Académique Documents

Professionnel Documents

Culture Documents

Specification For The Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys and Composites For The Corrosion Protection of Steel

Transféré par

vijay rajputTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Specification For The Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys and Composites For The Corrosion Protection of Steel

Transféré par

vijay rajputDroits d'auteur :

Formats disponibles

NACE No. 12/AWS C2.23M/SSPC-CS 23.

00

Specification for the Application of Thermal Spray

Coatings (Metallizing) of Aluminum, Zinc, and

Their Alloys and Composites for the Corrosion

Protection of Steel

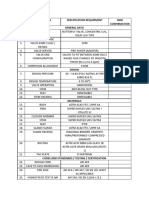

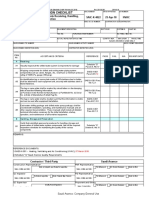

SSPC-SP 1

UV light Test/ Solvent evaporation test to confirm

Degreasing solvent free surface.

Compressed air shall be checked for oil & moisture

Air Test presence as Per ASTM D 4285.

Surface profile Min 70 1. NACE No 2 Near white metal finish,

µm verify using SSPC VIS 1.

2.Steel surface temp at least 3°C above dew point,

RH should be below 80%.

3.Angular Profile Measurement ASTM D 4417

Method C Replica tape. one measurement every 10

to 20 m2.

4.Clear cello tape test to confirm absence of dust as

per ISO 8502-3

5. Method for testing Soluble salts as ISO 8502-6

and ISO 8502-9.

Masking 1. All fit & function surfaces

2.Overspary control areas

3. Areas not to be TSC

Blasting Media ( Should 1. Copper Slag, Size G16 to G 24,

be free from oil 2.Blasting media Selection as per As per SSPC AB1.

contamination, sodium 3. Salt in Blasting media Contamination measured

chloride, sulphur salts) As per ASTM D 4940.

JCR Job control Record As per NACE No 12 Appendix B

JRS Job reference 1.Is a job site pass/fail test coupon, Required at

standard beginning of each work shift.

Size 18"X18"X0.25" 2. Shall be provided & prepared by TSC applicator.

3. Made with actual field equipment & process

parameters.

4. Tensile Bond test as per ASTM D 4541 ( Refer Fig

5, NACE No 12).

Min Tensile Bond Required Zn 3.45 Mpa ( 500 psi)

Bend Test Table 4 NACE No 12,

Test Coupon 1.Is a job site pass/fail test coupon, Required at

50x100to200x1.3mm beginning of each work shift.

2. No peeling Crack or peeling with lifting

Holding Period 1. Time Between completion of blasting &

completion of thermal spraying should be max 6

hours.

2. 25to50 µm flash coat of TSC may be applied

within 6 hr of completing blasting to extend hold

period for more 4 hr

2. If Rust bloom appears within 6 hr window

reblasting required

TSC application 1. TSC Wire feedstock material & thickness as per

AWS C2.18, C2.25 or ASTM B 833

2. Spray gun perpendicular stand off 150to200 mm,

spray width 75 to 150 mm( Table D1 NACE NO 12),

Spray gung angle 30° to perpendicular.

2. TSC Thickness 100 to 150 µm, ( Measurement as

per SSPC PA 2 Type 2). Five reading in one line in 10

to 20 m2.

3.one portable tensile bond test shall be made

every 50m2.

4.TSC thickness shall be applied in several Crossing

passes, gives greater strength

Sealer + Top Coat All paints applied according to SSPC PA1 & TDS,

1.Heat resistant silicone alkyd aluminium paint or

equivalent sealant if operating temp greater than

80 °C

2. Sealer thin coat of 38 µm thick that is absorbed

into pores of TSC. Should be applied within 8 hr

after TSC.

3. Top Coat Should be 50 µm Which is compatible

with Sealer.

Reference Codes and Standards

The following codes and standards (latest issue) apply:

ASTM B 833, Standard Specification for Zinc Wire for Thermal Spraying (Metallizing).

ASTM C 633, Test Method for Adhesive/Cohesive Strength of Flame Sprayed

Coatings.

