Académique Documents

Professionnel Documents

Culture Documents

Engine Remote Interface Installation and Programming Guide Dde & Mbe

Transféré par

Victor MontesdeocaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Engine Remote Interface Installation and Programming Guide Dde & Mbe

Transféré par

Victor MontesdeocaDroits d'auteur :

Formats disponibles

Engine Remote Interface Installation

and Programming Information

Detroit Diesel® or Mercedes-Benz® Engine in a

Business Class® M2 or Sterling Vehicle

This vehicle is equipped with an engine remote interface. The intended function of the interface, connector

location, and specific interlock conditions are included in the vehicle specifications.

This document provides information on how to configure the engine remote interface for rpm control

applications, including both the physical connection and engine programming. This information applies to

Freightliner Business Class M2 and Sterling vehicles equipped with a DDC or MB engine.

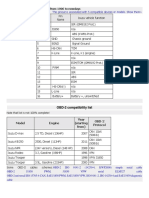

Table 1 provides engine remote interface connector pin numbers and part numbers. The mating connector,

without terminals, is supplied with the engine interface harness. Fourteen terminals for the mating connector

are supplied separately with this document as part of the installation kit. Additional connectors and terminals

are available from Framatome Connectors International, Automotive Division. A crimping tool is also

available from this vendor.

Table 2 provides Freightliner circuit numbers and descriptions for each cavity. See Figure 1 for a typical

schematic of a user interface for all available connections.

• The 483Z ECU Sensor Common Ground w/Interlock circuit must be used as the return for all

switched inputs.

• The 492Y ECU Remote Signal Ground circuit is intended for use only with the remote throttle and

the 492W ECU PTO Active output.

• The 439A Ignition Power Supply circuit is required to pull up the tachometer output.

• Circuits labeled CAVXX provide no connection to the DDC/MB Common Powertrain Controller.

• The tachometer and remote throttle position sensor must be compatible with the Common Powertrain

Controller.

Engine Remote Interface Mating Connector

(Apex 150 Series 16-pin connector)

Freightliner Part Number Vendor Part Number

23-13153-031 54241600

Table 1, Engine Remote Interface Mating Connector

(face view)

Freightliner LLC 24-01547-000 REV -

Engine Remote Interface Connector Pinout

Cavity Circuit Description Note

1 483Z ECU Sensor Common Ground w/Interlock Return for all switched ECU inputs

2 439U ECU Remote PTO Switched ECU input

3 492U EENG ECU CC/PTO Remote On/Off Switched ECU input

4 483A EENG ECU PTO Set Switched ECU input

5 483B EENG ECU PTO Resume Switched ECU input

6 439V1 ECU Remote Set Speed A Switched ECU input

7 439V2 ECU Remote Set Speed B Switched ECU input

8 483E EENG ECU Tach + SIG, ENG RPM Complementary zero-crossing output

9 492Z ECU Throttle Inhibit Switched ECU input

10 483N Remote Throttle On/Off Switched ECU input

11 483C ECU Remote Throttle Signal PWM ECU input

12 483D ECU Remote Throttle Power Ignition Power (12V)

Return for Remote Throttle and

13 492Y EENG ECU Remote Signal Ground

Tachometer only (483D, 483E)

14 492W EENG ECU PTO Active High Side Driver

15 CAV15 Optional Circuit —

16 CAV16 Optional Circuit —

Table 2, Engine Remote Interface Connector Pinout

Figure 1, Typical Schematic of a User Interface

Freightliner LLC 24-01547-000 REV -

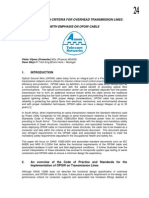

Table 3 provides factory settings for engine parameters related to basic uses of the remote interface. These

settings may differ from the parameters loaded in the vehicle if different settings were specified when the

vehicle was ordered. After delivery, use the DDDL 7.0 service software to change the engine parameters if

necessary.

The Remote Accelerator Enable parameter cannot be set at the factory because an engine fault code would

occur when there is no remote throttle position sensor installed. For more information on the Detroit Diesel

and Mercedes-Benz engine interface and how to configure it, see the DDEC VI Reference Guide. This

document is available on the Detroit Diesel Web site www.ddcsalespro.com.

