Académique Documents

Professionnel Documents

Culture Documents

SDU Ver142beta1 - Demo Print 1 PDF

Transféré par

reza khTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SDU Ver142beta1 - Demo Print 1 PDF

Transféré par

reza khDroits d'auteur :

Formats disponibles

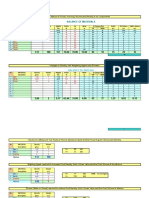

Well

Name Horizontal Demo Well Rig / String / Casing / Hole -configuration

FALSE

Use actual survey for string weight Cum. Bouyed Avg. Body Internal Internal

Length Weight ID OD capacity Riser / Casings / Liners - Top Bottom ID capacity

String - top to bottom Length [feet] [lbs] [inches] [inches] [bbl] Top to bottom [feet] [feet MD] [inches] [bbl]

1 5-1/2" DP, 21.9 ppf, S-135, HT-55 9,277 ft 9,277 123,308 4.6940 5.500 198.57 1 Riser (Rotary Table --> Wellhead) 0 65 ft 13.625 11.72

2 5" DP, 19.5 ppf, NC50, S-135 8,000 ft 17,277 19,733 4.2106 5.000 137.78 2 9.625 inch casing, 47 ppf 65 ft 8308 ft 8.681 603.44

3 5" HWDP, 49.3 ppf, NC50, G-105 31 ft 17,308 37 3.0149 5.000 0.27 3 < no selection > 8308 ft 12182 ft 0.000 0.00

4 6-1/2" Jar 30 ft 17,338 105 2.2500 6.500 0.15 4 < no selection > 0 ft 0.000 0.00

5 5" HWDP, 49.3 ppf, NC50, G-105 31 ft 17,369 36 3.0149 5.000 0.27 5 < no selection > 0 ft 8000 ft 0.000 0.00

6 6-3/4" AutoTrack assy (no motor) 72 ft 17,441 247 2.2500 7.000 0.35 Only the innermost casing string shall be selected. Plus any liner strings. 615.2 bbl

7 < no selection > 0 ft 17,441 0 0.0000 0.000 0.00 Open Hole Mud Pumps

8 < no selection > 0 ft 17,441 0 0.0000 0.000 0.00 Hole size 8.500 in (incl. wash-out) Pump Rate 135 SPM 576 gpm 13.7 bpm

9C < no selection > 0 ft 17,441 0 0.0000 0.000 0.00 Total Depth 17,441 ft (MD) Liner size 6.0 inch Efficiency 97 %

h

10 < no selection > 0 ft 17,441 0 0.0000 0.000 0.00 ROP 50 ft/hr Cuttings Conc 0.4 % vol Pump output 0.10167 bbl/stroke.

Error Message Centre

System Pressure Loss

Blocks 175 klbs 0

3000 Hook Load 318,466 lbs Volumetric Calculations with bottom of string at 17441 ft MD

2500No errors. Pressure Loss Summary String volume = 337.4 bbls = 3318 strokes = 25 minutes.

1)2000 Surface lines 47 psi Bottoms up = 783.1 bbls = 7702 strokes = 57 minutes.

Pressure [ psi ]

2) Drill String 1,659 psi Empty hole volume from surface to TD: 1256.2 bbls.

1500

3) Motor/RSS/MWD 500 psi Empty hole volume from shoe to TD: 641 bbls.

4)1000 Bit 202 psi Cased hole annulus volume: 371.03 bbls = 3649 strokes.

5) OH annulus 184 psi Open hole annulus volume: 412.1 bbls = 4053 strokes.

500

6) Btm of string Cased annulus 180 psi Approximate closed-end string displacement: 473.1 bbls.

0 Total 2,770 psi Approximate string metal displacement: 135.7 bbls.

0 2000 4000 6000 8000 10000 12000 Place Bit on Btm Approximate empty hole volume from bit to TD: 0 bbls.

Strokes On bottom

Place Bit at Shoe

Hide Plots Select Mini-Plot Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Hydraulics

Input Mud Rheology

Hole Size 8.50 in Jet 1 24 [/32 in] Power

Power Law

Law

Hole depth 17,441 ft Jet 2 24 [/32 in]

Mud weight 11.60 ppg Jet 3 24 [/32 in] Fann 3 reading 8 Approx equal to 10 sec gel

PV 25 cp Jet 4 Fann 100 reading 25.0 Approx: 300_reading - 2/3 of PV

YP 25 lbs/100sqft Jet 5 Fann 300 reading 50

10 sec gel 8 lbs/100sqft Jet 6 Fann 600 reading 75

TVD @ TD 6,749 ft Jet 7 Pipe Annulus

Flow rate 576 gal/min Jet 8 Rheological Index, "n" -----------------------------> 0.585 0.325

Last casing shoe, MD 8,308 ft TFA = 1.325 sq in Consistency Index, "K" -----------------------------> 6.65316 24.05424

Last casing shoe,TVD 5,275 ft Enter TFA 3.000 sq in PV [cP] = 600_reading - 300_reading AV [cP] = 300_reading

Additional pressure Select MWD / LWD, RSS YP [lbs/100sqft] = 300_reading - PV

500 psi ---> and Motor config.

drop across BHA

Output Buyancy Factor: 0.8227

Bit Pressure Loss Summary ECD's

Jet Velocity 140 (fps) Click here Surface lines 47 psi @ shoe 12.26 ppg

Bit Pressure Loss 202 (psi) Drill String 1,659 psi @ TD 12.64 ppg

Bit Power 68 (hhp) Motor/RSS/MWD 500 psi

Bit Power/Area 1.2 (hsi) for detailed Bit 202 psi with 0 % of flow bypassing bit.

Bit Impact Force 483 (lbs) annulus data OH annulus 184 psi Change %

Impact Force/Area 8.5 (psi) Cased annulus 180 psi by-pass

% loss across bit 7.3 (%) Total 2,770 psi

OD ID Length Pressure Loss

Drill String

(inches) (inches) (feet) (psi)

Surface Lines (or choke/kill lines) 3.0000 in 100.00 ft 47 psi

5-1/2" DP, 21.9 ppf, S-135, HT-55 5.5000 in 4.6940 in 9,277.00 ft 613 psi

5" DP, 19.5 ppf, NC50, S-135 5.0000 in 4.2106 in 8,000.00 ft 850 psi

5" HWDP, 49.3 ppf, NC50, G-105 5.0000 in 3.0149 in 31.00 ft 14 psi

6-1/2" Jar 6.5000 in 2.2500 in 30.00 ft 49 psi

5" HWDP, 49.3 ppf, NC50, G-105 5.0000 in 3.0149 in 31.00 ft 14 psi

6-3/4" AutoTrack assy (no motor) 7.0000 in 2.2500 in 72.00 ft 118 psi

< no selection > 0.0000 in 0.0000 in 0.00 ft 0 psi

< no selection > 0.0000 in 0.0000 in 0.00 ft 0 psi

< no selection > 0.0000 in 0.0000 in 0.00 ft 0 psi

< no selection > 0.0000 in 0.0000 in 0.00 ft 0 psi

Mud motor / MWD , etc 500 psi

Bit pressure drop 202 psi

Total drill string friction loss >> 17,441.00 ft 2,407 psi

Pressure

Annulus

(psi)

