Académique Documents

Professionnel Documents

Culture Documents

Automated Monitoring of The Utilization Rate of Onsite Construction Equipment

Transféré par

akayaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Automated Monitoring of The Utilization Rate of Onsite Construction Equipment

Transféré par

akayaDroits d'auteur :

Formats disponibles

Computing in Civil Engineering 2017 74

Automated Monitoring of the Utilization Rate of Onsite Construction Equipment

Xiaoning Ren1; Zhenhua Zhu2; Chantale Germain3; Roger Belair4; and Zhi Chen5

1

Dept. of Building, Civil, and Environmental Engineering, Concordia Univ., Montreal, Canada

H3G 1M8. E-mail: ryanren528@gmail.com

2

Dept. of Building, Civil, and Environmental Engineering, Concordia Univ., Montreal, Canada

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

H3G 1M8. E-mail: zhenhua.zhu@concordia.ca

3

Direction Ingénierie de Production Hydro-Québec, 855 Ste-Catherine est, Montréal, QC,

Canada H2L 4P5. E-mail: Germain.Chantale@hydro.qc.ca

4

Nouveaux aménagements et marches Hydro-Québec, 855 Ste-Catherine est, Montréal, QC,

Canada H2L 4P5. E-mail: Belair.Roger@hydro.qc.ca

5

Dept. of Building, Civil, and Environment Engineering, Concordia Univ., Montreal, Canada

H3G 1M8. E-mail: zhi.chen@concordia.ca

Abstract

The efficient utilization of construction equipment plays a significant role in engineering and

building operations, since the utilization information is instrumental for construction equipment

management and project cost control. Therefore, it is necessary to monitor the utilization rate of

onsite equipment in order to maintain the efficiency of construction operations. In current

practices, the monitoring of the utilization rate of onsite construction equipment mainly relies on

the manual observations by field engineers, which is time-consuming and labor-intensive. The

main objective of this paper is to present a vision-based method to automate the monitoring of

the utilization rate of onsite construction equipment. Under this method, the equipment of

interest is firstly localized and tracked in video frames. Also, the positions of the equipment in

video frames are extracted. Then, the location information of equipment is analyzed in

comparison with the location information of work zones at the jobsite. Such way, the utilization

rate of construction equipment in each work zone can be measured. Accordingly, construction

professionals can conduct the further analysis, in terms of productivity analysis and equipment

rental expense calculation. The method has been tested on the construction site of Poste De

Lorimier in Canada. The test results demonstrated the capability and effectiveness of the method

to monitor the utilization rate of construction equipment in an automatic manner.

INTRODUCTION

The utilization rate of construction equipment is concerned with identifying the total available

time of the onsite equipment for production (Ahn and Lee 2013). The efficient utilization of

construction equipment plays an indispensable role on the success of a construction project. It

could contribute not only to support the construction equipment management, but manage the

project cost. In order to achieve the maximum equipment investment return, it is necessary to

collect the utilization information of onsite equipment in a timely and accurate manner.

Traditionally, the equipment utilization data collection is conducted by field engineers through

manually observations, which is time-consuming, labor-intensive and inaccurate. Thus, a

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 75

plethora of studies have been investigated using tracking technologies, such as Global

Positioning Systems (GPS) (Pradhananga and Teizer 2013), Ultra-Wide Band (UWB) (Cheng et

al. 2012) and Radio Frequency Identification (RFID) (Ergen and Akinci 2007). The tests have

showed the promising performance and ability to find the correspondence equipment and its

trajectory on construction sites. However, it is required to install tags or sensors on each piece of

equipment of interest using these technologies. This requirement limits their applications on

large-scale construction sites where tens of equipment needs to be tagged. Therefore, it is

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

pressing to identify a method to monitor and collect equipment utilization information in a cost-

effective and efficient manner.

The main objective of this paper is to present a vision-based method of automatically locating

and tracking the onsite equipment to facilitate the measurement of equipment utilization rate.