Engine Remote Interface Programming

Increment/ Multiple Remote Not

Fast Idle

Parameter Options (148-070)

Decrement Set Speeds Throttle Configured

(148-071) (148-072) (148-073) (148-074)

0 = No PTO dropout with

clutch pedal

PTO Dropout on Clutch

1 = Causes PTO to drop out 1 1 1 1 1

Enabled

if the clutch is being

depressed

Remote Accelerator 0 = Disable

0 0 0 0 0

Enable 1 = Enable

0 = 1 pulsed input

Remote PTO Speed

1 = 2 Gray-coded inputs 0 0 2 0 0

Selection Mode

2 = 2 binary-coded inputs

Resume Accel Switch

0 to 3000 rpm 950 950 950 950 500

PTO Set Speed

Set Coast Switch PTO Low Idle Low Idle Low Idle Low Idle

0 to 3000 rpm 500

Set Speed + 50 + 50 + 50 + 50

Speed 1 via Remote

500 to 3000 rpm 950 950 950 950 950

PTO

Speed 2 via Remote

500 to 3000 rpm 1250 1250 1250 1250 1250

PTO

Speed 3 via Remote

500 to 3000 rpm 1850 1850 1850 1850 1850

PTO

Table 3, Engine Remote Interface Programming

Freightliner LLC 24-01547-000 REV -

Vous aimerez peut-être aussi

- Freightliner - FLC CAT Schematic (D06-25073)Document2 pagesFreightliner - FLC CAT Schematic (D06-25073)Victor Montesdeoca100% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusD'EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusPas encore d'évaluation

- Mmcflash Vehicle ReprogrammingDocument11 pagesMmcflash Vehicle ReprogrammingMetro WirandaPas encore d'évaluation

- 06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFDocument4 pages06-fc1682 Aftertreatment Diesel Exhaust Fluid Dosing Control Unit Input Lines - Condition Exists PDFSuryadiPas encore d'évaluation

- Bosch Edc17c53 Irom TC1767 Egpt SameDocument2 pagesBosch Edc17c53 Irom TC1767 Egpt SameAlpine Lee100% (1)

- Wabco SlabsDocument7 pagesWabco SlabsJonathan GridleyPas encore d'évaluation

- User Manual CKP-CMP Simulator Model Venom 4Document14 pagesUser Manual CKP-CMP Simulator Model Venom 4niarsace100% (1)

- VP44 Fuel Pump Engine Sync TroubleshootingDocument6 pagesVP44 Fuel Pump Engine Sync TroubleshootingEnrrique LaraPas encore d'évaluation

- 06-fc1676 Exhaust Gas Temperature 2 - Data Erratic, Intermittent, or Incorrect PDFDocument3 pages06-fc1676 Exhaust Gas Temperature 2 - Data Erratic, Intermittent, or Incorrect PDFSuryadiPas encore d'évaluation

- PACCAR - MX (2017 Emissions)Document6 pagesPACCAR - MX (2017 Emissions)luis manuelPas encore d'évaluation

- Diaframa cm850Document1 pageDiaframa cm850ViniPas encore d'évaluation

- Instrumentation ControlDocument84 pagesInstrumentation ControlIsaac Newton100% (1)

- Gliderlink ManualDocument8 pagesGliderlink ManualMagdiel Eliu Hernandez FloresPas encore d'évaluation

- Isuzu vehicle pinouts and OBD compatibility from 1996-presentDocument3 pagesIsuzu vehicle pinouts and OBD compatibility from 1996-presentEdwinAyalaPas encore d'évaluation

- ECM - No CommunicationDocument22 pagesECM - No CommunicationMohamed ZakiPas encore d'évaluation

- Shift Selector Operation and Code ManualDocument18 pagesShift Selector Operation and Code Manualkengo2xPas encore d'évaluation

- Body Control Module X4Document4 pagesBody Control Module X4Men PanhaPas encore d'évaluation

