soniaPas encore d'évaluation

- Pipeline Internal InspectionDocument31 pagesPipeline Internal InspectionHussain ElboshyPas encore d'évaluation

- Gas Level Detecting SystemDocument8 pagesGas Level Detecting SystemsandeepPas encore d'évaluation

- Advanced Wireless Multipurpose Mine Detection RobotDocument7 pagesAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsPas encore d'évaluation

- Suman PresentaniaDocument9 pagesSuman PresentaniaSuman LenkaPas encore d'évaluation

- SB05 02 Rev. 2 October 15 2018Document4 pagesSB05 02 Rev. 2 October 15 2018BoulHich BoulHichPas encore d'évaluation

- A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2Document1 pageA85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2BoulHich BoulHichPas encore d'évaluation

- A0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2Document32 pagesA0K5Y4 - Attachment No. 1 - Specification SP 51-32 Rev. 2BoulHich BoulHichPas encore d'évaluation

- A2D6V0 R2 O MSM 0510 InstallationOfHotTapConnectionsDocument14 pagesA2D6V0 R2 O MSM 0510 InstallationOfHotTapConnectionsShahrin KamaruzamanPas encore d'évaluation

- 3594 Mirage Checklist v2Document6 pages3594 Mirage Checklist v2BoulHich BoulHichPas encore d'évaluation

- Oil & Gas Solutions: Trelleborg Fluid Handling SolutionsDocument20 pagesOil & Gas Solutions: Trelleborg Fluid Handling SolutionssegunoyesPas encore d'évaluation

- PTC 2017 AchterkampDocument12 pagesPTC 2017 AchterkampBoulHich BoulHichPas encore d'évaluation

- What Is A Hot Tap, Why It Is Made and How To Make A Hot Tap in A Pipe LineDocument9 pagesWhat Is A Hot Tap, Why It Is Made and How To Make A Hot Tap in A Pipe LineBoulHich BoulHichPas encore d'évaluation

- Service Life Models and Design Procedure of Metal Fasteners Subjected To Corrosion in Timber StructuresDocument9 pagesService Life Models and Design Procedure of Metal Fasteners Subjected To Corrosion in Timber StructuresBoulHich BoulHichPas encore d'évaluation

- A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2Document1 pageA85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2BoulHich BoulHichPas encore d'évaluation

- Research Article: A Theoretical Model For Metal Corrosion DegradationDocument8 pagesResearch Article: A Theoretical Model For Metal Corrosion DegradationBoulHich BoulHichPas encore d'évaluation

- Pipe Material Specs (MCP)Document106 pagesPipe Material Specs (MCP)BoulHich BoulHichPas encore d'évaluation

- Pipeline External Corrosion Analysis Using A 3D Laser ScannerDocument9 pagesPipeline External Corrosion Analysis Using A 3D Laser ScannerBoulHich BoulHichPas encore d'évaluation

- Met 54 3 539 542 PDFDocument4 pagesMet 54 3 539 542 PDFBoulHich BoulHichPas encore d'évaluation

- Code of ConductDocument1 pageCode of Conductangeloflight179Pas encore d'évaluation

- Guidelines SmawDocument28 pagesGuidelines SmawD S Sagar TripuramalluPas encore d'évaluation

- Met 54 3 539 542 PDFDocument4 pagesMet 54 3 539 542 PDFBoulHich BoulHichPas encore d'évaluation

- Sampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingDocument12 pagesSampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingBoulHich BoulHichPas encore d'évaluation

- 2 JASA2008v123 p1706 StreamingDocument15 pages2 JASA2008v123 p1706 StreamingBoulHich BoulHichPas encore d'évaluation

- PTC 2017 AchterkampDocument12 pagesPTC 2017 AchterkampBoulHich BoulHichPas encore d'évaluation

- Pipeline External Corrosion Analysis Using A 3D Laser ScannerDocument9 pagesPipeline External Corrosion Analysis Using A 3D Laser ScannerBoulHich BoulHichPas encore d'évaluation

- PTC 2017 AchterkampDocument12 pagesPTC 2017 AchterkampBoulHich BoulHichPas encore d'évaluation

- NoiseMap - Real-Time Participatory Noise MapsDocument5 pagesNoiseMap - Real-Time Participatory Noise MapsBoulHich BoulHichPas encore d'évaluation

- A85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2Document1 pageA85780-20 Attachment 18 To Ir No. 5.1 - l3r-Wpds-18 Rev. 0 - A5t7s2BoulHich BoulHichPas encore d'évaluation

- Oil & Gas Solutions: Trelleborg Fluid Handling SolutionsDocument20 pagesOil & Gas Solutions: Trelleborg Fluid Handling SolutionssegunoyesPas encore d'évaluation

- Dot 22407 DS1Document95 pagesDot 22407 DS1BoulHich BoulHichPas encore d'évaluation

