Académique Documents

Professionnel Documents

Culture Documents

Vehicle-Bridge Interaction Element For Dynamic Analysis PDF

Transféré par

Bindu SrirangamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vehicle-Bridge Interaction Element For Dynamic Analysis PDF

Transféré par

Bindu SrirangamDroits d'auteur :

Formats disponibles

VEHICLE-BRIDGE INTERACTION ELEMENT FOR DYNAMIC ANALYSIS

By Yeong-Bin Yang; Member, ASCE, and Jong-Dar Yau 2

ABSTRACT: The objective of this study is to develop an element that is both accurate and efficient for modeling

the vehicle-bridge interaction (VBI) in analysis of railway bridges carrying high-speed trains, which may consist

of a number of cars in connection. In this study, a train is modeled as a series of sprung masses lumped at the

bogie positions and a bridge with track irregularities by beam elements. Two sets of equations of motion that

are coupled can be written, one for the bridge and the other for each of the sprung masses. To resolve the

problem of coupling, the sprung mass equation is first discretized using Newmark's finite difference formulas

and then condensed to that of the bridge element in contact. The element derived is referred to as the vehicle-

bridge interaction element, which has the same number of degrees of freedom (OaF) as the parent element,

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

while possessing the properties of symmetry and bandedness in element matrices. For this reason, conventional

assembly procedures can be employed to forming the structure equations. The applicability of the VBI element

is demonstrated in the numerical studies.

INTRODUCTION ceed to solve the bridge equations for improved values of dis-

placements for the contact points. The advantage of such an

Following the pioneer works of Stokes (1849) and Willis approach is that the reponse of vehicles and bridges at any

(1849) in the mid-19th century, the vibration of bridges caused time step is made available. However, the convergence rate of

by the passage of railroad cars has been investigated by a great iteration is likely to be low, when dealing with the more re-

number of researchers. Partly enhanced by the construction of alistic case of a bridge carrying a large number of vehicles in

high-speed rails worldwide, this subject is becoming a focus motion, for there exists twice the number of contact points if

of increasing interest. In a survey paper by Diana and Cheli each vehicle is modeled as two sprung mass systems.

(1989), issues relating to the train-bridge interactions have Other approaches for solving the VBl problems include

been discussed, with 90 papers cited. By modeling a moving those based on the condensation method. Garg and Dukkipati

vehicle as a moving load, moving mass, or moving sprung (1984) used the Guyan reduction scheme to condense the ve-

mass considering the suspension effects, the dynamic response hicle degrees of freedom (DOF) to the associated bridge DOF.

of bridges induced by moving vehicles has been studied by Recently, Yang and Lin (1995) used the dynamic condensation

researchers from time to time (Timoshenko 1922; Jeffcott method to eliminate all the vehicle DOF on the element level.

1929; Lowan 1935; Ayre and Jacobsen 1950; Ayre et al. 1950; However, if the behavior of the vehicle is concerned, which

Biggs 1964; Fryba 1972; Chu et al. 1979; Stangic 1985; Sa- serves as an indicator of the riding comfort, these two ap-

diku and Leipholz 1987; Chatterjee et al. 1994). More proaches cannot be considered acceptable, because of the ap-

sophisticated models that consider the various dynamic char- proximations made in relating the vehicle to bridge DOF. Such

acteristics of vehicles or railroad cars have also been imple- a drawback will be overcome in this paper.

mented in the study of vehicle-bridge interactions (VBIs) (Ve- To resolve the dependency of system matrices on the wheel

letsos and Huang 1970; Garg and Dukkipati 1984; Yang and load positions, the condensation technique that eliminates the

Lin 1995). Recently, closed-form solution has been obtained vehicle DOF on the element level will be adopted in this paper.

by Yang et al. (1996) for the response of simple beams sub- First, two sets of equations of motion are written, one for the

jected to action of high-speed trains modeled as a sequence of bridge and the other for each of the sprung masses that make

moving loads with regular nonuniform intervals. In his study, up the train. The sprung mass equation is then discretized,

the resonant and cancellation effects of waves generated by using Newmark's finite difference formulas, and condensed to

the motion of wheel loads on the bridge have been related to those of the bridge element in contact. The result is a VBI

the ratio of the railroad car to bridge lengths. element that possesses the same number of DOF as the parent

In studying the dynamic response of a vehicle-bridge sys- element. The applicability of the present VBI element will be

tem, two sets of equations of motion can be written, each for illustrated in the numerical studies.

the vehicle and the bridge. It is the interaction forces existing

at the contact points of the two subsystems that make the two VBI ELEMENT

sets of equations coupled. Because the contact points are time As shown in Fig. I, a bridge is modeled as a beam-like

dependent, so are the system matrices, which therefore must structure and the train traveling over the bridge with constant

be updated and factorized at each time step. To solve these speed v is idealized as a series of lumped masses supported

two sets of equations, procedures of an iterative nature are by the suspension systems, as represented by the springs and

usually adopted (Hwang and Nowak 1991; Green and Cebon dashpots, which in turn are acting on the bridge. In this study,

1994; Yang and Fonder 1996). For instance, by first assuming an interaction element is defined such that it consists of a

the displacements for the contact points, one can solve the bridge (beam) element and the masses and suspension units of

vehicle equations to obtain the interaction forces and then pro- the car bodies directly acting on it, as shown in Fig. 2, where

'Prof. and Chair, Dept. of Civ. Engrg., Nat. Taiwan Univ., Taipei, Tai-

the rail irregularity r(x) and ballast with stiffness kB are also

wan 10617, Republic of China. indicated. For the parts of the birdge that are not directly under

2Postdoctoral Res., Dept. of Civ. Engrg., Nat. Taiwan Univ., Taipei, the action of the vehicles, they are modeled by conventional

Taiwan 10617, Republic of China. bridge elements. However, for the remaining parts that are in

Note. Associate Editor: James M. Nau. Discussion open until April I, direct contact with the vehicles, interaction elements consid-

1998. To extend the closing date one month, a written request must be ering the effects of suspension units have to be used instead.

filed with the ASCE Manager of Journals. The manuscript for this paper In this study, the notation [ ] is used for a square matrix, { }

was submitted for review and possible publication on December 2, 1996.

