Académique Documents

Professionnel Documents

Culture Documents

54 M.bow String Girder-10410-9

Transféré par

SANJEEV VERMADescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

54 M.bow String Girder-10410-9

Transféré par

SANJEEV VERMADroits d'auteur :

Formats disponibles

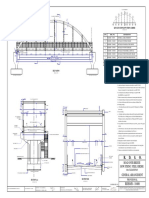

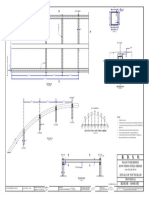

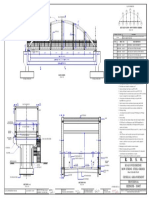

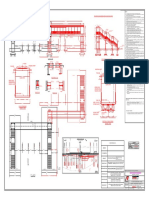

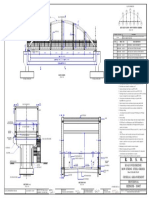

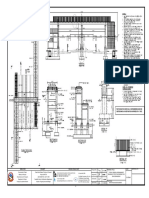

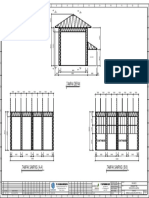

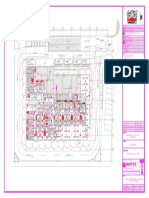

880 800 800 800

A F G

H

B B B

229

229

229

229

C C C C

D D D D

E E E E

860 860 860 860

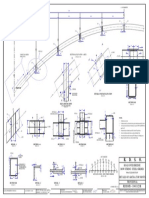

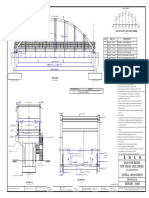

LONG.-GUIDE BEARING ASSEMBLY LGB TRANS.-GUIDE BEARING ASSEMBLY TGB FREE - BEARING ASSEMBLY FB FIXED - BEARING TGB

(SCALE 1:7.5) (SCALE 1:7.5) (SCALE 1:7.5) (SCALE 1:7.5)

X-SECTIONAL VIEW ACROSS LONGITUDINAL AXIS OF GIRDER (CENTER LINE OF THE GIRDER COINCIDES WITH CENTER LINE OF BEARING SHOWN)

2+2

419 3

STAINLESS STEEL PLATE 20

880 6 MM THICK, WELD 3mm

35

780 380

53

ELEVATION

35

(SCALE 1:7.5) 85 85

10 800

DETAIL X

3

700

10

50

60

STAINLESS STEEL PLATE

70

53 40x3x690, WELD 2mm STAINLESS STEEL

PLATE 35x3x590,

ELEVATION 420

600

590

53

WELD 2 MM

30

(SCALE 1:7.5) LEGEND SYMBOL

50 40 680 50 ELEVATION

880

PTFE SHEET 5 MM 860 (SCALE 1:7.5) HARDENED SURFACE 300 BHN MINIMUM

50

50 34 53 606 53 34 50 THICK, DIMPLED OR

MODULAR, PASTED IN

ELEVATION

50

STAINLESS STEEL PLATE DUST SEAL

2 MM DEEP RECESS 40x3x780 WELD 2mm

10 (SCALE 1:7.5)

POLY TETERA FLUORO ETHYLENE (PTFE)

5

500 380

53 34

HIGH STRENGTH BOLT

175

420

PISTON BASE

DUST SEAL 10x15 ALLROUND

600 SURFACE HARDENED TO

VIEW FROM TOP

195

300 BHN MINIMUM

5

VIEW FROM TOP PART C: BRASS RINGS 5

(SCALE 1:7.5) FOR RETAINING 550 NOTE:

175

ELASTOMER IN POT

4

1. All dimensions are in MM.

(SCALE 1:7.5)

PISTON WALL

2. The design is in accordance with IRC- 83 (PART-III)-2002.

650

800

195

420 10 3. The concrete in bed block shall be of min M40 GRADE.

420

175

4. Bearings shall be provided before concreting of deck slab is taken up.

606

500

880

ELEVATION

36

45

40

10

(SCALE 1:7.5) 5. Bearings shall be protected during concreting or providing holding down bolts

40

DETAIL Y operations. Any mortar or foreign material contaminating the bearing shall be

STAINLESS STEEL PLATE

195

419 completely removed.