- Corrosion Protection of Flanges and Valves: E. Lyublinski, G. Begunova, E. Kopilova, M. Schultz and R. SinghDocument7 pagesCorrosion Protection of Flanges and Valves: E. Lyublinski, G. Begunova, E. Kopilova, M. Schultz and R. SinghBoulHich BoulHichPas encore d'évaluation

- 6869-24178-1-SM - Do Sau An Mon Theo KlinsmithDocument10 pages6869-24178-1-SM - Do Sau An Mon Theo KlinsmithLe Anh Thu KhuatPas encore d'évaluation

- Sampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingDocument12 pagesSampling Phased Array - A New Technique For Signal Processing and Ultrasonic ImagingBoulHich BoulHichPas encore d'évaluation

- ATM Top Tips: Supervisor Mode and Logical Cash OutsDocument2 pagesATM Top Tips: Supervisor Mode and Logical Cash OutsSrinivas Borra100% (1)

- DAHUA HTTP API FOR IPC Version 1.40Document106 pagesDAHUA HTTP API FOR IPC Version 1.40atsroot100% (1)

- Cyber CrimeDocument15 pagesCyber Crimerahulpandey29Pas encore d'évaluation

- SAP Security GRC CVDocument4 pagesSAP Security GRC CVKumarReddy100% (1)

- Risk Assessment GuidanceDocument1 pageRisk Assessment Guidancesuresh kumar100% (2)

- Major Report On Website Of: Submitted ByDocument46 pagesMajor Report On Website Of: Submitted BysaPas encore d'évaluation

- Book Review - Digital Fortress by Dan BrownDocument4 pagesBook Review - Digital Fortress by Dan BrownJPas encore d'évaluation

- Operation Manual Multi-Parameter Transmitter M400 PADocument140 pagesOperation Manual Multi-Parameter Transmitter M400 PAFilipe AlemãoPas encore d'évaluation

- ISO27k FMEA Spreadsheet 1v1Document16 pagesISO27k FMEA Spreadsheet 1v1Tahir100% (1)

- Assignement 4Document6 pagesAssignement 4sam khanPas encore d'évaluation

- Cisco Jasper Achieving End To End Security in IoT - WP - 0Document11 pagesCisco Jasper Achieving End To End Security in IoT - WP - 0jagaenatorPas encore d'évaluation

- Cloudera Administration PDFDocument476 pagesCloudera Administration PDFAnkesh Tiwari100% (1)

- MegaMatcher SDK Brochure 2019-10-03Document65 pagesMegaMatcher SDK Brochure 2019-10-03Eduardo Arrieta EspinozaPas encore d'évaluation

- 03 TPDocument2 pages03 TPPhilip John1 Gargar's100% (1)

- AIX SambaPware PDFDocument37 pagesAIX SambaPware PDFoliversusPas encore d'évaluation

- Student Information: Admission TicketDocument2 pagesStudent Information: Admission TicketAydan MammadovaPas encore d'évaluation

- IBM AIX Security ChecklistDocument22 pagesIBM AIX Security ChecklistBalamurugan ViswanathanPas encore d'évaluation

- Crosby Rigging EquipmentDocument20 pagesCrosby Rigging EquipmentJason MillerPas encore d'évaluation

- Project/programme Management Project/programme ManagementDocument32 pagesProject/programme Management Project/programme ManagementGabriel DracinschiPas encore d'évaluation

- Database Upgrade GuideDocument463 pagesDatabase Upgrade GuideAntonioPas encore d'évaluation

- EU Digital COVID Certificate Certificat Digital European COVIDDocument2 pagesEU Digital COVID Certificate Certificat Digital European COVIDRamona LungescuPas encore d'évaluation

- EmbassiesDocument13 pagesEmbassiesejusdem generisPas encore d'évaluation

- KetabDocument9 pagesKetablittlefarbod100% (1)

- Delete Bank Key - SCNDocument3 pagesDelete Bank Key - SCNrafael.mcpPas encore d'évaluation

- Attacks To SAP Web Applications: Your Crown Jewels OnlineDocument63 pagesAttacks To SAP Web Applications: Your Crown Jewels OnlineCiber KataPas encore d'évaluation

- ECMP Load Balancing With MasqueradeDocument6 pagesECMP Load Balancing With Masqueradenadit88Pas encore d'évaluation

- Name: - Jasmine Joyce D. Mamawal Section: BSGE 2 Date: - July 29, 2021 Year/Semester: - 2 Year/ OffsemDocument4 pagesName: - Jasmine Joyce D. Mamawal Section: BSGE 2 Date: - July 29, 2021 Year/Semester: - 2 Year/ OffsemKaye EspinosaPas encore d'évaluation

- Roger Thomas Clark, Amended ComplaintDocument20 pagesRoger Thomas Clark, Amended ComplaintJoseph CoxPas encore d'évaluation

- Dynamic Security Testing of CAN-bus SystemsDocument4 pagesDynamic Security Testing of CAN-bus SystemsNon SensePas encore d'évaluation

- Prepking MK0-201 Exam QuestionsDocument11 pagesPrepking MK0-201 Exam QuestionsCameron555Pas encore d'évaluation