This paper is part of the Journal of Structural Engineering, Vol. 123, for a column vector, and ( ) for a row vector.

No. II, November, 1997. ©ASCE, ISSN 0733-9445/97/0011-1512- The model depicted in Fig. 2 will be grossly referred to the

1518/$4.00 + $.50 per page. Paper No. 14646. sprung moss model throughout this paper. Let the stiffness and

1512/ JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997

J. Struct. Eng., 1997, 123(11): 1512-1518

trices, respectively, of the bridge element; and {Pb} = external

nodal loads. Regarding the bridge element as a three-dimen-

sional solid beam element, one can assign six DOF to each

node of the element, with three for translations and the other

three for rotations. For damping of the Rayleigh type, the three

matrices [mb], [Cb] , and [kb) are available elsewhere [see for

instance paz (1986)].

As can be seen from (1) and (3), the vehicle and the bridge

interact with each other through the contact force!c, which

varies as a function of time and position. To ensure that the

vehicle is in contact with the bridge, the reactive force exerted

by the bridge on the sprung mass must be of sufficiently low

amplitude. Whenever the contact force!c is less than zero, the

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

wheel mass jumps upward and the contact condition between

the vehicle and the bridge is violated. Such a condition will

be excluded from the present discussion. From the first line of

(1), along with the second line, the contact force Ie also can

(b)

be expressed as

FIG. 1. Train-Bridge System: (a) General Model; (b) Sprung

Mass Model (4)

L

z,

v .. From (3) and (4), it is obvious that the dynamic response of

the beam is affected not only by the moving loads, but also

by the suspension systems.

The system equations as given in (1)-(3) are nonlinear in

nature, which can only be solved by incremental methods, with

iterations for removing the unbalanced forces. Consider a typ-

y

ical incremental step from time t to t + At. To this end, the

system equations in (1)-(3) should be interpreted as those es-

tablished for the deformed position at time t + At. Let

{z}t+~t = {z}t + {Az} = vehicle displacement increments oc-

curring during the step considered. By the use of (2), the

Xc sprung mass equation in (1) can be written in an incremental

form using the strategy presented by Yang et al. (1990) as

FIG. 2. Vehicle-Bridge Interaction Element

follows:

damping coefficients of the suspension system be denoted by

k v and c v , respectively, the mass of the wheel assembly by

fflw, and the lumped mass of the car body by M v • Also, let the

vertical displacements of the two nodes from the static equi-

librium positions be denoted by the generalized coordinates

+ [~vCv

-Cv]

CV

{~I}

Z2 t+~t

+ [kv _+ kB - k v] {IlZI}

kv kv Ilz2

{zf = (Zh Z2)' Corresponding to the nodal displacements {zf

are the external forces {Pv}T = (p, 0), where p = -(Mv + mw)g ={p + kB«N~{Ub} + rc>} _ {qsl}

and g = the acc~leration of gravity. The equations of motion ,+~t qs2 t (5)

for the sprung mass model in Fig. 2 can be written as (Fryba

1972) where {qs}, = internal resistant forces of the vehicle suspension

at time t, i.e.

qsl} = [kv_+ kB -k v] {ZI}

{ qs2 (6)

, kv kv Z2,

Similarly, by the use of (2) and noting that {Ub}t+~t = {Ub}, +

(I)

{AUb}, the bridge equation in (3) can be written in incremental

where!c = the interaction force existing between the wheel form as

mass and the bridge element. Let Xc denote the acting position

[mb]{Ub},+t<1t + [Cb]{Ub},Ht + [[kb] + kB{Nc}(Nc)]{IlUb}

of the sprung mass (see Fig. 2) and {Nc } a vector containing

cubic Hermitian interpolation functions for the vertical dis- ={Pb}t+<1t - {Nc}kB(rc - ZI),Ht - [[kb] + kB{Nc}(Nc)]{Ub},

placement of the beam evaluated at the contact point Xc, i.e., (7)

{Nc } = (N{(x c )}' The interaction force can be expressed as

As can be seen, the two system equations as presented in (5)

fc = kB«Nc){ub} + rc - ZI) ~ 0 (2) and (7) for the sprung mass and the bridge, respectively, are

where the condition of fc ~ 0 is imposed to exclude the sep- coupled. In the following, the sprung mass equation in (5) will

aration of the vehicle from the bridge; k B = ballast stiffness; first be reduced to an equivalent stiffness equation using New-

{Ub} = nodal displacements of the beam; and rc = rail irregu-

mark's single-step finite difference scheme. The sprung mass

larity at the contact point Xc, which is given for any instant. DOF can then be eliminated and condensed to those of the

The equations of motion for the bridge element can be written bridge element in contact.

as Based on Newmark's ~ method with constant average ac-

celeration, i.e., with ~ =0.25 and 'Y =0.5 (Clough and Penzien

[mb]{Ub} + [Cb]{Ub} + [kb]{Ub} = {Pb} - {Nc}fc (3) 1993)

where [mb], [Cb], and [kb] = mass, damping, and stiffness ma- (8a)

JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997/1513

J. Struct. Eng., 1997, 123(11): 1512-1518

{Z},+.11 = {Z}, + {z},~t + [(0.5 - l3){z'}, + l3{z}'HI]~t2 (8b) r ao

[Kb] = [kb] + kB D [(Mv + fnw)(k v + atcv) + aoMvfnwl{Nc}{Nc>

from which

(16a)

= {Z}, + {~z}

{Z'},+.11

{Z},+.11

= ao{~Z} - adz}' - a3{Z'}r

(9a)

(9b)

{P,}r+.11 = -kB [rc.r+.1r - (p + kBrC ,r+.1I) h (kv + aoMv + atCv)] {Nc}

(16b)

{i},+.1t = {z}, + a {z'}, + a7{Z'},+.1, (9c)

[h

6

where the coefficients and those to appear are defined as {f,.}, = kB {(q'I,r + q.I,r)aoMv

a4 = '1. -

13

1; + (q,.1 + q..,)(k v + alc v)} - ZI.,J {Nc}

(l6c)

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

Clearly, the stiffness matrix [kb ] is step dependent, because it

(10) is a function of the loading position Xc, as implied by the shape

With the relations given in (9), the sprung mass equation in function {Nc }. The equations as given in (15) represent exactly

(5) can be manipulated to yield the equivalent stiffness equa-

the equations of motion for the VBI element. With the use of

tion the present element, the maximum element length must be less

than the minimum spacing between axles. Such a restriction

kv + kB + aofnw + atCv -kv - atCv ] {~Zt} can be released if the foregoing procedure is generalized to

[ -k v - atCv kv + aoMv + alC v ~Z2 include the effect of multiaxle loadings.