Cased hole annular friction loss 8,308.00 ft 180 psi

Open hole annular friction loss 9,133.00 ft 184 psi

Total annulus friction loss >> 17,441.00 ft 363 psi

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Pre-Recorded Well Data

Date Tuesday, February 07, 2006 Hole Size 8.500 inch Riser Margin at current bit depth

Rig Jack-up Demo Rig Hole depth 17,441 ft MD / 6,749 ft TVD RT with current mud weight:

Well Horizontal Demo Well Bit depth 17,441 ft MD / 6,749 ft TVD RT Water Gradient 0.445 psi/ft

Last csg shoe 8,308 ft MD 9.625 inch casing, 47 ppf Riser Margin 0.28 ppg

Pump liner size 6.00 in Burst (100%) 5750 psi

Pump efficiency 97.0 %

Pump output 0.10167 bbl/stk

Subsea

Slow Circ. Rates @ 17,000 ft MD 30 spm 40 spm 80 spm Leak-off Test Data Shoe Fracture Pressure 3941 psi

BOP RRCP (up riser) 300 psi 350 psi 450 psi Pump 1 MW 9.50 ppg Present Mud Weight 11.60 ppg

Surface RRCP (up riser) 310 psi 360 psi 460 psi Pump 2 TVD 5,275 ft TVD RT Present MAASP 765 psi

BOP Choke Line Friction 100 psi 0 psi 200 psi Leak-off 1340 psi Max allowable MW 14.39 ppg

Length in Length in OD ID Drill String Cased Hole Open Hole

Drill String Configuration casing open hole Internal Capacity Annular Capacity Annular Capacity

(to BOP only) [inches] [inches] [bbl] [strokes] [bbl] [strokes] [bbl] [strokes]

5-1/2" DP, 21.9 ppf, S-135, HT-55 8243.0 ft 969.0 ft 5.5 4.694 198.57 1953 361.2 3553 39.5 389

5" DP, 19.5 ppf, NC50, S-135 0.0 ft 8000.0 ft 5 4.2106 137.78 1355 0.0 0 367.2 3612

5" HWDP, 49.3 ppf, NC50, G-105 0.0 ft 31.0 ft 5 3.01492 0.27 3 0.0 0 1.4 14

6-1/2" Jar 0.0 ft 30.0 ft 6.5 2.25 0.15 1 0.0 0 0.9 9

5" HWDP, 49.3 ppf, NC50, G-105 0.0 ft 31.0 ft 5 3.01492 0.27 3 0.0 0 1.4 14

6-3/4" AutoTrack assy (no motor) 0.0 ft 72.0 ft 7 2.25 0.35 3 0.0 0 1.6 16

< no selection > 0.0 ft 0.0 ft 0 0 0.00 0 0.0 0 0.0 0

< no selection > 0.0 ft 0.0 ft 0 0 0.00 0 0.0 0 0.0 0

< no selection > 0.0 ft 0.0 ft 0 0 0.00 0 0.0 0 0.0 0

< no selection > 0.0 ft 0.0 ft 0 0 0.00 0 0.0 0 0.0 0

8243.0 ft 9133.0 ft 337.4 3318 361.2 3553 412.1 4053

Volume of mud in active surface system 500 bbl

Density of insoluble weighting agent (barite = 35 ppg) 35.0 ppg (=SG x 8.3452) Time @ 30 SPM Time @ 40 SPM Time @ 80 SPM

Total Drill String - surface to bit 17441 ft 337.4 bbl 3318 strokes 110.6 minutes 83.0 minutes 41.5 minutes

Annulus - bit to shoe 9133 ft 412.1 bbl 4053 strokes 135.1 minutes 101.3 minutes 50.7 minutes

Annulus - shoe to BOPs 8243 ft 361.2 bbl 3553 strokes 118.4 minutes 88.8 minutes 44.4 minutes

Choke line 3.500 inch ID 50 ft 0.59 bbl 6 strokes

Total Annulus - bit to choke manifold 17426.0 ft 773.9 bbl 7612 strokes

Total system - Rotary Table to Choke Manifold 1111.3 bbl 10930 strokes 364.3 minutes 273.3 minutes 136.6 minutes

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

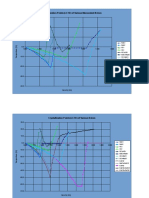

Kill Sheet for Vertical Well

Surface BOP - Driller's Method

Note: Pertinent well data (in dark blue) has been transferred from the Pre-Recorded Well Data page. Bit depth 17,441 ft MD

Date Tuesday, February 07, 2006 Well name Horizontal Demo Well Bit TVD 6,749 ft TVD RT

Rig Jack-up Demo Rig Mud Weight 11.60 ppg

Kick Data Kill Fluid Density

Shut-in drill pipe pressure SIDPP 500 psi SIDPP

KMW= + MW = 13.028 ppg

Shut-in drill casing pressure SICP 150 psi 0.0519xTVD

Pit Gain 20 bbl Kill Fluid Gradient 0.676 psi/ft Weighting agent req'd

Chosen Kill Mud Weight 13.10 ppg 164,094 lbs

Initial Circulating Pressure (ICP) Final Circulating Pressure (FCP) = 74.4 MT

ICP = Dynamic Pressure Loss + SIDPP Chosen KMW * Dynamic Pressure Loss

FCP =

ICP = 360 psi + 500 psi = 860 psi MW

The Dynamic Pressure Loss is the selected SCR pressure. FCP = 407 psi

Strokes - Pressure Schedule Surface-to-bit volume = 337.4 bbl 3318 strokes 1st Circulation: Hold DPP constant at ICP until influx is

Bit-to-surface volume = 773.9 bbl 7612 strokes out.

1st Circulation 2nd Circulation: Follow step-down graph until kill mud

Strokes Pressure Comments reaches bit, then hold DPP constant at FCP until kill mud

back at surface.

0 860 psi ICP

7612 860 psi ICP

Close in well and confirm that SIDPP = SICP, indicating influx is out. Re-set stroke counter.

2nd Circulation

Drillers Method - 2nd Circulation

Strokes Pressure Comments 1000 psi

0 860 psi ICP. Start pumping kill mud. 900 psi

800 psi

Drill Pipe Pressure

332 815 psi

700 psi

664 769 psi

600 psi

996 724 psi 500 psi

1327 679 psi 400 psi

1659 633 psi 300 psi

200 psi

1991 588 psi

100 psi

2323 543 psi 0 psi

2655 497 psi 0 2000 4000 Strokes6000 8000 10000 12000

2987 452 psi

3318 407 psi FCP. Kill mud at bit. Hold DPP constant (at FCP) from now on until kill mud back at surface.

10930 407 psi FCP. Confirm kill mud back at surface, then close in well and confirm zero pressure.