6 MM THK, WELD 3 MM STAINLESS STEEL PLATE

ALL ROUND 35x3x590, WELD 2 MM ELASTOMERIC PAD STAINLESS STEEL PLATE 6. Manufacture & finishing of bearings shall be as per para 927.2 & 927.3 of IRC 83

175

SURFACE HARDENED TO

300 BHN MINIMUM

ELEVATION (NOT TO BE PROVIDED IN 6 MM THICK, WELD 3 MM Part III

(SCALE 1:7.5) FREE BEARING) ALL ROUND

7. Manufacturing tolerances shall be as per para 927.1 of IRC 83 Part III

5

8. Acceptance of bearing shall be as per para 928 of IRC 83 Part III.

195

STAINLESS STEEL PLATE 9. Material to be used for pot, piston and top plate including all guides, lugs etc shall

34 53

3

5

33x3x790 WELD 2 mm be of cast steel to IS 1030:1989 grade 340-570W.

5

50

3

10. All the flame cut, sawn or planed edges of the plates should be machined. All

50

sheared corners shall be rounded off with 2 MM radius.

VIEW FROM BOTTOM SURFACE HARDENED TO 50 700 50 11. For welding stainless steel sheet, M1 electrode type with stainless steel core wire as

PART A: TOP PLATE FOR LONG. GUIDE 300 BHN MINIMUM 380

per IRS: M-28-2012 shall be used.

(SCALE 1:7.5) 800

420 12. PTFE sheet shall be pure poly tetra fluoro ethylene, and shall be 4.5 mm thick,

600

having either dimples (hot pressed or moulded) or modules as per IRC 83 Part III.

VIEW FROM TOP VIEW FROM BOTTOM These shall be pasted in recess 2.5 MM deep in the bearing and the peel strength of

PART D: ELASTOMER VIEW FROM TOP PART F: TOP PLATE FOR TRANSVERSE GUIDE glue to be used shall not be less than 4 N/MM.

(SCALE 1:7.5)

PAD FOR BEARINGS PART E: POT FOR BEARINGS 13. Material to be used for wiper seal and dust seal shall be of microcellular

(SCALE 1:7.5) polychloroprene rubber or polythene foam & it's adhesion to metal shall be with

(SCALE 1:7.5) polychloroprene rubber based adhesive dunlop S-758, dendrite PC-65 or any other

800 50 700 50 equivalent brands.

PISTON 10

50 700 50

R5 14. All non-working surfaces shall be given protective coating comprising of 2 coats

419 of epoxy primer enriched with metallic zinc, one intermediate coat of high build

R209 epoxy paint reinforced with mio (micaceous iron oxide) & one coat of high

88

3 600 3

AFTER 15 MM

performance epoxy finish paint as per para 39.2.2 of IRS B1.

CURVE

580

15

DETAIL Y 15. All bearings shall be sent by manufacturer duly set. Marked with center line of

VIEW FROM BOTTOM

35

SURFACE HARDENED TO bearing along the girder and across it, along with the shipping mark of the bearing

ELEVATION

AFTER 40 MM

15

300 BHN MINIMUM 419

and fitted with transportation clamps. It is prohibited to open transportation clamps

PART B: PISTON FOR

50

(SCALE 1:7.5) ELEVATION

40

CURVE

50

40

before final assembly of the bearing on the girder without the presence of bearing

FREE/SLIDING BEARINGS (SCALE 1:7.5) R209 manufacturer representative.

(SCALE 1:7.5) 16. After the girders are properly leveled/ aligned and bearings tied to the girder using

Class 8.8 bolts, transportation clamps shall be opened and all expansion type

DETAIL X DETAIL Y bearing shall be set properly as per ambient temperature. Thereafter holes in

SURFACE HARDENED (SCALE 1:5) (SCALE 1:5) substructure already provided (shall be drilled at this stage if not already provided),

175

TO 300 BHN MINIMUM 175 shall be filled with holding down bolts and quickly grouted.

17. Anchor bolts shall be provided in holes (max. dia 40 MM) made in pier top/

OF BOTTOM LONG. BEAM

NUT pedestals.