Consider the special case of moving loads. By letting k v =

={p + kBrc +0 kB(Nc){Ub}}

IHI

_ ({q'l} {q.t})

q,2 I

+

q.2 r (11)

0, mw = 0, and C v = 0, one can obtain from (14) the determinant

as D = aoMvkB , from (6) the resistant force q,l.t =

kBz t •t , and from (12a) the sprung mass force q<t.t = 0. Further,

where from (16a)-(16c), the following can be obtained: [kb ] = [kb ],

{P,},Ht = p{Nc } and {f,.}, = {O}. Consequently, the condensed

beam equation in (15) reduces to

q.2,r = -Mv(a2Z2 + a 3Z'2) - c v[a4(Z2 - Zt) + a3(Z'2 - Z't)] (12b)

As can be seen, the equivalent stiffness equation in (II) is a (17)

single-step finite difference equation, from which the displace-

ment increments {~z} of the sprung mass can be solved and where the term p{Nc } = action of the moving load, as is ex-

related to the bridge displacements {Ub}'+.1' as pected. On the other hand, by setting the damping coefficient

C v and the mass mw of the wheel set assembly equal to zero

{ ~ZI} 1 {kv + aoMv + alcv}

~2 = -V k + alC

v v

( >

(p + kBr ,r+.1r + kB Nc (Ub},+.1r) C

and assigning a very large number to the stiffnesses k v and k B ,

one can arrive at the moving mass model.

Because the VBI element has exactly the same number of

1{ (q'I.1 + q.l.r>aoMv + (qs,r + q•.,)(kv + alc v) } DOF as the parent beam element and because it possesses the

D (q,I.1 + q.t.,)(aofnw + k B) + (qs,r + q.,r)(kv + atcv) (13) property of symmetry in element matrices, conventional ele-

ment assembly processes can be applied to constructing the

where q•., = (q.t + q.2)" q,., = (q'l + q'2)' = kBz t." and equations of motion for the entire vehicle-bridge system based

on the element equations in (15), that is

D = Ik v + k B + aofnw + alC v -kv - alC v I (14)

-k v - atCv kv +aoMv + atCv [Mbl{ V b},+.11 + [Cbl{ Ub},HI + [Kb]{~Ub} = {Pb},+.11 - {Fb},

(18)

The equation as given in (13) is exactly the master-slave re-

lation for condensing the sprung mass DOF to the bridge DOF, where {~Ub} = displacement increments of the bridge from

of which the order of error is not greater than that implied by time t to t + ~t

the finite difference formulas in (8). Compared with the ap-

proximate master-slave relation used by Yang and Lin (1995), (19)

the present relation in (13) has the advantage of being simple, and each of the terms is obtained by assembling over all beam

accurate, and explicit. Because of this, the element to be de- elements of the bridge, in particular

rived in this paper can be used effectively in computation of

both the vehicle and the bridge responses.

By the fact that Zt.I+.1t = ZI.t + ~t and using the first line {Pb},+.11 = 2:

elm-t

[{Pb},+.11 + {PS},+"'] (20a)

of (13) for ~I' one can derive from (7) the condensed equa-

tions of the beam at time t + ~t with the interaction effect of

the sprung mass taken into account, that is {Fb}, = 2: [{is}, + [kb]{Ub},] (20b)

tlm .. t

By the same Newmark procedure, the displacement increments

{~Ud at time t + ~t can be solved from the system equations

(15) in (18). Correspondingly, the acceleration and velocity can be

where [k b ] = stiffness matrix for the condensed system; calculated from equations similar to (9) for the bridge element

{p, },+.11 = external loads caused by the sprung mass; {f,.}, = as

resistant forces associated with the sprung mass; and {Vb},+.1r = ao{~Ub} - a2{Ub}, - a3{Vb}, (21a)

[kbl{ Ub}, = resistant forces exerted by the bridge element at

time t {Ub},+.11 = {Ub}, + a 6 { Vb}, + a7{ Vb},HI (21b)

1514/ JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997

J. Struct. Eng., 1997, 123(11): 1512-1518

Moreover, the vehicle displacement increments {az} can be encountered in the study of a great number of nonlinear prob-

obtained from (13) and the total responses from the Newmark- lems. To solve problems of this sort, the (modified) Newton-

type equations in (9). Here, it is noted that the vehicle accel- Raphson method that performs iterations at constant loads can

eration {i} serves as a measure of riding comfort for passen- be employed (Yang and Kuo 1994). The initial conditions to

gers. the system equations in (25) are

As was stated, because of condensation of the VBIs on the

element level, conventional element assembly procedures can (27)

be directly applied using the present approach. For this reason,

the amount of effort required in programming and computation where the right superscript l = the last iteration of the previous

is minimal, compared with approaches that perform conden- time step. Accordingly, the system equations in (25) reduce to

sation on the structure level or with no condensation at all. the following for the first iteration of each time step:

Such an advantage becomes more obvious in the study of

(28)

bridges subjected to a sequence of moving vehicular loads. In

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

such cases, all one needs is a proper bookkeeping scheme to Here, it should be noted that the effective stiffness matrix

identify at each time step the acting position of each wheel [K]'+4' remains constant within each incremental step, which

load of the cars composing the train. It should be noted that need not be updated for each iteration.

the VBI element derived here is applicable not only for mod- For each iteration, the displacement increments {Ud i can

eling railroad cars with regular intervals and constant sizes, be solved from (25) and the total displacements of the bridge

but also for vehicles that constitute a random traffic flow are

through the highway bridges.

