Académique Documents

Professionnel Documents

Culture Documents

Data Book de Bomba

Transféré par

Sharon BotinyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Data Book de Bomba

Transféré par

Sharon BotinyDroits d'auteur :

Formats disponibles

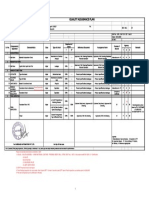

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No.

100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 1 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

1 Pump Casing C PS-3104 D D - - 3.1

1.1 Material Certification ASTM A351, Gr CF3M D D - - 3.1

1.2 Chemical Analysis

NACE Compliant, HRC 22Max

1.3 Heat Treatment Hardness Report required.

1.4 Mechanical Properties

1.5 Visual Inspection of casting TP-0012 / MSS-SP55 3 7

Weld repair (as applicable ) and pipe

1.6 ASME Sect IX 6 WO WO, Work Order (traveller)

attachment welds

Note 1

1.7 PT- Casting TP-0001 / ASME Sec. VIII Div 1. App7 QC-5

100% Accessible Surfaces

TP-0014 / B31.3 for welds 3

1.8 Visual inspection of welds WO

TP-0012 / MSS-SP55 for casting repair 1

Note 2

1.9 Hydro Test TP- 0020 / 1080 Psi, no leaks for ½ Hr. 9 W 6 QC-101 Non-Witness Hydro Test

Certificate.

2 Pump Cover C PS-3104 D D - - 3.1

2.1 Material Certification ASTM A351/ Gr CF3M D D - - 3.1

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 2 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

2.2 Chemical Analysis

NACE Compliant, HRC 22Max,

2.3 Heat Treatment Hardness Report required.

2.4 Mechanical Properties

2.5 Visual Inspection of casting TP-0012 / MSS-SP55 3 7

Weld repair (as applicable ) and pipe

2.6 ASME Sect IX 6 WO WO, Work Order (traveller)

attachment welds

Note 1

2.7 PT- Casting TP-0001 / ASME Sec. VIII Div 1. App7 QC-5

100% Accessible Surfaces

TP-0014 / B31.3 for welds 3

2.8 Visual inspection of welds WO

TP-0012 / MSS-SP55 for casting repair 1

Note 2

2.9 Hydro Test TP- 0020 / 1080 Psi, no leaks for ½ Hr. 9 6 QC-101 Non-Witness Hydro Test

Certificate.

3 Impeller C PS-2102 D D - - 3.1

3.1 Material Certification ASTM A743/351, Gr CF3M D D - - 3.1

3.1 Chemical Analysis

NACE Compliant, Hardness

3.2 Heat Treatment Control

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 3 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

3.3 Mechanical Properties

3.4 Visual Inspection of casting TP-0012 / MSS-SP55 3 7

WO, Work Order (traveller)

3.5 Weld repair (as applicable ) ASME Sect IX 6 WO In-house weld hardness control

TP-0014 / B31.3 for welds 3

3.6 Visual inspection of welds WO WO, Work Order (traveller)

TP-0012 / MSS-SP55 for casting repair 1

3.7 Balance ISO 13709 / 0.252 Gr/In @3560 Rpm 6 QC-20 2 Planes Balalnce

4 Shaft B PS-2000 D D - - 3.1

HRC 35 Max – Hardness

4.1 Material Certification ASTM A479, Type XM-19 Hot rolled Properties D D - - 3.1 Control

4.2 Chemical Analysis

4.3 Heat Treatment

4.4 Mechanical Properties

4.5 Visual Inspection TP-0015 / Material Specification 1 7 No weld repair permit

5 Bearing Cover C PS-1101 D D 2.1

5.1 Material Requirement AC ATM A216 Gr WCB

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 4 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

5.2 Visual Inspection of casting TP-0012 / MSS-SP55 3 7

5.3 Visual inspection of welds TP-0012 / MSS-SP55 for casting repair 1 7 WO

6 Bearing Housing C PS-1101 D D 2.1

6.1 Material Certification ATM A216 Gr WCB

6.2 Visual Inspection of casting TP-0012 / MSS-SP55 3 7

6.3 Visual inspection of welds TP-0012 / MSS-SP55 for casting repair 1 7 WO

Pressure Retaining Fasteners;

7 B, F PS-2000 D D ST – 3.1

Studs, Nuts

Cadmium plated boliting

7.1 Material Certification ASTM A193 B7, A194 2H 6 prohibited .

7.2 Visual Inspection TP-0015 / Material Specification 1 7

8 Pipe Fittings F,W PS-2000 D D ST – 3.1

NACE Compliant,

8.1 Material Certification ASTM A105 6 Hardness report required ;

187 HB Max

8.2 Visual Inspection TP-0015 / Material Specification 1 7

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 5 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

