Académique Documents

Professionnel Documents

Culture Documents

CDE washing plant increases Lagan Group quarry production by over 30

Transféré par

Velina MilevaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CDE washing plant increases Lagan Group quarry production by over 30

Transféré par

Velina MilevaDroits d'auteur :

Formats disponibles

Part of the new CDE washing and screening plant at the Lagan Group’s Duleek Quarry, Co.

Meath, Ireland

By-product to

Commercial Output

Lagan Group increase production with CDE washing plant

ore than 200,000 tonnes of material and south of the border and a combined

M have passed through the CDE

washing plant at Irish Asphalt’s

Duleek Quarry, in Co. Meath, since

its installation in the summer of 2003. In July

2004 the plant’s ownership will transfer to

production capacity of over 2 million tonnes.

They are also a major supplier of asphaltic

material, and their bitumen division is at the

leading edge of binder and emulsion ➤

The contrast between the

clay-bound raw material (left)

and the washed stone (right)

Irish Asphalt, part of the Lagan Holdings

Group, having been operated on a price-per-

tonne basis by CDE since its installation. The

Euro 1.5 million contract represented a major

investment for Northern Ireland company

CDE, and while their processing systems have

previously been chosen for applications

ranging from specialist sand classification to

quarry-dust washing, the raw material at

Duleek provided them with a considerable

challenge.

The Lagan Group are one of Ireland’s

largest quarry operators with sites both north

QM June 2004 www.qmj.co.uk 13

High-tensile offset finger bars highest-quality aggregates for both in-house

are standard specification on use and external sales, and it was clear that

CDE grizzly screens our existing process could not achieve this.

Our partnership with CDE has been rewarded

with consistent quality aggregates and

production capacity has increased by more

than 30% on initial figures.’

Other prominent CDE washing plants and

contracts have been established throughout

Ireland, the UK and Sweden, and the

experience gained from these, together with

CDE’s growing reputation for innovation, led

to the Lagan Group contract.

The plant born of these negotiations has

already attracted numerous visitors from the

UK and further afield. What draws them is the

consistently high quality of the sand and

aggregates produced by the plant, in spite of

the poor-quality raw material. Up to 25% of

the –90mm raw feed, and often up to 50% of

the –5mm fraction, can be less than 75µm.

Since final commissioning the plant has

consistently supplied clean and dry outputs

technology. Lough Neagh in Northern Ireland, comprising 20mm, 14mm, 10mm, 6mm and

the largest freshwater lake in the British Isles, concrete sand, allowing Lagan to offer

is the base for the Group's sand division, while customers commercial Type 1 and concrete

Lagan’s concrete division operates one of the constituents, all from a material previously

most modern concrete block and brick- regarded as waste.

making plants in Europe.

The Duleek site is situated on what is Processing plant

A shovel-loaded 50-tonne capacity feed

essentially a Carboniferous limestone deposit

hopper and belt-feeder arrangement

but bands of heavy and extremely plastic clay

discharges the raw feed material on to a 20m

are prevalent. Large stockpiles of overburden

long inclined conveyor. This feeds a 1.5m x

and clay-bound material had been building up

4.0m CDE 2SG60 grizzly screen that removes

as waste by-products for some time and were

any +90mm oversize, which falls into a walled

seriously compromising the efficiency of the

bay. Previously tested grizzly bars had a

operation. Identifying and responding to this,

tendency to block owing to the highly plastic

Lagan’s regional quarry manager, Paul Tuite,

nature of the material, especially in wet

initiated discussions with CDE in early 2003.

weather. This led to a new design of high-

Mr Tuite commented: ‘We demand the

The primary stage at Duleek

showing the grizzly screen,

CDE Rotomax 1828 log-

washer and primary rinsing

screen, with the Tesab mobile

impactor in the foreground

14 www.qmj.co.uk QM June 2004

General view of the entire

CDE plant

tensile offset finger-bars, which are now a Another 20m conveyor carries the rinsing

standard CDE specification. These offer screen’s –24mm +4mm intermediate product

maximum flexibility and ensure that capacity is to a second log-washer, a 7m long Rotomax

not compromised, even with variations in the 827 that removes any residual clay particles

raw material. The –90mm material is from the aggregate; the success of this is

conveyed by a second 20m conveyor to a evident from the clean nature of the finished