Close-up of step-down graph

1000 psi

900 psi

800 psi

Drill Pipe Pressure (psi)

700 psi

600 psi

500 psi

400 psi

300 psi

200 psi

100 psi

0 psi

0 500 1000 1500 2000 2500 3000 3500

Strokes

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Nav. Well Control Kill Sheet for Deviated and Horizontal Well

Menu Simulator Surface BOP

Pertinent well data (in dark blue) has been transferred from the Pre-Recorded Well Data page. Survey used is the "Active" listing on survey sheet

Date Tuesday, February 07, 2006 Well name Horizontal Demo Well Bit depth 17,441 ft MD

Rig Jack-up Demo Rig Bit TVD 6,749 ft TVDRT

Mud weight 11.60 ppg

Kick Data Numbers in green are for optional influx calculations/simulation Kill Fluid Density (assuming influx point at bit)

Shut-in drill pipe pressure SIDPP 386 psi Formation Pressure SIDPP

KMW = + MW =12.702 ppg

Shut-in casing pressure SICP 392 psi 4,449 psi 0.0519*TVD Weighting agent req'd

Pit gain 19.7 bbl Calculated influx gradient Kill Fluid Gradient 0.659 psi/ft 119,283 lbs

Influx gradient to be used 0.100 psi/ft 0.101 psi/ft Chosen Kill Mud Weight 12.710 ppg = 54.1 MT

Initial Circulating Pressure (ICP) Length of influx Final Circulating Pressure (FCP)

ICP = Dynamic Pressure Loss + SIDPP 477 ft MD RT Chosen KMW * Dynamic Pressure Loss FCP =

FCP =

ICP = 360 psi + 386 psi = 746 psi MW 394 psi

The Dynamic Pressure Loss is the selected SCR pressure. Reservoir temperature 100 deg F Flowline temp 100 deg F

Survey Data Horizontal Demo Well

Surveys: 511 Deepest survey station at: 17,442 ft

Horizontal Demo Well String / BHA components (bottom)

0

1000

2000

True Vertical Depth [ft TVD RT]

3000

4000

5000

6000

7000

8000

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

Measured Depth [ft]

String Configuration & Capacities

MD MD MD TVD RT TVD RT BBLs in Strokes in Cumulative

String Configuration Length Top Bottom Top Bottom component Component strokes

1 5-1/2" DP, 21.9 ppf, S-135, HT-55 9,277.0 ft 0.0 ft 9,277.0 ft 0.0 ft 5,680.6 ft 198.57 bbl 1953 1953

2 5" DP, 19.5 ppf, NC50, S-135 8,000.0 ft 9,277.0 ft 17,277.0 ft 5,680.6 ft 6,743.9 ft 137.78 bbl 1355 3308

3 5" HWDP, 49.3 ppf, NC50, G-105 31.0 ft 17,277.0 ft 17,308.0 ft 6,743.9 ft 6,744.8 ft 0.27 bbl 3 3311

4 6-1/2" Jar 30.0 ft 17,308.0 ft 17,338.0 ft 6,744.8 ft 6,745.7 ft 0.15 bbl 1 3312

5 5" HWDP, 49.3 ppf, NC50, G-105 31.0 ft 17,338.0 ft 17,369.0 ft 6,745.7 ft 6,746.6 ft 0.27 bbl 3 3315

6 6-3/4" AutoTrack assy (no motor) 72.0 ft 17,369.0 ft 17,441.0 ft 6,746.6 ft 6,748.6 ft 0.35 bbl 3 3318

7 < no selection > 0.0 ft 17,441.0 ft 17,441.0 ft 6,748.6 ft 6,748.6 ft 0.00 bbl 0 3318

8 < no selection > 0.0 ft 17,441.0 ft 17,441.0 ft 6,748.6 ft 6,748.6 ft 0.00 bbl 0 3318

9 < no selection > 0.0 ft 17,441.0 ft 17,441.0 ft 6,748.6 ft 6,748.6 ft 0.00 bbl 0 3318

10 < no selection > 0.0 ft 17,441.0 ft 17,441.0 ft 6,748.6 ft 6,748.6 ft 0.00 bbl 0 3318

17,441 ft 337.40 bbl 3318

Drill Pipe Kill Graph for Deviated / Horizontal Well - Pumping Kill Mud to Bit

Strokes Pressure

800

0 strks 746 psi

ICP

166 strks 702 psi

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

332 strks 659 psi 700

498 strks 619 psi

664 strks 584 psi

600

830 strks 558 psi

995 strks 540 psi

DRILL PIPE PRESSURE (psi)

1161 strks 523 psi 500

1327 strks 504 psi

1493 strks 487 psi

400 FCP

1659 strks 470 psi

1825 strks 452 psi

1991 strks 434 psi 300

2157 strks 412 psi

2323 strks 392 psi

2489 strks 388 psi 200

2654 strks 388 psi

2820 strks 389 psi

100

2986 strks 389 psi

3152 strks 391 psi

3318 strks 392 psi 0

0 500 1000 1500 2000 2500 3000 3500

10930 strks 392 psi STROKES

Drill Pipe Kill Graph for Deviated / Horizontal Well - Pumping Sequence, 2nd circulation

800

ICP

700

600

DRILL PIPE PRESSURE (psi)

500

FCP

400

300

200

100

0

0 2000 4000 6000 STROKES 8000 10000 12000

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Mini

Menu

Conductor Cementation to Seabed (inner-string cementation) for jack-ups only

Tapered string (e.g. 20" x 30") One size conductor only (e.g. 20")

test

Seabed 289 ft 36 in hole down to 673 ft 25-Dec-05

X-over point at 339 ft 24 in hole down to 673 ft Calc. by TSL

Shoe Depth 663 ft Fill rathole with cement

Capacity Cl-end Displ. Nominal ID Lead Tail

Casing 20 inch casing, 106.5 ppf 0.35068 bpf 0.38857 bpf 19.000 in Excess 200% 200%

Lower casing 20 inch casing, 106.5 ppf 0.35068 bpf 0.38857 bpf 19.000 in Top of cmt 289 ft 463 ft

Lead Slurry 454.3 bbls 2161.9 sxs 92.2 MT cement 26.92 tanks Lead Mix Water

Weight 15.8 ppg Dead vol 0 bbl 0.0 sxs Lead Mix Fluid Composition

Cost - incl discount -

Yield 1.18 cuft/sk Downhole Dead vol Total Unit excl dead volume Current inventory % of one job

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error

Sea

Sea Water

Water 5.220 gps 268.698 0.000 268.698 bbl 0$ 10000 bbls

D-Air

D-Air 3000L

3000L 0.010 gps 0.515 0.000 0.515 bbl 432 $ 0 gal

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

Total mixing fluid 5.230 gal/sk 432 $

Tail Slurry 140.4 bbls 667.8 sxs 28.5 MT cement 8.32 tanks Tail Mix Water

Weight 15.8 ppg Dead vol 0 bbl 0.0 sxs Tail Mix Fluid Composition

Yield 1.18 cuft/sk Downhole Dead vol Total Unit

Cost - incl discount -

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error excl dead volume Current inventory % of one job

