Académique Documents

Professionnel Documents

Culture Documents

Christo Lube MCG 134 Tech Data

Transféré par

robertoalfaro4920230 évaluation0% ont trouvé ce document utile (0 vote)

56 vues1 pageLUBRICACION

Titre original

Christo Lube Mcg 134 Tech Data

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentLUBRICACION

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

56 vues1 pageChristo Lube MCG 134 Tech Data

Transféré par

robertoalfaro492023LUBRICACION

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

LUBRICATION TECHNOLOGY INC.

7595 Gallia Pike

Franklin Furnace, Ohio, USA 45629

Phone: 740-574-5150

Fax: 740-574-4740

CHRISTO-LUBE® MCG 134

CHRISTO-LUBE® MCG 134 is a wide temperature range, perfluoropolyether grease suitable for use in low-pressure

systems where non-reactivity with chemicals, strong acids and oxidizers, fuels, solvents, etc. is mandatory. It is especially

suitable for use in applications including electrical contacts, valves, threads, screws, bearings, and in systems employing

elastomeric and plastic seals, gaskets, and o-rings. Although CHRISTO-LUBE® MCG 134 is very inert, newly exposed

rubbing surfaces of aluminum and magnesium may react with the grease under certain extreme conditions.

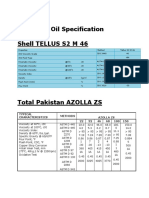

PERFORMANCE TEST TEST METHOD CONDITION TYPICAL VALUE

Temperature Range -59°C to 260°C

NLGI No. 1-2

Unworked Penetration ASTM D-1403 25°CF 265-320

Worked Penetration ASTM D-1403 60 strokes 265-330

Evaporation ASTM D-2595 22 hrs, 204°C, max 0.05%

232°C 0.10%

Oil Separation FED-STD-791, Method 321 30 hrs, 204°C, max 10.50%

Copper Corrosion FED-STD-791, 24 hrs, 100°C 1a, no stain

Method 5309

Fuel Solubility FED-STD-791 8 hrs, 25°C 0.12%

Resistance to Fuel Method 5414 No deterioration

Film Stability and Corrosion on Steel MIL-PRF-27617F 168 hrs, 100°C No resinous deposit

No corrosion

Water Washout ASTM D-1264 1 hr, 38°C 0.05%

Four Ball Wear ASTM D-2266 1200 rpm, 40 kg, 52100

steel, 75°C, 1 hr

2 hrs 0.70 mm

0.80 mm

Low Temperature Torque ASTM D-1478 @ -59°CF, Starting 3965 g-cm

10 min Running 2800 g-cm

60 min Running 2050 g-cm

LOX Impact Sensitivity ASTM D-2512 20 Impacts No Reaction

from 1100 mm

Oxidation Stability ASTM D-942 121°C, 100 hrs 0 psi Drop

Vapor Pressure Knudsen 20°C 10-5 Torr

FREE OF OZONE DEPLETION COMPOUNDS (ODC)

This information gives typical properties only and is not to be used for specification purposes. Lubrication Technology Inc. does not make any warranty,

express or implied, or accept any liability in connection with this information or its use. Lubrication Technology Inc. reserves the right to make additions,

deletions or modifications to the information at any time without prior notification. For any health, hazard or environmental concerns, please refer to this

products Material Safety Data Sheet.

Vous aimerez peut-être aussi

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartPas encore d'évaluation

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesD'EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesPas encore d'évaluation

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliPas encore d'évaluation

- Gas Sweetening and Processing Field ManualD'EverandGas Sweetening and Processing Field ManualÉvaluation : 4 sur 5 étoiles4/5 (7)

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041Pas encore d'évaluation

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidentePas encore d'évaluation

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyPas encore d'évaluation

- Daphne Alpha Screw 32: Lubricant Product InformationDocument2 pagesDaphne Alpha Screw 32: Lubricant Product InformationSadid ShahzadPas encore d'évaluation

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiPas encore d'évaluation

- Product Data: Sealants, IncDocument2 pagesProduct Data: Sealants, IncSantoshPas encore d'évaluation

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358Pas encore d'évaluation

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamPas encore d'évaluation

- LNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetDocument1 pageLNP™ THERMOCOMP™ Compound - WF0069 - Global - Technical - Data - SheetWang MbaoPas encore d'évaluation

- Mov Long Life Grade 0 Product Data Sheet: Typical Values: General PropertiesDocument1 pageMov Long Life Grade 0 Product Data Sheet: Typical Values: General PropertiesJuan Manuel Gutierrez AguilarPas encore d'évaluation

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanPas encore d'évaluation

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaPas encore d'évaluation

- Magna PM 220-Pds-EngDocument2 pagesMagna PM 220-Pds-EngVusal HasanovPas encore d'évaluation

