Académique Documents

Professionnel Documents

Culture Documents

Tuercas de Eje Posterior AXILOCK

Transféré par

eloyabnerCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tuercas de Eje Posterior AXILOCK

Transféré par

eloyabnerDroits d'auteur :

Formats disponibles

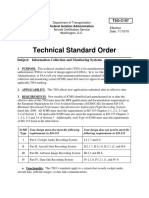

Unitized Wheel Bearing Nut System

Installation and Removal Procedures

Pre-Installation Procedure Axilok Size

Marking Locking Clip

Installation Procedure

Support Rivet

Nut Body

Before installing Axilok, check the following: NOTE

1. Inspect Axilok for two locking clips. Refer to Figure 1. Locking When using the Axilok product with a bearing containing an internal spacer,

Clip

● Each locking clip should be securely fastened to the nut body and have a follow the original equipment manufacturer’s torque specification. Ensure locking

rivet that passes through the top of the locking clip body. clips protrude through the adjustment slots after applying torque. If locking clips

● Each locking clip should have a locking clip tab protruding completely do not protrude through the adjustment slots, rotate the Axilok product slightly

through the retainer cage adjustment slot (when properly aligned and not clockwise. Refer to Figures 2, 3, and 4. If locking clips are broken or damaged,

compressed by a socket). Refer to figures 2, 3, and 4. replace the Axilok product and repeat the installation instructions.

● Locking clips should not be bent, cracked or broken.

● Determine if you have slot style or D flat style axle and use appropriate Equipment Required:

Axilok product. See Figure 6. ● Six-point socket, sized according to the markings stamped on the face

Locking Clip Retainer Cage of the Axilok. Refer to Figure 1 and Table 1.

2. Inspect Axilok retainer cage condition. Tab Socket Size

Marketing

● Torque wrench.

Retainer Cage Slot

● There should be no cracks or other damage to the retainer cage. ● Dial indicator.

● Retainer cage should be secured to the nut body and not fall off when the

locking clips are compressed by the socket. AXILOK Component View 1. Before installation, perform pre-installation checks:

FIGURE 1.

● The retainer cage tab or “D” flat should be free of damage, such as cracks, ● Be sure the spindle slot is clean and free of burrs and foreign material

scarring, gouges or distortion. Refer to Figure 6. before installing Axilok.

● Be sure the thread size is the same on both components.

3. Inspect Axilok threads. Locking ● Put a few drops of oil through one of the retainer cage holes. This will

● The threads should show no sign of wear or damage. Clip Tab ensure friction-free movement.

● Wipe the threads to remove excess oil or debris.

2. Put Axilok in the correct size six-point socket (refer to Table 1) and verify that

4. If Axilok fails any of the checks above, the Axilok is unfit for use. DO NOT USE. the locking clips are compressed. Refer to Figure 2. Retainer cage should

Replace the unfit Axilok with a new Axilok and repeat all checks. spin freely.

5. Free rotation inspection. This test will check for nut and socket compatibility. 3. Align Axilok retainer cage tab or “D” flat. Be sure to start and run down the

● With correct size six-point socket turned upside down, insert Axilok Axilok by hand. Do not use power tools. Rotate the socket clockwise until

completely into the socket, compressing the locking clips. Refer to Locking contacting bearing. Refer to Figure 9.

Figure 8. Clip

● Retainer cage should spin freely with no interference between locking 4. Using a properly calibrated torque wrench, torque Axilok to the initial torque of

clip tabs and retainer cage. Tab Engaged Tab Disengaged 200 ft-lbs, rotate hub 1 full turn minimum.

● If locking clip tabs interfere with rotation of the retainer cage, the socket Locking ● Re-Torque to 200 ft-lbs, rotate 1 full turn min.

is not fully compressing the locking clips. This indicates that the socket is Clip ● Re-Torque to 200 ft-lbs

the incorrect size, worn or out of specifications and must be replaced. ● Back off ½ turn

● Torque to 75 ft-lbs, rotate 1 full turn min.

6-Point ● Back off 1/10 turn (1 wheel stud) Check Endplay. Refer to Figure 10.