The construction site of Poste De Lorimier funded by Hydro-Qeubec in Montreal was selected as

the test bed. In order to achieve the goal, a high definition camera was statically placed at the

jobsite to record the construction activities. Under the proposed method, the construction site

was firstly divided into several work zones based on the construction site plan drawings, which

were highlighted in video frames. The equipment was detected and tracked in video frames, and

then their locations (2D coordinates in images) were extracted. Following that, the equipment

location information was compared with the location information of work zones to determine

which work zone the equipment resided in. At the end, a detailed report of the equipment

utilization in the corresponding work zone across time was generated for further analysis. The

utilization report could be used by contractors to facilitate the construction equipment

management. Also, it can be employed to assist the owners in verifying the bills of equipment

rental expenses. The results indicate the proposed method is effective and efficient in monitoring

the onsite equipment utilization information.

BACKGROUND

In recent years, a plethora research efforts have been placed on the automatic monitoring of

construction resources using state-of-the-art tracking technologies, such as GPS, RFID and UWB.

Numerous tracking technologies-based systems were developed to monitor project related

entities. For example, Caldas et al. (2006) investigated a study that aimed to determine the

potential benefits of the deployment of GPS technology for the materials tracking processes of

large-scale construction projects. Song et al. (2006) presented an approach whereby construction

materials equipped with RFID tags can be automatically identified and tracked on construction

sites without any regular site operations. Chen et al. (2011) conducted a study to measure the

performance of the UWB technology for tracking mobile resources con construction sites.

However, the need for the installation of tags on each entity limits their use for tracking on large-

scale sites where there are hundreds of equipment.

As an alternative, vision-based methods have gained a lot of interests in construction community,

since the cameras can capture a wealth of construction site information for decision-makers and

professionals. For example, in construction performance monitoring, Bohn and Teizer (2010)

introduced that cameras are instrumental in monitoring the real-time construction progress,

allowing for early detection of construction deviations and better planning for following tasks.

Memarzadeh et al. (2013) presented a vision-based method to automatically detect standing

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 76

construction workers and idle equipment in site video streams. In resource tracking and

recognition, Brilakis et al. (2008) proposed a novel machine vision-based method for project

related entities tracking with construction cameras on open sites. Chi and Caldas (2011)

proposed a method for automated object detection for the moving equipment and personnel using

video cameras for heavy-equipment-intensive construction sites. In safety control, Yang et al.

(2010) developed a machine-learning-based multiple worker tracking scheme using video frames

for the onsite safety concerns. Han et al. (2012) proposed a vision-based method to detect unsafe

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

actions in site videos through motion capture techniques. Although the effectiveness of the

vision-based method in the engineering applications has been testified, few research efforts have

been investigated to demonstrate its efficiency in monitoring the equipment utilization. Therefore,

the main motivation of this study is to test the effectiveness of the vision-based method in

automatically monitoring the equipment utilization.

OBJECTIVE AND PROPOSED FRAMWORK

The main objective of this paper is to present a vision-based method for automatically

monitoring the equipment utilization on construction sites. With such method, contractors and/or

owners can obtain the equipment utilization information in a timely and automatic manner. Also,

an equipment utilization report can be generated for further analysis, such as equipment rental

expense verification and construction equipment management.

The proposed method mainly consists of 4 steps: 1) equipment detection; 2) equipment tracking;

3) work zone classification; 4) equipment utilization analysis. The positions of the utilized

equipment are detected, tracked and marked with the corresponding work zones. Then, a report

of the equipment utilization on the construction site can be generated to assist practitioners in

project cost control and construction equipment management. Figure 1 illustrates the overview of

the proposed framework.

New video

frames

Equipment Bounding Equipment Tracking

Detection Box Tracking Results

First video Equipment

Work Zone Work Zone Utilization

frame Utilization

Classification Information Report

Analysis

Site

Planning

Drawings

Figure 1. Flowchart of the proposed method

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 77

Equipment Detection

In this step, the equipment was detected and enclosed with the bounding boxes in the first video

frame. Specifically, the videos were firstly extracted into images, which were divided into two

datasets, one training dataset and one test dataset. Then, the equipment recognition models were

trained based on the Histogram of Orient Gradients (HOG) method using the training images.

The equipment recognition models are focused on the most common used machinery types, the

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

excavators and trucks. When the equipment is detected in the video frame, the bounding box will

be used to initialize the tracker in the following video sequences.

Work Zone Classification

The second step is to classify the construction site into work zones in the image frame based on

the site planning drawings. Since the camera was statically mounted at the jobsite, the pixel

regions of the construction site in each video frame are constant. Therefore, pixel regions of each

work zone can be highlighted in the video frames.

