Académique Documents

Professionnel Documents

Culture Documents

Operation Manual: Caution: Warning: Danger

Transféré par

isaias martinezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Operation Manual: Caution: Warning: Danger

Transféré par

isaias martinezDroits d'auteur :

Formats disponibles

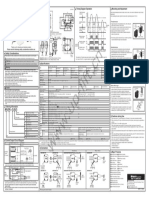

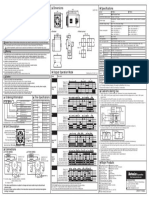

Fieldbus system Names and Functions of Product

(5)Fix the manifold by tightening the DIN rail fixing

screws of the EX600-ZMA2. (M4x20)

5

LED Display

Tightening torque: 0.7 to 0.8 Nm.

The tightening torque at the valve side depends on

Operation Manual Names of individual parts The status display LED displays the power supply and communication status.

the valve type.

1 2 Refer to the operation manual of the corresponding Display Content

3 4

5 valve manifold. ST(M) Displays the diagnosis status of the unit.

End plate bracket

EX600-SDN A (EX600-ZMA2) PWR Displays the status of the power supply voltage for control and input.

6 12 PWR(V) Displays the status of the power supply voltage for outputs.

Thank you for purchasing an SMC EX600 Series Fieldbus system. Wiring MS Displays the module status.

Please read this manual carefully before operating the product and make sure you •Connect the M12 connector cable. M12 connector is applicable for SPEEDCON NS Displays the network status.

understand its capabilities and limitations. 11 connector. •SI unit common status

Please keep this manual handy for future reference. 10 7 SPEEDCON connector wiring method is explained below.

8 LED display Content

(1)Align the mark B on the metal bracket of the cable side connector (plug/socket) with

9

the mark A.

To obtain more detailed information about operating this product, No. Description Function Off

The power supply for control and input is Off.

please refer to the SMC website (URL http://www.smcworld.com) or 1 Status display LED Displays the status of the unit.

(2)Align the mark C on the unit and insert the connector into the unit vertically.

contact SMC directly. If they are not aligned, the connector cannot be joined properly. The unit is in normal operation.

2 Display cover Open for the setting of switch. Green LEDs are On

3 Display cover tightening screw Loosen to open the display cover. (3)When the mark B of the connector has been turned 180 degrees (1/2 turn), wiring is

A component failure inside the SI unit.

completed. Confirm that the connection is not loose. If turned too far, it will become

Safety Instructions 4

5

Connector (BUS OUT)

Marker groove

Connects the cable for fieldbus outputs.

Groove to mount a marker.

hard to remove the connector.

Red ST(M) LED is On

The power supply voltage for control and input is abnormal.

6 Connector (PCI) Connects the cable of the handheld terminal.

(1) (2) (3) Red PWR LED is On

These safety instructions are intended to prevent hazardous situations and/or

7 Valve plate mounting screw hole Fixes the valve plate.

equipment damage. The power supply voltage for output is abnormal.

8 Valve plate mounting groove Groove to insert the valve plate into. Red PWR(V) LED is On

These instructions indicate the level of potential hazard with the labels of

9 Joint bracket Bracket for joining to adjacent units. Mark A at cable end

"Caution", "Warning" or "Danger". They are all important notes for safety and must A unit other than the SI unit has been diagnosed and

Mark B at cable end detected.

be followed in addition to International standards (ISO/IEC), Japan Industrial 10 Unit connector (plug) Transmits signals and power supplies to adjacent units.

Green ST(M) LED is flashing

Standards (JIS) and other safety regulations. 11 Connector (BUS IN) Connects the cable for fieldbus inputs. Either of the following conditions:

12 Seal cap (2 pcs.) Mounted on to unused connectors. (BUS OUT and PCI) •The valve On/Off counter has exceeded the set value.

Mark C on the unit Red ST(M) LED is flashing •The valve is short circuited or disconnected.

CAUTION indicates a hazard with a low level of risk which, if

Caution: not avoided, could result in minor or moderate injury.

Assembly Red/green ST(M) LED is flashing alternately

Connection error between units occurred.

WARNING indicates a hazard with a medium level of risk

Warning: which, if not avoided, could result in death or serious injury.

Composing the unit as a manifold

•Connector pin assignment

Configuration Pin

Signal name

•DeviceNetTM status

LED display Content

BUS IN BUS OUT number

DANGER indicates a hazard with a high level of risk which, if (1)Connect the unit to the end plate.

