Académique Documents

Professionnel Documents

Culture Documents

Pp4 CM Ir 1004 001 - Rev. A - Itp For Piping

Transféré par

HungManhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pp4 CM Ir 1004 001 - Rev. A - Itp For Piping

Transféré par

HungManhDroits d'auteur :

Formats disponibles

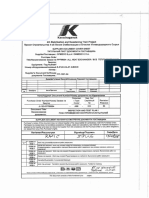

PRJOJECT NAME: HSVC1 PP4 PROJECT

INSPECTION AND TEST PLAN FOR PIPING

Document Number:

PP4-CM-IR-1004-001

Issued for N.V.

A 01-4-19 N.Q. HOAN

Approval HOAI

Purpose Prepared Approved Approved Approved Approved

Rev. Date

of Issue by by PTSC by Yusung by ETEC by Hyosung

HSVC1 PP4 PROJECT

INSPECTION AND TEST PLANT FOR PIPING

RECORD OF REVISION

Rev. Date Purpose Description of Updated/ Modified

No. Sections (if any)

A 01-4-2019 Issued for Approval First Issue

Document No.: PP4-CM-IR-1004-001 Rev. A Page No.: 2 of 5

HSVC1 PP4 PROJECT

INSPECTION AND TEST PLANT FOR PIPING

TABLE OF CONTENTS

1.0 PURPOSE ............................................................................................................................................. 4

2.0 SCOPE ................................................................................................................................................... 4

3.0 REFERENCE ........................................................................................................................................ 4

4.0 DEFINITION ........................................................................................................................................ 4

5.0 RECORDS ............................................................................................................................................. 4

6.0 APPENDIX ........................................................................................................................................... 5

Document No.: PP4-CM-IR-1004-001 Rev. A Page No.: 3 of 5

HSVC1 PP4 PROJECT

INSPECTION AND TEST PLANT FOR PIPING

1.0 PURPOSE

This Plan establishes the work process sequence, inspections and tests that are to be

executed, documented and required by ETEC/ HYOSUNG.

2.0 SCOPE

In addition, this procedure to aid production and quality control personnel in the

performance of their work, the Plan identifies the various types of inspections to be

performed during various phases of work.

3.0 REFERENCE

Document No. Title

ASME B31.3 Process Piping

ASME IX Qualification standard for welding, brazing and fusing procedures;

Welders; Brazers; and welding, brazing, and fusing operators

PP4-PI-0509S Specification for Construction Work of Piping

HSVN-HS-PI- Piping material specification

0002

4.0 DEFINITION

H - Hold Point

To indicate mandatory to fully compliance in area of inspection beyond which work shall

not proceed without the specified activity, work or function being witnessed or verified by

Inspector.

M - Monitoring Point

Fabrication activities are being randomly monitored, work or function is observed by

Inspector, and normal notice is not required to be given.

W - Witness Point

To indicate mandatory to fully compliance in area of inspection this will be witnessed or

verified by Inspector. If Inspector is not available fabrication process can proceed.

R - Review Point

The inspection reports, quality records and certificates applicable must be reviewed and

endorsed by PTSC or ETEC/ HYOSUNG.

I - Inspection Point

Inspection activities are being carried out on random sampling basic.

5.0 RECORDS

All inspection documents and QC Summary sheets shall be compiled by Quality

management department on an ongoing basis to maintain for fabrication.

Document No.: PP4-CM-IR-1004-001 Rev. A Page No.: 4 of 5

HSVC1 PP4 PROJECT

INSPECTION AND TEST PLANT FOR PIPING

6.0 APPENDIX

Appendix 1: ITP for piping

Document No.: PP4-CM-IR-1004-001 Rev. A Page No.: 5 of 5

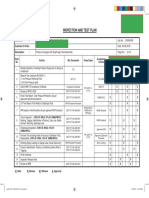

APPENDIX 1 - INSPECTION AND TEST PLAN FOR PIPING

CONTROLLING VERIFY

ACTIVITY ACCEPTANCE CRITERIA SURVEILLANCE

DOCUMENT DOCUMENT

DOCUMENT

ITEM DESCRIPTION REF/ NO. REF/ NO. PTSC YUSUNG ETEC HYOSUNG

REFERENCE

1.0 PRIOR TO COMMENCING WORK

To satisfy the requirement HSVN-HS-PI-

Material

1.1 Material check of piping material 0002: Piping R R R R

Certificate

specification material spec

Welder's performance Welder

Welder

1.2 Welder's performance qualification qualification certificate Qualification R R R R

certificate

authorized by Client Register

To satisfy applicable codes Material Control Material

1.3 Electrode R R R R

and standards Procedure certificate

2.0 PRIOR TO WELDING WORK

End preparations: To satisfy the requirements;