Equipment Tracking

In this step, a particle filtering-based tracking method (Zhu et al. 2016) is employed to track

construction equipment. The effectiveness of the method in tracking construction related entities

under the occlusion and clutter conditions has been tested. After the equipment was tracked, the

centroid coordinates of the bottom boundary of the bounding box are computed. Then, the

centroid coordinates are used to compare with the location information of each work zone. Such

way, the location of utilized equipment is labeled in the corresponding work zone. Based on the

utilization information, the time of the equipment spent on the construction site is identified for

further analysis.

Equipment Utilization Analysis

The fourth step is to generate the equipment utilization report. After the acquisition of marked

equipment location, the equipment location information is tabulated along with the time and the

corresponding location information of work zones. It is common that the machinery is paid on an

hourly basis. No matter whether the activity they have done is a value-added one or not, owners

have to pay for the expense once they are at the jobsite. With such report, owners and contractors

could conduct analysis on the equipment management and verify the bills.

IPLEMENTATION AND RESULTS

Implementation

The proposed method had been implemented as a prototype in the Matlab R2015a platform. The

method was tested in a 64-bit operating system, Microsoft Windows 7 Enterprise. The hardware

configuration for the test includes an Intel® Core-i7-4770 CPU @3.40GHz and 8 gigabytes

memory, and an NVIDIA Quadro 600 GPU (graphic processing unit).

Project Background

In order to test the effectiveness of the proposed method, a high definition camera was placed on

the construction site, Poste De Lorimier in Montreal, Canada, to record the construction activities.

The project is funded by Hydro-Quebec, which is going to build a transformer substation with

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 78

315/25 KV.

K Also, it is to place twot 315-kV undergrounnd lines of ab about 7 kilom

meters to connnect

the new De

D Lorimierr substation tot other subsstations. Thee captured vvideos were ttransmitted tto the

server thrrough the local wireless networking.

Results

A high definition

d caamera (Axiss P1425-LE E, Sweden) was staticallly placed aat the top oof the

building to record coonstruction activities

a into

o videos (Shhown in Figuure 2 (a, b)). All videos were

captured in the outdooor environmment with thee resolution of 1920 * 1080 at 25 frrames per seccond.

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

An exam mple of videoo frames is displayed in Figure

F 2 (c).

Figure 2. (a) Camera set-up

p; (b) Cameera placemeent; (c) An eexample of vvideo framees

Figure

F 3. Work

W zone cllassification

n

The consstruction sitee was firstlyy classified into work zzones in acccordance to the site plannning

drawingss, as shown in Figure 3.. Figure 4 illustrates thee equipment detection reesults. The ttipper

truck and d the excav vator are en

nclosed in th he boundingg boxes. Thhen, the cooordinates of each

bounding g box can bee obtained. After

A the acqquisition of thhe coordinattes of each bbounding boxx, the

particle filter-based

f tracker

t can be

b initializedd. As shown in Figure 5,, examples oof tracking reesults

for excavvator are deescribed. The excavator was movinng from one side of thee work zonee 2 to

another side.

s The traacker could keep

k trackinng even whenn the pose oof the excavaator was sevverely

changed. Similarly, thet tracking results

r for th

he truck are ddisplayed inn Figure 6.

Figure 4. Examples

E of equipmen

nt detection results

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 79

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

Figure

F 5. Ex

xamples of tracking results for exccavator

Figure 6. Examples of

o tracking results for ttruck

After ob btained the tracking

t ressults, the ceentroid coorddinates of tthe bottom boundary oof the

bounding g box in each h video fram

me are calcullated. Since the goal of this study iss to automatiically

monitor the

t utilizatioon rate of th

he equipmen nt, the approoximate equiipment posittion can meeet the

monitorin ng purposess. Thereforee, the centrroid coordinnates of thhe bottom bboundary of the

bounding g box can be b assumed as the equip pment posittions. Then, the coordinnates are used to

compare with the loccation inform mation of eaach work zoone. Such waay, the equippment of intterest

can be taagged with the

t corresponding work zone. Figurre 7 shows aan example of the excavvator.

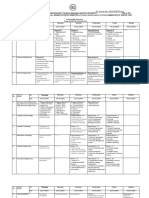

When th he equipmen nt is tagged d with the correspondding work zzone, a dettailed equippment

utilization report caan be generaated, as sho own in Figuure 8. Withh the report,, contractorss can

conduct the analysiss of the equ uipment utiliization rate calculation based on thhe appearannce in

work zon nes. Also, the

t equipmeent utilizatio on informattion can be used to veerify the billls of

equipmen nt rental exp

pense by own ners.