Sea

Sea Water

Water 5.220 gps 83.003 0.000 83.003 bbl 0$ 10000 bbls

D-Air

D-Air 3000L

3000L 0.010 gps 0.159 0.000 0.159 bbl 134 $ 0 gal

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

< no

< no selection

selection > > 0.000 FALSE FALSE 0.000 unit error 0$ 00

Total mixing fluid 5.230 gal/sk 134 $

Displacement 9.6 bbl Cost Summary

Inner string capacity 0.0174 bpf Lead Mix Water 432 $

Under-displacement 3.0 bbl Lead Cement 92 $

Stick-up 5 ft Tail Mix Water 134 $

Surface lines 1.00 bbl Tail Cement 28 $

687 $

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Casing Cementation

OD ID Capacity Shoe depth Well Name:

Last casing 13.375 inch

13.375 inch casing,

casing, 68 pp68 ppf 13.375 in 12.415 in 0.149728 bpf 4873 ft Horizontal Demo Well

This casing 9.625 inchcasing,

9.625 inch casing,

47 ppf47 ppf 9.625 in 8.681 in 0.073206 bpf 8308 ft 23-Dec-05

Stage cementation, using inflatable packer / stage collar Calc. by TSL

Hole Size 12.25 in Top of shoe track 8216 ft Normal cement job (bottom plug, Packer/Stage Collar @ 2785 ft

Lead, Tail, top plug, displace)

Casing stick-up above rig

TD 8322 ft floor

6 ft

Capacity of landing string from

0.00 bbls Surface BOP Subsea BOP

darts to cmt plugs

Lead Slurry 389.1 bbls 1560.4 sxs 66.5 MT cement 67 $ Mix Water 25.98 tanks

Excess CSG 0% Dead volume 0 bbl 0.0 sxs

Weight 14.6 ppg Excess OH 80% Top of cmt 2873 ft

Yield 1.40 cuft/sk Mix Fluid Composition

Downhole Dead vol Total Unit

Drill

Drill Water

Water 5.730 gps 212.878 0.000 212.878 bbl

Gascon22

Gascon 0.330 gps 12.260 0.000 12.260 bbl Slurry in cased annulus 119.5 bbl

CFR-3L

CFR-3L 0.050 gps 1.858 0.000 1.858 bbl Slurry in OH annulus 269.6 bbl

HR-4-DK

HR-4-DK 0.280 gps 10.402 0.000 10.402 bbl 389.1 bbl

NF6

NF6 0.003 gps 0.111 0.000 0.111 bbl

Halad

Halad 413L

413L 0.600 gps 22.291 0.000 22.291 bbl

< noselection

< no selection>> 2.000 0 FALSE FALSE 0.000 unit error Thickening time to 70 BC

Total mixing fluid 6.993 gal/sk 1,680 $ 0$ 1,680 $ 210 minutes

Tail Slurry 83.5 bbls 397.4 sxs 16.9 MT cement 17 $ Mix Water 5.00 tanks

Excess CSG 0% Dead volume 0 bbl 0.0 sxs

Weight 15.8 ppg Excess OH 75% Top of cmt 7558 ft Fill rathole with cement

Yield 1.18 cuft/sk Mix Fluid Composition

Downhole Dead vol Total Unit

Drill

Drill Water

Water 4.250 gps 40.215 0.000 40.215 bbl

Gascon22

Gascon 0.230 gps 2.176 0.000 2.176 bbl Slurry in shoetrack 6.7 bbl

CFR-3L

CFR-3L 0.150 gps 1.419 0.000 1.419 bbl Slurry in cased annulus 0.0 bbl

HR-4-DK

HR-4-DK 0.250 gps 2.366 0.000 2.366 bbl Slurry in OH annulus 73.2 bbl

Halad

Halad 413L

413L 0.400 gps 3.785 0.000 3.785 bbl Slurry in rathole 3.6 bbl

NF6

NF6 0.003 gps 0.028 0.000 0.028 bbl 83.5 bbl

< noselection

< no selection>> 0.000 0 FALSE FALSE 0.000 unit error Thickening time to 70 BC

Total mixing fluid 5.283 gal/sk 328 $ 0$ 328 $ 110 minutes

Displacement, Tail / 1st stage Csg P-test against plug to Duration Rate Duration Cost Summary

Liner size 6.0 inches 4000 psi req's approx Batch-up 5 min (including dead volumes)

Eff. 97 % 7.2 bbls to reach. Pump slurry 4.2 bpm 93 min Lead Mix Water 1,680 $

Output 0.1017 bbl/stk Batch-up 10 min Lead Cement 67 $

Displacement from cement unit 10 bbl Pump slurry 3.5 bpm 24 min Tail Mix Water 328 $

Displacement with rig pumps 591.9 bbl 5822 strks Drop plug(s) 20 min Tail Cement 17 $

Overdisplace shoetrack at 598.6 bbl 5888 strks Displace plug 10.0 bpm 59 min Total 2,091 $

211 min

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Nav.

Menu Brine Calculations for NaCl / KCl / CaCl2

Weight

Weight up

up water

water or

or brine

brine with

with dry

dry salt

salt CaCl2

CaCl2

Base fluid density 8.60 ppg Base2 (heavy or light brine) density 9.80 ppg

Target brine weight 9.47 ppg Volume of low-density base fluid 100 bbls

Target brine volume 2000 bbl Req'd volume of base2 brine 233.1 bbls

Req'd volume of base fluid 1926.7 bbl

Req'd amount of selected salt 99612 lbs

45.2 MT

Calcium Chloride, CaCl2 (94%-97%), at 70°F

Min

Density Specific CaCl2 Water CaCl2 Min Ca++ Approx Cl- TCT TCT

CaCl2

[ppg} Gravity [lb/bbl] [bbl/bbl] [kg/m3] [mg/l] [mg/l] [°F] [°C]

[%wt]