Danger: not avoided, will result in death or serious injury. The Digital unit, Analog unit can be connected in any order.

Tighten the bracket of the joint using tightening torque 2 1

1 2

1

2

DRAIN

V+

Off

The power supply for control and input is Off.

1.5 to 1.6 Nm. 3 V-

•Double checking the node address.

Operator 5 5

4 CAN_H

Green MS LED is On •Communication error.

(2)Add more units. 4 3

This operation manual is intended for those who have knowledge of machinery Up to 10 units (including the SI unit) can be 3 4 5 CAN_L Communication is normal.

connected to one manifold. 2 Green MS and NS LEDs are both On

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenace of such equipment. Only those persons are allowed •Mounting the marker

(3)Connecting the SI unit. Signal name of the input or output devices and unit Connection is not established.

to perform assembly, operation and maintenance. After connecting the necessary units, connect the SI unit. 1 Green MS LED is On and green NS LED is flashing

address can be written to the marker, and it can be

Read and understand this operation manual carefully before assembling, Connecting method is the same as above (1), (2). installed to each unit. The element in SI unit is broken.

operating or providing maintenance to the product. Mount the marker (EX600-ZT1) into the marker groove Red MS LED is On

(4)Mounting the valve plate. 4 as required.

Mount the valve plate (EX600-ZMV ) to the valve Fatal communication error.

manifold using the valve set screws. (M3x8) Green MS LED is On and red NS LED is On

Valve plate

Apply 0.6 to 0.7 Nm tightening torque to the screws. (EX600-ZMV )

Safety Instructions (5)Connect the SI unit and the valve manifold.

Insert the valve plate to the valve plate Setting and Adjustment Minor communication error.

Green MS LED is On and red NS LED is flashing

Warning set groove on the side of SI unit.

Then, tighten it with the valve plate x10 x1 Flashes when performing self diagnosis test when the

Do not disassemble, modify (including changing the printed circuit board) or repair. set screws (M4x6) to fix the plate. ON 9

0 1

9

0 1

9

0 1

An injury or failure can result. Red/green MS LED is flashing alternately. power supply starts.

Tightening torque for set screws 0.7

2 3

2 3

2 3

7 8

7 8

7 8

Then, Red/green NS LED is flashing alternately

Do not operate the product outside of the specifications. to 0.8 Nm. 1 2 3 4 5 6

4

5 6

4

5 6

4

5 Refer to the SMC website (URL http://www.smcworld.com) to obtain more detailed

Do not use for flammable or harmful fluids. Setting1 Address Data Rate

Fire, malfunction, or damage to the product can result.

ON

information about LED display.

Verify the specifications before use.

Mounting and Installation

Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

1

Setting2

2 3 4 5 6 7 8

Troubleshooting

This product is not designed to be explosion proof.

Installation •Address setting switch •Data Rate setting switch

Refer to the LED Display. Refer to the SMC website (URL http://www.smcworld.com)

If using the product in an interlocking circuit: •Direct mounting Address X10 Address X1 Node Address Data Rate Communication speed

•Provide a double interlocking system, for example a mechanical system. to obtain more detailed information about troubleshooting.

•Check the product regularly for proper operation. (1)When joining six or more units, fix the middle 0 0 0 (Default setting) 0 125 kbps (Default setting)

Otherwise malfunction can result, causing an accident. part of the complete EX600 unit with an 0 1 1 1 250 kbps

The following instructions must be followed during maintenance:

intermediate reinforcing brace (EX600-ZMB1)

before mounting using 2-M4x5 screws.

: : : 2 500 kbps Specification

•Turn off the power supply. 6 3 63 3

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing Tightening torque: 0.7 to 0.8 Nm.

Power Control and input 24 VDC Class2, 2 A

maintenance. 6 4 : PGM

(2)Fix and tighten the end plates at one end of the supply Output 24 VDC Class2, 2 A

Otherwise an injury can result. : : PGM 9

unit. (M4) Connected load Solenoid valve with lamp and circuit of protection of surge voltage of 24 VDC 1.5 W (SMC)

9 9

Caution Tightening torque: 0.7 to 0.8 Nm.

Fix the end plate at the valve side while referring Intermediate reinforcing brace •V_SEL switch: The number of outputs (size) occupied by the SI unit is selected.

