Académique Documents

Professionnel Documents

Culture Documents

Me8493 Te Rejinpaul Iq Am19 PDF

Transféré par

Angelin0 évaluation0% ont trouvé ce document utile (0 vote)

89 vues2 pagesThis document provides 28 practice questions related to thermal engineering that may be asked on exams for 4th semester BE/BTECH students at Anna University. The questions cover topics like cycles for internal combustion engines (Otto, Diesel, Brayton), gas turbines, air compressors, properties of fuels, engine components and systems, testing procedures, and calculations of efficiency, power, work, temperatures and pressures at different points in thermodynamic cycles. The document encourages students to learn from the questions but warns against directly copying or republishing the content.

Description originale:

Titre original

ME8493_TE_REJINPAUL_IQ_AM19.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides 28 practice questions related to thermal engineering that may be asked on exams for 4th semester BE/BTECH students at Anna University. The questions cover topics like cycles for internal combustion engines (Otto, Diesel, Brayton), gas turbines, air compressors, properties of fuels, engine components and systems, testing procedures, and calculations of efficiency, power, work, temperatures and pressures at different points in thermodynamic cycles. The document encourages students to learn from the questions but warns against directly copying or republishing the content.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

89 vues2 pagesMe8493 Te Rejinpaul Iq Am19 PDF

Transféré par

AngelinThis document provides 28 practice questions related to thermal engineering that may be asked on exams for 4th semester BE/BTECH students at Anna University. The questions cover topics like cycles for internal combustion engines (Otto, Diesel, Brayton), gas turbines, air compressors, properties of fuels, engine components and systems, testing procedures, and calculations of efficiency, power, work, temperatures and pressures at different points in thermodynamic cycles. The document encourages students to learn from the questions but warns against directly copying or republishing the content.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

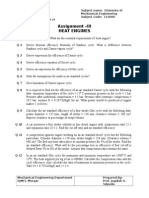

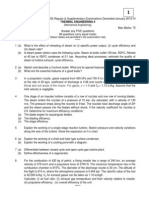

Anna University Exams April / May 2019 – Regulation 2017

Rejinpaul.com Unique Important Questions – 4th Semester BE/BTECH

ME8493 – THERMAL ENGINEERING

1. A Dual combustion air standard cycle has a compression ratio of 10. The constant

pressure part of combustion takes place at 40 bar. The highest and the lowest temperature of

the cycle are 1725degree C and 27 0 C respectively. The pressure at the beginning of

compression is 1 bar. Calculate (I) the pressure and temperature at’ key points of the cycle. (ii)

The heat supplied at constant volume, (iii) the heat supplied at constant pressure. (iv) The heat

rejected. (v) the work output. (vi) the efficiency and (vii) mep.

2. An Engine-working on Otto cycle has a volume of 0.45 m3 , pressure 1 bar and temperature

30o,Cat the beginning of compression stroke. At the end of compression stroke, the pressure is

11 barand 210 KJ of heat is added at constant volume. Determine

(i)Pressure, temperature and volumes at salient points in the cycle. (ii) Efficiency.

3. Air enters the compressor of a gas turbine at 100 KPa and 25 o C. For a pressure ratio of

5 and a maximum temperature of 850°C. Determine the thermal efficiency using the

Brayton cycle

4. A steam power plant equipped with regenerative as well as reheat arrangement is supplied

with steam to the H.P. turbine at 80 bar 470oC. For feed heating, a part of steam is extracted at

7 bar and remainder of the steam is reheated to 350oC in a reheaters and then expanded in

L.P. turbine down to 0.035bar. Determine: 1. Amount of steam bled-off for feed heating. 2.

Amount of steam supplied to L.P. turbine. 3. Heat supplied in the boiler and reheater.4. Cycle

efficiency and 5. Power developed by the system. The steam supplied by the boiler is 50 kg/s.