- Mercedez ConfiguracionDocument7 pagesMercedez ConfiguracionCarlos HernandezPas encore d'évaluation

- Daimler Trucks Connector DetailsDocument63 pagesDaimler Trucks Connector DetailsJames WoolleyPas encore d'évaluation

- Mid 130Document50 pagesMid 130Julio Jara AguileraPas encore d'évaluation

- 3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsDocument6 pages3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsElectroventica ElectroventicaPas encore d'évaluation

- Idle ShutdownDocument5 pagesIdle ShutdownMarco MelchorPas encore d'évaluation

- Boot Cable PDFDocument2 pagesBoot Cable PDFSonny Jendhool SetyawanPas encore d'évaluation

- Additions, Revisions, or Updates: Subject DateDocument7 pagesAdditions, Revisions, or Updates: Subject DateGeoff AndrewPas encore d'évaluation

- @detroit.: Service Information BulletinDocument53 pages@detroit.: Service Information BulletinhaviettuanPas encore d'évaluation

- NT CNH 1851862-30 CNH 1033Document6 pagesNT CNH 1851862-30 CNH 1033TomasPas encore d'évaluation

- Allison Transmission 1000 - 2000 Fault Codes DTCDocument3 pagesAllison Transmission 1000 - 2000 Fault Codes DTCVusal AbdullayevPas encore d'évaluation

- Uce-Ct220S Fault Locator: User ManualDocument13 pagesUce-Ct220S Fault Locator: User ManualWawan sahiriPas encore d'évaluation

- Asssssss SramdfdfdDocument6 pagesAsssssss SramdfdfdOctavio RamosPas encore d'évaluation

- Boletin Enfriamiento de Mack EgrDocument25 pagesBoletin Enfriamiento de Mack Egrcristian picado100% (1)

- Wiring Diagram MACKDocument90 pagesWiring Diagram MACKchrizPas encore d'évaluation

- Printing From UndefinedDocument289 pagesPrinting From UndefinedING. RUBENSPas encore d'évaluation

- Man Electrical System ManualDocument17 pagesMan Electrical System ManualmohanPas encore d'évaluation

- Cummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Document4 pagesCummins: Fault Code: 382 PID: S237 SPN: 626 FMI: 11Enrrique LaraPas encore d'évaluation

- Auto Firmware UpdateDocument4 pagesAuto Firmware UpdateJulian Arcila ValenciaPas encore d'évaluation

- Usage:: TolerancesDocument39 pagesUsage:: TolerancesMANUEL VICTORPas encore d'évaluation

- 4 EngineDocument14 pages4 EngineSoeAyePas encore d'évaluation

- Manual 7600Document49 pagesManual 7600laymeperalta67% (3)

- How To Use KTAG Programmer To Read Detroit DD15 ACM2 Data - Auto Repair Technician HomeDocument1 pageHow To Use KTAG Programmer To Read Detroit DD15 ACM2 Data - Auto Repair Technician HomeSergiiPas encore d'évaluation

- Kenworth Pin LayoutDocument5 pagesKenworth Pin Layoutcristian picadoPas encore d'évaluation

- 1998 Dodge Pickup R1500 1998 Dodge Pickup R1500Document3 pages1998 Dodge Pickup R1500 1998 Dodge Pickup R1500jairo neiraPas encore d'évaluation

- Hydro-Ax Wiring Diagram PDFDocument1 pageHydro-Ax Wiring Diagram PDFJohnny BranamPas encore d'évaluation

- 164.IBM - ThinkPad R61, R61e and R61i (15.4-Inch Wide Screen)Document239 pages164.IBM - ThinkPad R61, R61e and R61i (15.4-Inch Wide Screen)Soporte Tecnico Buenos AiresPas encore d'évaluation

- 2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XDocument12 pages2008 Jeep Wrangler Unlimited X 2008 Jeep Wrangler Unlimited XJorge RaulPas encore d'évaluation

- Codes MWM PDFDocument5 pagesCodes MWM PDFDagar GRPas encore d'évaluation

- Peterbilt Smart Nav Manual BasicoDocument149 pagesPeterbilt Smart Nav Manual BasicoDIONYBLINKPas encore d'évaluation

