Académique Documents

Professionnel Documents

Culture Documents

BFW Steam Turbine

Transféré par

Ilman MughniCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BFW Steam Turbine

Transféré par

Ilman MughniDroits d'auteur :

Formats disponibles

BOILER FEED WATER STEAM TURBINE IN BADAK LNG UTILITIES

By : Muhammad Ilman Mughni (6517010083)

A. Preliminary

BFW pumps are one of the most critical equipment manufactured by

Sulzer Bingham. BFW pumps are pumps that serve to pump feed water

into the boiler. Which is where feed water that has been converted into

steam will be distributed mostly to drive steam turbines. BFW pumps

themselves have a capacity of 450 m3/h in all pumps in either utility 1 or 2.

The total amount of BFW pumps in utilities 1 and 2 are 9 pumps. In

utility 1, the pump is driven by using a steam turbine of 8 pieces (31GT-

1/2/3/4/55/56/57/59) while 1 more pump is driven by a 4.16 kV motor

(31GT-58). In utility 2, the pump is driven by using a steam turbine of 5

pieces (31GT-112/142/143/144/145) while 4 more pumps are driven by

4.16 kV motors (31GT-111/113/140/141).

B. Boiler Feed Water Steam Turbine Specification

Utilities 1 Utilities 2

Equipment Tag Number 31GT-1/2/3/4/55/56/57/59 31GT-112/142/143/144/145

Brand Terry Elliott

Model GA/NB DYRPG

Quantity 8 5

Speed 4250 rpm 4200 rpm

Power 1734 hp 1974 hp

Inlet Temperature 600oF 600oF

Outlet Temperature 426oF -

Inlet Pressure 250 psig 250 psig

Outlet Pressure 60 psig 60 psig

Steam Rate 35,97 lb/hp.hr -

C. Plant System Description

The fresh water that use in daily production system comes from eight

fresh water well that scatter in the Badak LNG complex. Water is pumped

from the well to be filtered first. Then, fresh water will be streamed to the

aerator. The function of aerator is to precipitate iron particles that dissolve

in the water by contacting water with air.

To increase contacting surface, raschig ring is added. The air is

blown using the blower. Inside the aerator, water is rotated so Fe2+ ion

will oxydize with air. The deposit from previous process will be filtered

using Iron Removal Filter and disposed through blowdown process.

The water which undergoes aeration process still has low pH value.

To increase pH value, Natrium Hydroxyde (NaOH) is added. The finish

product then stored in filter tank.

Before the water is tranferred to BFW pumps, it is pumped first to

the ion exchanger. From the ion exchanger, the water then pumped into the

deaerator to relieve gas contaminant in the water using low pressure steam.

After deaeration process, finally the water is ready to be use and pumped

by BFW pumps into the boilers

Vous aimerez peut-être aussi

- One Subic Power PlantDocument12 pagesOne Subic Power PlantKeiPas encore d'évaluation

- O & M Manual For BoilerDocument146 pagesO & M Manual For BoilerAshwani Dogra100% (14)

- NSTM 505 Piping 10.7Document276 pagesNSTM 505 Piping 10.7asmaPas encore d'évaluation

- MitsubishiDocument10 pagesMitsubishiPrabhat Kisku100% (1)

- Operating Mannua2Document96 pagesOperating Mannua2Ajay Kumar0% (1)

- Power Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011Document332 pagesPower Boilers-A Guide To Section I of The Asme Bpvc-2nd Ed.-2011hainguyenbkvhv100% (6)

- Power Engineering Fourth Class Q and ADocument152 pagesPower Engineering Fourth Class Q and AMatt Wilson83% (6)

- NTPCDocument32 pagesNTPC12 EC ATUL KUMAR SRIVASTAVAPas encore d'évaluation

- 1204-Barge 2 Tech SpecsDocument13 pages1204-Barge 2 Tech SpecsmardiradPas encore d'évaluation

- Auxiliary BoilerDocument56 pagesAuxiliary BoilerNirdosh AnanthPas encore d'évaluation

- 500MW-Boiler - Salient FeatureDocument7 pages500MW-Boiler - Salient FeatureAhemadPas encore d'évaluation

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- Summary Pocket BookDocument13 pagesSummary Pocket Booksas13Pas encore d'évaluation

- Presentation On CDCP Boilers - NEWDocument145 pagesPresentation On CDCP Boilers - NEWmohanivar77100% (4)

- Study of Boiler Efficiency in Visakhapatnam Steel PlantDocument39 pagesStudy of Boiler Efficiency in Visakhapatnam Steel PlantPhanindra Guttula50% (2)

- Booster Korean Steam Generator ManualDocument26 pagesBooster Korean Steam Generator ManualUmar MajeedPas encore d'évaluation

- Suplementary HVAC ProblemsDocument7 pagesSuplementary HVAC ProblemsNeko-neko CasugaPas encore d'évaluation

- Hiranmaye Energy LimitedDocument37 pagesHiranmaye Energy LimitedBïműřţã Đåś100% (1)