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 80

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

Figuree 7. (a) Traccking resultss (b) Centro

oid coordinaates calculaation (c) Loccation taggin

ng

Figurre 8. Snapsh

hot of utilizaation reportt

LUSION

CONCL

The equiipment utilizzation plays an importan nt role on thhe success oof a construcction projectt. The

efficient equipment utilization doesd not suppport the coonstruction eequipment m managementt, but

ntly facilitatte the projecct cost contrrol. Thereforre, it is neceessary to moonitor and coollect

significan

the equippment utilizaation in an efffective and accurate maanner. The m main objectivve of this stuudy is

to propoose a vision--based meth hod for auto omatically mmonitoring tthe equipmeent utilizatioon on

constructtion sites. Under

U this method,

m a dettailed equipm ment utilizaation report can be geneerated

for decission-makers and professsionals. Thee utilization report coulld be used bby contractoors to

support the

t constructtion equipm ment managem ment. Also, it can be em mployed to assist the ow wners

in verifyiing the billss of equipmeent rental ex xpenses. Thee results testtified the efffectiveness oof the

proposedd method in the automattic monitorin ng of the equuipment utillization on cconstruction sites.

Besides, this method d is particulaarly suitablee for remotes constructioon sites wheere is not allways

accessiblle for engineeers to collecct data.

© ASCE

Computing in Civil Engineering 2017

Computing in Civil Engineering 2017 81

ACKNOWLEDGEMENT

This paper is based in part upon work supported by the National Science and Engineering

Research Council (NSERC) of Canada. Any opinions, findings, and conclusions or

recommendations expressed in this paper are those of the author(s) and do not necessarily reflect

the views of the NSERC.

REFERENCES

Downloaded from ascelibrary.org by University of California, San Diego on 06/14/17. Copyright ASCE. For personal use only; all rights reserved.

Ahn, C. and Lee, S. (2013). "Importance of Operational Efficiency to Achieve Energy Efficiency

and Exhaust Emission Reduction of Construction Operations." J. Constr. Eng. Manage.,

10.1061/(ASCE)CO.1943-7862.0000609, 404-413.

Bohn, J. and Teizer, J. (2010). “Benefits and Barriers of Construction Project Monitoring Using

High-Resolution Automated Cameras.” J. Constr. Eng. Manage., 136(6), 632–640.

Brilakis, I., Cordova, F., and Clark, P. (2008). “Automated 3D vision tracking for project control

support.” Proc., Joint US-European Workshop on Intelligent Computing in Engineering,

487–496.

Caldas, C.H., Torrent, D.G., Haas, C.T., (2006). “Using global positioning system to improve

materials-locating processes on industrial projects.” J. Constr. Eng. Manage., 132 (7)

(2006), pp. 741–749

Cheng, T., Mantripragada, U., Teizer, J., Vela, P.A., (2011). Automated trajectory and path

planning analysis based on ultra-wide band data, J. Comput. Civ. Eng. 26 (2012) 151–

160.

Chi, S. and Caldas, C. (2011). “Automated object identification using optical video cameras on

construction sites.” Computer-Aided Civil and Infrastructure Engineering, 26(5): 398-

380.

Ergen, E. and Akinci, B. (2007), “An overview of approaches for utilizing RFID in construction

industry.” 1st Annual RFID Eurasia, IEEE, 2007, pp. 1–5.

Fan, H., AbouRizk, S., and Kim, H. (2007) “Building Intelligent Applications for Construction

Equipment Management.” Computing in Civil Engineering (2007): pp. 192-199. doi:

10.1061/40937(261)24

Han, S., Lee, S., and Peña-Mora, F. (2012) “Vision-Based Motion Detection for Safety Behavior

Analysis in Construction.” Construction Research Congress 2012: pp. 1032-1041.