8.33 1.000 0.0 0 1.0000 0.0 0 0 32 0.0

8.40 1.010 1.0 3.8 0.9989 10.7 3,900 6,900 32 0.1

8.50 1.022 2.5 9.4 0.9951 26.8 9,700 17,100 30 1.0

8.60 1.034 3.9 14.9 0.9914 42.5 15,400 27,200 29 1.9

8.70 1.046 5.3 20.4 0.9875 58.3 21,100 37,300 27 2.8

8.80 1.058 6.7 26 0.9836 74.2 26,800 47,400 25 3.7

8.90 1.070 8.0 31.6 0.9796 90.2 32,600 57,600 24 4.7

9.00 1.081 9.4 37.2 0.9755 106.0 38,400 67,900 22 5.7

9.10 1.094 10.7 42.9 0.9714 122.0 44,200 78,200 20 6.8

9.20 1.106 11.9 48.6 0.9671 139.0 50,100 88,600 18 8.0

9.30 1.118 13.2 54.3 0.9627 155.0 56,000 99,000 15 9.3

9.40 1.130 14.5 60.1 0.9583 171.0 61,900 109,500 13 10.7

9.50 1.142 15.7 65.9 0.9537 188.0 67,900 120,100 10 12.2

9.60 1.154 16.9 71.7 0.9491 205.0 73,900 130,700 7 13.8

9.70 1.166 18.1 77.5 0.9443 221.0 79,900 141,300 4 15.6

9.80 1.178 19.3 83.4 0.9395 238.0 86,000 152,100 1 17.5

9.90 1.190 20.4 89.4 0.9346 255.0 92,100 162,900 -3 19.6

10.00 1.202 21.6 95.3 0.9296 272.0 98,200 173,700 -7 21.8

10.10 1.214 22.7 101.3 0.9245 289.0 104,400 184,600 -12 24.3

10.20 1.226 23.8 107.3 0.9193 306.0 110,600 195,600 -16 26.9

10.30 1.238 24.9 113.4 0.9140 323.0 116,800 206,600 -22 29.8

10.40 1.250 26.0 119.4 0.9086 341.0 123,100 217,700 -27 32.9

10.50 1.262 27.0 125.6 0.9031 358.0 129,400 228,900 -33 36.2

10.60 1.274 28.1 131.7 0.8975 376.0 135,700 240,100 -39 39.7

10.70 1.286 29.1 137.9 0.8918 393.0 142,100 251,400 -46 43.5

10.80 1.298 30.2 144.1 0.8860 411.0 148,500 262,700 -51 46.1

10.90 1.310 31.2 150.4 0.8801 429.0 155,000 274,100 -36 37.8

11.00 1.323 32.2 156.7 0.8741 447.0 161,400 285,600 -22 30.2

11.10 1.335 33.2 163 0.8680 465.0 168,000 297,100 -10 23.1

11.20 1.347 34.2 169.4 0.8618 483.0 174,500 308,700 2 16.6

11.30 1.359 35.2 175.8 0.8555 501.0 181,100 320,400 13 10.7

11.40 1.371 36.1 182.2 0.8491 520.0 187,700 332,100 22 5.4

11.50 1.383 37.1 188.7 0.8426 538.0 194,400 343,900 31 0.7

11.60 1.395 38.1 195.2 0.8360 557.0 201,100 355,800 38 3.4

11.70 1.407 39.0 201.7 0.8293 576.0 207,800 367,700 44 6.9

11.80 1.418 39.9 208.1 0.8227 594.0 214,400 379,300 50 9.8

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Balanced Cement Plug

Nav.

Menu

Plug set inside casing (only) Plug set in open hole & casing Plug set in open hole (only)

Bottom of plug 21000 ft EAP-1D

Plug Length (with no pipe in) 500 ft Top plug: 20500 ft 11-Jul-04

Cementing String (from top to bottom) Length Calc. by TOL

Metal Displ. Capacity CE Displ. Average ID OD

5"5"

DP,DP,

19.519.5 ppf, NC50,

ppf, NC50, G-105 G-105 20400 ft 0.00691 bpf 0.01738 bpf 0.02429 bpf 4.2293 in 5.0000 in

3.5

3.5 inchinch tubing,

tubing, 10.2 ppf

10.2 ppf 600.0 ft 0.00361 bpf 0.00829 bpf 0.01190 bpf 2.9220 in 3.5000 in

Last Casing Shoe Depth

9.625

9.625 inchinch casing,

casing, 40 ppf40 ppf 4736 ft 0.07583 bpf 8.8350 in

Slurry 35.1 bbls 171.3 sxs 7.3 MT cement 2.01 tanks Mix Fluid

Fluid

Gauge hole size 8.50 in Excess 0% Mix in displacement tanks Dead vol 15.0 bbls 128.0 sxs

distribution

Slurry weight 15.8 ppg Water Ahead 15.0 bbls around pipe

Slurry yield 1.15 cuft/sk

Mix Fluid Composition

Chemicals Downhole Dead vol Total Unit Current inventory

Drill

Drill Water

Water 4.910 gps 20.030 14.970 35.000 bbl 1700 bbls

D-Air

D-Air 3000L

3000L 0.010 gps 0.041 0.030 0.071 bbl 0 gal

CFR-3

CFR-3 0.100 %bwoc 16.106 12.037 28.142 lbs 0 lbs

<< no

noselection

selection> > 0.000 0 FALSE FALSE 0.000 unit error 00

HR-4

HR-4 0.170 %bwoc 27.380 20.462 47.842 lbs 0 lbs

Total mixing fluid 4.920 gps 710 $ 531 $ 1,241 $

Top of cement 20473 ft with pipe in. Pumping Schedule

Top of water 20166 ft with pipe in. a) 15.0 bbls water ahead

Water behind 4.67 bbls b) 35.1 bbls slurry

Slurry distribution with string in the hole Displacement c) 4.7 bbls water behind

OH / Stinger: 35.09 bbls 527 ft String 350.40 bbls d) 349.9 bbls mud

OH / DP: 0.0 bbls 0 ft Surface lines 2.0 bbls

Casing/Stinger 0.00 bbls 0 ft Under-displacement 2.5 bbls Cost Summary (incl dead volume)

Casing / DP: 0.00 bbls 0 ft Actual Displacement 349.90 bbls Mix Water 1,241 $

Height of Slurry with pipe in: 527 ft Cement 7$

Height of Water Ahead: 307 ft Total 1,249 $

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

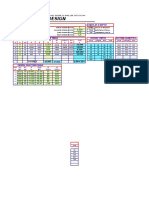

Circulating out gas influx taken at the bit, using Driller's Method, the active survey

and Boyle's law: P1 * V1 / T1 = P2 * V2 / T2. Surface BOP

Casing Pressure (1st circulation) DPP (1st circulation) DPP (2nd circulation) Casing Pressure (2nd circulation) MAASP

1,600

1,400

1,200

Pressure (psi)

1,000

800

600

400

200

0

0 2000 4000 6000 8000 10000

Strokes 12000 14000 16000 18000 20000

Shoe Pressure Survey Top of Influx Kill Mud

Fracture Pressure

Shoe Pressure 2nd circ Casing Shoe Pressure & Fracture Pressure Shoe String Components (btm) Btm of Influx

4,000 0

True Vertical Depth (ft TVDRT)

1,000

3,900

2,000

3,800

Pressure (psi)

3,000

3,700 4,000

5,000

3,600 Shoe

6,000

3,500 7,000

3,400 8,000

0.0 2000.0 4000.0 6000.0 8000.0 10000.0 12000.0 14000.0 16000.0 18000.0 20000.0

0 2000 4000 6000 Strokes

8000 10000 12000 14000 16000 18000 20000 Measured Depth (MD) (ft)

Surface-to-Bit strokes 3318

Overbalance on DP side - 1st circ. (psi) Overbalance on DP side - 2nd circ. (psi)

3.00

Bit-to-Shoe strokes 4053

Shoe-to-Surface strokes 3553

2.00 Currently 7,606 strokes into 1st circulation. Influx is out.

Currently 10,925 strokes into 2nd circulation. Kill mud all around.