5. Define Diesel Cycle with Derivation for Air Standard Cycle & Mean Effective Pressure.

6. Define Otto Cycle with Derivation for Air Standard Cycle & Mean Effective Pressure.

7. Estimate the lose in air standard efficiency for the diesel engine for the compression ratio

14 and the cutoff changes from 6% to 13% of the stroke.

8. A single stage single acting air compressor is used to compress air from 1.013 bar and

25° C to 7 bar according to law PV 1.3 = C. The bore and stroke of a cylinder are

120mm and 150mm respectively. The compressor runs at 250 rpm .If clearance volume

of the cylinder is 5% of stroke volume and the mechanical efficiency of the compressor

is 85%, determine volumetric efficiency, power, and mass of air delivered per minute.

9. A single stage single acting air compressor is used to compress air from 1 bar and 22° C to 6 bar

according to the law PV1 .25 = C. The compressor runs at 125 rpm and the ratio of stroke

length to bore of a cylinder is 1.5. If the power required by the compressor is 20 kW, determine

the size of the cylinder.

10. Discuss with suitable sketches the working of two stage air compressor with actual p-v

Diagram

11. A two stages, single acting air compressor compresses air to 20bar. The air enters the L.P

cylinder at 1bar and 27oc and leaves it at 4.7bar. The air enters the H.P. cylinder at 4.5bar and

27oc. the size of the L.P cylinder is 400mm diameter and 500mm stroke. The clearance volume

In both cylinder is 4% of the respective stroke volume. The compressor runs at 200rpm, taking

index of compression and expansion in the two cylinders as 1.3, estimate 1. The indicated

power required to run the compressor; and 2. The heat rejected in the intercooler per minute.

12. A single stage single acting air compressor is used to compress air from 1.013 bar and 25° C to 7

bar according to law PV 1.3 = C.The bore and stroke of a cylinder are 120mm and 150mm

respectively. The compressor runs at 250 rpm .If clearance volume of the cylinder is 5% of

stroke volume and the mechanical efficiency of the compressor is 85%, determine volumetric

efficiency, power, and mass of air delivered per minute.

13. The following results refer to a test on a petrol engine Indicated power = 30 Kw, Brake power =

26 Kw. Engine speed = 1000 rpm Fuel brake power/ hour = 0.35 kg Calorific value of fuel =

43900kj/kg Calculate The indicated Thermal efficiency, The brake Thermal efficiency, The

Mechanical efficiency

14. A four cylinder 2 stroke cycle petrol engine develops 23.5 kw brake power at 2500 rpm. The

mean effective pressure on each piston in 8. 5 bar and mechanical efficiency in 85% Calculate

the diameter and stroke of each cylinder assuming the length of stroke equal to 1.5 times the

diameter of cylinder.

15. The following data to a particular twin cylinder two stroke diesel engine. Bore 15 cm stroke. 20

cm. speed 400 rpm. Indicated mean effective pressure 4 bar, dead weight on the brake drum

650 N. spring balance reading 25 N Diameter of the brake drum 1 m .Fuel consumption 0.075

kg/min and calorific value of the fuel is 44500 kJ/kg. Determine i) Indicated Power ii) Brake

Power iii) Mechanical efficiency iv) Indicated thermal efficiency v)Brake thermal efficiency.

16. The following observations are recorded during a test on a fourstroke petrol engine, F.C = 3000

of fuel in 12sec, speed of the engine is 2500rpm, B.P = 20KW, Air intake orifice diameter =

35mm,Pressure across the orifice = 140mm of water coefficient of discharge of orifice = 0.6,

piston diameter = 150mm, stroke length = 100mm, Density of the fuel = 0.85gm/cc , r=6.5, Cv

of fuel = 42000KJ/Kg, Barometric pressure = 760mm of Hg , Room temperature = 24oc