Memarzadeh, M., Golparvar-Fard, M., Niebles, J.C., (2013). “Automated 2D detection of

construction equipment and workers from site video streams using histograms of oriented

gradients and colors.” Automation in Construction, 32 (2013), pp. 24–37 ISSN 0926-

5805

Pradhananga, N. and Teizer J. (2013). “Automatic spatio-temporal analysis of construction site

equipment operations using gps data.” Autom. Construct., 29 (2013), pp. 107–122

Song, J., Haas, C.T. and Caldas, C.H. (2006). “Tracking the location of materials on

construction job sites.” ASCE, Journal of Construction Engineering and Management,

132 (9) (2006), pp. 911–918

Yang, J., Arif, O., Vela, P. A., Teizer, J., and Shi, Z. (2010). “Tracking multiple workers on

construction sites using video cameras.” Adv. Eng. Inform., 24(4), 428–434.

Zhu, Z., Ren, X., and Chen, Z. (2016). "Visual Tracking of Construction Jobsite Workforce and

Equipment with Particle Filtering." J. Comput. Civ. Eng., 10.1061/(ASCE)CP.1943-

5487.0000573, 04016023.

© ASCE

Computing in Civil Engineering 2017

Vous aimerez peut-être aussi

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successD'EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- 5-6 Semester 0 PDFDocument39 pages5-6 Semester 0 PDFCG13698Pas encore d'évaluation

- Fface Isarc15 3063655Document8 pagesFface Isarc15 3063655imW3RazeemPas encore d'évaluation

- BTECH All Branch 7th-Semt CBCS_3Document3 pagesBTECH All Branch 7th-Semt CBCS_3Sushant VyasPas encore d'évaluation

- Bachelor of Science in Civil EngineeringDocument7 pagesBachelor of Science in Civil EngineeringViele Antonette NaranjoPas encore d'évaluation

- Politecnico Di Milano - BrochureDocument6 pagesPolitecnico Di Milano - BrochureMuhammad UsmanPas encore d'évaluation

- 7-Sem Corrected Time-Table BTech 7-Sem All Br. CBCSDocument3 pages7-Sem Corrected Time-Table BTech 7-Sem All Br. CBCSPratham WakdePas encore d'évaluation

- Weekly Accompishment Report Format WPR 002 (18 - 24) February 2023Document29 pagesWeekly Accompishment Report Format WPR 002 (18 - 24) February 2023rhannie garciaPas encore d'évaluation

- Mehedi Hasan's Resume_B.SC_Resume-Document3 pagesMehedi Hasan's Resume_B.SC_Resume-mehedePas encore d'évaluation

- Volume I BSC Engineering Curriculum For Intake 2020 OnwaDocument246 pagesVolume I BSC Engineering Curriculum For Intake 2020 OnwaSiduhar SharmaPas encore d'évaluation

- CP11Document9 pagesCP11Bharat KhandekarPas encore d'évaluation

- MUT Civil Engineering DegreeDocument7 pagesMUT Civil Engineering DegreeZoom LotusPas encore d'évaluation

- BTECH All Branch 7th-Semt CBCS - 2Document3 pagesBTECH All Branch 7th-Semt CBCS - 2navneetburnure8766Pas encore d'évaluation

- Batangas State University BSCE CurriculumDocument6 pagesBatangas State University BSCE CurriculumNioro FuriscalPas encore d'évaluation

- 2006 - Article - Hatch - Wind Farm Design OptimizationDocument9 pages2006 - Article - Hatch - Wind Farm Design OptimizationUeliquis Jose da SilvaPas encore d'évaluation

- Malnad College of Engineering, Hassan: (An Autonomous Institution Affiliated To VTU, Belagavi)Document66 pagesMalnad College of Engineering, Hassan: (An Autonomous Institution Affiliated To VTU, Belagavi)Keerthana KeerthanaPas encore d'évaluation

- BTech Civil Curriclum2014 15Document128 pagesBTech Civil Curriclum2014 15Rajath BysaniPas encore d'évaluation

- Course Directory For B.Tech - in Chemical Engineering: Offered by The School of Chemical and BiotechnologyDocument26 pagesCourse Directory For B.Tech - in Chemical Engineering: Offered by The School of Chemical and BiotechnologyGaurav BfgPas encore d'évaluation

- Project Instruction Software 2Document2 pagesProject Instruction Software 2Dg IRfanPas encore d'évaluation

- CV Civil Engineer 10+ Years ExperienceDocument4 pagesCV Civil Engineer 10+ Years ExperienceMahibul HasanPas encore d'évaluation

- CSCEC M&E Works in The Construction Industry (Engineering, Procurement and Construction Contractor)Document3 pagesCSCEC M&E Works in The Construction Industry (Engineering, Procurement and Construction Contractor)nik haslaPas encore d'évaluation