(29)

INCREMENTAL DYNAMIC ANALYSIS WITH

ITERATIONS The acceleration and velocity of the bridge can be computed

from (21) with due account taken into the feature of iteration

During the passage of vehicles over a bridge, on the one

hand, the vehicles excite the bridge by their interaction forces;

on the other hand, the bridge affects the behavior of the ve-

hicles by its motion. Such a phenomenon is typical of a non-

linear interaction problem, which can only be solved by

procedures of incremental and iterative nature. For the present Once the bridge displacements {Ub}:+4' are made available, the

purpose, consider the system equations of motion in (18). By element displacements {Ub} :+4,can be computed thereby. It

the finite difference equations in (19) and (21), the equations follows that the vehicle displacement increments {az}i can be

of motion in (18) can be manipulated to yield the following computed from (13), by treating terms with subscript t + at

equivalent stiffness equations: as those associated with the ith iterative step and terms with

subscript t associated with the (i - l)st iterative step. The total

[Kb]t+~{aUb} = {Pb}'+~ - {Pb}, (22) responses for the sprung mass can be determined from (9) as

where the effective stiffness matrix [Kb ],+4' is (3Ia)

[Kb],+4' =ao[Mb] + at[Cb] + [Kb] (23)

(3Ib)

and the effective resistant force vector {Fb }, is

(3Ic)

{Fb},= {Fb}, - [Mb](a2{ Ob}, + a3{ Db},) - [Cb](a4{ O}, + a,{ Db},)

(24) with the following initial condition: {Z}?+4' = {z}:.

Here, it should be noted that both the effective stiffness matrix

[Kb],+4' and the load vector {Pb},+4, remain constant within PROCEDURE OF ITERATIVE ANALYSIS

each time step.

For the purpose of performing iterations, the equivalent The following is a summary of the procedure for performing

stiffness equations for the bridge in (22), which has been pre- the incremental-iterative analysis based on the modified New-

sented in incremental form, should be modified to include the ton-Raphson algorithm:

feature of iteration, that is

1. Read in all the structure and vehicle data.

[Kb]t+~{.:lUbV = {Pb},+4' - {Fb}:~l, (25)

2. Start with time t = 0 and set up the following initial

in which the right superscript i on each symbol indicates the conditions: {Fb}~ = {O}, {Ub}~ = {Ob}~ = {Db}~ = {O},

number of iterations. The right hand of (25) should now be and {z}~ = {i}~ = {z'}~ = {OJ. Calculate the mass matrices

interpreted as the extemalload increments for the first iteration [mb] for all elements and assemble the structure mass

(i = 1) and as the system unbalanced forces for the following matrix [Mb ]. Select a proper time increment at for the

iterations (i ~ 2) (Yang and Kuo 1994). The philosophy for Newmark integration scheme.

modifying an equation originally presented in incremental 3. For the incremental step, let t = t + at and i = 1. If t is

form into one in iterative form is that throughout the process larger than a specified value, stop the process. Otherwise,

of iteration, all the terms associated with time t be interpreted determine the acting position Xc of each wheel load, the

as those for the (i - l)st iterative step and all the terms as- rail irregularity re , and the shape vector {Ne } for elements

sociated with time t + at as the ith iterative step. For instance, with wheel loads acting on them.

the resistant force vector in (24) should be interpreted as 4. For elements carrying no wheel loads, calculate the el-

ement matrix [kb ]; and for elements in contact with wheel

(Pb}:~l, = {Fb}:~l, - [Mb](a2{Ob}:~l, + a3{Db}:~l,) loads, calculate the modified element matrix [kb ] using

(100).

(26)

5. Assemble the bridge matrix [Kb ] and load vector

Eq. (25) represents a typical nonlinear equation that can be {Pb },+4" using (20a) for the latter. The damping matrix

JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997/1515

J. Struct. Eng., 1997, 123(11): 1512-1518

[C b ] is calculated by assuming it to be of the Rayleigh Simple Beam Subjected to Moving Sprung Mass

type. Compute the equivalent stiffness matrix [Kb]t+At us-

ing (23). For the present problem, the system matrices As shown in Fig. 3, a simple beam of span length L = 25

[Kb]t+At and {Pb}t+At are constant for each time step. m is subjected to a moving sprung mass. The following data

6. Determine the resistant force vector {Fb}:~it using (26). are adopted: Young's modules E = 2.87 GPa, Poisson's ratio

For i 2: I, check if the unbalanced forces ({Pb},+At - v = 0.2, moment of inertia I = 2.90 m\ mass per unit length

{Fb } :~i,) are less than a given tolerance. If yes and if the m = 2,303 kglm, suspended mass M v = 5,750 kg, suspension

contact condition fc 2: 0 as given in (2) is satisfied, go stiffness k v = 1,595 kN/m, speed v = 100 km/h, frequency of

to step 3 for the next increment. the bridge WI = 30.02 radls, frequency of the sprung mass

7. Solve the displacement increments {aUb}i from the sys- system W v = 16.66 rad/s, and mass ratio MJmL = 0.1. By

tem equations in (25). Determine the vehicle displace- representing the deflection of the beam as Ub = qb(t)sin( miL),

ment increments {aZ}i from (13), where terms with sub- the displacement of sprung mass as qJt) and neglecting the

script t + at should be interpreted as those for the ith effect of damping, the equations of motion for the vibration

iterative step and terms with subscript t for the (i - l)st of the beam and the sprung mass moving at speed v can be

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

step. given as (Biggs 1964)

8. Find the total displacements {Ub}:+At for the bridge from

(29) and {Z}:+At for the vehicle from (31a). Compute the 2M" . 2 7Tvt

2wv - sm - + 2

7Tvt]

v

Ms i n

-2w 2 - -

::

WI

displacement derivatives {Ob}~+At and {Ob}:+At for the "

qb + mL L v

mL L {}

{iiv} 7Tvt

bridge using (30) and {i}:+At and {Z'l:+At for each sprung [ 2 M" .

w;

mass using (31b) and (31c). -W v mL sm!:

9. Let i = i + 1 and go to step 6 for the next iterative step.

Mvg

-2- - s.m7Tvt}

-

Using the present procedure, the coupling effect between ={ mL L

the bridge and the vehicle is considered through the condensed o (33)

elements. Because of this, the number of cycles required for

iteration is generally small, compared with approaches that do The dynamic responses of the midpoint displacement of the

not rely on the condensation technique. The other advantage beam subjected to the moving load and the sprung mass have

is that the vertical response of the sprung masses is obtained been plotted in Fig. 4. As can be seen, the response obtained

as part of the solution, which serves as a measure of the riding by the present procedure using the VBI element and based on

comfort of passengers, in addition to the response of the the sprung mass assumption agrees well with the single mode

bridge. solution to (33).