17. Explain the different types of cooling systems with neat sketches

18. Explain the components of fuel injection system for diesel engines.

19. Explain the working of 4-stroke petrol engine.

20. Explain any one lubrication system adopted in multi cylinder SI engine

21. Mention the various methods of lubrication system and explain any two in detail

22. Compare petrol and diesel engine.

23. Explain the construction and working of fuel injector.

24. An ideal Brayton-cycle gas turbine with regeneration but no reheat or intercooling

operates at full load with an inlet temperature to the compressor of 60 oF and an inlet

temperature to the turbine of 1540 oF. The cycle is also to be operated at part load at a

pressure ratio of 3.0 with a turbine inlet temperature of 1100 oF. Compare the thermal

efficiency and net work output per lbm flow for the two operating points if the working fluid

(air) is treated as a perfect gas and the maximum possible regeneration is obtained.

25. Air enters the compressor of a gas turbine at 100 KPa and 25 o C. For a pressure ratio of 5 and a

maximum temperature of 850°C. Determine the thermal efficiency using the Brayton cycle

26. Drive the expression for air standard efficiency of Brayton cycle in terms of pressure ratio.

27. In a gas turbine cycle, air at atmosphere pressure is compressed adiabatically from 27oC and

1.01325bar to 5.741 bar and then the air absorbs heat from the exhaust gases at constant

pressure at a rate of 84kJ per kg. The air is further expanded at constant pressure by the

combustion of 0.012 kg of fuel per kg of air. The calorific value of fuel is 42000kJ/kg. The

products of combustion are expanded adiabatically in the turbine to 1.01325 bar. Being

exhausted with negligible velocity after yielding some of their heat to the air leaving the

compressor. Cp for air = 1 kJ/kg K

28. Derive the expression for work done in the open cycle gas turbine with reheating and explain

the importance of regeneration

Questions Are Expected for University Exams This May or may Not Be Asked for Exams

Please do not Copy (or) Republish This Questions, Students if You Find the Same Questions in Other

Sources, Kindly report us to rejinpaulteam@gmail.com

Vous aimerez peut-être aussi

- ICE All ExercisesDocument10 pagesICE All ExercisesB Ninh100% (1)

- Ejercicios Motores.Document10 pagesEjercicios Motores.Daniel ArmasPas encore d'évaluation

- Us Work Excel Mini Work SheetDocument36 pagesUs Work Excel Mini Work SheetAngelinPas encore d'évaluation

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraPas encore d'évaluation

- Crane Fluid Flow ProblemsDocument276 pagesCrane Fluid Flow ProblemsDanny Nguyen100% (2)

- Cycle Q'sDocument3 pagesCycle Q'sloolmoom100% (1)

- Sheet 1Document3 pagesSheet 1saad ElsheikhPas encore d'évaluation

- Thermal EnggDocument9 pagesThermal Enggmadhume01Pas encore d'évaluation

- Assignment 1 ATDDocument4 pagesAssignment 1 ATDPrashant Singh0% (1)

- Thermal Engineering Question BankDocument33 pagesThermal Engineering Question BankmechgokulPas encore d'évaluation

- ICE Assignment 15032017 035808AMDocument5 pagesICE Assignment 15032017 035808AMGerlan Madrid MingoPas encore d'évaluation

- Gas TurbineDocument6 pagesGas TurbineShashank SrivastavaPas encore d'évaluation

- Channabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)Document2 pagesChannabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)cenu 1999Pas encore d'évaluation

- Assgnment 1Document3 pagesAssgnment 1GaneshGaniPas encore d'évaluation

- Thermal Engineering-Question BankDocument32 pagesThermal Engineering-Question BankAlfred Franklin VPas encore d'évaluation

- ICE RevisionDocument4 pagesICE RevisionjehadyamPas encore d'évaluation

- 4 - Gas Power CycleDocument4 pages4 - Gas Power CycleMohamed MohamedPas encore d'évaluation

- ICE Assignment 8AMDocument5 pagesICE Assignment 8AMRushabh PatelPas encore d'évaluation