ASTM D 4285, Method for Indicating Oil or Water in Compressed Air.

ASTM D 4417, Test Method for Field Measurement of Surface Profile of Blasted

Steel.

NACE Standard RP0287, Field Measurement of Surface Profile of Abrasive Blast

Cleaned Steel Surfaces Using a Replica Tape.

ASTM D 4541, Test Method for Pull-Off Strength of Coating Using Portable Adhesion

Testers.

ANSI/AWS C2.18, Guide for the Protection of Steel with Thermal Spray Coatings

of Aluminum, Zinc, and Their Alloys and Composites.

NACE No. 12/AWS C2.23M/SSPC-CS 23.00, Specification for the Application of

Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys

and Composites for the Corrosion Protection of Steel.

SSPC Publication, The Inspection of Coatings and Linings: A Handbook of Basic

Practice for Inspectors, Owners, and Specifiers.

SSPC-AB 1, Mineral and Slag Abrasives.

SSPC-AB 3, Ferrous Metallic Abrasives.

SSPC-PA 1, Shop, Field, and Maintenance Painting of Steel.

SSPC-PA 2, Measurement of Dry Coating Thickness with Magnetic Gages.

NACE No. 1/SSPC-SP 5, White Metal Blast Cleaning.

NACE No. 2/SSPC-SP 10, Near-White Metal Blast Cleaning.

SSPC-VIS 1, Guide and Reference Photographs for Steel Surfaces Prepared by

Dry Abrasive Blast Cleaning.

Vous aimerez peut-être aussi

- Construction Management ReportDocument23 pagesConstruction Management ReportJanmar CordaPas encore d'évaluation

- Specification For The Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys and Composites For The Corrosion Protection of SteelDocument3 pagesSpecification For The Application of Thermal Spray Coatings (Metallizing) of Aluminum, Zinc, and Their Alloys and Composites For The Corrosion Protection of Steelvijay rajputPas encore d'évaluation

- Technical Specification - FilterDocument15 pagesTechnical Specification - FilterMurli RamchandranPas encore d'évaluation

- Estimation and Costing: Unit 2 6Document40 pagesEstimation and Costing: Unit 2 6Funny VinesPas encore d'évaluation

- Aerospace Material Specification: Plating, Nickel General PurposeDocument8 pagesAerospace Material Specification: Plating, Nickel General PurposeSURYAS63Pas encore d'évaluation

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesD'EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesPas encore d'évaluation

- Datasheet For Butterfly ValveDocument3 pagesDatasheet For Butterfly ValvevishnuvarthanPas encore d'évaluation

- Astm C418 PDFDocument3 pagesAstm C418 PDFmjgutierrezperalta100% (1)

- Astm A210Document3 pagesAstm A210Rajan SteevePas encore d'évaluation

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFvijay rajputPas encore d'évaluation

- Tank-API-650-docx V-V-I-P PDFDocument20 pagesTank-API-650-docx V-V-I-P PDFtomj9104100% (1)

- SSPC QP 1Document10 pagesSSPC QP 1vijay rajputPas encore d'évaluation

- Post Tensioning ManualDocument11 pagesPost Tensioning Manualimzee25100% (7)

- Ford ABS Plating Spec.Document7 pagesFord ABS Plating Spec.Pieter100% (2)

- D130-12 Corrosiveness To Copper From Petroleum Products PDFDocument10 pagesD130-12 Corrosiveness To Copper From Petroleum Products PDFL Ayquipa MerinoPas encore d'évaluation

- Refractories For The Lime Kiln IndustriesDocument8 pagesRefractories For The Lime Kiln IndustriesFarshid Torabi100% (1)

- Thermal Spray Aluminium CoatingDocument5 pagesThermal Spray Aluminium CoatingMythri Metallizing Pvt Ltd Projects100% (2)

- Astm C 1136Document4 pagesAstm C 1136Mohamed100% (1)

- API 570 - Mockup OP - Paper 2 + MDocument13 pagesAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesD'EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesPas encore d'évaluation