From the response of vertical acceleration for the midpoint

DEFINITION FOR IMPACT FACTOR of the beam shown in Fig. 5, one observes that inclusion of

the higher modes can result in oscillation of the acceleration

In the design of bridge structures, the dynamic response response, which was neglected in the solution of (33). The

resulting from the passage of moving vehicles has been con- responses of the deflection and vertical acceleration of the

sidered indirectly by increasing the stresses caused by static sprung mass have been plotted in Figs. 6 and 7, respectively.

live loads by an impact factor, which is defined as the ratio of The differences in these two figures between the present so-

the maximum dynamic response to the maximum static re- lution and that of (31) can be attributed mainly to the omission

sponse of the bridge under the same load minus one. The im- of higher modes in the latter. A comparison of Figs. 5 and 7

pact factor adopted in this study is defined as follows:

I = RAx)- R.(x) qv

(32)

__--l-k=r--l~-····· _f_

R.(x)

where Rd(x) and R.(x) = maximum dynamic and static b

response, respectively, of the bridge at cross section x because __

of the passage of the moving load. Such a definition is more

rational and computationally more convenient than the dy- ~ ~

1 L ,

namic increment factor used by the American Association of

State Highway and Transportation Officials (AASHTO), be-

cause both the maximum dynamic and the static responses are

FIG. 3. Beam with Moving Sprung Mass

calculated for the same cross section. Such an advantage will

become obvious when dealing with moving loads that appear

as a series or as a random flow (Yang and Yau 1996).

NUMERICAL EXAMPLES

Three examples are prepared to verify the VBI element and

the procedure of solution presented in this paper. First, the

dynamic responses solved by the present method for a simple

beam subjected to a moving sprung mass will be compared

with those considering the contribution of the first mode of

vibration. Second, by modeling a train as a sequence of mov-

ing lumped loads or lumped masses, the impact responses of

bridges excited by the train will be investigated and compared

with existing solutions. Finally, the dynamic responses of a -2.0 ~""""'~"""","="!""'~!'1!"',","~TTTT"",,!,!",,,~!'1!"'''''''-=TT"n'",!,!:!"",""~,,=

0.0 0.1 0.2 0.3 0.4 0.0 0.11 0.7 0.11 0.1

cantilever subjected to different models of vehicles in motion Time (8)

will be studied. In each case, the beam is modeled as 10 ele-

ments. FIG. 4. Midpoint Vertical Deflection of Beam

1516/ JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997

J. Struct. Eng., 1997, 123(11): 1512-1518

0.1 +"' "t

215.6 leN and the mass to be M v = 22,000 kg and mw = 0 kg.

- Analytic (Sprun. Man, 1 Mode)

- - Preeent (Spruq Maeej Two cases are considered herein. In the first case, by letting

.•.•••• Preeent (lCovin. Load) the suspension stiffness kv , damping cv , and ballast stiffness ks

equal zero, the moving load model can be obtained. In the

second case, by letting the stiffnesses kv and ks equal a very

large number, say, with k v = k s = 9.0 X 106 leN/m, the moving

mass model is obtained. The impact factors I calculated for

the midpoint displacement of the beam subjected to the mov-

ing loads using the two models have been plotted in Fig. 8,

against a nondimensional speed parameter S, defined as the

ratio of the exciting frequency of the moving vehicle Trv/L to

the fundamental frequency w of the bridge. Also shown in the

-0.4 .-lrn~'"T'~TT'O'!"t!""'

........:!'1!TTTTT~ ........""":!t!""'~:!'1J"TTTT":'.::;"""''"'';!''Z'"''''''';~

figure are the results based on the analytical work of Yang et

0.0 0.1 0.1 0.1 0.4 0.1 0.1 0.7 0.1

al. (1996) by eigenfunction expansion. From this figure, it is

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

Time (8)

obvious that the present solutions correlate very well with

FIG. 5. Midpoint Vertical Acceleration of Beam those of the analytical study. Besides, the moving mass model

tends to reduce the frequency of vibration of the vehicle-bridge

system, in the sense that the critical speed for the peak re-

..\....... - - Analytic.

....... Preaent Sprun. Man, sponse to occur becomes smaller.

Free-Fixed Beam with Various Models for Moving

Vehicles

:III \.\\ ........./ Fig. 9 shows a cantilever subjected to a moving lumped

mass. The following data are assumed: length L = 7.62 m;

*_1.0

~'"

~

/J;

................ 00000

--

Movln.

Movin.

Load Ipre.ent)

Load Yan. et al.)

••••• Movln. Ma.. Preeent)

•.•.... Movin. Mea. Yan. et al.)

"" 1.0

-1.OO-+.OTTTT"'"'O.,.,.I........~O'l!.ITTTT~O.~1 "TTTT"':0!"':.4~...-.:!0'l!.0Tn'T~0.1J'1 "TTTT'":0rl:.7!'"""'""'::0",:,

Time (8)

••TTTT"""rt

O••·

.s

CJ

III

roo.

FIG. 6. Deflection of Sprung Mass

...

CJ

1.0

--

"", - - Analytic, Sprun. Maee, 1 Mode e

III

! ....... Preeent _ 1.0

II

o

:J 0.1

:! 0.0 -1-~~~=:::::CTTTTTTTTT'rT":O"l7'",,"""'T!1:"""""""'':'''':''''''~

0.0 0.1 0.1 0.1 0.4 0.0 0.. 0.7 0••

.!l Speed Parameter S

~

"

CI

FIG. 8. Impact Response for Bridge Sustaining a Moving Train

'"

--

:-0.1

::Il v = 2,000 in./s

~...