6-Point Locking Clip

Socket

Socket Compressed

5. Remove socket and verify locking clip tabs have engaged the adjustment slots

in the retainer cage. Refer to Figures 2, 3, and 4.

Checking Position of Locking Clip Tabs

FIGURE 2.

*Light burnishing of the retainer cage bearing surface after use is normal. 6. Measure end play using a dial indicator. If correct end play is not achieved,

adjust according to adjustment increments shown in Table 1.

● Rotate Axilok clockwise to reduce end play.

Failure to observe the following warnings can result in separation of (Example: from 0.004” to 0.002” end play.)

the wheel from the vehicle, creating a risk of death or serious injury. ● Rotate Axilok counterclockwise to increase end play.

(Example: from 0.001” to 0.003” end play.)

●This same procedure can be used to achieve a controlled pre-load condition.

This Axilok product is not compatible with all axles currently in use. Do not use this Axilok

product on an incompatible axle. Review axle or vehicle manufacturer’s literature to determine

(Example: from 0.001” end play to 0.001” pre-load.)

if the Axilok product is compatible. Inappropriate use could produce a “wheel off” condition, INCORRECT 7. After end play adjustment, make sure that both locking clip tabs are protruding

which may result in serious bodily injury and/or equipment failure.

Broken Locking Tab through the slots in the retainer cage. Refer to Figures 2, 3, and 4.

If Axilok has not been selected as standard equipment by the Original Equipment Manufacturer

(OEM), do the following: Review axle manufacturer’s bulletins to be sure axle is compatible

with Axilok.

Locking Clip Tabs Broken

FIGURE 3.

AXILOK Part Socket Initial Initial Final Final Increments

Number Size Torque Backoff Torque Backoff of Adjustment Failure to observe the following warnings can result in separation of

6-Point (in lbs/ft) (in lbs/ft) (per slot) the wheel from the vehicle, creating a risk of death or serious injury.

AX-12-1500D 39129 2 1/8” 200 1/2 turn 75 1/10 turn 0.0038”

AX-18-1500 39131 2 1/8” 200 1/2 turn 75 1/10 turn 0.0025”

Proper maintenance and handling practices are critical. Always follow installation instructions

AX-12-1750D 39121 3 1/4” 200 1/2 turn 75 1/10 turn 0.0030”

INCORRECT and maintain proper lubrication.

AX-12-2625 39023 3 1/4” 200 1/2 turn 75 1/10 turn 0.0030”

AX-16-2625 39025 3 1/4” 200 1/2 turn 75 1/10 turn 0.0022” Improperly Positioned Do not use this Axilok product if locking clips are broken or damaged.

AX-12-3250 39043 4” 200 1/2 turn 75 1/10 turn 0.0023” Locking Tab

AX-12-3480 39026 4 1/8” 200 1/2 turn 75 1/10 turn 0.0023” Always inspect the installation of the Axilok product when it is completed to ensure that locking

clip tabs protrude through the adjustment slots.

See Installation Procedure for Full Details

If locking clip tabs do not protrude through the adjustment slots, rotate Axilok slightly clockwise.

AXILOK Part Numbers and Installation Torque Refer to Figures 2, 3, and 4. If locking clip(s) are broken, replace Axilok and repeat installation

procedures.

TABLE 1.

Locking Clip TabsImproperly Positioned

FIGURE 4.

Place Axilok in correct size 3.5

Removal Procedure

socket and check for free Pre-Load End-Play

3.0

rotation.

TMC*

2.5 NOTE

FIGURE 8. Recommended

Component Life

Do not use chisel, hammer or any power tool to remove the Axilok product.

2.0

Range

1.5 Equipment Required:

● Six-point socket, sized according to the markings stamped on the face of the

1.0

Axilok. Refer to Figure 1 and Table 1.

0.5 ● Torque wrench.

0

.004 .002 0 .002 .004 .006 .008 1. Install correct size six-point socket completely over the hex of the Axilok. Be sure

*TMC – The Maintenance Council of ATA. that both the locking clips are completely disengaged from the retainer

Start Axilok by hand Initial Setting cage, permitting free rotation. Refer to Figure 2.

FIGURE 9.