- API 570 Open BookDocument9 pagesAPI 570 Open BookMusa ÇelikPas encore d'évaluation

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Prestressed ConcreteDocument14 pagesPrestressed ConcretekomalPas encore d'évaluation

- Main Alloys PDFDocument6 pagesMain Alloys PDFMohan RajPas encore d'évaluation

- Boiler Operation and ControlDocument99 pagesBoiler Operation and Controlwassli100% (1)

- Case Study of Multi-Functional Sports Hall at RomaniaDocument4 pagesCase Study of Multi-Functional Sports Hall at Romaniadamandadino50% (2)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingD'EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghPas encore d'évaluation

- Asme Section II A Sa-395Document12 pagesAsme Section II A Sa-395Anonymous GhPzn1xPas encore d'évaluation

- QC TolaranceDocument35 pagesQC TolaranceRajkumar A100% (1)

- Painting Scheme StructureDocument10 pagesPainting Scheme StructureVeerapandianPas encore d'évaluation

- Everyday DetailsDocument7 pagesEveryday DetailsJake WilliamsPas encore d'évaluation

- Specification For High Performance MC - PCN - 123Document12 pagesSpecification For High Performance MC - PCN - 123Danny SeePas encore d'évaluation

- TCZ 2Document3 pagesTCZ 2vijay rajputPas encore d'évaluation

- TCZ1Document3 pagesTCZ1vijay rajputPas encore d'évaluation

- SSPC-SP 27.00Document6 pagesSSPC-SP 27.00manoses100% (1)

- Sp-123-2018 Rev - 2 - 0Document12 pagesSp-123-2018 Rev - 2 - 0Thiruvasakan KaliyaperumalPas encore d'évaluation

- Fusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardDocument12 pagesFusion Bonded Epoxy Coated Reinforcing Bars - Specification: Indian StandardsssmouPas encore d'évaluation

- Revise 111 2006 Annexure IIDocument12 pagesRevise 111 2006 Annexure IIchepurthiPas encore d'évaluation

- S.I NO Description Specification Requirment SNW Confirmation General DataDocument3 pagesS.I NO Description Specification Requirment SNW Confirmation General DatavishnuvarthanPas encore d'évaluation

- Material Data Sheet MDS - C21 Rev. 2Document3 pagesMaterial Data Sheet MDS - C21 Rev. 2Shakinah As SaadPas encore d'évaluation

- Painting Insulation CPDocument4 pagesPainting Insulation CPvinothPas encore d'évaluation

- Elastomeric Materials m17Document5 pagesElastomeric Materials m17Mad WonderPas encore d'évaluation

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument5 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForahmedPas encore d'évaluation

- Engineering Material SpecificationDocument9 pagesEngineering Material SpecificationVeysel Emre BozkurtPas encore d'évaluation

- ANEXO 2 - LaserLine 2205 Coiled Tubing SpecificationDocument7 pagesANEXO 2 - LaserLine 2205 Coiled Tubing SpecificationCoco SanchezPas encore d'évaluation

- Plant Building - Epoxy PaintDocument2 pagesPlant Building - Epoxy PaintNavaneethan NatarajanPas encore d'évaluation

- C617Document5 pagesC617Rajesh KumarPas encore d'évaluation

- Ceramic SpecDocument8 pagesCeramic SpecpujadagaPas encore d'évaluation

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument4 pagesRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingskhuzafaPas encore d'évaluation

- Corrosion Astm D 1838-07Document5 pagesCorrosion Astm D 1838-07Cecilia Cruz Toribio100% (1)

- A1020A1020M-02 (2012) Standard Specification For SteeDocument4 pagesA1020A1020M-02 (2012) Standard Specification For SteeRony YudaPas encore d'évaluation

- A1014Document3 pagesA1014malika_00Pas encore d'évaluation

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarPas encore d'évaluation

- Astm C 1081-98Document3 pagesAstm C 1081-98Indira BanerjeePas encore d'évaluation

- Norsok ExtractDocument2 pagesNorsok ExtractElliott RussellPas encore d'évaluation