Operating temperature range -10 to 50 oC (Max. surrounding air temperature rating: 50 oC)

When handling the unit or assembling/replacing units: (EX600-ZMB1) Storage temperature range -20 to 60 oC

to the operation manual of the corresponding Settings1

•Do not touch the sharp metal parts of the connector or plug for connecting units. Content SI unit output data size Pollution degree For use in Pollution Degree 2 Environment (UL508)

•Take care not to hit your hand when disassembling the unit.

valve manifold. 1 2

The connecting portions of the unit are firmly joined with seals. 10 to 57 Hz: constant amplitude 0.75 mm p-p

OFF OFF Number of occupied valve 32 outputs 4 byte (Default setting) Vibration resistance 57 to 150 Hz: constant acceleration 49 m/s2

•When joining units, take care not to get fingers caught between units. •DIN rail mounting

OFF ON Number of occupied valve 24 outputs 3 byte for 2 hours each in direction X, Y and Z respectively (De-energized)

An injury can result. (Available for series other than SY series. Refer

to the catalog for SY series.) ON OFF Number of occupied valve 16 outputs 2 byte Impact resistance 147 m/s2 3 times each in directions of X, Y and Z respectively (De-energized)

After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly. (1)When joining six or more units, fix the middle ON ON Number of occupied valve 8 outputs 1 byte Refer to the product catalog or SMC website (URL http://www.smcworld.com) to

Safety cannot be assured in the case of unexpected malfunction. part of the complete EX600 unit with an •Switch for diagnosis: Allocates the diagnostic data to the input data.

intermediate reinforcing brace (EX600-ZMB2)

obtain more detailed information about product specifications.

Provide grounding to assure the safety and noise resistance of the Fieldbus system. Intermediate reinforcing brace Settings2 Diagnostic size set for

Individual grounding should be provided close to the product with a short cable.

before mounting, using 2-M4x6 screws. (EX600-ZMB2) Mode Content

Tightening torque: 0.7 to 0.8 Nm. 1

OFF OFF

2

0 Input data only (Default setting)

the input

0 byte

Commissioning

NOTE 1 OFF ON 1 Input data + System diagnosis 4 byte

•Parameter Setting •Hardware Configuration (EDS file) •I/O Map

The direct current power supply to combine should be UL1310 Class2 power (2)Mount the end plate bracket (EX600-ZMA2) to the end ON OFF 2 Input data + System diagnosis + Unit diagnosis (Up to 10 units) 6 byte •Diagnostic •DeviceNetTM Object

plate at the opposite end to the valves, using 2-M4x14 •HOLD/CLEAR switch: Sets the output status when the Fieldbus has a communication error or is in idling state.

supply when conformity to UL is necessary. screws. Refer to the SMC website (URL http://www.smcworld.com) to obtain more detailed

Tightening torque: 0.7 to 0.8 Nm.

Settings2

Content

information about these setting above.

3

Maintenance End plate bracket

(EX600-ZMA2)

OFF Output is Off. (Default setting)

Outline with Dimensions

ON Holds the output.

•Maintenance should be performed according to the Safety Instructions. 2

•HW/SW switch: Select the selection method of the Fieldbus address and Data Rate. Refer to the product catalog or SMC website (URL http://www.smcworld.com) to

•Perform regular maintenance and inspections.

There is a risk of unexpected malfunction. (3)Hook the DIN rail mounting groove to the DIN rail. 3 Settings2

obtain more detailed information about outline dimensions.

Content

•Do not use solvents such as benzene, thinner etc. to clean each unit. 4

They could damage the surface of the body and erase the markings on the body. DIN rail mounting groove

OFF Address and Data Rate are set by the SI unit switch. (Hardware) (Default setting) URL http://www.smcworld.com

Use a soft cloth to remove stains.

For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed, then wipe up ON Address and Data Rate are set via the PLC. (Software) * Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

the stains again with a dry cloth. DIN rail *: In order to set software via PLC, set the address or Data Rate switch to PGM. Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

Refer to the SMC website (URL http://www.smcworld.com) to obtain more detailed (4)Press the manifold using its side hooked to the Refer to the SMC website (URL http://www.smcworld.com) to obtain more detailed Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

DeviceNetTM is a trademark of ODVA.

information about maintenance. DIN rail as a fulcrum until the manifold is locked. 4 information about setting and adjustment. © 2009 SMC Corporation All Rights Reserved

Vous aimerez peut-être aussi

- VentilationDocument92 pagesVentilationRobert Nixon100% (1)

- Build Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDocument21 pagesBuild Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDanCurtis100% (1)

- Industry 4.0 Extended Presentation en EKZ IPT2016 KeynoteDocument72 pagesIndustry 4.0 Extended Presentation en EKZ IPT2016 Keynoteisaias martinezPas encore d'évaluation