- Problem Set #2 - ChE 124 - Summer 2018Document3 pagesProblem Set #2 - ChE 124 - Summer 2018SkambalahardarPas encore d'évaluation

- Srinivasan Engineering College, Perambalur-621212: Question Bank Unit I Gas Power CyclesDocument18 pagesSrinivasan Engineering College, Perambalur-621212: Question Bank Unit I Gas Power CyclesagrikarthiPas encore d'évaluation

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfPas encore d'évaluation

- Tutorials 1-4Document6 pagesTutorials 1-4KrishnaPas encore d'évaluation

- Fluid Mechanics QuestionsDocument3 pagesFluid Mechanics QuestionsWaleed UsmanPas encore d'évaluation

- Tutorial-3 Updated 6-4-2015Document7 pagesTutorial-3 Updated 6-4-2015Sai Bala100% (1)

- Numerical Problems: Power Plant Equipment (Electrical IV/I)Document3 pagesNumerical Problems: Power Plant Equipment (Electrical IV/I)Rishav niroulaPas encore d'évaluation

- Unit I: Gas Power CyclesDocument78 pagesUnit I: Gas Power CyclesBalaji DsPas encore d'évaluation

- Tutorial Gas Turbine CyclesDocument6 pagesTutorial Gas Turbine CyclesPranav MishraPas encore d'évaluation

- Assignment2 - 110006 - Elements of Mechenical EngineeringDocument6 pagesAssignment2 - 110006 - Elements of Mechenical EngineeringSaniya Jumani0% (1)

- Ques - Eee MTDocument12 pagesQues - Eee MTKumaran PalaniPas encore d'évaluation

- Ic Engines & Jet PropulsionsDocument11 pagesIc Engines & Jet Propulsionschoudary garuPas encore d'évaluation

- Chapter 6 - Gas Power Cycles - Updated - 2023Document2 pagesChapter 6 - Gas Power Cycles - Updated - 2023Yonas BelaynehPas encore d'évaluation

- Tutorial Sheet (ME324) 2018-19Document1 pageTutorial Sheet (ME324) 2018-19Asif SadarPas encore d'évaluation

- ATD - I B.techDocument4 pagesATD - I B.techKarthiKeyanPas encore d'évaluation

- T E - Assig Q'sDocument2 pagesT E - Assig Q'sDinesh PaudelPas encore d'évaluation

- 7.1.prob - Sheet Gas Power CyclesDocument3 pages7.1.prob - Sheet Gas Power CyclesAnonymous mXicTi8hB0% (1)

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyPas encore d'évaluation

- Adv IC Engines Assignment No 2.Document3 pagesAdv IC Engines Assignment No 2.Madhupriya KalahastiPas encore d'évaluation

- Sheet 2 - Air Stanard CycleDocument5 pagesSheet 2 - Air Stanard CycleFarah SayedPas encore d'évaluation

- Solutions Gas Turbines Q1-8Document18 pagesSolutions Gas Turbines Q1-8Tom TambePas encore d'évaluation

- Assignment - 2 TE-1-1Document1 pageAssignment - 2 TE-1-1Lalith SunkojuPas encore d'évaluation

- 16marks QueusionDocument19 pages16marks QueusionprasanthprpPas encore d'évaluation

- EI6403-Applied Thermodynamics and Fluid Dynamics PDFDocument13 pagesEI6403-Applied Thermodynamics and Fluid Dynamics PDFHarish prajenPas encore d'évaluation

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilPas encore d'évaluation

- Gas TurbineDocument1 pageGas TurbineSayan DasPas encore d'évaluation

- Thermal Univ PDFDocument8 pagesThermal Univ PDFNithin Mathew EyyalilPas encore d'évaluation

- ITK-233-6 - Power Production & RefrigerationDocument30 pagesITK-233-6 - Power Production & RefrigerationAndy Noven KrisdiantoPas encore d'évaluation