- Instrument Panel ClusterDocument36 pagesInstrument Panel Clusterkvp61327Pas encore d'évaluation

- Auto Firmware UpdateDocument4 pagesAuto Firmware UpdateVictor GarciaPas encore d'évaluation

- Appendix D-Wire/Connector Tables: Allison 1000 and 2000 Product Families Electronic Controls Troubleshooting ManualDocument12 pagesAppendix D-Wire/Connector Tables: Allison 1000 and 2000 Product Families Electronic Controls Troubleshooting Manualluis eduardo corzo enriquezPas encore d'évaluation

- Cummins engine performance wiring diagramDocument3 pagesCummins engine performance wiring diagramEduardo AlvarezPas encore d'évaluation

- Engine Config SettingsDocument28 pagesEngine Config Settingsgustavoqr27Pas encore d'évaluation

- 2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Document14 pages2007-Current MaxxForce Engine Breakout Harness Reference (EGES545)Enrrique LaraPas encore d'évaluation

- Ddec VDocument30 pagesDdec Vllama100% (1)

- Color-coded wires CascadiaDocument1 pageColor-coded wires CascadialuisPas encore d'évaluation

- Faultcode 687Document3 pagesFaultcode 687Abel OrtegaPas encore d'évaluation

- Service Bulletin Trucks: Special Tools, Group 7Document8 pagesService Bulletin Trucks: Special Tools, Group 7mattkidoPas encore d'évaluation

- Accent P0068 MAP (MAF) - Throttle Position Sensor CorrelationDocument6 pagesAccent P0068 MAP (MAF) - Throttle Position Sensor Correlationflash_24014910Pas encore d'évaluation

- Batteries: Color Code For Schematic LinesDocument2 pagesBatteries: Color Code For Schematic LinesIsaac NewtonPas encore d'évaluation

- Diagnostic Trouble Codes (DTC) : DTC P0562 System Voltage LowDocument3 pagesDiagnostic Trouble Codes (DTC) : DTC P0562 System Voltage Lowluis eduardo corzo enriquezPas encore d'évaluation

- How To Identify NPN and PNP Transistor Using MultimeterDocument3 pagesHow To Identify NPN and PNP Transistor Using MultimeterPatil Amol PandurangPas encore d'évaluation

- Government Regulations: 1. Safety Standards 2. Vehicle Noise Regulations Information 3. Emission Control RegulationsDocument10 pagesGovernment Regulations: 1. Safety Standards 2. Vehicle Noise Regulations Information 3. Emission Control RegulationsVictor MontesdeocaPas encore d'évaluation

- 09-017 Graphing DX Data Monitor FilesDocument6 pages09-017 Graphing DX Data Monitor FilesVictor MontesdeocaPas encore d'évaluation

- US Chap04Document63 pagesUS Chap04Victor MontesdeocaPas encore d'évaluation

- Hino Chassis Installation Manual Chapter 1 PrefaceDocument4 pagesHino Chassis Installation Manual Chapter 1 PrefaceAndres GomezPas encore d'évaluation

- REP Needed: Step 1 Step 2Document2 pagesREP Needed: Step 1 Step 2TriyonoPas encore d'évaluation

- 09-014 Oil in Turbocharger and Air PipingDocument6 pages09-014 Oil in Turbocharger and Air PipingVictor MontesdeocaPas encore d'évaluation

- REP Needed: Step 1 Step 2Document2 pagesREP Needed: Step 1 Step 2TriyonoPas encore d'évaluation

- 09-016 Enabling Engine Shutdown FeatureDocument5 pages09-016 Enabling Engine Shutdown FeatureVictor MontesdeocaPas encore d'évaluation

- Service Information Bulletin: Subject: Addition of Sensor Cover For J08E EngineDocument2 pagesService Information Bulletin: Subject: Addition of Sensor Cover For J08E EngineVictor MontesdeocaPas encore d'évaluation

- Engine Tech Tips: Subject: DPR Inspection 1. Relevant ModelsDocument4 pagesEngine Tech Tips: Subject: DPR Inspection 1. Relevant ModelsVictor MontesdeocaPas encore d'évaluation