9 Wear Rings, Centre Sleeve & Bushing B, C

9.1 Throat BSHG B, C PS-2000 D D - - 3.1

9.1.1 Material Requirements RM ATM AISI 316L D 3

9.1.2 VT - Machined Surfaces FM TP-0015 / Material Specification D 7

9.1.3 SUME SA Coating As per PO requirements Note 3 SUME SA coating

10 Mechanical Seal F Mechanical Seal Drawing ST

10.1 Visual Inspection TP-0015 / Mechanical Seal Drawomg 1 7 Similar to DWG as per PO

11 Pump Complete To Approved GA Drawing 6

11.1 Painting carbon steel surfaces Customer Painting Spec 6 QC-19

11.2 Protection & preservation Sulzer Standard

11.3 Marking, labelling and nameplate To Contract Specific Info ST Nameplate

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 6 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Inspectorate

Standard Rev.

Third Party

Product Type of No. of

Task /

Customer

Control/Test Operation Form / Specification / Acceptance Criteria Document Document/ Remarks

Supplier

Item No.

Sulzer

Mat. Status / Record Record

QC-15A

Approved GA Drawing QC-15B

11.4 Final Inspection and release Dimensional and Running Clearance 6 QC-15C

Assembly In-Process Record QC-30

QAB-39

History

11.5 Preparation of QA history docket Required Contract QA Documents 6

Docket

11.6 Package and crate D60 CR-001(D) 3

Ship completed pump and QA history

11.7

docket to customer

Notes in the Quality Plan

O : No notice is given. Client can witness if present at time of test

H : Notice I given and test held until client attendance or receipt of written waiver. Notice period 10 working days or according contract

A

W: Notice I given and test carried out whether client attends or not provided the notice period agreed. Notice period 10 working days or according contract

D : Review of documents in Manufacturing Record Book (MRB) or similar Type of Documentation

1 PT Case, Cover & all attachment Welds; on all accessible surfaces as defined in E66.

2 Hydro Test Case & End Cover at 1080 Psi for ½ Hr.

3 HVOF Coated (SUME SA) on Wear Rings is applicable.

Revison Detail

Rev 1 Equipment # changed as per ORM correction.

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

SAP doc No. QQP100290979-0010 Technical Quality Sulzer Pumps Tender/Project No. 100290979

Purchaser : BIX OIL, S.A. Issued by (Name/LE) Mona Saee

Sulzer P.O. No. 3203 Standard Quality Plan Released by (Name/LE) Mona Saee

TAG No. – Special Quality Plan Rev. 1 Date 28 Feb 2018 Page 7 of 7

Market / Business Segment(s) Oil and Gas

Pump Type(s) 3 x 4 x 17; CAP8 Pressure Retaining Material

Project /Site: DUPLICATE BARESHAFT (to 01708072) Application Code: Offshore Water Injection

1 Stage A-8 A351 - Gr CF3M

Serial# 596785 (Rev 1) Liquid Type: Water- Sour

Project and/or customer specific notes

This block could be added in case of issuing an Order Related Quality Plan, which needs approvals !!

Approvals Sulzer Pumps Customer 3rd Party

Name

Signature

Stamp

SUBMIT FOR INFO ONLY

Date

Position

Inspectorate (see Note A) Product Form Material Status Type of Document/Record

O Observed B Bar AC As Cast 1 EN 10204 – 2.1 5 CE-Declaration/Marking

H Hold Point C Casting AF As Forged 2 EN 10204 – 2.2 6 With Report

W Witness F Forging FM Finish Machined 3 EN 10204 – 3.1 7 Without Report

D Document Review W Wrought PM Proof Machined 4 EN 10204 – 3.2 ST Product Marking

H HIP-Component RM Raw Material

P Plate

Subject to legislation, verification documentation detailed above may be held at Sulzer or supplier premises. When required, Manufacturing Record Dossiers shall be compiled in accordance with project

requirements and held by Sulzer.

Revision: Date: Amendment:

This Quality Plan has been issued and released by the Concept Responsible LE and is published under the authority of the Technical Quality Working Group Doc No:

Vous aimerez peut-être aussi

- Material Test Certificates: Supplied ToDocument2 pagesMaterial Test Certificates: Supplied ToShaheen Andre ChikkuPas encore d'évaluation

- Sample Valve Material CertificatesDocument18 pagesSample Valve Material CertificatesFLOW VALVE AUTOMATION100% (2)

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickPas encore d'évaluation

- Material Test Certificate SummaryDocument1 pageMaterial Test Certificate Summarymohamadhakim.19789Pas encore d'évaluation

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- DVS 2207-3Document12 pagesDVS 2207-3gura9054Pas encore d'évaluation

- Colour Code Chart PDFDocument1 pageColour Code Chart PDFNiraj Pandey100% (1)

- Field Joint Coating Installation ProcedureDocument2 pagesField Joint Coating Installation Procedureunix manPas encore d'évaluation