- Thermal Questions KonguDocument9 pagesThermal Questions Konguabu19870% (1)

- Wor ShopDocument4 pagesWor ShopDavid Santiago Ayala RodriguezPas encore d'évaluation

- Assignment and Its Solution - Airstandardcycle and VapourcycleDocument24 pagesAssignment and Its Solution - Airstandardcycle and VapourcycleMatthias100% (1)

- Tutorial4 QuestionsDocument2 pagesTutorial4 QuestionsVincent WongPas encore d'évaluation

- AT Question BankDocument3 pagesAT Question BankShubham Vijay JadhavPas encore d'évaluation

- Questions - Otto & Diesel CycleDocument1 pageQuestions - Otto & Diesel CycletalkeennomaniPas encore d'évaluation

- GT Powerplants Additional ExamplesDocument8 pagesGT Powerplants Additional ExamplesKarina Nur Rakhmawaty25% (4)

- Me2301 QBDocument7 pagesMe2301 QBbalajigandhirajanPas encore d'évaluation

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianPas encore d'évaluation

- Applied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetDocument4 pagesApplied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetShashi Kant KhalkhoPas encore d'évaluation

- Ar Cycle 2Document4 pagesAr Cycle 2ELEONOR TABLINGONPas encore d'évaluation

- ATD Question Bank-Mid 2-V6Document3 pagesATD Question Bank-Mid 2-V6vijayavijju1047Pas encore d'évaluation

- Power Plant New QuestionDocument2 pagesPower Plant New QuestionRishav niroulaPas encore d'évaluation

- AET Question Bank For AUC R2013 - SDocument5 pagesAET Question Bank For AUC R2013 - SGurunath AeroPas encore d'évaluation

- CalculusofCloudComputingSunRG2019 IIDocument8 pagesCalculusofCloudComputingSunRG2019 IIAngelinPas encore d'évaluation

- Ec6601 2m Rejinpaul IDocument21 pagesEc6601 2m Rejinpaul IAngelinPas encore d'évaluation

- Cement: CELL: 9943933546 8220943926Document1 pageCement: CELL: 9943933546 8220943926AngelinPas encore d'évaluation

- Ec6302 Digital Electronics PDFDocument206 pagesEc6302 Digital Electronics PDFAngelinPas encore d'évaluation

- Ge8151 Problem Solving and Python Programming Reg 2017Document2 pagesGe8151 Problem Solving and Python Programming Reg 2017AngelinPas encore d'évaluation

- Ar8121 Architectural Drawing Reg 2017Document3 pagesAr8121 Architectural Drawing Reg 2017AngelinPas encore d'évaluation

- Ge8152 Engineering Graphics Reg 2017Document2 pagesGe8152 Engineering Graphics Reg 2017AngelinPas encore d'évaluation

- Cy8101 Chemistry For Marine Engineering Reg 207Document2 pagesCy8101 Chemistry For Marine Engineering Reg 207AngelinPas encore d'évaluation

- Ar8101 History of Architecture and Culture Reg 2017Document2 pagesAr8101 History of Architecture and Culture Reg 2017AngelinPas encore d'évaluation

- Docit - Tips In5 PDFDocument1 pageDocit - Tips In5 PDFAngelinPas encore d'évaluation

- In 4Document2 pagesIn 4AngelinPas encore d'évaluation

- It8201 Ite Rejinpaul Iq Am19Document1 pageIt8201 Ite Rejinpaul Iq Am19AngelinPas encore d'évaluation

- HC HFO ManualDocument95 pagesHC HFO ManualGermán P. Fuentes DuránPas encore d'évaluation

- 2062 0 4 SPV (Vacuum)Document12 pages2062 0 4 SPV (Vacuum)Trần Phước TrungPas encore d'évaluation

- Three Way Transfer Valve CY8000-0990Document4 pagesThree Way Transfer Valve CY8000-0990Elmer Ernesto Castillo HernándezPas encore d'évaluation