- SB-15-020 Correction of DTC P0A78 Workshop ManualDocument5 pagesSB-15-020 Correction of DTC P0A78 Workshop ManualVictor MontesdeocaPas encore d'évaluation

- 09-014 Oil in Turbocharger and Air PipingDocument6 pages09-014 Oil in Turbocharger and Air PipingVictor MontesdeocaPas encore d'évaluation

- 07-002 Oil in Air CompressorDocument1 page07-002 Oil in Air CompressorVictor MontesdeocaPas encore d'évaluation

- 09-011 BP Oil Analysis ProgramDocument2 pages09-011 BP Oil Analysis ProgramVictor MontesdeocaPas encore d'évaluation

- 08-003 Injector Mounting BoltDocument2 pages08-003 Injector Mounting BoltVictor MontesdeocaPas encore d'évaluation

- Vehicle Leaning WorksheetDocument4 pagesVehicle Leaning WorksheetVictor MontesdeocaPas encore d'évaluation

- Engine Tech Tips: Subject: DPR Inspection 1. Relevant ModelsDocument4 pagesEngine Tech Tips: Subject: DPR Inspection 1. Relevant ModelsVictor MontesdeocaPas encore d'évaluation

- 07-008 Exporting and Printing Past Work InformationDocument10 pages07-008 Exporting and Printing Past Work InformationVictor MontesdeocaPas encore d'évaluation

- 08-002 Exhaust Control Valve AdjustmentDocument2 pages08-002 Exhaust Control Valve AdjustmentVictor MontesdeocaPas encore d'évaluation

- 08-001 Davco Fuel Filter Change & Priming ProcedureDocument1 page08-001 Davco Fuel Filter Change & Priming ProcedureVictor MontesdeocaPas encore d'évaluation

- 07-006 Voltage Drop TestDocument6 pages07-006 Voltage Drop TestVictor MontesdeocaPas encore d'évaluation

- 07-002 Oil in Air CompressorDocument1 page07-002 Oil in Air CompressorVictor MontesdeocaPas encore d'évaluation

- Fix Low Power Issues with Fuel Filter CheckDocument1 pageFix Low Power Issues with Fuel Filter CheckVictor MontesdeocaPas encore d'évaluation

- 06-012 Speedometer Conversion FormDocument1 page06-012 Speedometer Conversion FormAprizal AzisPas encore d'évaluation

- Chassis Tech Tips: Subject: Service Manual Revision Outer Wheel Bearing Nut Torque ReductionDocument2 pagesChassis Tech Tips: Subject: Service Manual Revision Outer Wheel Bearing Nut Torque ReductionVictor MontesdeocaPas encore d'évaluation

- Hino trailer brake controller installationDocument4 pagesHino trailer brake controller installationVictor MontesdeocaPas encore d'évaluation

- 06-011 High Pressure Fuel Pump Front Seal FailureDocument1 page06-011 High Pressure Fuel Pump Front Seal FailureVictor MontesdeocaPas encore d'évaluation

- 06-009 Brake CaliperDocument3 pages06-009 Brake CaliperVictor MontesdeocaPas encore d'évaluation

- 06-009 Brake CaliperDocument3 pages06-009 Brake CaliperVictor MontesdeocaPas encore d'évaluation

- 06-008 ABS Extension HarnessDocument2 pages06-008 ABS Extension HarnessVictor MontesdeocaPas encore d'évaluation

- AnsysEMInstallGuide Linux PDFDocument64 pagesAnsysEMInstallGuide Linux PDFAleAcostaPas encore d'évaluation

- Config Advisor 5.4 Quick Start GuideDocument45 pagesConfig Advisor 5.4 Quick Start GuideKumar KushaalPas encore d'évaluation

- Watchdog Timer For Robust Embedded SystemsDocument5 pagesWatchdog Timer For Robust Embedded SystemsÁsgeirr Ánsgar Ósgar CanuroPas encore d'évaluation

- ZTE Product Reference GuideDocument21 pagesZTE Product Reference GuideAlexander PischulinPas encore d'évaluation