OF SYMMETRY

600

18. Anchor bolts and nuts shall be hot dip galvanized 100 micron thick, as per IS:

175

FIXED BEARING BOTTOM LONG. BEAM LONG. GUIDE BEARING 4759.

175

90

800

800

KNURLING TOOL OR CHISELLING

32

ROUND WASHER FOR 32 DIA. BOLT

BOTTOM CROSS BEAM

ISOMETRIC THREAD

DIA.

R. D. S. O.

MIN EMBEDDED LENGTH 330

175

175

SURFACE ROUGHENED BY

12000

DIRECTION OF TRAFFIC ROAD OVER BRIDGE

OF BOTTOM LONG. BEAM

175

PISTON

175

BOW STRING STEEL GIRDER

54m CLEAR SPAN

50

WELD 2 MM ALL ROUND

50

50 700 50 50 700 50

800 800

56000

DETAILS OF PTFE POT BEARING

600

TRANS. GUIDE BEARING FREE BEARING

VIEW FROM BOTTOM ANCHOR BOLT

(SCALE 1:5) VIEW FROM BOTTOM ARRANGEMENT OF POT PTFE BEARINGS PROVISIONAL

PART G: TOP PLATE FOR (SCALE 1:200)

PART H: PISTON FOR FIXED

FREE BEARING

(SCALE 1:7.5) BEARING

(SCALE 1:7.5)

(PAPER SIZE A1) RDSO/B - 10410/9

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/21 AutoCAD FILE NO.: B-10410 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V. K. PANDEY (SSE) VIVEK KUMAR (XEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

Vous aimerez peut-être aussi

- All RDSO Bow String Girder of Span 60-72 MDocument9 pagesAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)

- 60 M.bow String Girder-10411-RDocument1 page60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- BSR - NH - Circle - Jaipur - 2019 Final PDFDocument109 pagesBSR - NH - Circle - Jaipur - 2019 Final PDFRohit Bali100% (1)

- Rdso Bow String Girder-10411-9Document1 pageRdso Bow String Girder-10411-9a Rawat100% (1)

- 60 M.bow String Girder 10411 1 RDocument1 page60 M.bow String Girder 10411 1 RkesharinareshPas encore d'évaluation

- RDSO B 11754 4R1 (Mod)Document1 pageRDSO B 11754 4R1 (Mod)shibnath lahiriPas encore d'évaluation

- 60 M.bow String Girder 10411 2 RDocument1 page60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- Rdso B-11753 5R1Document1 pageRdso B-11753 5R1shibnath lahiriPas encore d'évaluation

- 60 M.bow String Girder 10411 3 RDocument1 page60 M.bow String Girder 10411 3 RkesharinareshPas encore d'évaluation

- RDSO Drawing ListDocument42 pagesRDSO Drawing Listkaushik96040% (5)

- 42 M Bow String Girder-10408-2-R PDFDocument1 page42 M Bow String Girder-10408-2-R PDFPhanindra MajetiPas encore d'évaluation

- 48m BowStringDocument1 page48m BowStringgoutammand100% (2)

- 42 M Bow String Girder-10408-3-R PDFDocument1 page42 M Bow String Girder-10408-3-R PDFPhanindra MajetiPas encore d'évaluation

- IRC - SP Well Foundation by Balwant Rao PDFDocument133 pagesIRC - SP Well Foundation by Balwant Rao PDFAnoopPas encore d'évaluation

- RCC Encasing Pipe CulvertDocument40 pagesRCC Encasing Pipe CulvertVM&CO VM&CO0% (1)

- Design of PSC Cross Girder As Per IRC 112Document2 pagesDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- Modified LVUP DrawingsDocument1 pageModified LVUP DrawingsAldrinPas encore d'évaluation

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiPas encore d'évaluation

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithPas encore d'évaluation

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshPas encore d'évaluation

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- 42m BowStringDocument1 page42m BowStringsorowarePas encore d'évaluation

- 42 M Bow String Girder-10408-8-R1 PDFDocument1 page42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiPas encore d'évaluation

- Bow String Girder QuantityDocument3 pagesBow String Girder Quantityvsballa25% (4)

- 42 M Bow String Girder-10408-R PDFDocument1 page42 M Bow String Girder-10408-R PDFPhanindra MajetiPas encore d'évaluation