Recommended End Play Range 2. Turn counterclockwise to remove Axilok. If Axilok does not move freely, stop

FIGURE 5. removal. Check that the socket is completely and fully engaged on the Axilok

and that the locking clips are fully retracted from the retainer cage slots. If

Axilok still will not turn freely, rotate slightly clockwise to tighten, and then

Axilok for Radius Slot Style Axle Axilok for D Flat Style Axle loosen again. The nut should rotate counterclockwise freely.

3. Continue counterclockwise rotation until Axilok threads disengage from the

spindle threads.

Retainer Retainer Cage

Cage Tab D Flat

Torque Axilok to initial torque

value while rotating hub to

properly seat bearings.

FIGURE 10.

Retainer Cage

Adjustment Slot

Axilok with retainer cage tab should only be used for radius slot style axle.

Axilok with retainer cage D flat should only be used for D flat style axle. is manufactured by

METFORM, LLC

A division of MacLean-Fogg Component Solutions

Axilok Styles

FIGURE 6.

SVA-ENG-W-009 Rev. A

Vous aimerez peut-être aussi

- Chevy Differentials: How to Rebuild the 10- and 12-BoltD'EverandChevy Differentials: How to Rebuild the 10- and 12-BoltÉvaluation : 5 sur 5 étoiles5/5 (8)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Brake EntretienDocument12 pagesBrake Entretienrene chapdelainePas encore d'évaluation

- Gives You The Techlock System AdvantageDocument8 pagesGives You The Techlock System AdvantageMTK2016Pas encore d'évaluation

- v40 Tailgate Lock Assembly ReplacingDocument2 pagesv40 Tailgate Lock Assembly ReplacingDaniel ParryPas encore d'évaluation

- Axilok InstallatTuercasDocument1 pageAxilok InstallatTuercasalxsscabal100% (1)

- Flowserve Pusher Seal ManualDocument16 pagesFlowserve Pusher Seal ManualNikhil Princeton AndradePas encore d'évaluation

- Mahula de PeçasDocument411 pagesMahula de PeçasRUBSONMOTAPas encore d'évaluation

- GS-KB55S Operating InstuctionsDocument8 pagesGS-KB55S Operating InstuctionsPiero CaprettiPas encore d'évaluation

- คู่มือซ่อมเครื่องยนต์นิสสันเทียน่าJ31เครื่องVQ23Document152 pagesคู่มือซ่อมเครื่องยนต์นิสสันเทียน่าJ31เครื่องVQ23Nuttapong SukganPas encore d'évaluation

- Para-Flex Couplings: Includes ATEX Certified Couplings Instruction ManualDocument4 pagesPara-Flex Couplings: Includes ATEX Certified Couplings Instruction Manualrrobles011Pas encore d'évaluation

- Alcoa CamlocDocument81 pagesAlcoa CamlocWK SinnPas encore d'évaluation

- SV-860 Rev02Document41 pagesSV-860 Rev02Amjad HossenPas encore d'évaluation

- Operating Instructions: Safety Module Combination KB55-EB75KS EU-SG 333 / EU-SG 313 GeneralDocument8 pagesOperating Instructions: Safety Module Combination KB55-EB75KS EU-SG 333 / EU-SG 313 GeneralPiero CaprettiPas encore d'évaluation

- BR3 002 ManualDocument10 pagesBR3 002 ManualEric LempkePas encore d'évaluation

- 2531Document5 pages2531sangkil05Pas encore d'évaluation

- Instructions & Precautions: Complete Strut AssemblyDocument2 pagesInstructions & Precautions: Complete Strut AssemblyOKIDI Thomas BecketPas encore d'évaluation

- SI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemDocument1 pageSI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemboomissyPas encore d'évaluation

- Record HubsDocument2 pagesRecord HubsJerry JohnsonPas encore d'évaluation

- Eich Split Bearing Instruction Manual 07 19Document5 pagesEich Split Bearing Instruction Manual 07 19huseyinPas encore d'évaluation

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETPas encore d'évaluation

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_Pas encore d'évaluation

- Note!: Shock Absorber For Honda Forza 350-MY2020Document8 pagesNote!: Shock Absorber For Honda Forza 350-MY2020Quang Trong ChuPas encore d'évaluation

- ME432STI Service Manual - Pages.1 24Document24 pagesME432STI Service Manual - Pages.1 24Paul MartinPas encore d'évaluation