- L8 Engineer in Society (2017 R)Document18 pagesL8 Engineer in Society (2017 R)CheongPas encore d'évaluation

- Application of DOE-TOPSIS Technique in Decision-Making ProblemsDocument5 pagesApplication of DOE-TOPSIS Technique in Decision-Making ProblemsDeclan AnassPas encore d'évaluation

- 6 CEng 154 - SLGDocument3 pages6 CEng 154 - SLGJoenem AbenojaPas encore d'évaluation

- UG 4-1 R19 Civil SyllabusDocument42 pagesUG 4-1 R19 Civil SyllabusMasimukkala SunithaPas encore d'évaluation

- NYCU-CoE Information Session 2023Document13 pagesNYCU-CoE Information Session 2023HERLINA PEBRIANIPas encore d'évaluation

- Naukri RajeshKumarRoyChoudhury[22y 0m]Document6 pagesNaukri RajeshKumarRoyChoudhury[22y 0m]sushil.tripathiPas encore d'évaluation

- What Is Engineering Dr. Siddharth G. Shah.Document64 pagesWhat Is Engineering Dr. Siddharth G. Shah.SG ShahPas encore d'évaluation

- CV 2023111510522526Document2 pagesCV 2023111510522526sathishganeshan2000Pas encore d'évaluation

- XXX QA KPI PerformanceDocument1 pageXXX QA KPI Performanceamin talibinPas encore d'évaluation

- Gujarat Technological University: Society Management SystemDocument5 pagesGujarat Technological University: Society Management SystemBirjuPas encore d'évaluation

- DocxDocument5 pagesDocxPedro de Lima NetoPas encore d'évaluation

- Delay Factors: A Comparative Analysis Between Road Infrastructure and Building ProjectsDocument9 pagesDelay Factors: A Comparative Analysis Between Road Infrastructure and Building ProjectsSANTIAGO OSORIO GALINDOPas encore d'évaluation

- Short Term CoursesDocument14 pagesShort Term CoursesMd SajidPas encore d'évaluation

- IOP Conference Series: Materials Science and Engineering Assessment of BIM ProcessesDocument7 pagesIOP Conference Series: Materials Science and Engineering Assessment of BIM ProcessesMárcio Mota JúniorPas encore d'évaluation

- 8 Waste ManagemnetDocument52 pages8 Waste ManagemnetMayurkumar patilPas encore d'évaluation

- REDA HAMAD CV - Senior Project EngineerDocument8 pagesREDA HAMAD CV - Senior Project EngineerRida Hamad100% (1)

- 2021 - Lean Construction Analysis of ConcreteDocument8 pages2021 - Lean Construction Analysis of ConcreteMichellPas encore d'évaluation

- BC3-2013 - Cal Sample Calculations For SeismicDocument11 pagesBC3-2013 - Cal Sample Calculations For SeismicLau Kim HwaPas encore d'évaluation

- Career Episode 2 Nguyen Anh TaiDocument9 pagesCareer Episode 2 Nguyen Anh TaiDavid TranPas encore d'évaluation

- Proposal For UTeM Falculty of Engineering TechnologyDocument7 pagesProposal For UTeM Falculty of Engineering TechnologyWinsonLimHuiWahPas encore d'évaluation

- MECH R2020 V VI SyllabusDocument62 pagesMECH R2020 V VI SyllabusAshvanee GargPas encore d'évaluation

- Integrating A Procurement Management Process IntoDocument22 pagesIntegrating A Procurement Management Process Intofrancis pacaiguePas encore d'évaluation

- Integrating Supply Chain and Critical Chain Concepts in Engineer-Procure-Construct (EPC) ProjectsDocument10 pagesIntegrating Supply Chain and Critical Chain Concepts in Engineer-Procure-Construct (EPC) Projectsapi-3707091Pas encore d'évaluation

- Batangas State University BS Sanitary Engineering CurriculumDocument5 pagesBatangas State University BS Sanitary Engineering CurriculumNioro FuriscalPas encore d'évaluation

- Civil Engineering - Civil Engineering ReviewDocument2 pagesCivil Engineering - Civil Engineering ReviewFrancis Philippe Cruzana CariñoPas encore d'évaluation