- Siemens STLDocument272 pagesSiemens STLhaist10% (1)

- DIAGRAM RAYMOND 4150-4250 - 30000-Up - SC - 1124958CDocument10 pagesDIAGRAM RAYMOND 4150-4250 - 30000-Up - SC - 1124958CRicardo Javier Lopez GarciaPas encore d'évaluation

- Hyundai R140W-7 Hydraulic SystemDocument33 pagesHyundai R140W-7 Hydraulic SystemHai VanPas encore d'évaluation

- Earthing of GIS Type ELK - GTIDocument20 pagesEarthing of GIS Type ELK - GTIJairo MoralesPas encore d'évaluation

- Healthcare Financing in IndiADocument86 pagesHealthcare Financing in IndiAGeet Sheil67% (3)

- WinTotal v6 User GuideDocument283 pagesWinTotal v6 User Guideisaias martinez100% (1)

- Heal Yourself in Ten Minutes AJDocument9 pagesHeal Yourself in Ten Minutes AJJason Mangrum100% (1)

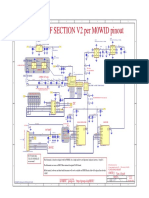

- Tinysa RF Section V2 Per M0Wid Pinout: Sma SKT EdgeDocument1 pageTinysa RF Section V2 Per M0Wid Pinout: Sma SKT EdgePisu Miau Pisu Miau60% (5)

- Holy Cross Academy Quarterly Cookery ExamDocument4 pagesHoly Cross Academy Quarterly Cookery ExamAlle Eiram Padillo95% (21)

- Honeywell - MasterLogic 50 - MLF-DX04C - DatasheetDocument2 pagesHoneywell - MasterLogic 50 - MLF-DX04C - DatasheetSoofi AthamPas encore d'évaluation

- Autonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentDocument1 pageAutonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentRebecca DangPas encore d'évaluation

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinPas encore d'évaluation

- Pneumatic solenoid and air valves dimensionsDocument8 pagesPneumatic solenoid and air valves dimensionsVivin Welroy RodriguesPas encore d'évaluation

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiPas encore d'évaluation

- PZ DSP28335 L开发板原理图Document1 pagePZ DSP28335 L开发板原理图Shwe Thin AungPas encore d'évaluation

- Power BD LS-4851PDocument1 pagePower BD LS-4851PRoberto MouraPas encore d'évaluation

- 2078-2 Delta VFD037EL43A 400v-400v 3.7kW Quick Start ManualDocument1 page2078-2 Delta VFD037EL43A 400v-400v 3.7kW Quick Start ManualOmar Shady100% (1)

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemĐạt VươngPas encore d'évaluation

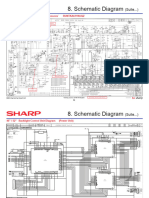

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićPas encore d'évaluation

- Pioneer Xdj-1000mk2 Rrv4661 SMDocument38 pagesPioneer Xdj-1000mk2 Rrv4661 SMThieb MeyaPas encore d'évaluation

- Cepex Electric Butterfly Valve ExtremeDocument2 pagesCepex Electric Butterfly Valve ExtremegastonPas encore d'évaluation

- BC 5300&5380 (1) FluidicDocument8 pagesBC 5300&5380 (1) FluidicCHARLIE BRICEPas encore d'évaluation

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaPas encore d'évaluation

- SOLENOID VALVE SPECIFICATIONSDocument2 pagesSOLENOID VALVE SPECIFICATIONSsahraoui brahimPas encore d'évaluation

- Momentum Two SpeedDocument9 pagesMomentum Two Speedahsan ullahPas encore d'évaluation

- AGN 035 - Protect alternators from overloads and faultsDocument10 pagesAGN 035 - Protect alternators from overloads and faultsariwibowoPas encore d'évaluation

- 42H10 Service ManualDocument46 pages42H10 Service ManualalgenygPas encore d'évaluation

- Arbonia Column RadiatorsDocument100 pagesArbonia Column RadiatorsMikhailPas encore d'évaluation

- ERA Mono PERC 325W 60cDocument1 pageERA Mono PERC 325W 60cAngel M Granados EscalonaPas encore d'évaluation

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerPas encore d'évaluation

- Valbia Actuator SetupDocument1 pageValbia Actuator SetupkikinPas encore d'évaluation