CDE Rotomax 1828 twin-shaft log-washer. products. As with the primary log-washer, the

This 8m long machine is believed to be one of speed and inclination of this unit are easily

Close-up of the second stage

the largest log-washers currently operating in adjusted to accommodate variable feed

showing (from top to bottom)

Europe, with each shaft measuring 1.8m in materials and tonnages. Material from the log- the Rotomax 827 log-washer,

diameter from tip to tip. The unit can accept washer is delivered directly to a dewatering Dw43 dewatering screen and

up to 250 tonnes/h of –90mm material, and screen mounted over the final dry- D2M60 dry-classification

retention time can be easily adjusted by classification screen. The Dw43 dewatering ➤ screen

altering the inclination and running speed,

aided by the single motor and gearbox design.

CDE say that unlike many log-washers, the

special Rotomax design allows feed containing

up to 30% –5mm material to be efficiently

handled without the need for preliminary fines

screening. Each shaft is fitted with heavy-duty

chrome-molybdenum tips for maximum wear

resilience.

Scrubbed material is fed directly to an

R2M108 twin-deck primary rinsing screen.

This 1.8m x 6.0m unit was one of the first of

CDE’s latest-generation rinsing screens,

incorporating rubber and polyurethane decks.

The top deck is fully enclosed by a splash-

proof cover, ensuring maximum water

retention and a clean operative environment.

Five spray-bars per deck (with individual

controls) and flexible rubber screen seals for

each bar are included. The top deck separates

+24mm material, which is conveyed to a

mobile impact crusher for reduction to

commercial Clause 804 specification. The

underflow from the lower deck, comprising a

–4mm water, sand and clay slurry, is flumed to

the sump of a CDE C-62 compact sand plant.

QM June 2004 www.qmj.co.uk 15

The C-62 compact sand plant 4.0m twin-deck dry screen with a split bottom

deck. The efficiency of the CDE dewatering

screen is highlighted by the unusually dry

aggregates produced; moisture content is

consistently less than 5%.

Sand production

Sand slurry leaving the primary rinsing screen

is piped to the C-62 compact sand plant,

which is rated at 120 tonnes/h. The compact

sand plant is CDE’s best-known single product

and has no trouble handling the high clay

volumes in the feed (the –4mm can contain up

to 50% clay). The plant consists of a

hydrocyclone mounted over a dewatering

screen and sump. Slurry is fed directly into the

sump and is then sent to the custom-sized

hydrocyclone by a Warman 10/8E-M pump.

The silt cut-point can be set to suit

customers’ specific product requirements, but

here the sand consistently contains less than

3% –75µm material, with typically 50% passing

600µm. Sand and residual water exit from the

base of the hydrocyclone and pass to a

dewatering screen mounted underneath

screen is equipped with spray-bars in the first before the sand is discharged, via a rubber-

screen section to give the material a final light lined chute, to the sand conveyor at a typical

rinse. This unit includes modular polyurethane 12% moisture content. The waste water

panels and side protection as standard. containing clays passes directly to an 8m

Filtrates from both the dewatering screen and diameter CDE T-08 high-rate thickener,

the log-washer overflow to a ground sump for complete with a fully automatic

recovery. The recovered water/fines slurry is polyelectrolyte dosing station, for further

returned, by means of a Warman QV65SP treatment.

submersible pump, to the primary rinsing Waste-water treatment is perhaps one of

screen. This offers increased fluidization of the the most crucial elements of the entire plant.

feed material, retains water within the system Given the dirty nature of the feed, many

and is a valuable aid to site cleanliness and traditional treatment systems would demand

plant wash-down. Aggregates are classified large volumes of water, which is not always

into four final products by a D2M60 1.5m x practical in quarry applications. Here, the