- INS0008 FordAOD KickdownDocument4 pagesINS0008 FordAOD KickdownAndreas HochmeisterPas encore d'évaluation

- Bearing Mounting Procedure: (Page 1 of 6)Document6 pagesBearing Mounting Procedure: (Page 1 of 6)JoséMiguelSánchezGPas encore d'évaluation

- MODEL H6162 Trailer Screw Jack 2000 LB.: Instruction SheetDocument2 pagesMODEL H6162 Trailer Screw Jack 2000 LB.: Instruction Sheetjunaid76Pas encore d'évaluation

- Ratchet Style Jack Stands: Operating Instructions & Parts ManualDocument12 pagesRatchet Style Jack Stands: Operating Instructions & Parts ManualxtusPas encore d'évaluation

- EVK Seal ManualDocument18 pagesEVK Seal Manualgelo_17100% (1)

- GB 82 InstallationDocument14 pagesGB 82 InstallationAkbarmoradiPas encore d'évaluation

- Wheel and Tire Assembly - Remove and Install ALL Derivatives 0.20 Used WithinsDocument6 pagesWheel and Tire Assembly - Remove and Install ALL Derivatives 0.20 Used WithinsKhaled AlhamawiPas encore d'évaluation

- PUB-ome 100 SuspensionDocument10 pagesPUB-ome 100 SuspensionJuan Camilo García DuránPas encore d'évaluation

- MKA-55 Stabilizer Kit Instruction Sheet 2374952rcDocument16 pagesMKA-55 Stabilizer Kit Instruction Sheet 2374952rcCoryPas encore d'évaluation

- Instruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsDocument2 pagesInstruction Manual For DODGE Setscrew, Eccentric Collar, D-Lok, H-E Series, E-Z Kleen, Ultra Kleen and Food Safe Mounted Ball BearingsRichard VachonPas encore d'évaluation

- XT 2012 Brake SystemDocument1 pageXT 2012 Brake SystemMarPas encore d'évaluation

- Omega Rail InstructionsDocument1 pageOmega Rail InstructionsPanthep PattongPas encore d'évaluation

- QRC Rockers JK4dr 3 0Document8 pagesQRC Rockers JK4dr 3 0Camilo ArenasPas encore d'évaluation

- Cooling Tower Fan 301 Sr. DS Installation Manual 2006.12Document8 pagesCooling Tower Fan 301 Sr. DS Installation Manual 2006.12Krishna BadhePas encore d'évaluation

- Trail-Safe™ Nissan Patrol Y60 Knuckle Wiper Seal Kit: Usa Toll Free: WorldwideDocument6 pagesTrail-Safe™ Nissan Patrol Y60 Knuckle Wiper Seal Kit: Usa Toll Free: WorldwideSlavenko DolinaPas encore d'évaluation

- Installation and Removal of Q.D. and Taper Lock Bushings: Exercise E223-S05-EXR-RV1.wpdDocument7 pagesInstallation and Removal of Q.D. and Taper Lock Bushings: Exercise E223-S05-EXR-RV1.wpdirawan malikPas encore d'évaluation

- Backstop Assembly CycloDocument3 pagesBackstop Assembly CycloJonathan ApontePas encore d'évaluation

- Seat Belt, Srs AirbagDocument16 pagesSeat Belt, Srs AirbagJipsonCuevaPas encore d'évaluation

- Free HubDocument4 pagesFree HubDony WinarnoPas encore d'évaluation

- Applications & Parts: SliderDocument6 pagesApplications & Parts: SliderperryPas encore d'évaluation

- DM HB0003 06 EngDocument17 pagesDM HB0003 06 EngGaudencio LingamenPas encore d'évaluation

- Reconnect Battery or Replace Fuse and Enjoy Your New WheelDocument1 pageReconnect Battery or Replace Fuse and Enjoy Your New WheelLuis SilvaPas encore d'évaluation

- ParrotDocument1 pageParrotMasterbin2010Pas encore d'évaluation

- Technical Service Information: Component Rebuild SectionDocument4 pagesTechnical Service Information: Component Rebuild SectionEdgarditoPas encore d'évaluation

