Académique Documents

Professionnel Documents

Culture Documents

Me 407 Mechatronics

Transféré par

AbelCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Me 407 Mechatronics

Transféré par

AbelDroits d'auteur :

Formats disponibles

Course code Course Name L-T-P-Credits Year of Introduction

ME407 MECHATRONICS 3-0-0- 3 2016

Prerequisite: Nil

Course Objectives:

To introduce the features of various sensors used in CNC machines and robots

To study the fabrication and functioning of MEMS pressure and inertial sensors

To enable development of hydraulic/pneumatic circuit and PLC programs for simple

applications

Syllabus

Introduction to Mechatronics, sensors, Actuators, Micro Electro Mechanical Systems (MEMS),

Mechatronics in Computer Numerical Control (CNC) machines, Mechatronics in Robotics-Electrical

drives, Force and tactile sensors, Image processing techniques, Case studies of Mechatronics systems.

Expected outcome:

The students will be able to

i. Know the mechanical systems used in mechatronics

ii. Integrate mechanical, electronics, control and computer engineering in the design of

mechatronics systems

Text Books:

1. Bolton W., Mechatronics: Electronic Control Systems in Mechanical and Electrical Engineering,

Person Education Limited, New Delhi, 2007

2. Ramachandran K. P., G. K. Vijayaraghavan, M. S. Balasundaram, Mechatronics: Integrated

KTU STUDENTS

Mechanical Electronic Systems, Wiley India Pvt. Ltd., New Delhi, 2008.

3. Saeed B. Niku, Introduction to Robotics: Analysis, Systems, Applications, Person Education, Inc.,

New Delhi, 2006.

References Books:

1. David G. Aldatore, Michael B. Histand, Introduction to Mechatronics and Measurement Systems,

McGraw-Hill Inc., USA, 2003.

2. Gordon M. Mair, Industrial Robotics, Prentice Hall International, UK, 1998.

3. HMT, Mechatronics, Tata McGraw-Hill Publishing Company Ltd., New Delhi, 2004.

4. Vijay K. Varadan, K. J. Vinoy, S. Gopalakrishnan, Smart Material Systems and MEMS: Design

and Development Methodologies, John Wiley & Sons Ltd., England, 2006.

Course Plan

End

Module Contents Hours Sem.

Exam

Marks

Introduction to Mechatronics: Structure of Mechatronics system. Sensors

- Characteristics -Temperature, flow, pressure sensors. Displacement,

position and proximity sensing by magnetic, optical, ultrasonic,

I inductive, capacitive and eddy current methods. Encoders: incremental 8 15%

and absolute, gray coded encoder. Resolvers and synchros. Piezoelectric

sensors. Acoustic Emission sensors. Principle and types of vibration

sensors.

For more study materials>www.ktustudents.in

Actuators: Hydraulic and Pneumatic actuators - Directional control valves,

pressure control valves, process control valves. Rotary actuators.

II Development of simple hydraulic and pneumatic circuits using standard 7 15%

Symbols.

FIRST INTERNAL EXAM

Micro Electro Mechanical Systems (MEMS): Fabrication: Deposition,

Lithography, Micromachining methods for MEMS, Deep Reactive Ion

III 6 15%

Etching (DRIE) and LIGA processes. Principle, fabrication and working of

MEMS based pressure sensor, accelerometer and gyroscope.

Mechatronics in Computer Numerical Control (CNC) machines: Design of

modern CNC machines - Mechatronics elements - Machine structure:

guide ways, drives. Bearings: anti-friction bearings, hydrostatic bearing

and hydrodynamic bearing. Re-circulating ball screws, pre-loading

IV methods. Re-circulating roller screws. Typical elements of open and 8 15%

closed loop control systems. Adaptive controllers for machine tools.

Programmable Logic Controllers (PLC) –Basic structure, input/ output

processing. Programming: Timers, Internal Relays, Counters and Shift

registers. Development of simple ladder programs for specific purposes.

SECOND INTERNAL EXAM

System modeling - Mathematical models and basic building blocks of

general mechanical, electrical, fluid and thermal systems.

KTU V

STUDENTS

Mechatronics in Robotics-Electrical drives: DC, AC, brushless, servo and

stepper motors. Harmonic drive. Force and tactile sensors. Range finders:

ultrasonic and light based range finders

Robotic vision system - Image acquisition: Vidicon, charge coupled device

(CCD) and charge injection device (CID) cameras. Image processing

techniques: histogram processing: sliding, stretching, equalization and

6 20%

VI thresholding. 7 20%

Case studies of Mechatronics systems: Automatic camera, bar code reader,

pick and place robot, automatic car park barrier system, automobile

engine management system.

END SEMESTER EXAM

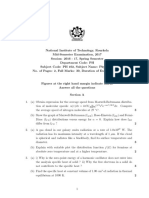

Question Paper Pattern

Maximum marks: 100 Time: 3 hrs

The question paper should consist of three parts

Part A

There should be 2 questions each from module I and II. Each question carries 10 marks. Students will

have to answer any three questions out of 4 (3X10 =30 marks)

Part B

There should be 2 questions each from module III and IV. Each question carries 10 marks. Students will

have to answer any three questions out of 4 (3X10 marks =30 marks)

Part C

There should be 3 questions each from module V and VI. Each question carries 10 marks

Students will have to answer any four questions out of 6 (4X10 marks =40 marks)

Note: Each question can have a maximum of four sub questions, if needed.

