Académique Documents

Professionnel Documents

Culture Documents

372 140 Weller WTCPT Manual 41680

Transféré par

VictorFaucheret0 évaluation0% ont trouvé ce document utile (0 vote)

280 vues4 pagesWeller WTCPT Soldering Iron Manual

Titre original

372 140 Weller Wtcpt Manual 41680

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentWeller WTCPT Soldering Iron Manual

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

280 vues4 pages372 140 Weller WTCPT Manual 41680

Transféré par

VictorFaucheretWeller WTCPT Soldering Iron Manual

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Weller Tech Shee

WTCPT Soldering Station

A transformer powered soldering station, complete with a

lightweight, heat insulated, low voltage, temperature con-

trolled soldering iron. The special Weller® “closed loop’

method of controlling maximum tip temperature is em-

ployed, thereby protecting temperature sensitive compo-

nents. The soldering iron features a stainless steal, plug in

heating element construction, anon-burning silicone rubber

ord, and @ large selection of tips in sizes from 1/64"

diameter to 15/64” diameter with a choice of tip temperature

‘of 600°F, 70°F and 80°F. The soldering iron is normally

provided with a PTAT 1/16” screwdriver 700°F tip.

Tho station features a housing of an impact resistant,

polycarbonate plastic for durability and protection against

accidental damage, a quick disconnect plug for the

soldering iron, a lighted on-off switch, and a flexible 3 wire

power cord.

‘The plastic soldering iron holder can be used attached to

elther side of the transformer case, or separated as shown,

The iron holder incorporates a water reservoir with wick to

keep the tip wiping sponge moist,

‘The station housing and hand piece are grounded with a separate conductor that terminates at the third pin on the power

cord. The Weller® WTCPT units are UL listed.

Specifications

Power Unit

Power input: 120 VAC, 60 Hz, (240VAC +/- 10%, 50/60hz) 60 watts.

Power unit output voltage: isolated 24 VAC @ 1.75 amperes,

Size: 4.5" x 5.875" x 3.625"

Line Cord: $ wire, U.L. recognized.

Soldering Iron

Wattage: 42 watts.

Iron weight: 2 ounces.

Recovery time (from 100°F drop) with PTAT tip: 11 seconds,

Cord: Silicone rubber, burn resistant, 4 feet

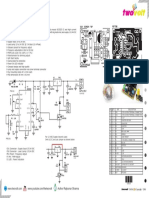

PRINCIPLE OF OPERATION

When the soldering tip is cold, a ferromagnetic temperature sensor (1) attached to the tip attracts a permanent magnet (2)

‘The magnet movement causes a shorting bar (4) to make contact with aset of isolated electrical contacts (3) thereby supplying

power to the heating element through the solder |ugs (6). When the tip reaches its idle temperature, the sensor becomes

onmagnetic and no longer attracts the magnet. Then a magnetic bushing (6) attracts the magnet causing the shorting bar to

break the circuit. In this manner, power to the heating element is turned on and off automatically

CAUTION: Tip is grounded, do not solder an energized circuit.

@suownna war wasnt

@ waonenc @ rewpenarune sensor

Basan |

(© so.08R ws vey

Beoorcr

WTCPT Operating instructions

Unpack unit carefully. Place spring and funnel in slot in top of tool stand. Attach tool stand to either side of power unit, it

desired. Fill reservoir with water and wet sponge, distilled water is preferred. Insert too! in holder and connect tool plug to

receptacle on power unit; rotate plug housing to lock plug into receptacle. Insure correct tip is installed in iron, insert line cord

plug into properly grounded AC receptacle and turn unit on. Wait 30 seconds and tin tip with solder. Unit is now ready for use.

All Weller® PT series soldering iron tips are plated with an exclusive process that deposits three protective coatings. The high

conductivity copper tips are iron plated, nickel plated, then chromium plated on the non-working surfaces. The working surface

is then pre-tinned. The chromium and nickel plating of the tip prevents oxidation of the iran plating which can cause freezing of

the tio in the iron. Weller® "temperature sensing’ tips have a small ferromagnet sensing element attached to the tip shank. The

sensing element is coded with a number to indicate the tip idle temperature in hunareds of degrees F. Thus a simple change of

tips is all that is necessary to adapt the tool to an entirely different temperature range. Use only original Weller® soldering tips.