- Maker Tauro enDocument2 pagesMaker Tauro enibrahim maulanaPas encore d'évaluation

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasPas encore d'évaluation

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SPas encore d'évaluation

- Gii Turbine Oil 32 46 68 77 100Document1 pageGii Turbine Oil 32 46 68 77 100Thaer HamedePas encore d'évaluation

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RosePas encore d'évaluation

- High Performance Lubricants: Molykote HP-870 GreaseDocument2 pagesHigh Performance Lubricants: Molykote HP-870 GreaseBruno FranPas encore d'évaluation

- Product Data Sheet: Gulfsea Gear Oil SeriesDocument2 pagesProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanPas encore d'évaluation

- PF7000Aliphatic PolyurethaneDocument2 pagesPF7000Aliphatic PolyurethaneLuis ArciaPas encore d'évaluation

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezPas encore d'évaluation

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangecarmaPas encore d'évaluation

- Crown Tech Plus 10 819Document2 pagesCrown Tech Plus 10 819rinthusPas encore d'évaluation

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemPas encore d'évaluation

- Wonderloy PC 540Document2 pagesWonderloy PC 540Phung LucPas encore d'évaluation

- Castrol Magna 150 Ep - TDSDocument2 pagesCastrol Magna 150 Ep - TDSHector Martin BarajasPas encore d'évaluation

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoPas encore d'évaluation

- Aircol SR 68Document2 pagesAircol SR 68nauta007Pas encore d'évaluation

- Omega Amide Nylon Pa CatalogueDocument5 pagesOmega Amide Nylon Pa Cataloguesoni10483Pas encore d'évaluation

- Shakun Polymers Limited: Spl-Afosr High Performance PVC CompoundDocument2 pagesShakun Polymers Limited: Spl-Afosr High Performance PVC CompoundquycoctuPas encore d'évaluation

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoPas encore d'évaluation

- PDS CSG-100 (ENG) - s-11521Document1 pagePDS CSG-100 (ENG) - s-11521huongktbPas encore d'évaluation

- Foodmax Grease ALU M 2 - TDS - 263700401 - ENDocument2 pagesFoodmax Grease ALU M 2 - TDS - 263700401 - ENDeath HeartPas encore d'évaluation

- Super Tauro PAG: LubricantsDocument1 pageSuper Tauro PAG: LubricantsSaurav SharmaPas encore d'évaluation

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenPas encore d'évaluation

- Oil Tubine DatasheetDocument2 pagesOil Tubine DatasheetHANIF AKBARPas encore d'évaluation

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraPas encore d'évaluation

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDocument1 pageTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardPas encore d'évaluation

- 4 - Epoksi Boya Technical Data Sheet PDFDocument2 pages4 - Epoksi Boya Technical Data Sheet PDFVasaPas encore d'évaluation

- CYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetRodrigoMachadoPas encore d'évaluation

- Agip Arnica S: Characteristics (Typical Figures)Document2 pagesAgip Arnica S: Characteristics (Typical Figures)AMAZING AGPas encore d'évaluation

- 226NDocument2 pages226NUmaibalanPas encore d'évaluation

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedPas encore d'évaluation

- Castrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Document2 pagesCastrol BRAYCOTE 601 EF - Pds - Eng - Rev. 2014.08.04Massimiliano VolaPas encore d'évaluation

- Quintolubric® 888 68Document2 pagesQuintolubric® 888 68Cédric LOUISPas encore d'évaluation

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimPas encore d'évaluation

- EPDM - Test by Romac Inc PDFDocument2 pagesEPDM - Test by Romac Inc PDFRajendra Kumar SharmaPas encore d'évaluation

- Humiseal 1R32 Conformal Coating English TdsDocument2 pagesHumiseal 1R32 Conformal Coating English TdsLee HitchensPas encore d'évaluation

- Alphasyn HG RangeDocument2 pagesAlphasyn HG RangeAlin BAMPas encore d'évaluation

- Procyon Cross ReferenceDocument1 pageProcyon Cross Referencerobertoalfaro492023Pas encore d'évaluation

- Panolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly BiodegradableDocument1 pagePanolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly Biodegradablerobertoalfaro492023Pas encore d'évaluation

- Analisis Transol Gax - Oil&transformersDocument1 pageAnalisis Transol Gax - Oil&transformersrobertoalfaro492023Pas encore d'évaluation

- Compressor Oil S3 RDocument1 pageCompressor Oil S3 Rrobertoalfaro492023Pas encore d'évaluation

- Chain and Cable Lube TdsDocument1 pageChain and Cable Lube Tdsrobertoalfaro492023Pas encore d'évaluation

- Pearl L110 CoaDocument1 pagePearl L110 Coarobertoalfaro492023Pas encore d'évaluation

- 1 11worldviewDocument1 page1 11worldviewrobertoalfaro492023Pas encore d'évaluation