- AT11DNDocument1 pageAT11DNJohn GarnetPas encore d'évaluation

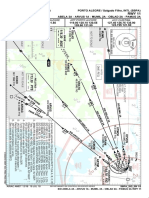

- RWY 11 (SI D) : ACC Curi TI BA TWR Porto Alegre APP Porto AlegreDocument2 pagesRWY 11 (SI D) : ACC Curi TI BA TWR Porto Alegre APP Porto AlegreArthur KretschmarPas encore d'évaluation

- LCD InfDocument1 pageLCD Infkottee1977100% (2)

- Wcenim2064 en AqDocument4 pagesWcenim2064 en AqalePas encore d'évaluation

- Remote Reading1Document2 pagesRemote Reading1joseph chungPas encore d'évaluation

- LAYOUT of OT Shelter PDFDocument1 pageLAYOUT of OT Shelter PDFBalaji YPas encore d'évaluation

- P&ID CWP Rev 2Document1 pageP&ID CWP Rev 2Ajeng OctaviaPas encore d'évaluation

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanPas encore d'évaluation

- L08284eng GSDocument2 pagesL08284eng GSLuciernagaPas encore d'évaluation

- Control Panel For 24 V Gearmotors: Installation ManualDocument20 pagesControl Panel For 24 V Gearmotors: Installation ManualBiiRon SuláPas encore d'évaluation

- KT-302H Series: Instruction ManualDocument1 pageKT-302H Series: Instruction ManualputrastevanofyPas encore d'évaluation

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Angel Simo MoralesPas encore d'évaluation

- Solenoid Valves Pilot Operated 2/2 Series NCDocument2 pagesSolenoid Valves Pilot Operated 2/2 Series NCKhyle Laurenz DuroPas encore d'évaluation

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroPas encore d'évaluation

- Micro Atmel 3 CH AFE W DSP For 1p M90E26-ApplicationNoteDocument19 pagesMicro Atmel 3 CH AFE W DSP For 1p M90E26-ApplicationNoteshuvo hasanPas encore d'évaluation

- Ceiling Mounted Cassette Type Air Conditioners with 360° Uniform AirflowDocument1 pageCeiling Mounted Cassette Type Air Conditioners with 360° Uniform AirflowFatih Al BaridPas encore d'évaluation

- UntitledDocument20 pagesUntitledSteve RindPas encore d'évaluation

- MCS 2 Video 003Document8 pagesMCS 2 Video 003tailieutonghop97Pas encore d'évaluation

- Datasheet VM332400 EVR-RDocument1 pageDatasheet VM332400 EVR-Rittg ittgPas encore d'évaluation

- Datasheet PDFDocument1 pageDatasheet PDFRycky de la CruzPas encore d'évaluation

- 《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00Document2 pages《Mctc Ard C系列电梯应急救援装置用户手册》 英文19010431 b00kolwin .chindwinPas encore d'évaluation

- DJ Controller: This Manual Is Applicable To The Following Model (S) and Type (S)Document30 pagesDJ Controller: This Manual Is Applicable To The Following Model (S) and Type (S)Matias Cruzat BurgosPas encore d'évaluation

- Turbofan SpecificationsDocument5 pagesTurbofan SpecificationsRasoul gholinia kiviPas encore d'évaluation

- Imm Ex260-Spr Tfn20gbDocument2 pagesImm Ex260-Spr Tfn20gbJeferson FigueiredoPas encore d'évaluation

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaPas encore d'évaluation

- STEVAL-SPIN3202: STSPIN32F0A Advanced 3-Phase BLDC Driver With Embedded STM32 MCU Single Shunt Evaluation BoardDocument7 pagesSTEVAL-SPIN3202: STSPIN32F0A Advanced 3-Phase BLDC Driver With Embedded STM32 MCU Single Shunt Evaluation Boardedst_tadPas encore d'évaluation

- Aoc E936swa Esquema El U00c9trico ScalerDocument1 pageAoc E936swa Esquema El U00c9trico ScalerClaudio Robson TobiasPas encore d'évaluation

- V381 20 (2019090500017967) DecryptDocument37 pagesV381 20 (2019090500017967) DecrypttrewePas encore d'évaluation

- CM-900 REV B Schematic20120906Document1 pageCM-900 REV B Schematic20120906jokowisPas encore d'évaluation

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemVu HoiPas encore d'évaluation

- Front Mulcher Specifications and Features for Skid Steer and Wheel Loaders Under 40 CharactersDocument1 pageFront Mulcher Specifications and Features for Skid Steer and Wheel Loaders Under 40 CharactersKft. Progép-TechnikaPas encore d'évaluation