The compact sand plant

alongside the 8m diameter

T-08 high-rate thickener

16 www.qmj.co.uk QM June 2004

complete plant operates at up to 220 The fully automated

tonnes/h, which equates to 44 tonnes/h of polyelectrolyte dosing station

waste solids. Polyelectrolyte dosing is carefully

monitored to ensure correct sludge

settlement/compaction without any risk of

flocculant carry-over in the recycled water. A

freshwater storage tank is located adjacent to

the thickener and the primary rinsing screen,

so only a relatively low-power recycled-water

pump is required. The sludge is sent to a

remote lagoon for further settlement, this

being approximately 200m away with a 35m

head. The material is sent to the lagoon by a

Warman 4/3C-AH pump. Final solids content

in the sludge is typically around 40–50%. CDE

say an interesting point to note is the

relatively compact size of the T-08 thickener

unit. Alternative treatment systems would,

they say, generally require a much larger unit

than the 8m diameter model specified here,

but this particular unit has proven to be well

able to cope with the 450m3/h of water within

the cycle, and overall only 50m3/h of top-up

water is required.

CDE and the Lagan Group are currently in

discussions aimed at moving the plant to a

more permanent on-site location. This move

is expected to see the addition of the latest- Asphalt, commented: ‘This CDE installation

model CDE plate-and-frame filter press. This represents a new generation of washing plants

technology will achieve maximum water for problem materials…we are now able to

recycling with top-up requirements reduced fully exploit this quarry, handling materials that

to a mere 20m3/h. The waste material will be were previously stockpiled as waste — but,

offered as easily handled dry cakes, completely crucially, making commercial-grade products

eliminating the need for settlement lagoons. from them.’

Current investigations are exploring the

possibility of using this dried clay in Lagan’s Acknowledgement

newly commissioned cement plant. The editor would like to thank both the Lagan

Anticipating the plant’s handover from CDE Group and Iain Walker of CDE for their co-

in July 2004, Terry Lagan, director of Irish operation in producing this article. ❚

One of the final stockpiles of

clean, dry aggregate

QM June 2004 www.qmj.co.uk 17

Vous aimerez peut-être aussi

- Atoz IN Cement Industry: Unit Three CrushingDocument20 pagesAtoz IN Cement Industry: Unit Three Crushingrk21101981Pas encore d'évaluation

- Brochure SuperSettlerDocument8 pagesBrochure SuperSettlerJesús RiberaPas encore d'évaluation

- CPT Cavitation SystemDocument9 pagesCPT Cavitation SystemLuis Gutiérrez AlvarezPas encore d'évaluation

- Hydrocyclone HarmonyDocument2 pagesHydrocyclone HarmonyPv RohithPas encore d'évaluation

- ALFA LAVAL - Spiral PDFDocument8 pagesALFA LAVAL - Spiral PDFlaquetengoPas encore d'évaluation

- How To Size A ThickenerDocument7 pagesHow To Size A ThickenerJesus Sing RoblesPas encore d'évaluation

- General Kinematics - UncoalerDocument38 pagesGeneral Kinematics - UncoalerJogesh NarulaPas encore d'évaluation

- Deister Bulletin 300 D - 1 PDFDocument16 pagesDeister Bulletin 300 D - 1 PDFcandra trisilawatiPas encore d'évaluation

- Alfalaval Cip800l Pps00066enDocument2 pagesAlfalaval Cip800l Pps00066enHassan HelmyPas encore d'évaluation

- Alfalaval Cip1800l and Cip2800l Pps00064enDocument2 pagesAlfalaval Cip1800l and Cip2800l Pps00064engmatweakPas encore d'évaluation

- Lecture 7 SlidesDocument59 pagesLecture 7 SlidesHasil SharmaPas encore d'évaluation

- ISO 9001 Rochi Engineers profileDocument26 pagesISO 9001 Rochi Engineers profileGautamPas encore d'évaluation