1.00

0.00 Influx Size (bbls) Influx Height (ft)

80 1600

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

-1.00 70 1400

Strokes 1200

60

1000

50

Influx Height

Overbalance on Annulus side, 1st circ (psi) Overbalance on Annulus side, 2nd circ (psi)

800

Pit Gain

0.00

40

0.00 600

0.00 0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000 30

400

0.00 20 200

0.00

10 0

0.00

0 -200

0.00

0.00 0 5000 10000 15000 20000 0 5000 10000 15000 20000

Strokes Strokes Strokes

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Well: Horizontal Demo Well

Kick Tolerance - kick while drilling Hole size = 8.5 inch

Definition Formulars & Calculation Procedure

Kick Tolerance is the maximum allowable influx volume, of any 1) Calculate maximum allowable static weak point pressure:

stated intensity, which can safely be shut in and circulated out of (a) Pmax = Pleak-off - safety margin (to account for choke operator error, choke line friction, annulus friction).

the wellbore using a constant bottom-hole pressure method,

without breaking down the exposed formation or bursting the 2) Calculate the maximum allowable (vertical) height of influx in open hole section, that will not lead to exceeding Pmax:

casing. (b) H = (Pmax - Pf) + ((TVDbit - TVDwp) * MW * 0.052) / (0.052 * MW - G g), where Pf is the formation pressure at the bit.

Normally, the casing shoe is used as the weakest point in the

3) Calculate V1: The volume that this height (H) corresponds to at initial shut-in condition:

wellbore, however, this is not necessarily always the case. The

(c) V1 = H * AnnCapinflux point

formation could prove to be more competent than expected, in

which case the casing may be at jeopardy, if the casing design

4) Calculate the volume Vwp that this V1 corresponds to when the influx has been circulated to the weak point:

(and thus actual burst pressure) has been based on less

competent formations than actually encountered. (d) Vwp = H * AnnCapweak point

Conversely, the open hole section could comprise a zone below the 5) Calculate V2: What the weak point volume Vwp would be at initial shut-in conditions: Using Boyle's law: P*V / T =constant, this gives:

shoe which is weaker than the formation tested during the LOT or

FIT. (e) V2 = Pmax * Vwp / Pf * (tf + 460) /(twp + 460), where t = temperature in °F. If unknown, set tf = twp

The Kick Tolerance is the lower of V1 and V2.

Calculations below are based on the current well design as defined elsewhere in this workbook, such as Drill string / Casing / Hole -configuration, survey data, current mud weight, leak-off data, etc. You can

retrieve these data by pressing the "Retrieve…." button below. Subsequently, you can changes the numbers as required by changing directly in the cells (with red borders).

Leak-off pressure at weak point 3941 psi 2) H: Max allowable influx height in open hole 740.8 ft (= vertical height with top of influx at weak point)

Safety margin 0 psi Annular capacity at influx point (=at bit/BHA) 0.03000 bpf Comments to calculation

1) Pmax: Max allowable static press @ weak point 3941 psi 3) V1: Corresponding volume at bit depth 22.2 bbl Type your own comments regarding the kick

Depth (MD) at bit tolerance calculation here...

17441 ft Annular capacity at (below) weak point 0.03000 bpf

Depth (TVD) at bit 6749 ft 4) Vwp 22.2 bbl

Depth (MD) at weak point 8308 ft Temperature at influx point 100 °F

Depth (TVD) at weak point 5275 ft Temperature at weak point 100 °F

Mud weight in hole 11.60 ppg 5) V2 19.7 bbl

Influx (gas) gradient 0.100 psi/ft Kick Tolerance 19.7 bbls gas influx at bit

Kick Intensity 1.10 ppg SIDPP = 386 psi SICP = 392 psi TVD height = 12.7 ft

==> Pf: Formation pressure at bit depth 4457 psi

Sargent's Drilling Utilities Version 14.2 beta 1 February 2006 www.sargent.dk

SargentsDrillingUtilities.xls 2/7/2006 3:27 PM

Vous aimerez peut-être aussi

- 1000 Most Common Words (SAT)Document70 pages1000 Most Common Words (SAT)grellian95% (20)

- Halliburton Cementing 1 BookDocument238 pagesHalliburton Cementing 1 BookOlvin Hernandez100% (2)

- Mud Engineer User ManualDocument48 pagesMud Engineer User ManualstevebeardsleyPas encore d'évaluation

- TVD & Kill Weight CalculationsDocument40 pagesTVD & Kill Weight Calculationsfrancisryan4519Pas encore d'évaluation

- Well Life Cycle Integrity Guideline - Issue 4Document170 pagesWell Life Cycle Integrity Guideline - Issue 4petropao100% (10)

- Spot Heavy MudDocument1 pageSpot Heavy MudstevebeardsleyPas encore d'évaluation

- Drill String DesignDocument1 pageDrill String DesignmalikshababPas encore d'évaluation

- Casing & Cementing ConventionalDocument1 pageCasing & Cementing ConventionalDeepak TandonPas encore d'évaluation

- Drilling FormulasDocument87 pagesDrilling Formulaswhydowelove89% (9)

- Well: B-166 18-5/8" Casing Cementing DesignDocument8 pagesWell: B-166 18-5/8" Casing Cementing DesignIbnu HasanPas encore d'évaluation

- Well Head Chistmas TreeDocument9 pagesWell Head Chistmas TreeSatria 'igin' Girindra Nugraha100% (1)

- Filling The HoleDocument1 pageFilling The HolestevebeardsleyPas encore d'évaluation

- Tut-126 ProgramDocument28 pagesTut-126 Programhamdi1000Pas encore d'évaluation

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsDocument2 pagesBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarPas encore d'évaluation

- Blank Well Control Toolbox SheetDocument8 pagesBlank Well Control Toolbox SheetAhmedPas encore d'évaluation

- DOE Guidance WBS PDFDocument18 pagesDOE Guidance WBS PDFEl KhanPas encore d'évaluation

- Salt TableDocument25 pagesSalt TableHappiness ImuetinyanPas encore d'évaluation

- Amal-18 Sta DDR#18 29-02-2020Document30 pagesAmal-18 Sta DDR#18 29-02-2020eng7mohamed7hashimPas encore d'évaluation

- (Training Documents) Strokes Bit To SurfaceDocument2 pages(Training Documents) Strokes Bit To SurfaceHeris SitompulPas encore d'évaluation

- Drilling FormulaeDocument112 pagesDrilling FormulaeHunterPas encore d'évaluation

- Surge - Swab ProgramDocument1 pageSurge - Swab ProgramHenry BritoPas encore d'évaluation

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarPas encore d'évaluation

- 14b-Kill Sheet PreparationDocument10 pages14b-Kill Sheet PreparationLorenaStămulescuPas encore d'évaluation

- Manzalai-07 Daily Mud Report (10!7!20)Document1 pageManzalai-07 Daily Mud Report (10!7!20)Sharjeel AhmedPas encore d'évaluation

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiPas encore d'évaluation

- Defining Multilateral WellsDocument2 pagesDefining Multilateral WellsNhat CaoPas encore d'évaluation