- IITH Departmental Brochure Chemical Engineering 2023 v2.6Document47 pagesIITH Departmental Brochure Chemical Engineering 2023 v2.6Satyabrata PandaPas encore d'évaluation

- Batatota Popwer Plant Project 1 PDFDocument16 pagesBatatota Popwer Plant Project 1 PDFAnonymous DfaS5nSimJPas encore d'évaluation

- BTech 2022 Onwards 91043Document127 pagesBTech 2022 Onwards 91043jatinb.cm.22Pas encore d'évaluation

- 5520 BriefDocument3 pages5520 BriefJazib AliPas encore d'évaluation

- 5520 BriefDocument3 pages5520 BriefJazib AliPas encore d'évaluation

- Hemant C.V.Document9 pagesHemant C.V.hychauhan1Pas encore d'évaluation

- An P5808126 - Piping EngineendeDocument15 pagesAn P5808126 - Piping Engineendesharan21vPas encore d'évaluation

- 2 ElsevierDocument19 pages2 Elseviersanaz shoaiePas encore d'évaluation

- (Online First) : Cost Management of Mechanical and Electrical Engineering Project Based On Bim TechnologyDocument5 pages(Online First) : Cost Management of Mechanical and Electrical Engineering Project Based On Bim TechnologyDina ArifianthyPas encore d'évaluation

- Master C-Eng Mse - Web2019Document2 pagesMaster C-Eng Mse - Web2019Igor BarcelosPas encore d'évaluation

- Curriculum: Bachelor of Science in Chemical Engineering (Bsche)Document5 pagesCurriculum: Bachelor of Science in Chemical Engineering (Bsche)LORIA DAGLIPas encore d'évaluation

- Lecure-1 &2Document27 pagesLecure-1 &2Anusha DesaiPas encore d'évaluation

- Environmental Pollution Control MeasuresDocument12 pagesEnvironmental Pollution Control MeasuresAravinda RajhgopalPas encore d'évaluation

- A Smart Construction Object (SCO) - Enabled Proactive Data Management System For Construction Equipment ManagementDocument9 pagesA Smart Construction Object (SCO) - Enabled Proactive Data Management System For Construction Equipment ManagementakayaPas encore d'évaluation

- Visual Tracking of Construction Jobsite Workforce and Equipment With Particle FilteringDocument15 pagesVisual Tracking of Construction Jobsite Workforce and Equipment With Particle FilteringakayaPas encore d'évaluation

- Improve operations with work studyDocument5 pagesImprove operations with work studyMonika GadgilPas encore d'évaluation

- Construction Management Functions For Developing Countries: Case of CambodiaDocument9 pagesConstruction Management Functions For Developing Countries: Case of CambodianaveedPas encore d'évaluation

- Impacts of Construction Work Zone Equipment and Operations On Vehicle SpeedsDocument11 pagesImpacts of Construction Work Zone Equipment and Operations On Vehicle SpeedsakayaPas encore d'évaluation

- Tsim Be Rdon Is 1994Document14 pagesTsim Be Rdon Is 1994akayaPas encore d'évaluation

- Dewatering For ConstructionDocument14 pagesDewatering For ConstructionpabulumzengPas encore d'évaluation

- Kang2018 Case StudyDocument12 pagesKang2018 Case StudyakayaPas encore d'évaluation

- Engineering and Project and Construction Management Productivity 2014Document13 pagesEngineering and Project and Construction Management Productivity 2014akayaPas encore d'évaluation

- Earthmoving Equipment Fatalities in The Construction IndustryDocument8 pagesEarthmoving Equipment Fatalities in The Construction IndustryakayaPas encore d'évaluation

- Effects of Idle Time Restrictions On Excess Pollution From Construction EquipmentDocument9 pagesEffects of Idle Time Restrictions On Excess Pollution From Construction EquipmentakayaPas encore d'évaluation

- Improvement Management Tools in The Construction Industry: Case Study of MexicoDocument9 pagesImprovement Management Tools in The Construction Industry: Case Study of MexicoakayaPas encore d'évaluation

- Application of Low-Cost Accelerometers For Measuring The Operational Efficiency of A Construction Equipment FleetDocument11 pagesApplication of Low-Cost Accelerometers For Measuring The Operational Efficiency of A Construction Equipment FleetakayaPas encore d'évaluation

- Iec 60287 Grouping TableDocument2 pagesIec 60287 Grouping TableAnas Yousuf100% (1)