- Premalube XtremeDocument2 pagesPremalube Xtremerobertoalfaro492023Pas encore d'évaluation

- Review of Recent Changes To Mineral Insulating Oil SpecificationsDocument5 pagesReview of Recent Changes To Mineral Insulating Oil Specificationsrobertoalfaro492023Pas encore d'évaluation

- Isoflex Topas NB 52Document2 pagesIsoflex Topas NB 52c108Pas encore d'évaluation

- Hydrex 97-2000 & 95 PresentationDocument44 pagesHydrex 97-2000 & 95 Presentationrobertoalfaro492023Pas encore d'évaluation

- Boletin The Dirty Truth About Soot PDFDocument2 pagesBoletin The Dirty Truth About Soot PDFrobertoalfaro492023Pas encore d'évaluation

- Lubricantes Sinteticos IntroduccionDocument7 pagesLubricantes Sinteticos Introduccionrobertoalfaro492023Pas encore d'évaluation

- The Defeat of Cancer - La Derrota Del CáncerDocument21 pagesThe Defeat of Cancer - La Derrota Del Cáncerrobertoalfaro492023100% (1)

- 06 - Speciality GreasesDocument98 pages06 - Speciality Greasesrobertoalfaro492023100% (1)

- 13 - PcmoDocument33 pages13 - Pcmorobertoalfaro49Pas encore d'évaluation

- Compro Presentacion 2015 IngDocument22 pagesCompro Presentacion 2015 Ingrobertoalfaro492023Pas encore d'évaluation

- 08 - Super Compressor OilsDocument50 pages08 - Super Compressor Oilsrobertoalfaro492023Pas encore d'évaluation

- 07 - SynduroDocument14 pages07 - Syndurorobertoalfaro492023Pas encore d'évaluation

- 01 - Base OilsDocument43 pages01 - Base Oilsrobertoalfaro492023100% (3)

- 07 - SynduroDocument14 pages07 - Syndurorobertoalfaro492023Pas encore d'évaluation

- Driving Heavy Duty Engine Oil Towards API CI-4Document18 pagesDriving Heavy Duty Engine Oil Towards API CI-4robertoalfaro492023100% (1)

- High Efficiency Electrical Insulating FluidsDocument85 pagesHigh Efficiency Electrical Insulating Fluidsrobertoalfaro492023Pas encore d'évaluation

- 08 - Super Compressor OilsDocument50 pages08 - Super Compressor Oilsrobertoalfaro492023Pas encore d'évaluation

- 4 Good ReasonsDocument8 pages4 Good Reasonsrobertoalfaro492023Pas encore d'évaluation

- Driving Heavy Duty Engine Oil Towards API CI-4Document18 pagesDriving Heavy Duty Engine Oil Towards API CI-4robertoalfaro492023100% (1)

- 06 - Speciality GreasesDocument98 pages06 - Speciality Greasesrobertoalfaro492023100% (1)

- 09 - Refrigeration OilsDocument18 pages09 - Refrigeration Oilsrobertoalfaro492023Pas encore d'évaluation

- Case Study Paper Mill Vacuum PumpsDocument1 pageCase Study Paper Mill Vacuum Pumpsrobertoalfaro492023Pas encore d'évaluation

- 24528Document3 pages24528reeta ramPas encore d'évaluation

- 2 Introduction To XRPD Data AnalysisDocument25 pages2 Introduction To XRPD Data AnalysisMuthu KumarPas encore d'évaluation

- Reynolds-Averaged Navier-Stokes EquationsDocument3 pagesReynolds-Averaged Navier-Stokes EquationsMirko GranesePas encore d'évaluation

- Gujarat Technological University: Aeronautical EngineeringDocument16 pagesGujarat Technological University: Aeronautical EngineeringumodiPas encore d'évaluation

- Design Optimisation of Space Frame ChassisDocument40 pagesDesign Optimisation of Space Frame Chassisadj adj100% (1)

- Organic Lab ReportDocument3 pagesOrganic Lab Reportinaam0% (1)

- PolyolsDocument12 pagesPolyolsA MahmoodPas encore d'évaluation

- Mullarney Sweeteners Used in Chewable TabletsDocument10 pagesMullarney Sweeteners Used in Chewable TabletsKatherine PosadaPas encore d'évaluation

- Indian Standard For Industrial FlooringDocument10 pagesIndian Standard For Industrial FlooringRamprasad JeyaramPas encore d'évaluation

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocument6 pagesSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiPas encore d'évaluation

- Chemical Sensors: Comprehensive Sensor Technologies, Vol. 6: Chemical Sensors ApplicationsDocument77 pagesChemical Sensors: Comprehensive Sensor Technologies, Vol. 6: Chemical Sensors ApplicationsMomentum PressPas encore d'évaluation