- B-02 Mechnical Seal For SBPO LubeDocument8 pagesB-02 Mechnical Seal For SBPO LubeMarvin DuartePas encore d'évaluation

- Slide Cam Pulley: Instructions ManualDocument5 pagesSlide Cam Pulley: Instructions Manualhenrysaputra168Pas encore d'évaluation

- Wombot Exilis Kit Assembly ManualDocument67 pagesWombot Exilis Kit Assembly ManualwindharmenPas encore d'évaluation

- Manguito de FijaciónDocument39 pagesManguito de FijaciónIndustrial Estrumec Ltda.Pas encore d'évaluation

- Ремни и Подушки безопасности LGSRS-WE-0552Document117 pagesРемни и Подушки безопасности LGSRS-WE-0552Dmitry BondarPas encore d'évaluation

- PDFDocument10 pagesPDFPaul HuaraychiriPas encore d'évaluation

- Pilot 53in Sbach 342 ManualDocument23 pagesPilot 53in Sbach 342 ManualAlvaro ReyesPas encore d'évaluation

- Act Yon B 2402001Document2 pagesAct Yon B 2402001Sebastian Guzman camachoPas encore d'évaluation

- 6T40 Gen2 3 Zip inDocument10 pages6T40 Gen2 3 Zip inFernando Cedillo100% (1)

- Ez Lock - Usage and Maintenance Rev2 - 2020.1.16Document12 pagesEz Lock - Usage and Maintenance Rev2 - 2020.1.16Carol MurphyPas encore d'évaluation

- Rear Derailleur: Dealer's ManualDocument20 pagesRear Derailleur: Dealer's Manualnadeem javedPas encore d'évaluation

- Hausler 450 Se V2 Carbon Fiber Kit Builder's ManualDocument11 pagesHausler 450 Se V2 Carbon Fiber Kit Builder's ManualRiccardo StoccaPas encore d'évaluation

- Davco 487Document2 pagesDavco 487eloyabnerPas encore d'évaluation

- Manual Bateria Caterpillar PDFDocument373 pagesManual Bateria Caterpillar PDFFabian Eduardo Durán MartinezPas encore d'évaluation

- Tas 85Document3 pagesTas 85eloyabnerPas encore d'évaluation

- JOST Parts CatalogDocument44 pagesJOST Parts CatalogeloyabnerPas encore d'évaluation

- Compressor New StarDocument12 pagesCompressor New Stareloyabner100% (1)

- FreightlinerM2 112Document6 pagesFreightlinerM2 112eloyabnerPas encore d'évaluation

- Compresores WabcoDocument24 pagesCompresores WabcoQike FlowersPas encore d'évaluation

- DM Advantage Conversion Super Kits Part Nos. 995568 (Standard) and 995575 (Long-Bearing Spacer Applications), Includes 61 MM Bearing and Spacer KitsDocument2 pagesDM Advantage Conversion Super Kits Part Nos. 995568 (Standard) and 995575 (Long-Bearing Spacer Applications), Includes 61 MM Bearing and Spacer Kitseloyabner0% (1)

- Technology, LLC: Fuel Pro 382 Service PartsDocument4 pagesTechnology, LLC: Fuel Pro 382 Service PartsCarlos RiffoPas encore d'évaluation

- Cat TDTODocument4 pagesCat TDTOalexanderPas encore d'évaluation

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDocument12 pagesKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerPas encore d'évaluation

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner100% (2)

- TRW Cross ReferenceDocument2 pagesTRW Cross Referenceeloyabner100% (2)

- Clutch Solo y EasypedalDocument42 pagesClutch Solo y EasypedalaxollPas encore d'évaluation

- 14X Meritor Service ManualDocument113 pages14X Meritor Service Manualeloyabner100% (8)

- Ajuste Embrague Servicio Pesado (En Español)Document2 pagesAjuste Embrague Servicio Pesado (En Español)eloyabnerPas encore d'évaluation

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDocument12 pagesKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerPas encore d'évaluation

- Illustrated Parts List: Dana Spicer Tandem AxlesDocument24 pagesIllustrated Parts List: Dana Spicer Tandem AxleseloyabnerPas encore d'évaluation