- Pentadur 5540 (F6A)Document3 pagesPentadur 5540 (F6A)SiDdu Kalashetti0% (1)

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2Pas encore d'évaluation

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinPas encore d'évaluation

- 36 - Painting Procedure - Rev0Document21 pages36 - Painting Procedure - Rev0Duc ThinPas encore d'évaluation

- WPS - 2Document3 pagesWPS - 2aleventPas encore d'évaluation

- Atul 30,36-LoescheDocument16 pagesAtul 30,36-LoescheSales ITAPas encore d'évaluation

- Automotive Specification List PDFDocument14 pagesAutomotive Specification List PDFGilmarasanPas encore d'évaluation

- Hindustan Hydraulics EHPsh25 PDFDocument4 pagesHindustan Hydraulics EHPsh25 PDFshyam_ink50% (2)

- Refining Major Projects General ManagementDocument20 pagesRefining Major Projects General ManagementJacarreroPas encore d'évaluation

- Weld MapDocument1 pageWeld MapFerdie OSPas encore d'évaluation

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 pagePt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairPas encore d'évaluation

- Test CertificateDocument1 pageTest CertificateAvinash JadhavPas encore d'évaluation

- Original: Mill Test CertificateDocument3 pagesOriginal: Mill Test CertificateAhmad NafilulhudaPas encore d'évaluation

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzPas encore d'évaluation

- Metal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)Document3 pagesMetal Forgings Private Limited: (AN I.S.O. 9001-2008 COMPANY)rohitPas encore d'évaluation

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47Pas encore d'évaluation

- Cross Hatch Adhesion Testing - ASTM 3359 Method ADocument2 pagesCross Hatch Adhesion Testing - ASTM 3359 Method ASudhakar Mars ConsultantsPas encore d'évaluation

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Fepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmDocument4 pagesFepa P Paper Micron μm Fepa F Grain Micron μm JIS R6001 Japan 1973 Micron μmapi-19654224Pas encore d'évaluation

- Mill TC en 19 6.00MMDocument1 pageMill TC en 19 6.00MMKamal BhandariPas encore d'évaluation

- 1662 15Document117 pages1662 15RajamanikkamPas encore d'évaluation

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARPas encore d'évaluation

- G - 1 - A1 General Arrangment DrawingDocument1 pageG - 1 - A1 General Arrangment Drawingjonodo89Pas encore d'évaluation

- MTC - Astm A36 - Jis400 - Q235Document2 pagesMTC - Astm A36 - Jis400 - Q235nayeemPas encore d'évaluation

- MarcoDocument1 pageMarcobimboPas encore d'évaluation

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanPas encore d'évaluation

- Surface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801Document4 pagesSurface Treatments Rust Preventer Phosphatic Coating On Ferrous Materials Norm 2801anhthoPas encore d'évaluation

- SS 304 8MMDocument1 pageSS 304 8MMRavi MehtaPas encore d'évaluation

- Gyproc 2Document3 pagesGyproc 2Govind NataniPas encore d'évaluation

- Standard Specification For Hot Dip GalvanizingDocument4 pagesStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- Deviation List & FormDocument2 pagesDeviation List & FormRohit AttriPas encore d'évaluation

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedPas encore d'évaluation

- Material Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureDocument1 pageMaterial Test Certificate: To EN 10204 3.1:2004 Traceability Sheets/Mill/PressureMohamed RaafatPas encore d'évaluation

- Comment Response Sheet of Surface Preparation and Painting ProcedureDocument22 pagesComment Response Sheet of Surface Preparation and Painting ProcedureAgung PrasetyooPas encore d'évaluation

- Pull Off Test Report RefinaryDocument3 pagesPull Off Test Report RefinaryZaid Raslan AyoubPas encore d'évaluation

- Guide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)Document26 pagesGuide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)karthikkanda100% (1)

- FME-170011-DWRDocument6 pagesFME-170011-DWRKyPas encore d'évaluation

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmPas encore d'évaluation

- Carboline Carboguard 890 PDSDocument2 pagesCarboline Carboguard 890 PDSSamPas encore d'évaluation

- Welders Identity Card: Project: Sharjah Cement Factory Customer: PhotoDocument1 pageWelders Identity Card: Project: Sharjah Cement Factory Customer: Photoayoki100% (1)

- GTL WPSDocument6 pagesGTL WPSYoucef ChorfaPas encore d'évaluation

- Certificate 1700032F (2017001) (2) 4Document1 pageCertificate 1700032F (2017001) (2) 4Katty Elizabeth Mejia NarroPas encore d'évaluation

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirPas encore d'évaluation

- WPS-PQR - PipingDocument14 pagesWPS-PQR - PipingCharwin PicaoPas encore d'évaluation