- An 335 Natural ProductsDocument3 pagesAn 335 Natural ProductsTonnyLeitePas encore d'évaluation

- Mean Activity Coefficients of Electrolytes As A Function of ConcentrationDocument4 pagesMean Activity Coefficients of Electrolytes As A Function of ConcentrationLuis CarlosPas encore d'évaluation

- 06 05 16 Heko Bucket ElevatorDocument36 pages06 05 16 Heko Bucket ElevatorLeoncio Alexander Maza InfantesPas encore d'évaluation

- Homogeneous and Structured PCD-WC-Co Materials For DrillingDocument9 pagesHomogeneous and Structured PCD-WC-Co Materials For Drillingdan_cunningham_15Pas encore d'évaluation

- Sikasil 670 Fire - Pds enDocument4 pagesSikasil 670 Fire - Pds enTRI MINTO WIDODOPas encore d'évaluation

- Lab 2 - Turbidity and Solids UpdatedDocument14 pagesLab 2 - Turbidity and Solids UpdatedMuStafaAbbasPas encore d'évaluation

- FSX 414 Cobalt Base SuperalloyDocument4 pagesFSX 414 Cobalt Base SuperalloyJJPas encore d'évaluation

- GP2 Electric-FieldDocument28 pagesGP2 Electric-FieldChristine Karel Marcelino0% (1)

- Non Protein NitrogenousDocument19 pagesNon Protein NitrogenousWina AdrianPas encore d'évaluation

- ManuscriptDocument17 pagesManuscriptEidelsayedPas encore d'évaluation

- What Are The Properties of Air Entrained ConcreteDocument2 pagesWhat Are The Properties of Air Entrained ConcretesuryakantamePas encore d'évaluation

- Sample Planning and Designing Lab For Chemistry UpdatedDocument2 pagesSample Planning and Designing Lab For Chemistry UpdatedRangerPas encore d'évaluation

- Determination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationDocument6 pagesDetermination of Bendamustine Hydrochloride in Pure and Dosage Forms by Ion-Associative Complex FormationHeidi HughesPas encore d'évaluation

- Salt AnalysisDocument10 pagesSalt Analysisamrita girishPas encore d'évaluation

- Soil Answer To QuestionsDocument3 pagesSoil Answer To QuestionsNicolo SalvadorPas encore d'évaluation

- Mobil Dte 20Document3 pagesMobil Dte 20alexander900616Pas encore d'évaluation

- PhilosophyofTheism 10036021 PDFDocument354 pagesPhilosophyofTheism 10036021 PDFdydycookyPas encore d'évaluation

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pages09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Limit Theorems For Generalized Density-Dependent Markov Chains and Bursty Stochastic Gene Regulatory NetworksDocument29 pagesLimit Theorems For Generalized Density-Dependent Markov Chains and Bursty Stochastic Gene Regulatory NetworksGaston GBPas encore d'évaluation

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeD'EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeÉvaluation : 5 sur 5 étoiles5/5 (1)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincD'EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincÉvaluation : 3.5 sur 5 étoiles3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeD'EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeÉvaluation : 5 sur 5 étoiles5/5 (4)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactD'EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactÉvaluation : 5 sur 5 étoiles5/5 (5)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideD'EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuidePas encore d'évaluation

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableD'EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeD'EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticePas encore d'évaluation

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsD'EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsPas encore d'évaluation

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolD'EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolPas encore d'évaluation

- Chemistry for Breakfast: The Amazing Science of Everyday LifeD'EverandChemistry for Breakfast: The Amazing Science of Everyday LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (90)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeD'EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeÉvaluation : 4 sur 5 étoiles4/5 (1)

- Tribology: Friction and Wear of Engineering MaterialsD'EverandTribology: Friction and Wear of Engineering MaterialsÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Periodic Table: A Very Short IntroductionD'EverandThe Periodic Table: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Advanced Production Decline Analysis and ApplicationD'EverandAdvanced Production Decline Analysis and ApplicationÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsD'EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsÉvaluation : 4 sur 5 étoiles4/5 (146)

- Taste: Surprising Stories and Science About Why Food Tastes GoodD'EverandTaste: Surprising Stories and Science About Why Food Tastes GoodÉvaluation : 3 sur 5 étoiles3/5 (20)

- Ingredients: A Visual Exploration of 75 Additives & 25 Food ProductsD'EverandIngredients: A Visual Exploration of 75 Additives & 25 Food ProductsÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsD'EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Bioplastics: A Home Inventors HandbookD'EverandBioplastics: A Home Inventors HandbookÉvaluation : 4 sur 5 étoiles4/5 (2)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactD'EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fundamentals of Chemistry: A Modern IntroductionD'EverandFundamentals of Chemistry: A Modern IntroductionÉvaluation : 5 sur 5 étoiles5/5 (1)