‘The use of non-Weller components may void product warranty if the non-Weller component causes damage to the unit,

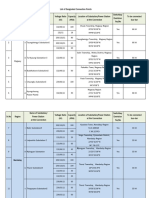

Selection of Weller® PT Series Tips

1. Selecta tip configuration with the maximum working surface, thickest cross section, and shortest reach compatible with the

size, the accessibility, and the visual restrictions of the solder joint.

2. Select a tip temperature based on the size of the solder joint, the temperature sensitivity of the components, and the

production rate required. Please note that tip life is directly related to tip temperature, the lower the tip temperature the

longer the tip lite.

00°F 70°F 80°F Description Tip

PAS pray Pras ‘Screwdriver 116"

PTAAG PTAAT PTAAS Single 116"

PBs PTs? Pres Screwdriver 3/82"

PTBBG PTSB7 PTeBs Single Fiat 3/32"

PTCS PTC? PTCE Screwdriver ve"

proce Prccr proce Single Flat v8"

PTOS prov PTo8 Screwdriver aie"

props PToDT Props Single Flat 3/16"

PTES PTET PTES Screwdriver 15/64"

PTFE PTF? PTFB Conical Fiat 1/32"

PTHE PTHT PTHS ‘Serowdriver 1/32"

PTJ6 PT? PTB Screwdriver Ves"

PTKS PTKT PTKa: Long Serewariver 3/64"

PTLs PTL? Pris Long Screwdriver 5/64"

PTM6 PIM? TMB Long Screwdriver 118

PTNS PINT PING Screwdriver ane"

TOS PTO PTO8 Long Conicat 1/32"

PTPS PIP? PTPB. Conical 32"

PTaS TOT Pras Single Flat 1/32"

PTAG PTR? PTRE Narrow Screwdriver 116"

PTs6 PTs? PTsa Long Conical 1784"

PrTs prT7 PTT Conical 025'

PIX6 PIX7 PTxe Bent, Slotted vse"

Prz6 Prz7 PIza Bent, Slotted 020"

Care Of Weller® PT Series Tips

Keep tinned, wipe only before using

Use rosin or activated rosin fluxes. Acid type fluxes will greatly reduce tip lif.

Flemove tip and clean with suitable cleaner for flux used. The frequency of cleaning will depend on the type of work and

usage. Tips in constant use should be cleaned atleast once a week

Don't try to clean tip with abrasive materials and never file tip, to do so will greatly reduce tip life. f the tip becomes

Unwettable, it may be cleaned with a soft iron or brass brush using solder flux as a solvent; or the Weller® WPBY

Polishing Bar.

5. Don't remove excess solder trom heated tip before storing. The excess solder will prevent oxidation of the wettable surface

when tip is reheated.

6. Don't use anti-seize compounds on tips, the tips have been plate¢ for oxidation protection,

WTCPT Troubleshooting Guide

WARNING: AC line voltage is present inside power unit even when power switch is off. Refer service to qualified personnel.

NOTE: Access to internal parts may be gained by removing four rubber feet, four bottom screws and top case.

1. Tool does not heat

1.4 Check at pin 1 and pin 2 of power unit too! receptacle for 24VAC. If not present, proceed to step 1.3. I power unit tests

9004, TO201T too! is defective

1.2 TC201T troubleshooting guide. (Tool does not heat)

1.2.1Tip check- inspect tip for missing magnastat or wrong type tip. Replace tip. Check tip spring action, there should be

41/16" minimum spring action.

1.2.2 Heating element check - check resistance at pin 1 and pin 2 of tool plug for 12 to 14 ohms. If too! tests good,

connector pins are worn or damaged and not making good contact. If tool tests bad, remove two screws from

ing element flange. Grasp heater barrel and black heat insulator, pull heating element free from tool, Check

1c@ at two closely spaced pins on heating element for 12 to 14 ohms.

1.2.8 Magnastat switch check - place tool on workbench with flat at rear of handle up. Insert 3/16” flatblade screw driver

into slot at rear of handle. Compress cord by pushing downward and toward handle until cordis pushed into handle

(do not pry on handle). This releases the strain relief catch, Slide handle down cord to expose switch terminals.