- Drawings For Culvert at 293+538 PDFDocument3 pagesDrawings For Culvert at 293+538 PDFSurya GowthamPas encore d'évaluation

- 42 M Bow String Girder-10408-5-R PDFDocument1 page42 M Bow String Girder-10408-5-R PDFPhanindra MajetiPas encore d'évaluation

- 42 M Bow String Girder-10408-1-RDocument1 page42 M Bow String Girder-10408-1-RPhanindra MajetiPas encore d'évaluation

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDIPas encore d'évaluation

- 36m BowString PDFDocument1 page36m BowString PDFgoutammand67% (3)

- JMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27Document1 pageJMPT Fob 28-01-2021 - V1 - Dyce-B&f-Bbs - P27RVNLPKG6B VBL-GTLM100% (1)

- 60 M.bow String Girder-10411-4-RDocument1 page60 M.bow String Girder-10411-4-RkesharinareshPas encore d'évaluation

- C/S of Staircase (SCALE-1:25) : Pradeep YadavDocument1 pageC/S of Staircase (SCALE-1:25) : Pradeep YadavRVNLPKG6B VBL-GTLM100% (1)

- Fabrication Inspection of Bow String GirdersDocument46 pagesFabrication Inspection of Bow String GirdersHabib Ur Rahman100% (1)

- 36m BowString PDFDocument1 page36m BowString PDFD SRINIVAS100% (1)

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- 60 M.bow String Girder-10411-5-RDocument1 page60 M.bow String Girder-10411-5-RkesharinareshPas encore d'évaluation

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderDocument10 pagesRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (1)

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocument1 pageRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspPas encore d'évaluation

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarPas encore d'évaluation

- PipeDocument30 pagesPipepudumai100% (1)

- Design of PSC Box 45.0 M Span PDFDocument89 pagesDesign of PSC Box 45.0 M Span PDFsiddharth yadavPas encore d'évaluation

- BR - No - Staging - Solid SlabDocument6 pagesBR - No - Staging - Solid Slabmohana tPas encore d'évaluation

- Amendment To IRC 24 - 2010Document6 pagesAmendment To IRC 24 - 2010mrraee4729100% (1)

- Rdso Guide Lines FR BridgesDocument76 pagesRdso Guide Lines FR BridgesUtpal KantPas encore d'évaluation

- Drawing Title: Employer Project Design Consultant: HouseDocument5 pagesDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalPas encore d'évaluation

- Bow-String Girder - Design & Construction AspectsDocument12 pagesBow-String Girder - Design & Construction Aspectsepcepcepc100% (1)

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuPas encore d'évaluation

- IRC 6-2017 Ammendment (Nov-17)Document9 pagesIRC 6-2017 Ammendment (Nov-17)avisek_basuPas encore d'évaluation

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Document4 pagesThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KaflePas encore d'évaluation

- M Bow String Girder-10409-9Document1 pageM Bow String Girder-10409-9prejithPas encore d'évaluation

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcPas encore d'évaluation

- For Plot - 2016-Ato Gari Simma 2020 April-ModelDocument1 pageFor Plot - 2016-Ato Gari Simma 2020 April-ModelJaspergroup 15Pas encore d'évaluation

- PMS - Detail Drawing Man Hole For BA SiloDocument3 pagesPMS - Detail Drawing Man Hole For BA Siloup_freeyantoPas encore d'évaluation

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcPas encore d'évaluation

- Standards: ISO 128 TOL: ISO 2768-mk Not For ScalingDocument1 pageStandards: ISO 128 TOL: ISO 2768-mk Not For ScalingmajidhaghpanahfbcPas encore d'évaluation

- 1077mmx1087 5mmx50mmDocument1 page1077mmx1087 5mmx50mmmajidhaghpanahfbcPas encore d'évaluation

- Ground Floor Plan: Fire Exit Stair (See Attached File For Details)Document1 pageGround Floor Plan: Fire Exit Stair (See Attached File For Details)Mark Kristoffer HilarionPas encore d'évaluation

- Chassis TA41-40026ADocument2 pagesChassis TA41-40026ARodrymix SoriaPas encore d'évaluation

- WORKSHOP - TYRE (Tampak Depan & Samping) .PDocument1 pageWORKSHOP - TYRE (Tampak Depan & Samping) .PRizky LssPas encore d'évaluation