- Well Control Data Sheet: Vertical WellsDocument2 pagesWell Control Data Sheet: Vertical WellsscrbdgharaviPas encore d'évaluation

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDocument8 pagesENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiPas encore d'évaluation

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranPas encore d'évaluation

- Swell Packer Case HistoriesDocument32 pagesSwell Packer Case Historiesapi-16218084Pas encore d'évaluation

- Bit Hyd Program - 1 1Document19 pagesBit Hyd Program - 1 1Heris SitompulPas encore d'évaluation

- Refinery Complexity IndexDocument66 pagesRefinery Complexity IndexyuliaPas encore d'évaluation

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsD'EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsPas encore d'évaluation

- Mud Engineer Tool Box - 050603Document46 pagesMud Engineer Tool Box - 050603SaravanaPas encore d'évaluation

- CDAMnemonicsDocument18 pagesCDAMnemonicsvanthodcPas encore d'évaluation

- Kick ToleranceDocument30 pagesKick ToleranceJoseph Oracion100% (3)

- 15 Day Well Service OperationsDocument3 pages15 Day Well Service OperationsOussPas encore d'évaluation

- 20 in Surf - 94 PPFDocument12 pages20 in Surf - 94 PPFAnonymous XbmoAFtIPas encore d'évaluation

- Kick Tolerance FactorDocument1 pageKick Tolerance FactorAhmedPas encore d'évaluation

- PSA 2006 - 12 - Requirements For CCTV Installation PDFDocument20 pagesPSA 2006 - 12 - Requirements For CCTV Installation PDFRaj RamachandranPas encore d'évaluation

- Well Engineering Guideline For Documentation of SISO-SIPROD Operations Rev 3 PDFDocument85 pagesWell Engineering Guideline For Documentation of SISO-SIPROD Operations Rev 3 PDFredseasearcherPas encore d'évaluation

- 0.0X.Basic Well Service OperationDocument10 pages0.0X.Basic Well Service OperationJujupPas encore d'évaluation

- Coiled Tubing Operation PDFDocument51 pagesCoiled Tubing Operation PDFMaleja Perpiñan Barrios89% (19)

- Drilling Mechanics - 7 Optimizing ROPDocument14 pagesDrilling Mechanics - 7 Optimizing ROPMaría MarquinaPas encore d'évaluation

- Peralatan PemboranDocument42 pagesPeralatan PemboranJimmy Agung Silitonga100% (1)

- Annular Pressure LossDocument2 pagesAnnular Pressure LossHenry BritoPas encore d'évaluation

- Fundamentals and Applications of Bionic Drilling FluidsD'EverandFundamentals and Applications of Bionic Drilling FluidsPas encore d'évaluation

- Well DataDocument5 pagesWell Datamohamed elshemyPas encore d'évaluation

- Api Casing Design: Design Parameters Loads at A DepthDocument2 pagesApi Casing Design: Design Parameters Loads at A DepthChak AlGhazelPas encore d'évaluation

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Document1 pageAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikPas encore d'évaluation

- Cementing: Habiburrohman, B.Eng, M.EngDocument52 pagesCementing: Habiburrohman, B.Eng, M.EngNamwangala Rashid NatinduPas encore d'évaluation

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoPas encore d'évaluation

- Pickering 1-18 Intermediate: Inner CSNGDocument1 pagePickering 1-18 Intermediate: Inner CSNGscrbdgharaviPas encore d'évaluation

- Cementing Design Liner GeneralDocument5 pagesCementing Design Liner GeneralnkhamidyPas encore d'évaluation

- Hole Size " Casing Size " Casing Weight LB/FT HWDP Size " DP Size " DC Size "Document2 pagesHole Size " Casing Size " Casing Weight LB/FT HWDP Size " DP Size " DC Size "PawanDeepSinghPas encore d'évaluation

- He-E10 Well MontageDocument1 pageHe-E10 Well MontageSaeid OrangiPas encore d'évaluation

- DDR 27-10Document1 pageDDR 27-10GPCPas encore d'évaluation

- Wellbore Schematic: GOK-12 - End of Well ReportDocument5 pagesWellbore Schematic: GOK-12 - End of Well Report-BloodSeeker-Pas encore d'évaluation

- Field Fluids QaqcDocument38 pagesField Fluids QaqcscrbdgharaviPas encore d'évaluation

- Bha# 4 Fishing With Spear Assy 1227 Grapple 3032Document1 pageBha# 4 Fishing With Spear Assy 1227 Grapple 3032Ivan Dario Benavides BonillaPas encore d'évaluation

- Schubert IADC WC ConferenceDocument31 pagesSchubert IADC WC ConferenceNekyneky NekyPas encore d'évaluation

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- WELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)Document5 pagesWELL: HH 83/1D: WIND SPEED at 6:00 AM 44-46 KNTS. (N-NW)anon_975742003Pas encore d'évaluation

- Drilling Technology and Costs - Chapter - 6Document51 pagesDrilling Technology and Costs - Chapter - 6zdq02Pas encore d'évaluation

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoPas encore d'évaluation

- Reverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesDocument5 pagesReverse-Circulation Cementing and Foamed Latex Cement Enable Drilling in Lost - Circulation ZonesRMolina65Pas encore d'évaluation

- Hosan 1 EWOR Final CheckDocument40 pagesHosan 1 EWOR Final CheckvengurionPas encore d'évaluation

- Cement Plug CalculationDocument7 pagesCement Plug CalculationEmad JamshidiPas encore d'évaluation

- Well Data Summary ProgramDocument13 pagesWell Data Summary ProgramTemitope BelloPas encore d'évaluation

- ADVANTAGE Hydraulics Spreadsheet Report: Case - RomaniaDocument1 pageADVANTAGE Hydraulics Spreadsheet Report: Case - RomaniatibismtxPas encore d'évaluation

- 37 - Primary CementationDocument2 pages37 - Primary CementationscrbdgharaviPas encore d'évaluation

- Petani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)Document30 pagesPetani-P18 7in CSG Confirmation Cementing Program Rev0.0 (Sept 12, 2022)handokoPas encore d'évaluation

- Well Plan Release NotesDocument28 pagesWell Plan Release Notesahmed_497959294Pas encore d'évaluation

- Drillers Method Report Kick ToleranceDocument23 pagesDrillers Method Report Kick ToleranceDylan Ho100% (1)

- Calculate Leak Off TestDocument5 pagesCalculate Leak Off Testmt59cool2089Pas encore d'évaluation

- Basics of Well ControlDocument45 pagesBasics of Well ControlRocard NgomaPas encore d'évaluation

- Third EAGE Workshop On Practical Reservoir On Practical Reservoir Monitoring MonitoringDocument4 pagesThird EAGE Workshop On Practical Reservoir On Practical Reservoir Monitoring Monitoringreza khPas encore d'évaluation

- Material Change Consultation Announcement Relating To WTI Crude Oil FuturesDocument7 pagesMaterial Change Consultation Announcement Relating To WTI Crude Oil Futuresreza khPas encore d'évaluation