1. Shape and dimension Welding

2.1 2. Cleanliness To be free from paint, oil, procedure - I M M M

rust, scale or other specification

foreign material

Tack weld: To be within the tolerance

specified; Welding

2.2 1. Root opening procedure - I M M M

2. Alignment Misalignment is not more specification

than 1.5mm

Electrode: To be in accordance with Welding

2.3 1. Drying temperature manufacturer's Consumable - M M M M

2. Drying time standard Control Procedure

3.0 AFTER WELDING WORK

Visual Inspection of weld:

PP4-PI-0509S:

1. Undercut Less than 0.3mm

Specification for Weld

3.1 2. Overlap Less than 1.0mm M M M R

Construction summary

3. Throat thickness of fillet Over 0.7t (t: thinner pipe

Work of Piping

weld thickness)

Document No.: PP4-CM-IR-1004-001 Rev. A Page 1 of 2

APPENDIX 1 - INSPECTION AND TEST PLAN FOR PIPING

CONTROLLING VERIFY

ACTIVITY ACCEPTANCE CRITERIA SURVEILLANCE

DOCUMENT DOCUMENT

DOCUMENT

ITEM DESCRIPTION REF/ NO. REF/ NO. PTSC YUSUNG ETEC HYOSUNG

REFERENCE

4. Weld reinforcement or Section 4.1 of spec.

internal weld protrusion

Non-destructive inspection:

1. Radiography To be in accordance with

ASME B31.3 Para. 344.5;

NDT

3.2 2. Liquid penetrant To be in accordance with NDT Procedures R R R R

Reports

ASME B31.3 Para. 344.4;

3. Ultrasonic To be in accordance with

ASME B31.3 Para. 344.6

4.0 AFTER COMPLETION OF WORK

Hydrostatic and pneumatic pressure No deformation and leak Hydrotest &

4.1 testing shall be acceptable. Flushing Test Report H W M R

Procedure

Leak test No leak shall be acceptable Leak test

4.2 Test Report H W M R

procedure

NOTES:

H: HOLD POINT;

W: WITNESS POINT;

M: MONITORING POINT;

I: INSPECTION POINT;

R: REVIEW POINT.

Document No.: PP4-CM-IR-1004-001 Rev. A Page 2 of 2

Vous aimerez peut-être aussi

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDocument2 pagesTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanPas encore d'évaluation

- Laporan Soil TestDocument11 pagesLaporan Soil TestMarvan Audy BurikoPas encore d'évaluation

- ITP - 003 - Rotating Equipment - IFRDocument3 pagesITP - 003 - Rotating Equipment - IFRMari Belajar100% (1)

- Field Joint Coating Installation ProcedureDocument2 pagesField Joint Coating Installation Procedureunix manPas encore d'évaluation

- ITPDocument1 pageITPVenkatesh PethurajPas encore d'évaluation

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- QATAR Pin Braze pdfr1Document14 pagesQATAR Pin Braze pdfr1Karunanithi NagarajanPas encore d'évaluation

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 pagesA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzPas encore d'évaluation

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarPas encore d'évaluation

- (WPQL) : Welder / Welding Operation Performance Qualified ListDocument2 pages(WPQL) : Welder / Welding Operation Performance Qualified ListTrương Đông HưngPas encore d'évaluation

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoPas encore d'évaluation

- Pipe Fabrication Brochure CompressedDocument2 pagesPipe Fabrication Brochure CompressedLeDzungPas encore d'évaluation

- Specification For 3 Layer Polyethylene CoatingDocument34 pagesSpecification For 3 Layer Polyethylene CoatingYogesh BaraskarPas encore d'évaluation

- ITP's and ITR's A Necessary - Monster - PDFDocument5 pagesITP's and ITR's A Necessary - Monster - PDFshastri85Pas encore d'évaluation

- Ug PipingDocument1 pageUg PipingVinoth KumarPas encore d'évaluation

- Test Pack Flow / Control Log: Punch List / Inspection Prior For Hydro TestDocument2 pagesTest Pack Flow / Control Log: Punch List / Inspection Prior For Hydro Testsyedahmad39Pas encore d'évaluation

- 1242352015di400100 D1Document6 pages1242352015di400100 D1Cristinel NechiforPas encore d'évaluation

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiPas encore d'évaluation

- Procédure MTDocument11 pagesProcédure MTAslaouiPas encore d'évaluation

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Document77 pagesT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahPas encore d'évaluation