- Vanpanel Wall: External and Internal SheetDocument3 pagesVanpanel Wall: External and Internal SheetMl JainPas encore d'évaluation

- Hse Approved SpecificationDocument16 pagesHse Approved SpecificationPrasit MeeboonPas encore d'évaluation

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument4 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDennise ChicaizaPas encore d'évaluation

- 1.0 SCOPE:: SL - No. Tag No. Area of Exchanger Coating Thickness RemarksDocument5 pages1.0 SCOPE:: SL - No. Tag No. Area of Exchanger Coating Thickness RemarksCorrosion FactoryPas encore d'évaluation

- Conducting Exterior Exposure Tests of Paints On Steel: Standard Practice ForDocument3 pagesConducting Exterior Exposure Tests of Paints On Steel: Standard Practice ForBrando VenturaPas encore d'évaluation

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocument5 pagesA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdPas encore d'évaluation

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTAPas encore d'évaluation

- MORTH 1600 2 Acrylic Elastomeric CoatingDocument4 pagesMORTH 1600 2 Acrylic Elastomeric CoatingRameshPas encore d'évaluation

- IGS-M-PL-02-1 (3) Jul. 2010: ApprovedDocument18 pagesIGS-M-PL-02-1 (3) Jul. 2010: ApprovedMehdi orojluPas encore d'évaluation

- T 90 Ep2 S: Motor Vehicle Transmission OilDocument1 pageT 90 Ep2 S: Motor Vehicle Transmission Oilrobertjob34Pas encore d'évaluation

- Astm D36Document4 pagesAstm D36Esteban FinoPas encore d'évaluation

- Materials and Equipment Standard: IPS-M-TP-290Document8 pagesMaterials and Equipment Standard: IPS-M-TP-290Peyman KhPas encore d'évaluation

- Section 07430 Composite PanelsDocument4 pagesSection 07430 Composite PanelsMØhãmmed ØwięsPas encore d'évaluation

- 123 12Document13 pages123 12anon_103239931Pas encore d'évaluation

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesD'EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášPas encore d'évaluation

- SSPC QP 2Document9 pagesSSPC QP 2vijay rajputPas encore d'évaluation

- Iimk Aoma BrochureDocument16 pagesIimk Aoma Brochurevijay rajputPas encore d'évaluation

- Img 0002Document1 pageImg 0002vijay rajputPas encore d'évaluation

- Hints For InterviewDocument20 pagesHints For Interviewsaurabh joshiPas encore d'évaluation

- Abroad News Paper 24 Aug 2022Document6 pagesAbroad News Paper 24 Aug 2022vijay rajputPas encore d'évaluation

- Table 1 Inspection and Testing Summary Work Stage Assessment Assessment Method Test Equipment NotesDocument6 pagesTable 1 Inspection and Testing Summary Work Stage Assessment Assessment Method Test Equipment Notesvijay rajputPas encore d'évaluation

- 41 Enterpreneship DevelopmentDocument36 pages41 Enterpreneship Developmentvijay rajputPas encore d'évaluation

- Bituminous Coatings: When and How To Use ThemDocument10 pagesBituminous Coatings: When and How To Use Themvijay rajputPas encore d'évaluation

- Bituminous Coatings: When and How To Use ThemDocument10 pagesBituminous Coatings: When and How To Use Themvijay rajputPas encore d'évaluation

- Welding DocumentDocument31 pagesWelding DocumentCak NhassPas encore d'évaluation

- Elcometer 456 User GuideDocument112 pagesElcometer 456 User Guidevijay rajputPas encore d'évaluation

- Elcometer 456 User GuideDocument112 pagesElcometer 456 User Guidevijay rajputPas encore d'évaluation

- 1 - Hydrotest Preparation PDFDocument32 pages1 - Hydrotest Preparation PDFvijay rajputPas encore d'évaluation

- Top 10 Sites For Your CareerDocument3 pagesTop 10 Sites For Your CareerCruz BrothersPas encore d'évaluation