CIl

-0.1O*.O........~O.'I71TTTT~0.1!!'""~0rl:.I~...-.:!017.4~"":!0.1J'0 ........"':0~.1:"""...-.:!0"'::.7~~0.1J'1 "TTTT'":0:t

.• .....-~~'- -----1"

M= 15 Ibm

Time (8)

L= 300 in,

FIG. 7. Vertical Acceleration of Sprung Mass 'I

FIG. 9. Cantilever with Mass Moving at Constant Speed

indicates that the sprung mass is more sensitive than the beam

to the omission of higher-order terms. It should be noted that IO+'-'- ~"-'-'- "-'-'-~ ~ "t

the vertical acceleration of the sprung mass serves as a mea- - lIovin, Lo.d (pre.ent)

••••• 1I0vin, Lo.d Akin" lIorld)

sure of the comfort level for passengers riding on the vehicle. - - - 1I09ln, II... Preeent)

00000 1109101 II... Akin " lIorld)

...... Sprunc II... Pr.-ent)

Simply Supported Beam Subjected to Moving Train

Consider a simply supported beam with the following prop-

erties: L = 20 m, 1= 3.81 m 4 , E = 29.43 GPa, m = 34,088

kg/m, and damping ratio = 2.5%. The train traveling over the

bridge contains 10 bogies, which can be modeled as a se-

quence of moving lumped loads with regular nonuniform in- •••••

...................................•••••••• ~ .P.. -

tervals as

.'

........ • .00.

... 0··· .••••••

I+-Lc~ I+-Ld~ , ... , +-Ld~ I+-Lc~ I+-Ld~ I+-Lc~ I o.:j.,o,~.......H'rl-;;-;.;:-;.;:"O-;;.;-:.,.,-.....-..-T'l(fT'-,.,..-.......,.......,,.,.... ~.-m-.

\"TT'I.,.,..,..............

0.00 0.01 0.01 O.Of 0.11 O. 0

Time (8)

where L c = 18 m; L d = 6 m; and "I" represents the lumped

load p. Assume the weight p of the lumped load to be p = FIG. 10. Comparison of Results for Cantilever

JOURNAL OF STRUCTURAL ENGINEERING I NOVEMBER 1997/1517

J. Struct. Eng., 1997, 123(11): 1512-1518

velocity v = 50.8 m/s; flexural rigidity EI = 9.474 X 106 NI span beam under the action of a moving alternating force." J. Appl.

m2 ; mass of the beam per unit length m = 0.1192 kg/m; Mech., 17(3),283-290.

Biggs, J. M. (1964). Introduction to structural dynamics. McGraw-Hill,

lumped mass M v = 6.81 kg; and moving load = 66.74 N. The Inc., New York, N.Y.

results for the free-end deflection of the cantilever obtained by Chatterjee, P. K., Datta, T. K., and Surana, C. S. (1994). "Vibration of

the moving mass and moving load models have been plotted suspension bridges under vehicular movement." J. Struct. Engrg.,

in Fig. 10, along with those of Akin and Mofid (1989). As can ASCE, 120(3), 681-701.

be seen, good agreement has been achieved between the pres- Chu, K. H., Garg, V. K., and Dhar, C. L. (1979). "Railway-bridge impact:

ent solutions and those of Akin and Mofid (1989). In addition, simplified train and bridge model," J. Struct. Div., ASCE, 105(9),

1823-1844.

by modeling the moving mass as a sprung mass with suspen- Clough, R. W., and Penzien, J. (1993). Dynamics of structures, 2nd Ed.,

sion stiffness k v = 10.43 kN/m, assuming 0.1 % damping for McGraw-Hill, Inc., New York, N.Y.

the cantilever, and letting the sprung mass be always in contact Diana, G., and Cheli, E (1989). "Dynamic interaction of railway systems

with the cantilever, the dynamic response solved for the free with large bridges." Vehicle System Dynamics, 18, 71-106.

end has also been shown in Fig. 10. It can be seen that for Fryba, L. (1972). Vibration of solids and structures under moving loads.

Downloaded from ascelibrary.org by University Of British Columbia on 10/15/18. Copyright ASCE. For personal use only; all rights reserved.

most of the acting period of the vehicle on the cantilever, i.e., Noordhoff International Publishing, Groningen, The Netherlands.

Garg, V. K., and Dukkipati, R. V. (1984). Dynamics of railway vehicle

0.15 s, the moving load model tends to produce the largest systems. Academic Press, Inc., Canada.

response, the sprung mass the second, and the moving mass Green, M. E, and Cebon, D. (1994). "Dynamic response of highway

the least. bridges to heavy vehicle loads: theory and experimental validation."

J. Sound Vib., 170(1),51-78.

CONCLUDING REMARKS Hwang, E. S., and Nowak, A. S. (1991). "Simulation of dynamic load

for bridges." J. Struct. Engrg., ASCE, 117(5), 1413 -1434.

In this study, the equations of motion for the vehicle is first Jeffcott, H. H. (1929). "On the vibration of beams under the action of

discretized using Newmark's finite difference formulas and moving loads." Philosophical Mag., Ser. 7, 8(48),66-97.

then condensed to the bridge equations, considering the con- Lewan, A. N. (1935). "On transverse oscillations of beams under the

action of moving variable loads." Philosophical Mag., Ser. 7, 19(127),

dition of contact between the vehicles and the bridge. The 708-715.

element thus derived is referred to as the VBI element, which Paz, M. (\986). Microcomputer-aided engineering: structural dynamics.

has the same number of OOF as the parent element, while Van Nostrand Reinhold, New York, N.Y.

possessing the properties of symmetry and bandedness in el- Sadiku, S., and Leipholz, H. H. E. (1987). "On the dynamics of elastic

ement matrices. As such, conventional assembly process can systems with moving concentrated masses." Ingenieur-Archiv, 57,

be directly applied to forming the equations of motion for the 223-242.