- PasteThickener TechnologyDocument5 pagesPasteThickener TechnologyRodri GermánPas encore d'évaluation

- A8 0 MineralsProcessing GBDocument6 pagesA8 0 MineralsProcessing GBAnonymous T8aah3JfPas encore d'évaluation

- Process Control in Metallurgical Plants: Towards OperationalDocument48 pagesProcess Control in Metallurgical Plants: Towards Operationalquinteroudina50% (2)

- Outotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Document8 pagesOutotec - Seismic Design of Elevated Slurry Storage Tanks For As NZS 1170 (Rosart)Serguei DobrinPas encore d'évaluation

- 2405 2 PDFDocument14 pages2405 2 PDFPrasenjit DeyPas encore d'évaluation

- Msand ManufacturingDocument66 pagesMsand ManufacturingRobert JamesPas encore d'évaluation

- Sediment Traps Sediment Traps: Design Criteria Design CriteriaDocument10 pagesSediment Traps Sediment Traps: Design Criteria Design CriterialokescPas encore d'évaluation

- Mechanical OPerationDocument10 pagesMechanical OPerationAnshika RajputPas encore d'évaluation

- Natural RubberDocument7 pagesNatural RubberFrancis AdrianPas encore d'évaluation

- Friction LossDocument11 pagesFriction LossŘǾċҚЂĂĽЬóĄ100% (1)

- Delkor EspesadorDocument21 pagesDelkor Espesadorrichard gutierrezPas encore d'évaluation

- Plant Performance Forecasting Using Geometallurgical DataDocument11 pagesPlant Performance Forecasting Using Geometallurgical DataDirceu NascimentoPas encore d'évaluation

- 578 Brissette Et Al Geometallurgy New Accurate Testwork To Meet Accuracy of Mining Project Development Reviewed R3Document13 pages578 Brissette Et Al Geometallurgy New Accurate Testwork To Meet Accuracy of Mining Project Development Reviewed R3GutierrezCPas encore d'évaluation

- Cono Sedimentador de LodosDocument16 pagesCono Sedimentador de LodosJaime Olazo MolloPas encore d'évaluation

- Cu ElectrowinningDocument17 pagesCu ElectrowinningJose Eduardo Osuna AraizaPas encore d'évaluation

- 236 04-204 Gmax BrochureDocument4 pages236 04-204 Gmax BrochurealtemiraPas encore d'évaluation

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- Thickeners: It Pays To Talk To A SpecialistDocument8 pagesThickeners: It Pays To Talk To A SpecialistKumardasNsPas encore d'évaluation

- Basic of Forging: Types, Methods, and ProcessesDocument53 pagesBasic of Forging: Types, Methods, and ProcessesKomal TagraPas encore d'évaluation

- Sand and Surki (1) (IUBAT)Document49 pagesSand and Surki (1) (IUBAT)MOIN UDDINPas encore d'évaluation

- Mineral Processing and MetallurgicalDocument14 pagesMineral Processing and MetallurgicalJoel CuevaPas encore d'évaluation

- Aib 012Document2 pagesAib 012acantillanapPas encore d'évaluation

- Is 6051 1970Document15 pagesIs 6051 1970harshal161987100% (1)

- Equipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyDocument14 pagesEquipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyWilson VicencioPas encore d'évaluation

- Vertical Shaft Impactor - Sand Making MachineDocument37 pagesVertical Shaft Impactor - Sand Making Machineaaronshakti100% (1)

- Vsi Crushing StationDocument1 pageVsi Crushing StationHritika PatelPas encore d'évaluation

- Breaking Down Energy Consumption in Industrial Grinding MillsDocument12 pagesBreaking Down Energy Consumption in Industrial Grinding Millsrolandoh1Pas encore d'évaluation

- EU Emission Standards PDFDocument5 pagesEU Emission Standards PDFStephanie StewartPas encore d'évaluation