For more study materials>www.ktustudents.in

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Blacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsDocument6 pagesBlacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsByram JPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Suzuki GSXS 1000 Manual Servicio Tecnico PDFDocument86 pagesSuzuki GSXS 1000 Manual Servicio Tecnico PDFRoberto Nicolás Mera Velásquez75% (8)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Engine Oil: Operation and Maintenance ManualDocument5 pagesEngine Oil: Operation and Maintenance ManualАлександр БудзинскийPas encore d'évaluation

- Electrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesDocument5 pagesElectrical Safety - EEE1021 Experiment - 6: Line Charging Current in AC More Over Poses Serious Problems in CablesRobert JrPas encore d'évaluation

- Special Electrical MachinesDocument5 pagesSpecial Electrical MachinesEswaran0% (1)

- SISTO-Diaphragm Valves: 1. Installation InstructionsDocument1 pageSISTO-Diaphragm Valves: 1. Installation InstructionsEric LarrondoPas encore d'évaluation

- Handbook of X-Ray Spectrometry Methods and TechniquesDocument6 pagesHandbook of X-Ray Spectrometry Methods and TechniquesAlexander José Sandoval FigueredoPas encore d'évaluation

- Dh3 Generation Lototo Plan Phase 2 RGC 08sep2023Document8 pagesDh3 Generation Lototo Plan Phase 2 RGC 08sep2023Borislav VulicPas encore d'évaluation

- PH102Document2 pagesPH102Shobhit ParkiPas encore d'évaluation

- List Three Examples of Matter Changing From One State To AnotherDocument31 pagesList Three Examples of Matter Changing From One State To AnotherygjyoPas encore d'évaluation

- Easy UPS 3S - E3SUPS30KHB2Document3 pagesEasy UPS 3S - E3SUPS30KHB2Birthley RagasaPas encore d'évaluation

- Product Information: Crawler Excavator: Generation EngineDocument16 pagesProduct Information: Crawler Excavator: Generation EngineTeguh J. AlkausarPas encore d'évaluation

- Module Reviews (Year 1)Document20 pagesModule Reviews (Year 1)Le Chriffe ChipPas encore d'évaluation

- Catalogue 1692356459Document144 pagesCatalogue 1692356459diavolorPas encore d'évaluation

- IELTS READING CHUYÊN ĐỀ - Matching /Heading (part 3 - advanced)Document3 pagesIELTS READING CHUYÊN ĐỀ - Matching /Heading (part 3 - advanced)TUTOR IELTSPas encore d'évaluation

- CF750Document9 pagesCF750Shilpi VirmaniPas encore d'évaluation

- Temperature MeasuremenntDocument25 pagesTemperature MeasuremenntJan Edward L. SuarezPas encore d'évaluation

- SREA-ECET (Mechanical) 8 Years Topic Wise Bit Bank-1 PDFDocument68 pagesSREA-ECET (Mechanical) 8 Years Topic Wise Bit Bank-1 PDFDhanunjay JaguPas encore d'évaluation

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyPas encore d'évaluation

- TYH - TYA-Inverter Ducted PAC - CatalogueDocument4 pagesTYH - TYA-Inverter Ducted PAC - CatalogueNguyễn Thành ChungPas encore d'évaluation

- A GCE Physics B 2865 01 January 2006 Question PaperDocument24 pagesA GCE Physics B 2865 01 January 2006 Question PaperMitul KaziPas encore d'évaluation

- Unit Merinyu Elektrik: Application For Certificate of CompetencyDocument4 pagesUnit Merinyu Elektrik: Application For Certificate of CompetencySaff MdPas encore d'évaluation

- MOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Document17 pagesMOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Emad AbushrarPas encore d'évaluation

- Physics NotesDocument13 pagesPhysics Noteswaheedlakho100% (2)

- Data Sheet P30-2Document4 pagesData Sheet P30-2Vlade NaumovskiPas encore d'évaluation

- V B TDocument12 pagesV B TAshish KatariaPas encore d'évaluation

- Besic Electrical Engineering Lab: Experiment - 8Document9 pagesBesic Electrical Engineering Lab: Experiment - 8Rajesh RajPas encore d'évaluation

- Dokumen - Tips - Astm A159 Standard Specification For Automotive Gray Iron CastingsDocument2 pagesDokumen - Tips - Astm A159 Standard Specification For Automotive Gray Iron CastingsJeovanne CabralPas encore d'évaluation

- ME8512 - TE - AU Practical Students Individual QuestionDocument4 pagesME8512 - TE - AU Practical Students Individual Questionsikkandar faizPas encore d'évaluation

- Genset DataDocument12 pagesGenset DatagebrePas encore d'évaluation