- Software Requirements Specification: For WhatsappDocument13 pagesSoftware Requirements Specification: For WhatsappSai krishna Sai krishna reddyPas encore d'évaluation

- Vibxpert-II Brochure Lit.53.400.EnDocument4 pagesVibxpert-II Brochure Lit.53.400.EnMoustafa HelmyPas encore d'évaluation

- Data Structure in MainframeDocument10 pagesData Structure in MainframeKunalPas encore d'évaluation

- Mobile Projector: Product ManualDocument18 pagesMobile Projector: Product ManualgandroiidPas encore d'évaluation

- EX600 DeviceNet Manual APR 08Document91 pagesEX600 DeviceNet Manual APR 08Esteban GonzalooPas encore d'évaluation

- WSDL2 WsDocument5 pagesWSDL2 WsgarcamePas encore d'évaluation

- Clevo W370et Service Manual PDFDocument109 pagesClevo W370et Service Manual PDFCosti UrzicaPas encore d'évaluation

- Nand FlashDocument118 pagesNand FlashRajesh Kumar KPas encore d'évaluation

- Viljoen Steyn DesignDocument9 pagesViljoen Steyn DesignPankaj_Taneja_9684Pas encore d'évaluation

- Defence Untouched Data 222Document48 pagesDefence Untouched Data 222kam6Pas encore d'évaluation

- A) A) B) C) B) : Make A Diffraction Grating From A DVD-R Cut and Fold Attach To A Webcam, Phone, or LaptopDocument2 pagesA) A) B) C) B) : Make A Diffraction Grating From A DVD-R Cut and Fold Attach To A Webcam, Phone, or LaptopDario OchoaPas encore d'évaluation

- Spacecraft 8 Attitude Control Anomaly ReportDocument70 pagesSpacecraft 8 Attitude Control Anomaly ReportBob AndrepontPas encore d'évaluation

- Fix Up An Old Laptop!: InstructablesDocument20 pagesFix Up An Old Laptop!: InstructablesMd.Tarequl IslamPas encore d'évaluation

- October 2012: Questions Must Be Answered in Accordance With The FollowingDocument47 pagesOctober 2012: Questions Must Be Answered in Accordance With The FollowingMight RamPas encore d'évaluation

- Cambridge International AS & A Level: Information Technology 9626/12Document16 pagesCambridge International AS & A Level: Information Technology 9626/12Janet HussainPas encore d'évaluation

- Balanta Mettler Toledo AT200Document44 pagesBalanta Mettler Toledo AT200Luca Cristian100% (1)

- ChangesDocument72 pagesChangesPobretanoPas encore d'évaluation

- Chevrolet MyLink Video Interface ManualDocument28 pagesChevrolet MyLink Video Interface ManualkoloristaPas encore d'évaluation

- Java Exceptions Explained: Keywords, Types, and HandlingDocument43 pagesJava Exceptions Explained: Keywords, Types, and HandlingrajuvathariPas encore d'évaluation

- Software Upgradation USB For DDB TV - Ver.18th Oct12Document40 pagesSoftware Upgradation USB For DDB TV - Ver.18th Oct12Rahul PatilPas encore d'évaluation

- Mks Toolkit For Interoperability Mks SoftwareDocument2 pagesMks Toolkit For Interoperability Mks Softwarealibob78Pas encore d'évaluation

- Canon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesDocument37 pagesCanon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesTariq MajeedPas encore d'évaluation

- Heights Training Conference AgendaDocument5 pagesHeights Training Conference AgendaDami HaPas encore d'évaluation

- Daftar Pasaran Harga Laptop HP - Report April 2012Document4 pagesDaftar Pasaran Harga Laptop HP - Report April 2012Pablo BalliboPas encore d'évaluation

- Digital Signal Processing: Jill, Jon, Kilo, RogerDocument19 pagesDigital Signal Processing: Jill, Jon, Kilo, RogerJose ChambillaPas encore d'évaluation

- Render point cloud in Blender with Skinner add-onDocument13 pagesRender point cloud in Blender with Skinner add-onbackyardcncPas encore d'évaluation