- 5LB - SO2 - InstructionsDocument1 page5LB - SO2 - InstructionsAtul SharmaPas encore d'évaluation

- Study of f1 Car Aerodynamic Rear Wing Using ComputationalDocument24 pagesStudy of f1 Car Aerodynamic Rear Wing Using ComputationalJorge Andres Cifuentes GutierrezPas encore d'évaluation

- Coke and Coal Gasification Plant 2 200 TPD 107Document1 pageCoke and Coal Gasification Plant 2 200 TPD 107osamaPas encore d'évaluation

- Chapter 2 Part 1Document16 pagesChapter 2 Part 1hafizahPas encore d'évaluation

- A Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporDocument3 pagesA Boiler Is Defined As "A Closed Vessel in Which Water or Other Liquid Is Heated, Steam or VaporAsim aliPas encore d'évaluation

- Flow Instruments: ScopeDocument29 pagesFlow Instruments: ScopesamboopathiPas encore d'évaluation

- Hydraulic CalculationDocument7 pagesHydraulic CalculationRais Rijal100% (1)

- JV350003 Storm ValveDocument1 pageJV350003 Storm Valvebig fishPas encore d'évaluation

- Cap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionDocument166 pagesCap 03 Mecanica Dos Fluidos Fox Mcdonald 8a Edicao SolutionAlice LimaPas encore d'évaluation

- Case Study - Turbine Bearing Housing Fire Accident Due To Hydrogen Inflow Into Nitrogen Line of Dry Gas SealDocument16 pagesCase Study - Turbine Bearing Housing Fire Accident Due To Hydrogen Inflow Into Nitrogen Line of Dry Gas SealLong NguyenPas encore d'évaluation

- Chapter 2Document22 pagesChapter 2Haikal HassanPas encore d'évaluation

- AFT Fathom 10 Data SheetDocument2 pagesAFT Fathom 10 Data SheetdelitesoftPas encore d'évaluation

- Hydraulically Actuated Valve Deluge SystemDocument2 pagesHydraulically Actuated Valve Deluge Systemzepol051Pas encore d'évaluation

- Sizing and Selecting Metering PumpsDocument4 pagesSizing and Selecting Metering PumpsMehdi Hajd KacemPas encore d'évaluation

- Dimensionless Numbers in Fluid MechanicsDocument7 pagesDimensionless Numbers in Fluid MechanicsEduardoPas encore d'évaluation

- Lab Report 3 (I)Document5 pagesLab Report 3 (I)Kinit KinitPas encore d'évaluation

- (Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumDocument3 pages(Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumIZZAN IZALIA MAHZANPas encore d'évaluation

- Atlascopco Oil DatasheetDocument2 pagesAtlascopco Oil DatasheetAmirmasoudPas encore d'évaluation

- Part I - 09 Compressed Gas CylindersDocument4 pagesPart I - 09 Compressed Gas Cylinderssalah abddayem100% (1)

- GT 11. Modul Operating ProcedureDocument19 pagesGT 11. Modul Operating Procedurepraztt69Pas encore d'évaluation

- Process Gas Compressors: Comprehensive Api 618 Compressor PortfolioDocument20 pagesProcess Gas Compressors: Comprehensive Api 618 Compressor PortfolioaliakbarPas encore d'évaluation

- Mine GasesDocument48 pagesMine GasesRavi Krishnan100% (1)

- Sen 96 GB PressureDocument3 pagesSen 96 GB PressureZsolt BodóPas encore d'évaluation

- Valvula Termostatica Parker TH-1000-16FO-57Document2 pagesValvula Termostatica Parker TH-1000-16FO-57andreshuertascalderon02Pas encore d'évaluation

- Chapter - 5 - Pressure Measurements RCOEM PDFDocument76 pagesChapter - 5 - Pressure Measurements RCOEM PDFHarshvardhan RaiPas encore d'évaluation