- Lean ToToolShedDocument18 pagesLean ToToolShedYolohtli Vazquez Castaneda100% (1)

- C45 2021 EngDocument16 pagesC45 2021 EngDavid AlorPas encore d'évaluation

- 3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Document3 pages3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Rexter UnabiaPas encore d'évaluation

- Brass Cable Glands Brochure 0703Document18 pagesBrass Cable Glands Brochure 0703IndraAtmajaPas encore d'évaluation

- 6 Different Types of Electrical ConduitsDocument2 pages6 Different Types of Electrical Conduitskash30Pas encore d'évaluation

- Potable Water Storage Tanks-Ring Beam Foundation DesignDocument22 pagesPotable Water Storage Tanks-Ring Beam Foundation DesignAhmedPas encore d'évaluation

- Is 6044 1 2000Document13 pagesIs 6044 1 2000Subhradeb PramanikPas encore d'évaluation

- CAPITAL BUDGETING Ultratech Cements 2015Document87 pagesCAPITAL BUDGETING Ultratech Cements 2015Nair D Sravan50% (2)

- (PDF) Goodweld Welding Products - Naufal Dzaky - Academia - EduDocument177 pages(PDF) Goodweld Welding Products - Naufal Dzaky - Academia - EduHoàng LongPas encore d'évaluation

- SSPC SP Cab 1Document5 pagesSSPC SP Cab 1mithileshPas encore d'évaluation

- 05Document37 pages05Elizabeth OctagonPas encore d'évaluation

- Datasheet Manifold 2 Valve Block Bleed v01Document2 pagesDatasheet Manifold 2 Valve Block Bleed v01Andree' WsPas encore d'évaluation

- CCUG P91 Fabrication Guidelines Dave Buzza-1Document22 pagesCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarPas encore d'évaluation

- Kelani Cable Installation DetailsDocument1 pageKelani Cable Installation DetailsHansika RajapakshaPas encore d'évaluation

- Materials As Per IRCDocument7 pagesMaterials As Per IRCAyyanna HabalPas encore d'évaluation

- 1700 Series Safety ValvesDocument32 pages1700 Series Safety ValvesVishnu PrasadPas encore d'évaluation

- Project On Powder Dispensing System of Sand 3d PrintingDocument101 pagesProject On Powder Dispensing System of Sand 3d PrintingSameer MandaogadePas encore d'évaluation

- TECVALDocument8 pagesTECVALRamaswamy Neelakantan NPas encore d'évaluation

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- 4 KEY STEPS TO MATCH A WELDING FILLER METAL TO A BASe METALDocument4 pages4 KEY STEPS TO MATCH A WELDING FILLER METAL TO A BASe METALAbraham RodríguezPas encore d'évaluation

- Drawn Checked: ApprovedDocument3 pagesDrawn Checked: ApprovedchethanPas encore d'évaluation

- Boronizing and Resistance of SteelDocument3 pagesBoronizing and Resistance of SteelELROHIR CULNAMOPas encore d'évaluation

- X FirefightingDocument1 pageX FirefightingArun UdayabhanuPas encore d'évaluation

- Alloy: Live GraphDocument13 pagesAlloy: Live GraphKasia MazurPas encore d'évaluation

- KLH Timber Concrete Composites PDFDocument12 pagesKLH Timber Concrete Composites PDFBasaraba Dragos100% (1)

- STAIRCASE DESIGN: Dog Legged StaircaseDocument2 pagesSTAIRCASE DESIGN: Dog Legged StaircasePraYush RajbhandariPas encore d'évaluation

- Draft WPSDocument3 pagesDraft WPSWale OyeludePas encore d'évaluation

- Science of Materials Science of Materials C: Dr. Andres MarquezDocument45 pagesScience of Materials Science of Materials C: Dr. Andres MarquezAPPas encore d'évaluation

- BTM Unit 4 QuizDocument4 pagesBTM Unit 4 QuizHarish sanglePas encore d'évaluation

- PRECAST ROOFING & FLOORING SYSTEMS - SDDocument14 pagesPRECAST ROOFING & FLOORING SYSTEMS - SDSubrata DeyPas encore d'évaluation