- Siemens Sirona C1+, M1+ Quick Reference GuideDocument2 pagesSiemens Sirona C1+, M1+ Quick Reference GuideMarjan StojnevPas encore d'évaluation

- Philco PH19M LED A Versao ADocument13 pagesPhilco PH19M LED A Versao AEdmilson Lanes RamosPas encore d'évaluation

- MP-Series Low-Inertia Brushless Servo Motors With 75 MM or Smaller Frame SizesDocument22 pagesMP-Series Low-Inertia Brushless Servo Motors With 75 MM or Smaller Frame Sizesisaias martinezPas encore d'évaluation

- MELSEC iQ-R EtherNet/IP Module ManualDocument56 pagesMELSEC iQ-R EtherNet/IP Module Manualisaias martinezPas encore d'évaluation

- Substation Design Guideliness PDFDocument40 pagesSubstation Design Guideliness PDFLimuel EspirituPas encore d'évaluation

- Servo Driver FESTO + UMI 7772Document1 pageServo Driver FESTO + UMI 7772isaias martinezPas encore d'évaluation

- Ex600 Sen1Document75 pagesEx600 Sen1isaias martinezPas encore d'évaluation

- Byk-A 525 enDocument2 pagesByk-A 525 enさいとはちこPas encore d'évaluation

- Energy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsDocument9 pagesEnergy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsIjrei JournalPas encore d'évaluation

- Product GuideDocument13 pagesProduct Guidekhalid mostafaPas encore d'évaluation

- Climate Change and Global Warming and Its Impact On BangladeshDocument7 pagesClimate Change and Global Warming and Its Impact On BangladeshAminulHoquePas encore d'évaluation

- Lab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Document17 pagesLab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Sunny BbaPas encore d'évaluation

- MSE 2103 - Lec 12 (7 Files Merged)Document118 pagesMSE 2103 - Lec 12 (7 Files Merged)md akibhossainPas encore d'évaluation

- Health Programs Activities Timeframe Expected Output Child CareDocument3 pagesHealth Programs Activities Timeframe Expected Output Child CareC SamPas encore d'évaluation

- Sunflower Herbicide ChartDocument2 pagesSunflower Herbicide ChartpapucicaPas encore d'évaluation

- EMI InstructionsDocument2 pagesEMI InstructionsAKSHAY ANANDPas encore d'évaluation

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (2)

- 3.SAFA AOCS 4th Ed Ce 2-66 1994Document6 pages3.SAFA AOCS 4th Ed Ce 2-66 1994Rofiyanti WibowoPas encore d'évaluation

- Cement Evaluation CAST-CBL HalliburtonDocument36 pagesCement Evaluation CAST-CBL HalliburtonrezaPas encore d'évaluation

- Lewis Heart Failure Care PlanDocument4 pagesLewis Heart Failure Care Plansarahbearcoups100% (1)

- Environmental Product Declaration: PU EuropeDocument6 pagesEnvironmental Product Declaration: PU EuropeIngeniero Mac DonnellPas encore d'évaluation

- Grade 9 P.EDocument16 pagesGrade 9 P.EBrige SimeonPas encore d'évaluation

- Final TLE9 Nail Care9 Q1 Module 3Document20 pagesFinal TLE9 Nail Care9 Q1 Module 3Ma. Andrea LagmanPas encore d'évaluation

- Evolution Chart 3Document1 pageEvolution Chart 3sasupraPas encore d'évaluation

- ENGLISH TEST 9 SMPDocument4 pagesENGLISH TEST 9 SMPMariatul afniPas encore d'évaluation

- Secondary AssessmentsDocument12 pagesSecondary Assessmentsapi-338389967Pas encore d'évaluation

- Corn Pulao Recipe With Sweet CornDocument2 pagesCorn Pulao Recipe With Sweet CornSudharshanPas encore d'évaluation

- Batson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Document15 pagesBatson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Julia GonzalezPas encore d'évaluation

- Rice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian FarmersDocument2 pagesRice Research: Open Access: Black Rice Cultivation and Forming Practices: Success Story of Indian Farmersapi-420356823Pas encore d'évaluation

- DOC023.97.80076 - 3ed Sensores ORPDocument148 pagesDOC023.97.80076 - 3ed Sensores ORPAlejandroPas encore d'évaluation

- App 17 Venmyn Rand Summary PDFDocument43 pagesApp 17 Venmyn Rand Summary PDF2fercepolPas encore d'évaluation