- Managing Your Money 2019-2020Document8 pagesManaging Your Money 2019-2020Jaan KalderPas encore d'évaluation

- Petroleum Economics and Management: Applied Graduate StudiesDocument2 pagesPetroleum Economics and Management: Applied Graduate StudiestonytrujilloPas encore d'évaluation

- Material Change Consultation Announcement Relating To WTI Crude Oil FuturesDocument7 pagesMaterial Change Consultation Announcement Relating To WTI Crude Oil Futuresreza khPas encore d'évaluation

- What Is Suspected Drug ActivityDocument5 pagesWhat Is Suspected Drug Activityreza khPas encore d'évaluation

- Mass Transfer CoefficientsDocument12 pagesMass Transfer CoefficientsAkash Goyal100% (1)

- 2019 Official Grand Slam Rule BookDocument84 pages2019 Official Grand Slam Rule BooknapierlogsPas encore d'évaluation

- 2Document7 pages2reza khPas encore d'évaluation

- WHO Growth Chart ExplanationDocument58 pagesWHO Growth Chart Explanation170692Pas encore d'évaluation

- GRE Guide Table1aDocument2 pagesGRE Guide Table1aCarolina González RestrepoPas encore d'évaluation

- Criminal Record ChecksDocument6 pagesCriminal Record Checksreza khPas encore d'évaluation

- Customer Service Exp.Document15 pagesCustomer Service Exp.Muhammad NaeemPas encore d'évaluation

- Part 1-Itf Rules of TennisDocument16 pagesPart 1-Itf Rules of Tennisreza khPas encore d'évaluation

- Chapter Two Literature Review and Theoretical BackgroundDocument24 pagesChapter Two Literature Review and Theoretical Backgroundreza khPas encore d'évaluation

- Chapter Two Literature Review and Theoretical BackgroundDocument24 pagesChapter Two Literature Review and Theoretical Backgroundreza khPas encore d'évaluation

- Numpy For Matlab UserDocument17 pagesNumpy For Matlab Userreza khPas encore d'évaluation

- Attachment E: Torque and Drag in ERD Wells: RotationDocument3 pagesAttachment E: Torque and Drag in ERD Wells: RotationbyedPas encore d'évaluation

- Challenge of Modeling Drilling SystemDocument10 pagesChallenge of Modeling Drilling Systemreza khPas encore d'évaluation

- Assessing Writing: Eun-Young Julia KimDocument3 pagesAssessing Writing: Eun-Young Julia Kimreza khPas encore d'évaluation

- SPE 131922 BHA and Drill String Fundamentals Technology Training For BeginnersDocument13 pagesSPE 131922 BHA and Drill String Fundamentals Technology Training For Beginnersmohamedabbas_us3813Pas encore d'évaluation

- Pressures in A Well 101Document1 pagePressures in A Well 101shoaib1985Pas encore d'évaluation

- Assessing Writing: Eun-Young Julia KimDocument3 pagesAssessing Writing: Eun-Young Julia Kimreza khPas encore d'évaluation

- (Doi 10.2118 - 28774-Ms) Agawani, Mamdouh Rahman, S.S. Maidla, E.E. - (Society of Petroleum Engineers SPE Asia Pacific Oil and Gas Conference - Melbourne, Australia (1994!11!07) ) SPE Asia Pacific ODocument9 pages(Doi 10.2118 - 28774-Ms) Agawani, Mamdouh Rahman, S.S. Maidla, E.E. - (Society of Petroleum Engineers SPE Asia Pacific Oil and Gas Conference - Melbourne, Australia (1994!11!07) ) SPE Asia Pacific Ofaishal hafizhPas encore d'évaluation

- PDF The Effect of Bottomhole Assembly Dynamics On The TrajectoryDocument4 pagesPDF The Effect of Bottomhole Assembly Dynamics On The Trajectoryreza khPas encore d'évaluation

- PunctuationsDocument2 pagesPunctuationsReza KhoshPas encore d'évaluation

- Permanent-Type Well Completion: SPE 231-GDocument6 pagesPermanent-Type Well Completion: SPE 231-GAndre YudhistiraPas encore d'évaluation

- Oil WellDocument6 pagesOil WellMustafa AnwarPas encore d'évaluation

- Pre-Job Information Sheet: Drilling Tools and Remedial Trackmaster Plus - Whipstock Information SheetDocument1 pagePre-Job Information Sheet: Drilling Tools and Remedial Trackmaster Plus - Whipstock Information SheetBalkis FatihaPas encore d'évaluation

- Kill Sheet UcupDocument3 pagesKill Sheet UcupYusuf ArifinPas encore d'évaluation

- Degassing StationsDocument12 pagesDegassing StationsashrafsaberPas encore d'évaluation

- Snubbing Unit Brings Middle East Well With Underground Blowout Under ControlDocument2 pagesSnubbing Unit Brings Middle East Well With Underground Blowout Under ControlRaditheo ZeoPas encore d'évaluation

- FBL FormDocument2 pagesFBL FormMarco Dela CruzPas encore d'évaluation

- CLJOC (Cuulong Joint Operating Company) : SD-25P-STDocument2 pagesCLJOC (Cuulong Joint Operating Company) : SD-25P-STThem Bui XuanPas encore d'évaluation

- Adaptive PI Control of Bottom Hole Pressurre During Oil We - 201t8 - IFAC PapersOnDocument6 pagesAdaptive PI Control of Bottom Hole Pressurre During Oil We - 201t8 - IFAC PapersOnsrhtsrtjyjmngcmnuPas encore d'évaluation

- Drilling Program Sumur C Onshore / Trisakti Teknik Pemboran LanjutanDocument1 pageDrilling Program Sumur C Onshore / Trisakti Teknik Pemboran LanjutanAbdu Rizky MahulauwPas encore d'évaluation

- Bit & Pressure Loss CalculationsDocument2 pagesBit & Pressure Loss CalculationsnjileoPas encore d'évaluation

- 3 +The+Anatomy+of+a+Well+LogDocument23 pages3 +The+Anatomy+of+a+Well+LogKeon GangadeenPas encore d'évaluation

- Cge578 Chapter 5 Well CPLDocument52 pagesCge578 Chapter 5 Well CPLNurfatini Che100% (2)

- Reservoir and WellheadDocument31 pagesReservoir and WellheadAbdalah BakayokoPas encore d'évaluation

- Introduction of Blowout in Oil Drilling - WikipediaDocument3 pagesIntroduction of Blowout in Oil Drilling - WikipediaFaiz AhmadPas encore d'évaluation

- 7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDDocument1 page7" Liner Cement Calculation Proposal: Marvin Peter Bjservices (M) SDN BHDshahaljawaie87Pas encore d'évaluation

- Hosan 1 EWOR Final CheckDocument40 pagesHosan 1 EWOR Final CheckvengurionPas encore d'évaluation

- MBH-A1 Completion Program - SignedDocument76 pagesMBH-A1 Completion Program - Signed杨建政Pas encore d'évaluation