- Synaxis Prequalification (2018)Document82 pagesSynaxis Prequalification (2018)Synaxis ReadymixPas encore d'évaluation

- Meng (2018) - Finite Element Analysis of Bridge Crane Metal Structure Based On ABAQUSDocument5 pagesMeng (2018) - Finite Element Analysis of Bridge Crane Metal Structure Based On ABAQUSGogyPas encore d'évaluation

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocument21 pagesCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- Iapmo Ues Er712Document10 pagesIapmo Ues Er712Ngân NguyễnPas encore d'évaluation

- Repair Concrete StructuresDocument3 pagesRepair Concrete StructuresSindhe SwethaPas encore d'évaluation

- On Vertical Formwork: Concr Ete PressureDocument7 pagesOn Vertical Formwork: Concr Ete PressureatiPas encore d'évaluation

- Hindware Sanitaryware Water Closets (WC) CatalogueDocument148 pagesHindware Sanitaryware Water Closets (WC) CatalogueKunNous DesignsPas encore d'évaluation

- Imphal EasaaDocument1 pageImphal EasaaKosygin LeishangthemPas encore d'évaluation

- Electrical Service Minimum RequirmentDocument97 pagesElectrical Service Minimum RequirmentachniajosiPas encore d'évaluation

- Concrete Shell ElementDocument25 pagesConcrete Shell ElementRudranath BhattacharyaPas encore d'évaluation

- Engineering Manager JD IHCCDocument3 pagesEngineering Manager JD IHCCDomie Neil Bucag SalasPas encore d'évaluation

- Pump (English) TemplateDocument1 pagePump (English) TemplateMichael HaisePas encore d'évaluation

- First Asian Experienced Plaxis User Course 2003 - 2Document377 pagesFirst Asian Experienced Plaxis User Course 2003 - 2Đại Ca MậpPas encore d'évaluation

- Engineering Geological Practice in Hong Kong Vol1Document155 pagesEngineering Geological Practice in Hong Kong Vol1Nguyen Thanh BinhPas encore d'évaluation

- PDS - SikaWrap FX-50 C-En PDFDocument3 pagesPDS - SikaWrap FX-50 C-En PDFjohanes b mudaPas encore d'évaluation

- Variable Hangers and Supports - 2018 - Rev.3.1Document19 pagesVariable Hangers and Supports - 2018 - Rev.3.1Nassim Ben AbdeddayemPas encore d'évaluation

- 04.new Liquid Overflow Handling System To Prevent Process Tank FiresDocument14 pages04.new Liquid Overflow Handling System To Prevent Process Tank FiresHerry SuhartomoPas encore d'évaluation

- Building Codes in Special RegionsDocument12 pagesBuilding Codes in Special RegionsMeghanaagarwal90% (1)

- 13 PT ProcedureDocument14 pages13 PT ProcedureThân KhaPas encore d'évaluation

- Series 175 56 KW: Drive ShaftDocument4 pagesSeries 175 56 KW: Drive Shaftjiten kumar BiswalPas encore d'évaluation

- Customer Outstanding Till 26-02-2013Document24 pagesCustomer Outstanding Till 26-02-2013Shekhar MahalePas encore d'évaluation

- Solid State WeldingDocument14 pagesSolid State WeldingRaju_pancal100% (1)

- Car Park DesignDocument71 pagesCar Park DesignAlf Horseman100% (1)

- Seismic Design Guide For Masonry Buildings: Donald Anderson Svetlana BrzevDocument113 pagesSeismic Design Guide For Masonry Buildings: Donald Anderson Svetlana BrzevVladimir Sánchez CalderónPas encore d'évaluation

- VP Task 3. NewwDocument40 pagesVP Task 3. NewwRidhwan KnwPas encore d'évaluation

- SOP's 2020-2021Document144 pagesSOP's 2020-2021Muhammad AbdullahPas encore d'évaluation

- Buttress DamDocument65 pagesButtress DamAF.RISHARD FAIS77% (13)

- Lecture Notes Contract Unit 1Document126 pagesLecture Notes Contract Unit 1Iyyer CookPas encore d'évaluation

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithPas encore d'évaluation

![Naukri RajeshKumarRoyChoudhury[22y 0m]](https://imgv2-1-f.scribdassets.com/img/document/719216431/149x198/26e9399d97/1712037932?v=1)