Check for proper magnastat switch operation by testing for continuity across magnastat switch terminals with tip

held against end of switch; and loss of continuity when tp is removed. If magnastat checks good, check iron cord

wiring for continuity.

1.3 PUT20T/PU240T power unit troubleshooting guide, (No 24VAC at tool receptacle, step 1.1)

1.3.1 Check for switch light when unit is turned on. if switch light is not illuminated, replace fuse located in base.

Use 6/10 amp fuse (315MA, 5X20MM an 240V models). I still not illuminated, the switch, line cord, or asso-

‘ciated wiring is defective. Unplug unit from AG line and check wiring.

41.3.2 Check for 26VAC, +/- 2V, between red and yellow transformer leads. Replace fuse or transformer if defective.

2. TC20NT iron overheats or temperature is higher than marked on tip.

2.1 Replace tip with Weller tip.

2.2 Check magnastat switch and heating element, Refer to step 1.2.2 and 1.2.3 above.

3. High tip voltage or inaication of circuit component damage,

3.1 Check for 2 ohms maximum from tip to ground prong on line cord plug, repair as required.

1004

f. RECEPTACLE

_ t2-14onms

of i | y nner

1 1

a

120 vac | I I SLND wroasrar®

ae i i eee

fk reo| % |.

Fg

a T i

i

at I |

ron | ewhron/vawe 2 |

orion oo é

pio

bo conweereo ro

ITT] HEATER BARREL

Vous aimerez peut-être aussi

- Gto Investment Climate Aug 04 (Westlb)Document21 pagesGto Investment Climate Aug 04 (Westlb)VictorFaucheretPas encore d'évaluation

- Science of Pyramid Energy PDFDocument105 pagesScience of Pyramid Energy PDFVictorFaucheret100% (1)

- Never Worry About Disease Again SlidesDocument51 pagesNever Worry About Disease Again SlidesVictorFaucheret100% (2)

- Chilliwack PotableWaterChemicalAnalysis 2017pdfDocument8 pagesChilliwack PotableWaterChemicalAnalysis 2017pdfVictorFaucheretPas encore d'évaluation

- Halogen Dimmer PDFDocument1 pageHalogen Dimmer PDFVictorFaucheretPas encore d'évaluation

- ElFinaldelaCaída RecuperaciónWIR2005Document1 pageElFinaldelaCaída RecuperaciónWIR2005VictorFaucheretPas encore d'évaluation

- Gto GM Intro To Puerto Interior Oct 04Document12 pagesGto GM Intro To Puerto Interior Oct 04VictorFaucheretPas encore d'évaluation

- OECD Trends&RecentDevelopmentsFDI June06Document26 pagesOECD Trends&RecentDevelopmentsFDI June06VictorFaucheretPas encore d'évaluation

- FDI&Maquiladora Méx 97 04 WIR2005Document1 pageFDI&Maquiladora Méx 97 04 WIR2005VictorFaucheretPas encore d'évaluation

- FDI Brief UNCTAD 06Document2 pagesFDI Brief UNCTAD 06VictorFaucheretPas encore d'évaluation

- Canadian Benefits Scorecard 2005 eDocument4 pagesCanadian Benefits Scorecard 2005 eVictorFaucheretPas encore d'évaluation

- FDI Trends2006 2007 UnctadDocument16 pagesFDI Trends2006 2007 UnctadVictorFaucheretPas encore d'évaluation

- Map of The CreatorDocument7 pagesMap of The CreatorVictorFaucheretPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- New Mantra: 8/14/2020 Prof Jayaraman K Competency in ICET 1Document56 pagesNew Mantra: 8/14/2020 Prof Jayaraman K Competency in ICET 1Sreejith S NairPas encore d'évaluation

- Pre-Amplifier Circuit DiagramDocument2 pagesPre-Amplifier Circuit DiagramrigaboPas encore d'évaluation

- Loading Movement IndicationDocument38 pagesLoading Movement IndicationSaud DhopawnkarPas encore d'évaluation

- 1 - 30 - VLSI Major Project Titles List 2021Document3 pages1 - 30 - VLSI Major Project Titles List 2021Chakhila 123Pas encore d'évaluation

- List of Designated Connection Points Name of Substation/ Power Station at The ConnectionDocument5 pagesList of Designated Connection Points Name of Substation/ Power Station at The Connection李雨Pas encore d'évaluation