Stabusit, M. M. (1985). "On a new theory of the dynamic behavior of

entire vehicle-bridge system. Characterized by the fact that the the structures carrying moving masses." Ingenieur-Archiv, 55, 176-

VBI is duly taken into account, the derived element can be 185.

reliably used in computing the vehicle response, which serves Stokes, G. G. (\849). "Discussion of a differential equation relating to

as a measure of passengers' riding comfort, in addition to the the breaking of railway bridges." Trans. Cambridge Phil. Soc., 8(5),

bridge response. The applicability of the derived element has 707-735.

Timoshenko, S. P. (1922). "On the forced vibrations of bridges." Phil-

been demonstrated in the numerical examples. Besides, it is osophical Mag., Ser. 6, 43, 1018-1019.

concluded that high modes of vibration of the bridge affect Veletsos, A. S., and Huang, T. (\970). "Analysis of dynamic response of

more significantly the response of the vehicle than the bridge. highway bridges." J. Engrg. Mech. Div., ASCE, 96(5), 593-620.

Compared with the moving load model, the use of the moving Willis, R. (1849). "Report of commissioners appointed to inquire the

mass model tends to reduce the frequency of vibration of the application of iron to railway structures, Appendix B." His Majesty's

entire vehicle-bridge system, as the critical speed at which the Stationary Office, London, England.

Yang, E, and Fonder, G. A. (1996). "An iterative solution method for

peak response occurs becomes smaller. dynamic response of bridge-vehicles systems." Earthquake Engrg. and

Struct. Dynamics, 25, 195-215.

ACKNOWLEDGMENTS Yang, Y. B., and Kuo, S. R. (1994). Theory and analysis of nonlinear

framed structures. Prentice-Hall, Inc., Singapore.

The research reported here has been sponsored in part by the National Yang, Y. B., Lee, T. Y., and TSai, I. C. (\990). "Response of multi-degree-

Science Council of the Republic of China through Grants NSC85-2211- of-freedom structures with sliding supports." Earthquake Engrg.

E002-002 and NSC86-2221-EOO2-074. Such financial aid is gratefUlly Struct. Dynamics, 19, 739-752.

acknowledged. Yang, Y. B., and Lin, B. H. (\ 995). "Vehicle-bridge interaction analysis

by dynamic condensation method." J. Struct. Engrg., ASCE, 121(11),

APPENDIX. REFERENCES 1636-1643.

Yang, Y. B., and Yau, J. D. (\996). "A review of researches on vehicle-

Akin, J. E., and Mofid, M. (1989). "Numerical solution for response of bridge interactions with emphasis on high speed bridges." Proc., 20th

beams with moving mass." J. Struct. Engrg., ASCE, 115(1), 120-131. Nat. Con! Theoretical and App. Mech., Nat. Taiwan Inst. Techno!.,

Ayre, R. S., Ford, G., and Jacobsen, L. S. (1950). "Transverse vibration Taipei, Taiwan, People'S Republic of China.

of a two-span beam under action of a moving constant force." J. Appl. Yang, Y. B., Yau, J. D., and Hsu, L. C. (1996). "Vibration of simple

Mech., 17(1), 1-12. beams due to trains moving at high speeds." accepted for publication

Ayre, R. S., and Jacobsen, L. S. (1950). "Transverse vibration of a two- in Engrg. Struct.

1518/ JOURNAL OF STRUCTURAL ENGINEERING / NOVEMBER 1997

J. Struct. Eng., 1997, 123(11): 1512-1518

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- PSC 05.07.17 PDFDocument6 pagesPSC 05.07.17 PDFBindu SrirangamPas encore d'évaluation

- PSC 14.07.17-1 PDFDocument8 pagesPSC 14.07.17-1 PDFBindu SrirangamPas encore d'évaluation

- Rajeshwari - Civil HPCDocument14 pagesRajeshwari - Civil HPCBindu SrirangamPas encore d'évaluation

- PSC 05.07.17 PDFDocument6 pagesPSC 05.07.17 PDFBindu SrirangamPas encore d'évaluation

- PSC 14.07.17 PDFDocument8 pagesPSC 14.07.17 PDFBindu SrirangamPas encore d'évaluation

- 1 - PSC 28.06.17 PDFDocument4 pages1 - PSC 28.06.17 PDFBindu SrirangamPas encore d'évaluation

- Gate SurvingDocument114 pagesGate SurvingBhushan PatilPas encore d'évaluation

- Recycling of ConcreteDocument28 pagesRecycling of ConcreteBindu SrirangamPas encore d'évaluation

- MoRTH CompleteDocument725 pagesMoRTH CompleteSekharmantri Sitapati85% (71)

- Theory of Elasticity - Navier Solution For SS Rectangular PlateDocument34 pagesTheory of Elasticity - Navier Solution For SS Rectangular PlateBindu SrirangamPas encore d'évaluation

- Geopolymer Concrete PPT-KVRDocument24 pagesGeopolymer Concrete PPT-KVRBindu Srirangam100% (2)

- Pile Foundation DesignDocument82 pagesPile Foundation Designcuongnguyen89% (28)

- Need For RSI - JournalDocument3 pagesNeed For RSI - JournalBindu SrirangamPas encore d'évaluation

- Dept. of Civil Engineering, JNTUHCEH M.Tech. (SE) (FT) W.E.F. 2015-16Document4 pagesDept. of Civil Engineering, JNTUHCEH M.Tech. (SE) (FT) W.E.F. 2015-16Bindu SrirangamPas encore d'évaluation

- RE Wall FormulaDocument3 pagesRE Wall FormulaBindu SrirangamPas encore d'évaluation

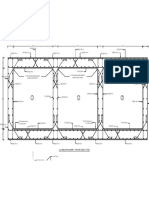

- 3x4x4.5 BOXDocument1 page3x4x4.5 BOXBindu SrirangamPas encore d'évaluation

- IRC 111 2009 Bituminous MixesDocument27 pagesIRC 111 2009 Bituminous MixesBindu SrirangamPas encore d'évaluation

- Slope Stability AnalysisDocument7 pagesSlope Stability AnalysisBindu SrirangamPas encore d'évaluation

- NCHRP RPT 611Document148 pagesNCHRP RPT 611tigredealica100% (3)

- Mystery of The Kingdom of Shambhala - Birthplace of Kalki AvatarDocument9 pagesMystery of The Kingdom of Shambhala - Birthplace of Kalki AvatarBindu SrirangamPas encore d'évaluation