- Ams 201404 enDocument139 pagesAms 201404 enLmf DanielPas encore d'évaluation

- Calculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)Document11 pagesCalculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)RAVI1972Pas encore d'évaluation

- Electrical Documentation For Radar Level TransmitterDocument6 pagesElectrical Documentation For Radar Level TransmittersatfasPas encore d'évaluation

- Dynamic Modeling and Simulation of Cone Crushing Circuits PDFDocument7 pagesDynamic Modeling and Simulation of Cone Crushing Circuits PDFmarceladeveraPas encore d'évaluation

- Clarifiers & Thickeners for Effluent TreatmentDocument1 pageClarifiers & Thickeners for Effluent TreatmentKartika Pratama SyafitriPas encore d'évaluation

- Vibrating Screen TestDocument2 pagesVibrating Screen TestdivPas encore d'évaluation

- 1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineDocument1 page1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineYeimsPas encore d'évaluation

- Ore Separation - Screening and Classification (Sizing-Ore Sorting)Document37 pagesOre Separation - Screening and Classification (Sizing-Ore Sorting)Maruti NandanPas encore d'évaluation

- Spiral Brochure 3-2007Document8 pagesSpiral Brochure 3-2007MikeWalshePas encore d'évaluation

- Metsim MMD Sizer Simulation Parameters and Crusher CapacitiesDocument6 pagesMetsim MMD Sizer Simulation Parameters and Crusher CapacitiesWalter Andrés OrqueraPas encore d'évaluation

- Create Innovate Invest: Astec Industries, IncDocument106 pagesCreate Innovate Invest: Astec Industries, IncAndres Perez100% (1)

- Kemix Interstage Screen BrochureDocument8 pagesKemix Interstage Screen BrochureFernandim SoaresPas encore d'évaluation

- Performance Slurry PumpDocument154 pagesPerformance Slurry PumpJhonny AlvarezPas encore d'évaluation

- Dense Medium SeparationDocument20 pagesDense Medium SeparationKatleho MohonoPas encore d'évaluation

- MiningDocument128 pagesMiningPrakash SundharamPas encore d'évaluation

- Process and Economic Considerations in Copper MetallurgyDocument53 pagesProcess and Economic Considerations in Copper Metallurgydars23Pas encore d'évaluation

- Successful Startup of Worlds Largest Dehydrogenation Plant Using 2019Document1 pageSuccessful Startup of Worlds Largest Dehydrogenation Plant Using 2019Anugerah GustiPas encore d'évaluation

- Proctor VCL Technical GuideDocument16 pagesProctor VCL Technical GuideRaduAxintePas encore d'évaluation

- Gas Analyser PDFDocument16 pagesGas Analyser PDFManish VermaPas encore d'évaluation

- 2013 - Recycling Glass Fibre Reinforced Composites - History and ProgressDocument5 pages2013 - Recycling Glass Fibre Reinforced Composites - History and ProgressSubramani PichandiPas encore d'évaluation

- Designcompon 2Document1 pageDesigncompon 2Velina MilevaPas encore d'évaluation

- GA 235 2017 Gypsum Board Typical Mechanical and Physical PropertiesDocument8 pagesGA 235 2017 Gypsum Board Typical Mechanical and Physical Propertiesb.fPas encore d'évaluation

- Grease Fitting PDFDocument20 pagesGrease Fitting PDFleonardsiregarPas encore d'évaluation

- SKF WhitePaper Grease AnalysisDocument10 pagesSKF WhitePaper Grease AnalysisedgarpolPas encore d'évaluation

- Leaflet English ILMEG Products ABDocument4 pagesLeaflet English ILMEG Products ABVelina MilevaPas encore d'évaluation

- 519379-Design A 100A Active Load To PDFDocument7 pages519379-Design A 100A Active Load To PDFVelina MilevaPas encore d'évaluation

- ORIGINAL EQUIPMENT NUMBERS vs KOJEN MODEL BRANDSDocument24 pagesORIGINAL EQUIPMENT NUMBERS vs KOJEN MODEL BRANDSVelina MilevaPas encore d'évaluation