- Bituminous Coatings: When and How To Use ThemDocument10 pagesBituminous Coatings: When and How To Use Themvijay rajputPas encore d'évaluation

- The Verified Log Book Will Become Mandatory For Renewal From January 2017Document1 pageThe Verified Log Book Will Become Mandatory For Renewal From January 2017vijay rajputPas encore d'évaluation

- Area CalculationsDocument12 pagesArea CalculationsFarooq BhuttaPas encore d'évaluation

- SIFE PublicationsEffectivitySheet 2017 Rev-012417Document2 pagesSIFE PublicationsEffectivitySheet 2017 Rev-012417ahmedzizo_2Pas encore d'évaluation

- 2Document2 pages2vijay rajputPas encore d'évaluation

- Repair and Rehabilitation of Structures Two Mark Questions With AnswerDocument13 pagesRepair and Rehabilitation of Structures Two Mark Questions With AnswerSony Sundar33% (3)

- Journal of Sustainable Mining: Research PaperDocument13 pagesJournal of Sustainable Mining: Research PaperAlket DhamiPas encore d'évaluation

- 1 Attempt Any Five of The Following 10: Q.No Chapter/ Topic No. MarksDocument2 pages1 Attempt Any Five of The Following 10: Q.No Chapter/ Topic No. MarksMADA VENUMADHAV RAOPas encore d'évaluation

- Aquacal Heat Pump Manual MultilanguageDocument214 pagesAquacal Heat Pump Manual MultilanguageavillafanaPas encore d'évaluation

- Ficha Tecnica - DuraliteDocument2 pagesFicha Tecnica - DuraliteedocducPas encore d'évaluation

- Sun and Solar DryingDocument26 pagesSun and Solar DryingMohammad Siddiq JalilPas encore d'évaluation

- A Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652Document6 pagesA Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652SUBHIKSHA D 1861738Pas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistjunaidPas encore d'évaluation

- Shoring and UnderpinningDocument16 pagesShoring and UnderpinningudithaireshaPas encore d'évaluation

- Lab Manual For MOS LabDocument30 pagesLab Manual For MOS LabShahazad ShaikPas encore d'évaluation

- Me 1303 Gas Dynamics and Jet Propulsion: Presented byDocument24 pagesMe 1303 Gas Dynamics and Jet Propulsion: Presented byArul SankaranPas encore d'évaluation

- Chemical Exergy CalculationDocument7 pagesChemical Exergy CalculationmaheshPas encore d'évaluation

- K - To - 12 - Electrical - Learning - Module v1Document178 pagesK - To - 12 - Electrical - Learning - Module v1Jose BundalianPas encore d'évaluation

- BPSC AE Paper 5 (Civil) 2022 (English)Document9 pagesBPSC AE Paper 5 (Civil) 2022 (English)धीरज कुमारPas encore d'évaluation

- Composition of PCDDocument3 pagesComposition of PCDHarsha MPPas encore d'évaluation

- Types of Abrasives: - Abrasives Can Be Broadly Divided IntoDocument31 pagesTypes of Abrasives: - Abrasives Can Be Broadly Divided Intojohn mwambuPas encore d'évaluation

- Calculate Door Size Based On Structural Opening (MM)Document4 pagesCalculate Door Size Based On Structural Opening (MM)Pablo González RamosPas encore d'évaluation

- Designing To Brickwork Dimensions: Brick Development AssociationDocument10 pagesDesigning To Brickwork Dimensions: Brick Development Associationdalton wongPas encore d'évaluation

- Bomba Gorman RuppDocument15 pagesBomba Gorman RuppdenisPas encore d'évaluation

- GB18045 2000 (E)Document15 pagesGB18045 2000 (E)Mehdi MosayebiPas encore d'évaluation

- Free Convection: Its Free, No Operating Cost! .. Its Natural .Document34 pagesFree Convection: Its Free, No Operating Cost! .. Its Natural .zeeshanahmad111Pas encore d'évaluation

- Section A PipeDocument18 pagesSection A PipeOsama sayedPas encore d'évaluation