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument11 pagesBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajPas encore d'évaluation

- Goal Report of NFL, BathindaDocument12 pagesGoal Report of NFL, BathindaAnkitaPas encore d'évaluation

- Presentation of Training in NTPC, FaridabadDocument24 pagesPresentation of Training in NTPC, Faridabadgauravsaurav100% (1)

- The Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamDocument5 pagesThe Function of Steam Boiler Is To Transfer Heat Produced by Burning of Fuel, To The Water and Thus To Produce Steam. Requirement of SteamSaurabh AryaPas encore d'évaluation

- PTPS Project 1Document69 pagesPTPS Project 1Manpreet Singh MudharPas encore d'évaluation

- GTG 1733PW LM6000 220MwBarge 50HzDocument11 pagesGTG 1733PW LM6000 220MwBarge 50Hzwidyo saptoto100% (1)

- Cust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantDocument14 pagesCust (Department of Mechanical Engineering) Project Report Designing Steam Power PlantShanzeh DaudPas encore d'évaluation

- Ajeet Singh Iffco PDFDocument38 pagesAjeet Singh Iffco PDFAjeet SinghPas encore d'évaluation

- Kota Super Thermal Power StationDocument21 pagesKota Super Thermal Power StationsatyendrajainPas encore d'évaluation

- 2019-250 MW Barge Technical DiaryDocument33 pages2019-250 MW Barge Technical Diarydasnulmadi61Pas encore d'évaluation

- Boiler TrainingDocument21 pagesBoiler TrainingYadav GaneshPas encore d'évaluation

- 2X70 Power Plant Technical SpecificationDocument53 pages2X70 Power Plant Technical SpecificationChanna BasavaPas encore d'évaluation

- Sinotec RB Poso-Jasmin EquipmentDocument18 pagesSinotec RB Poso-Jasmin EquipmentWaleedPas encore d'évaluation

- Thermal Power PlantDocument9 pagesThermal Power Plantmuneeb rafiqPas encore d'évaluation

- Exergy ArticleDocument17 pagesExergy ArticleMuhammad Haris HamayunPas encore d'évaluation

- Summer Training Report On NTPC Tanda Ambedkar NagarDocument9 pagesSummer Training Report On NTPC Tanda Ambedkar NagarNaman ShahPas encore d'évaluation

- Tour ReportDocument15 pagesTour ReportSindhu V MPas encore d'évaluation

- Bab 3Document18 pagesBab 3trisnadewiPas encore d'évaluation

- Chandrapur CTPS 15 Days Training ReportDocument21 pagesChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- TP1028ENDocument21 pagesTP1028ENramkeshmit_413125668Pas encore d'évaluation

- Boiler & Cogeneration PlantDocument28 pagesBoiler & Cogeneration Planttonful143Pas encore d'évaluation

- Salient Feature of GLWSSDocument8 pagesSalient Feature of GLWSSLalramhluna HmarPas encore d'évaluation

- Water Circulation Pump Offer For Mondol Cotton Club LTD 17.12.2020Document2 pagesWater Circulation Pump Offer For Mondol Cotton Club LTD 17.12.2020fakir mohammadPas encore d'évaluation

- NTPC Badarpur PPT 2012Document33 pagesNTPC Badarpur PPT 2012hemantparjapatiPas encore d'évaluation

- Report On NTPC Industrial Training at Barh (Patna)Document24 pagesReport On NTPC Industrial Training at Barh (Patna)Gautam KumarPas encore d'évaluation

- Cogen17 CDocument2 pagesCogen17 CppfahdPas encore d'évaluation

- Kota Thermal Power Plant Report in Standered FormDocument45 pagesKota Thermal Power Plant Report in Standered FormAbhishek Meena100% (2)

- List Equipment Pltu Pangkalan Susu 2x200mwDocument7 pagesList Equipment Pltu Pangkalan Susu 2x200mwDanny SurbaktiPas encore d'évaluation

- Training Report (Kbunl) 2019 Shanu PrakashDocument33 pagesTraining Report (Kbunl) 2019 Shanu PrakashShanu PrakashPas encore d'évaluation

- Gandhinagar Thermal Power PlantDocument45 pagesGandhinagar Thermal Power PlantChauhan Sudhir75% (4)

- Sheet (3) Regenerative Rankine Cycle A. Review QuestionsDocument6 pagesSheet (3) Regenerative Rankine Cycle A. Review QuestionsHamadaMohassabPas encore d'évaluation

- ICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselDocument8 pagesICES CM 2007/M:07 Design Concept For Low Energy Fishing VesselSaatnya TersenyumPas encore d'évaluation

- Iffco Aonla PresentationDocument16 pagesIffco Aonla PresentationDivya Prakash SrivastavaPas encore d'évaluation

- Byproduct Operations and ProcessDocument8 pagesByproduct Operations and ProcessAbhaySnghPas encore d'évaluation