- GA-227 Recommendations For The Prevention of Ceiling CrackingDocument3 pagesGA-227 Recommendations For The Prevention of Ceiling CrackingVelina MilevaPas encore d'évaluation

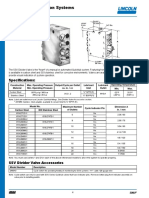

- Quicklub Lubrication Systems: SSV Divider ValvesDocument4 pagesQuicklub Lubrication Systems: SSV Divider ValvesVelina MilevaPas encore d'évaluation

- MagDocument12 pagesMagAvs ElectronPas encore d'évaluation

- CAN Troubleshooting Sheet v3Document1 pageCAN Troubleshooting Sheet v3Velina MilevaPas encore d'évaluation

- Preventing Ceiling Cracking With Resilient ChannelsDocument5 pagesPreventing Ceiling Cracking With Resilient ChannelsVelina MilevaPas encore d'évaluation

- Effective Use of Water in A System For Water Driven Hammer DrillingDocument10 pagesEffective Use of Water in A System For Water Driven Hammer DrillingVelina MilevaPas encore d'évaluation

- Underwater Explosive Shock Testing UNDEX CM2000 PDFDocument11 pagesUnderwater Explosive Shock Testing UNDEX CM2000 PDFFernando Raúl LADINOPas encore d'évaluation

- Contractors Price ListDocument25 pagesContractors Price ListVelina MilevaPas encore d'évaluation

- 9853 3221 01 Fluids and Lubricating GreasesDocument14 pages9853 3221 01 Fluids and Lubricating GreasesVelina MilevaPas encore d'évaluation

- Design and Fab of Inductors For HTDocument18 pagesDesign and Fab of Inductors For HTVelina MilevaPas encore d'évaluation

- Foundation Analysis and Design 1 PDFDocument48 pagesFoundation Analysis and Design 1 PDFagpsimoes100% (1)

- Bds en Iso 8469 2013Document20 pagesBds en Iso 8469 2013Velina MilevaPas encore d'évaluation

- Bds en 60065 2002 A11 2009Document16 pagesBds en 60065 2002 A11 2009Velina MilevaPas encore d'évaluation

- AWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFDocument56 pagesAWS A10.1M-2007 Calibration and Performance Testing of Secondary Current Sensing Coils and Weld PDFVelina MilevaPas encore d'évaluation

- NG CD 55a1111 A1-668341Document2 pagesNG CD 55a1111 A1-668341kpPas encore d'évaluation

- MatexDocument2 pagesMatexVelina MilevaPas encore d'évaluation

- Super TacDocument2 pagesSuper TacVelina MilevaPas encore d'évaluation

- Hydro Cyclone and JetDocument2 pagesHydro Cyclone and JetVelina MilevaPas encore d'évaluation

- 52285Document1 page52285Velina MilevaPas encore d'évaluation

- Performance Prediction Cf128G: Male Rotor Tip Speed in M/sDocument4 pagesPerformance Prediction Cf128G: Male Rotor Tip Speed in M/sVelina MilevaPas encore d'évaluation

- Eng CD 827881 P1Document1 pageEng CD 827881 P1Velina MilevaPas encore d'évaluation

- Technical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureDocument1 pageTechnical Information No. 12 Vermicular Graphite Cast Iron: MicrostructureVelina MilevaPas encore d'évaluation

- Gasoline Vapour RecoveryDocument48 pagesGasoline Vapour Recoveryusaid saifullahPas encore d'évaluation

- Catalog D-1c CR26 Series - 62015 - 2Document4 pagesCatalog D-1c CR26 Series - 62015 - 2Anup Lal RajbahakPas encore d'évaluation

- Er DiagramsDocument20 pagesEr DiagramsMatthew BloomfieldPas encore d'évaluation