- 07 EPANET Tutorial-SlidesDocument26 pages07 EPANET Tutorial-SlidesTarhata Kalim100% (1)

- Virtual Feeder Segregation Using IIoT and Cloud TechnologiesDocument7 pagesVirtual Feeder Segregation Using IIoT and Cloud Technologiespjgandhi100% (2)

- D15 Hybrid P1 QPDocument6 pagesD15 Hybrid P1 QPShaameswary AnnadoraiPas encore d'évaluation

- EC105Document14 pagesEC105api-3853441Pas encore d'évaluation

- Chanakya: For The Indian Television Series Based On His Life, SeeDocument11 pagesChanakya: For The Indian Television Series Based On His Life, SeeTrinadh CrazyguyPas encore d'évaluation

- Line Integrals in The Plane: 4. 4A. Plane Vector FieldsDocument7 pagesLine Integrals in The Plane: 4. 4A. Plane Vector FieldsShaip DautiPas encore d'évaluation

- UK Tabloids and Broadsheet NewspapersDocument14 pagesUK Tabloids and Broadsheet NewspapersBianca KissPas encore d'évaluation

- Acc 106 Account ReceivablesDocument40 pagesAcc 106 Account ReceivablesAmirah NordinPas encore d'évaluation

- Wordbank 15 Youtube Writeabout1Document2 pagesWordbank 15 Youtube Writeabout1Olga VaizburgPas encore d'évaluation

- Written Report in Instructional PlanningDocument6 pagesWritten Report in Instructional PlanningRose Aura HerialesPas encore d'évaluation

- Onco Case StudyDocument2 pagesOnco Case StudyAllenPas encore d'évaluation

- Discover It For StudentsDocument1 pageDiscover It For StudentsVinod ChintalapudiPas encore d'évaluation

- Heisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Document16 pagesHeisenberg, "Über Den Anschaulichen Inhalt Der Quantentheoretischen Kinematik Und Mechanik"Benjamin Crowell0% (1)

- Florida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts EvDocument1 pageFlorida Gov. Ron DeSantis Provides Update As Hurricane Ian Prompts Evedwinbramosmac.comPas encore d'évaluation

- A Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixDocument12 pagesA Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixPraveen KumarPas encore d'évaluation

- 12 Constructor and DistructorDocument15 pages12 Constructor and DistructorJatin BhasinPas encore d'évaluation

- Image Hosting SitesDocument16 pagesImage Hosting SitesstudentPas encore d'évaluation

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahPas encore d'évaluation

- Intergard 475HS - Part B - EVA046 - GBR - ENG PDFDocument10 pagesIntergard 475HS - Part B - EVA046 - GBR - ENG PDFMohamed NouzerPas encore d'évaluation

- License Fee PaidDocument1 pageLicense Fee Paidmy nPas encore d'évaluation

- S O S Services Alert Level Help Sheet - REFERENCIALESDocument20 pagesS O S Services Alert Level Help Sheet - REFERENCIALESDavid Poma100% (1)

- Multi Core Architectures and ProgrammingDocument10 pagesMulti Core Architectures and ProgrammingRIYA GUPTAPas encore d'évaluation

- Sinamics g120 BrochureDocument16 pagesSinamics g120 BrochuremihacraciunPas encore d'évaluation

- March 2023 (v2) INDocument8 pagesMarch 2023 (v2) INmarwahamedabdallahPas encore d'évaluation

- ABS Electrical System Tiba 2Document8 pagesABS Electrical System Tiba 2ﺍﻟﻄﺎﺋﺮ ﺍﻟﺤﺰﻳﻦPas encore d'évaluation

- AT10 Meat Tech 1Document20 pagesAT10 Meat Tech 1Reubal Jr Orquin Reynaldo100% (1)

- Mang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Document52 pagesMang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Anh Quân TrầnPas encore d'évaluation

- Elerick Ron Cynthia 1983 SouthAfricaDocument4 pagesElerick Ron Cynthia 1983 SouthAfricathe missions networkPas encore d'évaluation

- Shades Eq Gloss Large Shade ChartDocument2 pagesShades Eq Gloss Large Shade ChartmeganPas encore d'évaluation

- Tso C197Document6 pagesTso C197rdpereirPas encore d'évaluation