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngPas encore d'évaluation

- Specification FOR Painting: Vietnam Oil and Gas Group Long Phu 1 Thermal Power Plant ProjectDocument37 pagesSpecification FOR Painting: Vietnam Oil and Gas Group Long Phu 1 Thermal Power Plant ProjectLy Thanh HaPas encore d'évaluation

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriPas encore d'évaluation

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaPas encore d'évaluation

- Inspection Engineer - Senior Welding - Arunkumar Andavar - CVDocument7 pagesInspection Engineer - Senior Welding - Arunkumar Andavar - CVArun KumarPas encore d'évaluation

- MS For HDPE Pipes Laying ActivityDocument7 pagesMS For HDPE Pipes Laying ActivityJust Do LovePas encore d'évaluation

- Project Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesDocument12 pagesProject Name: Repair of Afam Vi Boiler (HRSG) Evaporator TubesLeann WeaverPas encore d'évaluation

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 pagesJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- PP1-2M90-1043-006 - B - Inspection Test Plan - CODE B PDFDocument5 pagesPP1-2M90-1043-006 - B - Inspection Test Plan - CODE B PDFfreeman11072000Pas encore d'évaluation

- Damage ReportDocument1 pageDamage ReportAMG Co.100% (1)

- Method Statement-HDPE-MWSPDocument16 pagesMethod Statement-HDPE-MWSPKumar AbhishekPas encore d'évaluation

- Cold Forming ProcedureDocument5 pagesCold Forming ProcedureMassimo FumarolaPas encore d'évaluation

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640Pas encore d'évaluation

- Piping Fabrication and Installation Procedure: Doc. No Rev. No DateDocument24 pagesPiping Fabrication and Installation Procedure: Doc. No Rev. No DateMechanical Static WRKPas encore d'évaluation

- Weld Identification Record FormDocument2 pagesWeld Identification Record FormDimitris NikouPas encore d'évaluation

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDocument16 pagesR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinPas encore d'évaluation

- Idc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingDocument18 pagesIdc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingJovan Poznan100% (1)

- Itp - 002 - Duct Installation - IfrDocument3 pagesItp - 002 - Duct Installation - IfrMari BelajarPas encore d'évaluation

- Inspection Test Plan (Itp) at Shop: Remark No DescriptionDocument2 pagesInspection Test Plan (Itp) at Shop: Remark No Descriptionanang_pri100% (1)

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198Pas encore d'évaluation

- Daily Report: 03 YG 00400 20-Jun-2017 Tuesday DPR-384Document4 pagesDaily Report: 03 YG 00400 20-Jun-2017 Tuesday DPR-384mcgPas encore d'évaluation

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -Pas encore d'évaluation

- O252-PI-SP-0126 - C04 - Specification For PaintingDocument26 pagesO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedPas encore d'évaluation

- MS For High Pressure Leak TestDocument10 pagesMS For High Pressure Leak TestNijo Jose100% (1)

- Gate Installation ReportDocument3 pagesGate Installation ReportKumar AbhishekPas encore d'évaluation

- Iooc Idhc BPD Ins Pro 007 R4Document8 pagesIooc Idhc BPD Ins Pro 007 R4Fatholla SalehiPas encore d'évaluation

- SAIC-W-2077 Weld Joint Identification SystemDocument1 pageSAIC-W-2077 Weld Joint Identification Systemkarioke mohaPas encore d'évaluation

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruPas encore d'évaluation

- DOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Document2 pagesDOD-ITP - INS-008-ITP FOR Installation and Testing of Fiber Optic Cable - Rev.0Bharathi100% (1)

- PLF-PRC-015 - R0 - Pipeline Dimensional Procedure and Pre-Execution ChecklistDocument40 pagesPLF-PRC-015 - R0 - Pipeline Dimensional Procedure and Pre-Execution ChecklistHafiz YunusPas encore d'évaluation

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimunthePas encore d'évaluation

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalPas encore d'évaluation

- LREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceDocument10 pagesLREF-00-VDR-BBB-PR-20-0020-A4 Procedure For Process Piping Golden Joint Fabrication, Inspection, and Final AcceptanceNauval Labiby Noor MohammadPas encore d'évaluation

- SA04C2-00-MET-MS-00007 MS Excavation and BackfillingDocument47 pagesSA04C2-00-MET-MS-00007 MS Excavation and BackfillingABAID ULLAHPas encore d'évaluation

- Nqd-Valve Installation ReportDocument21 pagesNqd-Valve Installation ReportprathameshPas encore d'évaluation

- HSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneDocument4 pagesHSVC Ol1/ Zone 2 Hydro Test Organization Chart: PhoneTuấn PhạmPas encore d'évaluation