- Hydraulic Shovel and Backhoe ExcavatorDocument8 pagesHydraulic Shovel and Backhoe ExcavatorAndi Wardiman AnwarPas encore d'évaluation

- Toshiba Satellite A200 (Compal LA-3661P)Document38 pagesToshiba Satellite A200 (Compal LA-3661P)Claudiu PetrachePas encore d'évaluation

- Buildsmart 11issue9Document20 pagesBuildsmart 11issue9Carlos Lopez FigueroaPas encore d'évaluation

- Seat & Seat Bar - S185Document2 pagesSeat & Seat Bar - S185Eider Arturo Garcia OsorioPas encore d'évaluation

- LG Ln549eDocument2 pagesLG Ln549eYudha YogaPas encore d'évaluation

- Layout and Construction of A Railway Track and Railway StationDocument12 pagesLayout and Construction of A Railway Track and Railway StationAli Hassan LatkiPas encore d'évaluation

- Arkaylite price list for copper and aluminum cablesDocument2 pagesArkaylite price list for copper and aluminum cablesPrateek Agarwal0% (1)

- Unified Business Permit Application FormDocument2 pagesUnified Business Permit Application FormCatherine Castro0% (1)

- The FlowTube SystemDocument170 pagesThe FlowTube SystemSalvador Parra FernandezPas encore d'évaluation

- Jessica Martin V American Education Services FDCPA FCRA ComplaintDocument46 pagesJessica Martin V American Education Services FDCPA FCRA ComplaintghostgripPas encore d'évaluation

- Artificial Inteligence NTU Tutorial 1 AnswerDocument1 pageArtificial Inteligence NTU Tutorial 1 AnswerbluepunchsPas encore d'évaluation

- 36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Document5 pages36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Jose Daniel RosarioPas encore d'évaluation

- E-Portfolio: by José Gabriel Mejia MarquezDocument15 pagesE-Portfolio: by José Gabriel Mejia MarquezGabriel MarquezPas encore d'évaluation

- Thinkpower Data Sheet Turtle Single Phase 1kw-6kw (OL)Document2 pagesThinkpower Data Sheet Turtle Single Phase 1kw-6kw (OL)RaulPas encore d'évaluation

- TransRec 125 SpecDocument15 pagesTransRec 125 SpecDavid HenrionPas encore d'évaluation

- Kerry George ResumeDocument3 pagesKerry George ResumemomnpopPas encore d'évaluation

- Meth Method Statement For Inside Working of PontoonsDocument2 pagesMeth Method Statement For Inside Working of PontoonsjhoniPas encore d'évaluation

- The Template For Physics EssayDocument13 pagesThe Template For Physics Essaylarisa2697Pas encore d'évaluation

- Inventory Management System for Sales & Stock TrackingDocument60 pagesInventory Management System for Sales & Stock TrackingAnimesh KharePas encore d'évaluation

- Stress Strain Relationship of Concrete FullDocument16 pagesStress Strain Relationship of Concrete Fullsreejithp104100% (1)

- Acl-03-04 - Exp-03-A1 PR PDFDocument11 pagesAcl-03-04 - Exp-03-A1 PR PDFDESMALANILS48Pas encore d'évaluation

- f1 Test 4 9sep19 (Key)Document11 pagesf1 Test 4 9sep19 (Key)shahabPas encore d'évaluation

- MCKQ Ford InterviewDocument10 pagesMCKQ Ford InterviewvikasnsitPas encore d'évaluation

- Modemlog - Zte Usb Modem Fff1 #2Document2 pagesModemlog - Zte Usb Modem Fff1 #2Qamar Zaman100% (1)

- WSO Resume Review - 012Document1 pageWSO Resume Review - 012John MathiasPas encore d'évaluation

- E Townhall 1108 MaitDocument43 pagesE Townhall 1108 MaitThe Press-Enterprise / pressenterprise.comPas encore d'évaluation

- Certificate of SuitabilityDocument1 pageCertificate of SuitabilityEvans OrlandoPas encore d'évaluation