- Tech SpecDocument4 pagesTech SpecAbdul Aziz FahadPas encore d'évaluation

- Chapter 7 - Geothermal PowerDocument2 pagesChapter 7 - Geothermal PowerHectorCabz100% (1)

- Twisted Tube TechnologyDocument5 pagesTwisted Tube TechnologylpczyfansPas encore d'évaluation

- Brief Description of Tanda Thermal Project: 1.1 Geographical LocationDocument22 pagesBrief Description of Tanda Thermal Project: 1.1 Geographical Locationcoolvipin1988Pas encore d'évaluation

- Project Report On Thermal PlantDocument58 pagesProject Report On Thermal PlantTech GuruPas encore d'évaluation

- GTG 1670RC FmPG6541CC 60HzDocument11 pagesGTG 1670RC FmPG6541CC 60HzVerananda AriyantoPas encore d'évaluation

- OM0401 Overview of Turbine Version GDocument41 pagesOM0401 Overview of Turbine Version Gمحمد خالدPas encore d'évaluation

- Act.3-9 - Florida, Mark ChristianDocument26 pagesAct.3-9 - Florida, Mark ChristianJOVELYN TACADINOPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- ESET 212 LECTURE - Week 7Document41 pagesESET 212 LECTURE - Week 7eglits4170Pas encore d'évaluation

- Valve Interview Questions Part-1Document6 pagesValve Interview Questions Part-1KalaiYarasan50% (2)

- Oisd STD 131Document25 pagesOisd STD 131Nanu PatelPas encore d'évaluation

- Surface Blowdown System: General FeaturesDocument5 pagesSurface Blowdown System: General FeaturesCristopher LobosPas encore d'évaluation

- Food Process Engineering Lab 3. BOILER OPERATIONDocument22 pagesFood Process Engineering Lab 3. BOILER OPERATIONMuhyiddin Noor AfandiPas encore d'évaluation

- Solutions For Sustainable Water Savings: A Guide To Water EfficiencyDocument32 pagesSolutions For Sustainable Water Savings: A Guide To Water EfficiencysrkPas encore d'évaluation

- Water Level 3 Automatic Level Control Systems - Spirax SarcoDocument14 pagesWater Level 3 Automatic Level Control Systems - Spirax SarcoCayixPas encore d'évaluation

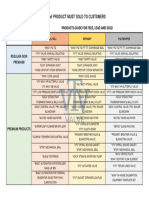

- List of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldDocument1 pageList of Product Must Sold To Customers: Products Guide For Feed, Lead and SoldFendy ShirahPas encore d'évaluation

- HACCP TemplateDocument28 pagesHACCP Templateraphael damanikPas encore d'évaluation

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonPas encore d'évaluation

- Efficient Uses of Steam EnergyDocument67 pagesEfficient Uses of Steam EnergytojinboPas encore d'évaluation

- Boiler Steam and Water System ProcedureDocument75 pagesBoiler Steam and Water System Procedurepradeep.selvarajanPas encore d'évaluation

- Boiler and Turbine For BOE ExamDocument71 pagesBoiler and Turbine For BOE Examkeerthi dayarathnaPas encore d'évaluation

- XIX Paper 50Document16 pagesXIX Paper 50JimmyJarufePas encore d'évaluation

- Lattner Boiler Company - Instruction Manual For He BoilersDocument41 pagesLattner Boiler Company - Instruction Manual For He Boilersdelta-scope100% (1)

- Chapter VII Boiler Operation (Compatibility Mode)Document13 pagesChapter VII Boiler Operation (Compatibility Mode)Kiên GiangPas encore d'évaluation

- Water Treatment For BoilersDocument48 pagesWater Treatment For BoilerssamettekPas encore d'évaluation

- Boiler KPI Webinar SlidesDocument45 pagesBoiler KPI Webinar SlidesEscobar ValderramaPas encore d'évaluation

- Control de Nivel Mcdonnell Miller 263Document5 pagesControl de Nivel Mcdonnell Miller 263Genrry EchaccayaPas encore d'évaluation

- 633LS ProdspecDocument14 pages633LS ProdspecAdrian AbellaPas encore d'évaluation

- MP 1200Document63 pagesMP 1200JUAN MARCO ALEXANDERPas encore d'évaluation

- Boiler Blow Down: Workshop On Efficient Operation & Maintenance of BoilersDocument3 pagesBoiler Blow Down: Workshop On Efficient Operation & Maintenance of Boilerskcp1986Pas encore d'évaluation

- 12.boiler System ComponentsDocument4 pages12.boiler System Componentskcp1986Pas encore d'évaluation

- Valmet Approach To Boiler Chemical Cleaning ConsultingDocument20 pagesValmet Approach To Boiler Chemical Cleaning ConsultingHimanshu ChaturvediPas encore d'évaluation

- Section 3-1 - Installation - Steam BoilersDocument65 pagesSection 3-1 - Installation - Steam BoilersWissam Jarmak100% (1)

- Boiler Flash UpDocument2 pagesBoiler Flash UpMuhdThaqifPas encore d'évaluation