- RetrofittingDocument6 pagesRetrofittingBindu SrirangamPas encore d'évaluation

- Unit 3 - Theory of Plates, UCE OUDocument2 pagesUnit 3 - Theory of Plates, UCE OUBindu SrirangamPas encore d'évaluation

- Course Curriculum-Land and BuildingDocument9 pagesCourse Curriculum-Land and BuildingBindu SrirangamPas encore d'évaluation

- Unit 1 - Theory of Plates, UCE OUDocument6 pagesUnit 1 - Theory of Plates, UCE OUBindu SrirangamPas encore d'évaluation

- Design Guide For MIDAS CIVIL For IRC112 - Prestressed Box GirderDocument51 pagesDesign Guide For MIDAS CIVIL For IRC112 - Prestressed Box GirderBindu SrirangamPas encore d'évaluation

- TOE NotesDocument21 pagesTOE NotesBindu SrirangamPas encore d'évaluation

- NCHRP RPT 611Document148 pagesNCHRP RPT 611tigredealica100% (3)

- NCHRP RPT 611Document148 pagesNCHRP RPT 611tigredealica100% (3)

- Thoery of PlatesDocument61 pagesThoery of PlatesBindu SrirangamPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Modeling of Fillets in Thin-Walled Beams Using Shell/Plate and Beam Finite ElementsDocument16 pagesModeling of Fillets in Thin-Walled Beams Using Shell/Plate and Beam Finite Elementsacar1Pas encore d'évaluation

- Open Flower Reference ManualDocument21 pagesOpen Flower Reference Manualjgraczyk007Pas encore d'évaluation

- S8 - Language Worksheets - Unit 3Document4 pagesS8 - Language Worksheets - Unit 3Nazima MunirPas encore d'évaluation

- Paper - Determination of Entropy For Reactions of The Born-Haber CycleDocument4 pagesPaper - Determination of Entropy For Reactions of The Born-Haber CycleJuan Sebastian Mora NavarretePas encore d'évaluation

- Hooks LawDocument4 pagesHooks Lawapi-255078290Pas encore d'évaluation

- N Une: INSTRUCTIONS: Solve The Following ProblemsDocument7 pagesN Une: INSTRUCTIONS: Solve The Following ProblemsAaron Elijah RabayaPas encore d'évaluation

- Patent CN1488854A - Antigravity Apparatus For Spaceship-Reverse Thrust Photon RocketDocument6 pagesPatent CN1488854A - Antigravity Apparatus For Spaceship-Reverse Thrust Photon RocketVictor Von DoomPas encore d'évaluation

- Deber Capitulo 2Document1 pageDeber Capitulo 2carloss antonio acosta lopezPas encore d'évaluation

- Nonlinear Analysis and Optimal Design of Reinforced Concrete Plates and ShellsDocument17 pagesNonlinear Analysis and Optimal Design of Reinforced Concrete Plates and Shellsrodain najjarPas encore d'évaluation

- Turnitin Originality ReportDocument26 pagesTurnitin Originality Reportrabia.malikPas encore d'évaluation

- Low Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 3Document4 pagesLow Speed Aerodynamics (Aerodynamics-I) : Multiple Choice Questions Set 3Harish MathiazhahanPas encore d'évaluation

- Exercises Part 1Document5 pagesExercises Part 1Le Thai SonPas encore d'évaluation

- Robotics: Chapter 1: Spatial Descriptions & TransformationsDocument39 pagesRobotics: Chapter 1: Spatial Descriptions & TransformationsNam NguyễnPas encore d'évaluation

- ME5521 Chapter4 4 2012Document37 pagesME5521 Chapter4 4 2012Sebastián EspinozaPas encore d'évaluation

- Dampers - A Configuration of Seismic Energy Dissipation System For Still StructuresDocument8 pagesDampers - A Configuration of Seismic Energy Dissipation System For Still Structurespepess2010Pas encore d'évaluation

- Uncertainty: Problems & Answers: CM CM CM CMDocument10 pagesUncertainty: Problems & Answers: CM CM CM CMarrowayPas encore d'évaluation

- N 0 T 0 M I M and Iare Taken With Respect To A CentroidalDocument6 pagesN 0 T 0 M I M and Iare Taken With Respect To A CentroidalRetro GamerPas encore d'évaluation

- Summative Test in Science VI 2014Document3 pagesSummative Test in Science VI 2014Mark Anthony Francisco100% (1)

- Biomechanics of The SpineDocument18 pagesBiomechanics of The SpineSudheer Jayaram100% (1)

- Lec 28Document18 pagesLec 28elene shopovaPas encore d'évaluation

- Pre-Dimensioning of Beams and ColumnsDocument30 pagesPre-Dimensioning of Beams and ColumnsWaheed AhmadPas encore d'évaluation

- Fracture Control For Pipeline Installation Methods Introducing Cyclic Plastic StrainDocument24 pagesFracture Control For Pipeline Installation Methods Introducing Cyclic Plastic StrainManohar SeetharamPas encore d'évaluation

- Bulk and Surface Acoustic Waves - Fundamentals, Devices, and Applications (Guigen Zhang) (Z-Library)Document361 pagesBulk and Surface Acoustic Waves - Fundamentals, Devices, and Applications (Guigen Zhang) (Z-Library)ostomaconsultingPas encore d'évaluation

- Heat Conduction Nuclear Heat SourceDocument18 pagesHeat Conduction Nuclear Heat SourceChaudhry ZaidPas encore d'évaluation

- Mitsuboshi Products ARPMDocument102 pagesMitsuboshi Products ARPMRizal Agus FiantoPas encore d'évaluation

- Grade 11 - Test Specification and Model Questions-14-22Document9 pagesGrade 11 - Test Specification and Model Questions-14-22Rabindra Raj BistaPas encore d'évaluation

- Response of A Light Aircraft Under Gust Loads: NomenclatureDocument6 pagesResponse of A Light Aircraft Under Gust Loads: NomenclatureSteve JeffPas encore d'évaluation

- SPHL Sample ProblemsDocument20 pagesSPHL Sample ProblemsĐức TiếnPas encore d'évaluation