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhPas encore d'évaluation

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyPas encore d'évaluation

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- WrittenReport Kiehl'sDocument41 pagesWrittenReport Kiehl'sNguyễn Hữu Gia HuyPas encore d'évaluation

- Project Plant Pals Operations & Training PlanDocument3 pagesProject Plant Pals Operations & Training PlanRandhir SwarnkarPas encore d'évaluation

- Knowledge Areas and Life Cycle of Project Management: BSIT-6Document27 pagesKnowledge Areas and Life Cycle of Project Management: BSIT-6Shopify SEOPas encore d'évaluation

- Test Bank For Contemporary Advertising 16th Edition William Arens Michael WeigoldDocument33 pagesTest Bank For Contemporary Advertising 16th Edition William Arens Michael Weigoldtonyriddlekjqofewcmi100% (32)

- Summer Internship Project: 2020-2022 SIP ProposalDocument3 pagesSummer Internship Project: 2020-2022 SIP ProposalRashi GhoshPas encore d'évaluation

- B-KAY Tech CaseDocument2 pagesB-KAY Tech Caseammi890Pas encore d'évaluation

- XPersys Balanced ScorecardDocument3 pagesXPersys Balanced Scorecardprincess QPas encore d'évaluation

- DaburDocument13 pagesDaburSWETA GOGOI-DM 21DM205Pas encore d'évaluation

- Analysis of Perfectly Competitive MarketDocument10 pagesAnalysis of Perfectly Competitive MarketSharif HassanPas encore d'évaluation

- Nike Sprints Ahead of Competition But Still Has A Long Way To RunDocument14 pagesNike Sprints Ahead of Competition But Still Has A Long Way To Rundollie100% (8)

- Sales and MarketingDocument14 pagesSales and MarketingPawar Shirish PrakashPas encore d'évaluation

- Mes LayerDocument59 pagesMes LayerhoaianPas encore d'évaluation

- Chapter 10 Quality Teamwork EmpowermentDocument4 pagesChapter 10 Quality Teamwork EmpowermentSheena RodriguezPas encore d'évaluation

- Chapter 01 - INCOTERMS 2000 - 2010 - 2020Document100 pagesChapter 01 - INCOTERMS 2000 - 2010 - 2020Anh NguyễnPas encore d'évaluation

- Hi! We Are Valtech - Absolunet: Ecommerce IntelligenceDocument21 pagesHi! We Are Valtech - Absolunet: Ecommerce IntelligenceJuan David PerafánPas encore d'évaluation

- Cutting-Plane Method: Gomory's CutDocument5 pagesCutting-Plane Method: Gomory's CutGulieMagdaPas encore d'évaluation

- Module 3 - Mature Business Analysis Practices v.2Document62 pagesModule 3 - Mature Business Analysis Practices v.2Alvaro SotomayorPas encore d'évaluation

- Quality Parts Case StudyDocument2 pagesQuality Parts Case StudyEngr Arslan RazaPas encore d'évaluation

- SCM (G4)Document13 pagesSCM (G4)gautamPas encore d'évaluation

- Marketing PlanDocument4 pagesMarketing PlanEunice S.Pas encore d'évaluation

- My DVC My Voice: Write Back Time Management Learning Curve Temporary Staffing Value Page Good ConductDocument8 pagesMy DVC My Voice: Write Back Time Management Learning Curve Temporary Staffing Value Page Good Conductlaloo01Pas encore d'évaluation

- Marketing Project On Magnum and CornettoDocument37 pagesMarketing Project On Magnum and CornettoMalik Muhammad Bilal50% (2)

- Continuous Process Improvement MethodsDocument76 pagesContinuous Process Improvement MethodsRahulPas encore d'évaluation

- AnswersDocument49 pagesAnswersLawry Enzo100% (3)

- C4 - DPM20033 EditedDocument6 pagesC4 - DPM20033 EditedDaksha queenPas encore d'évaluation

- Determinants of Brand Loyalty: A Study of The Experience-Commitment-Loyalty ConstructsDocument12 pagesDeterminants of Brand Loyalty: A Study of The Experience-Commitment-Loyalty ConstructsVinh VũPas encore d'évaluation

- Marketing Cheat SheetDocument3 pagesMarketing Cheat SheetCharlotte GillandersPas encore d'évaluation

- Portfolio Analysis and SWOTDocument14 pagesPortfolio Analysis and SWOTTera KiddPas encore d'évaluation

- Study of Foreign Trade in InidaDocument11 pagesStudy of Foreign Trade in InidaAYUSHI PATELPas encore d'évaluation

- MCQ On Plant LayoutDocument3 pagesMCQ On Plant LayoutMohan KumarPas encore d'évaluation