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaPas encore d'évaluation

- GSB-Form-247 Dimension Inspection Report (Nozzle)Document1 pageGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileePas encore d'évaluation

- Control PlanDocument4 pagesControl PlanJosué PérezPas encore d'évaluation

- Amercoat 68hs - Ingles 2015Document6 pagesAmercoat 68hs - Ingles 2015Peter CallánPas encore d'évaluation

- Qap CPVC Pro Fitting SDR 11Document1 pageQap CPVC Pro Fitting SDR 11amit rajputPas encore d'évaluation

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoPas encore d'évaluation

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BDocument11 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BAliasgar100% (1)

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayPas encore d'évaluation

- Pol Ops Pgs 120 PDFDocument3 pagesPol Ops Pgs 120 PDFMaah NoorPas encore d'évaluation

- Screw Pumps KRAL Double Station DKC DMC 01Document16 pagesScrew Pumps KRAL Double Station DKC DMC 01Eduardo MartinezPas encore d'évaluation

- PlywoodDocument4 pagesPlywoodaishu.fullscreenstatusPas encore d'évaluation

- Construction Contracts 200 Questions and AnswersDocument220 pagesConstruction Contracts 200 Questions and AnswersWael LotfyPas encore d'évaluation

- Project Risk ManagementDocument104 pagesProject Risk Managementtsrinivasan5083Pas encore d'évaluation

- BES 6EE Module 1 IntroductionDocument14 pagesBES 6EE Module 1 IntroductionEric John CruzPas encore d'évaluation

- Risk Register FormatDocument24 pagesRisk Register FormatShyam_Nair_9667Pas encore d'évaluation

- Tool Posts Tool HoldersDocument33 pagesTool Posts Tool HoldersFazry NurokhmanPas encore d'évaluation

- Express Gearbox FlyerDocument2 pagesExpress Gearbox FlyerFernando RomeroPas encore d'évaluation

- Icc 1740 V 3Document610 pagesIcc 1740 V 3Richard PuttPas encore d'évaluation

- Pinto Pm3 Ch08Document25 pagesPinto Pm3 Ch08AlbertoPas encore d'évaluation

- Primary Clarifier MechanismDocument12 pagesPrimary Clarifier MechanismKriztopher UrrutiaPas encore d'évaluation

- Breaker SeriesDocument6 pagesBreaker SeriesDeno Manuel LudzanPas encore d'évaluation

- Competency Requirements and Record Form (Example)Document2 pagesCompetency Requirements and Record Form (Example)srihari kallaPas encore d'évaluation

- ITP LegendDocument4 pagesITP LegendRezaSohrabiPas encore d'évaluation

- 5 Freight Elevator TypesDocument2 pages5 Freight Elevator TypesShoukath AliPas encore d'évaluation

- Plumbing N1 Hands-On!Document16 pagesPlumbing N1 Hands-On!Future Managers Pty Ltd38% (8)

- SME Grow FY2014 FINAL 111016Document24 pagesSME Grow FY2014 FINAL 111016faruq rahmatPas encore d'évaluation

- Signature Series Component Installation ManualDocument106 pagesSignature Series Component Installation Manualjavierchapa75100% (1)

- Qaissamani Dam Project LNPW3: in BriefDocument3 pagesQaissamani Dam Project LNPW3: in BriefHussein BeqaiPas encore d'évaluation

- Von Klip Tip 10 Commandments of Prop CareDocument16 pagesVon Klip Tip 10 Commandments of Prop CareaviationMYPas encore d'évaluation

- 2010 ASME Boiler & Pressure Vessel CodeDocument36 pages2010 ASME Boiler & Pressure Vessel CodeLokmane YellouPas encore d'évaluation

- Risk-Based Maintenance RBM A QuantitativDocument13 pagesRisk-Based Maintenance RBM A QuantitativandersonviPas encore d'évaluation

- PeristalticDocument12 pagesPeristalticAnonymous ItzBhUGoiPas encore d'évaluation

- Rim Design CompositeDocument28 pagesRim Design Compositepramo_dassPas encore d'évaluation

- As 1289.3.6.3-2003 Methods of Testing Soils For Engineering Purposes Soil Classification Tests - DeterminatioDocument2 pagesAs 1289.3.6.3-2003 Methods of Testing Soils For Engineering Purposes Soil Classification Tests - DeterminatioSAI Global - APAC0% (1)

- Gis Elk-04Document52 pagesGis Elk-04Richard GriffithPas encore d'évaluation

- Mokulele Airlines (Proposal)Document25 pagesMokulele Airlines (Proposal)Valley VoicePas encore d'évaluation

- Electronic Systems For Modern Construction MachinesDocument15 pagesElectronic Systems For Modern Construction Machinessvinaga100% (1)

- Module 5 QuizletDocument68 pagesModule 5 QuizletAhmad Rizudin Izzudin67% (3)