- METHODOLOGYDocument4 pagesMETHODOLOGYRaselle EbojoPas encore d'évaluation

- Instalation Guide SecantDocument53 pagesInstalation Guide SecantFranPas encore d'évaluation

- Water Spray Test DeviceDocument9 pagesWater Spray Test DeviceLisun GroupPas encore d'évaluation

- Ficha Tecnica E70 enDocument23 pagesFicha Tecnica E70 enAyan MajiPas encore d'évaluation

- 74LS190Document10 pages74LS190nukachPas encore d'évaluation

- Lecture Note 01 - Introduction and The History of MicroprocessorsDocument74 pagesLecture Note 01 - Introduction and The History of MicroprocessorsPANDHU ARDI PRASETYOPas encore d'évaluation

- Crystal Slant CabinetDocument32 pagesCrystal Slant Cabinet張斯朗Pas encore d'évaluation

- Reyes Exp2 PDFDocument9 pagesReyes Exp2 PDFHero CoursePas encore d'évaluation

- 2.0 Annexure A, I, II and V Has Been Amended As Under Instead of ExistingDocument42 pages2.0 Annexure A, I, II and V Has Been Amended As Under Instead of Existingsri_lntPas encore d'évaluation

- Iec-61082 2 PDFDocument84 pagesIec-61082 2 PDFGabriel Cardozo83% (6)

- Instruction Manual Руководство по эксплуатации: 4-209-278-21 (1) CECH-2508BDocument116 pagesInstruction Manual Руководство по эксплуатации: 4-209-278-21 (1) CECH-2508Bbest bestPas encore d'évaluation

- DC System PowerMaster1Document192 pagesDC System PowerMaster1aladin namlunPas encore d'évaluation

- Collins Catalog 1961 OCR Page 0014Document1 pageCollins Catalog 1961 OCR Page 0014Christian CespedesPas encore d'évaluation

- Investigation of Wi-Fi (Esp8266) Module and Application To An Audio Signal Transmission by Tatap PeretsDocument59 pagesInvestigation of Wi-Fi (Esp8266) Module and Application To An Audio Signal Transmission by Tatap Peretsnestor martourezPas encore d'évaluation

- Ce Series Ce Series Ce Series Ce Series Ce Series: Service ManualDocument581 pagesCe Series Ce Series Ce Series Ce Series Ce Series: Service ManualΠΕΤΡΟΣ ΛΟΥΚΑΣPas encore d'évaluation

- Flyg Publ Dok c2 History 070226 PDFDocument86 pagesFlyg Publ Dok c2 History 070226 PDFПриходько РомаPas encore d'évaluation

- What Is ContactorDocument7 pagesWhat Is ContactorDilip Gangopadhyay100% (1)

- TAIKAI Group-CompressedDocument27 pagesTAIKAI Group-CompressedGV TPas encore d'évaluation

- Moving Iron Instruments: Type Iq 48 Iq Iq 96Document1 pageMoving Iron Instruments: Type Iq 48 Iq Iq 96AkmalPas encore d'évaluation

- A Circularly Polarized 3-D Printed Dielectric Transmitarray Antenna at Millimeter-Wave BandDocument5 pagesA Circularly Polarized 3-D Printed Dielectric Transmitarray Antenna at Millimeter-Wave BandMahrukh BalochPas encore d'évaluation

- 100 TOP COMMUNICATION SYSTEMS Questions and Answers PDF COMMUNICATION SYSTEMS QuestionsDocument18 pages100 TOP COMMUNICATION SYSTEMS Questions and Answers PDF COMMUNICATION SYSTEMS QuestionsEr PavankumarPas encore d'évaluation

- Electric Gas Valve and Manual Reset Relay: FeaturesDocument2 pagesElectric Gas Valve and Manual Reset Relay: FeaturesAnonymous kdFzbQ4jfPas encore d'évaluation

- 240w BenQ Solar PanelDocument2 pages240w BenQ Solar PanelSolarisVPPas encore d'évaluation

- Manual Leviathan-V2.7Document20 pagesManual Leviathan-V2.7Javier GarciaPas encore d'évaluation

- 50471071M - Tilly 1Document120 pages50471071M - Tilly 1Nate Dimple-MaxPas encore d'évaluation