Académique Documents

Professionnel Documents

Culture Documents

Analysis of Prestressed Solid and Voided Slab Type Bridge Superstructure On Curved Alignment

Transféré par

ankitTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Analysis of Prestressed Solid and Voided Slab Type Bridge Superstructure On Curved Alignment

Transféré par

ankitDroits d'auteur :

Formats disponibles

Impact Factor (SJIF): 3.

632

International Journal of Advance Research in Engineering, Science &

Technology

e-ISSN: 2393-9877, p-ISSN: 2394-2444

Volume 3, Issue 3, March-2016

Analysis of Prestressed Solid And Voided Slab type Bridge Superstructure on

Curved Alignment

Ramparia Mohit1, Pokar Narendra2, Gandhi Dipesh3

1

HJD Institute of Technical Education and Research

2

Civil Engineering Department, HJD ITER, Kera-Kutch

3

Applied Mechanics Department, Government Engineering College, Bhuj

Abstract - When Solid slab becomes uneconomical we have to go for the next alternative to make our deck economical as well as

safe. The object of the paper is to analyze prestressed horizontal curved solid and voided slab for 25m bridge span

using grillage analogy method. The analysis presented illustrates the behavior of bending moments, Shear Force,

displacement due to change in curvature for various load conditions of solid and voided deck slab. Slab analyzed

under various loading conditions as per IRC and results has been compared to know the effect of the curvature on

bridge deck. Width of the deck slab keep constant (12m) for various degree of curvature (15 °, 30°, 45°, 60°) and

analysis has been done in STAAD Pro. In each analysis, the behavior of deck slabs was investigated, and maximum

bending moment, max shear forces and displacement developed in members were observed.

Keywords – Prestressed Slab Type Bridge Superstructure, Solid Slab, and voided slab, Curved Alignment, STAAD Pro

I. INTRODUCTION

Bridge is life line of road network, both in urban and rural areas. Horizontally curved bridges are the most feasible

options at complicated interchanges or river crossings where geometric restrictions and constraint of limited site space,

make difficult the adoption of standard straight superstructures. Contrary to straight bridges, a very limited

documentation on the study of horizontally curved bridges has been available. Generally for construction of a medium

bridge idea for selection depends upon various factors. When Solid slab becomes uneconomical we have to go for the

next alternative to make our deck economical as well as safe.

Bridge design is an important as well as complex approach of structural engineer. As in case of bridge design, span

length and live load are always important factor. Bridge design is an important as well as complex approach of structural

engineer. As in case of bridge design, span length and live load are always important factor. These factors affect the

conceptualization stage of design. The effect of live load for various span are varied. In shorter spans track load govern

whereas on larger span wheel load govern. Many methods are used in analyzing bridges such as grillage and finite

element methods. Generally, grillage analysis is the most common method used in bridge analysis. In this method the

deck is represented by an equivalent grillage of beams.

There is a very limited knowledge available about curved bridges, both in standard specifications and literature. In this

paper, analytical results of curved bridges are show in charts and tabular form for a various parameters such as shear,

bending and displacement for curved bridges. This type of work can be also useful for preliminary design of horizontally

curved bridge.

Hence to fill in the void for the realistic analysis, the work on the parametric study of curved bridges is performed.

Various behaviors like bending, shear, displacement of horizontally curved prestressed bridges is presented. In this study

for analyzing of bridge grillage analogy method is used using STAAD Pro. Eight models are prepared for 25m span

lengths keeping the same material properties with varying degree of curvature from 15° to 60° at 15° increment for

different load conditions and load combinations. Charts & tables for various parameters of curved bridges are presented

in this paper.

II. VOIDED DECK SLAB

Need of Voided deck Slab

Slab bridges are under-used principally because of lack of refinement of the preliminary costings carried out by most of

the contractors or Estimators. The unit costs of formwork, concrete, reinforcement and prestress tendons should be

clearly be lower for a solid slab deck than for more complex cross sections such as voided slab or multicellular slab

decks. However in early stages of the project when options are being compared, this is frequently overlooked.

Slabs allow the designer to minimize the depth of construction and provide a flat soffit where this is architecturally

desirable. Their use is limited principally by their high self-weight. Typical medium-span concrete bridge decks with

twin rib or box cross sections have an equivalent thickness (cross section area divided by width) that generally lies

between 450mm and 600mm. Thus when the thickness of slab exceeds about 700 mm, the cost of carrying the self-

weight tends to outweigh its virtues of simplicity.

All Rights Reserved, @IJAREST-2016

105

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

Voids Shape and Material

Voids may be circular, quasi-circular such as octagonal, or rectangular. Rectangular voids are assimilated to multi cell

Boxes.

Methods are used to Create Voids

The commonest is to use expanded polystyrene, which has advantage that it is light easy to cut. In theory, Polystyrene

voids can be made of any shape, either by building up rectangular sections, or by sharping standard sections. In practice,

the labour involved in building up or cutting sections is not economical there for cylindrical voids are usually used, these

cylinders may be cut away locally to widen ribs, or to accommodate prestress anchors, drainage gullies etc.

Development of Voided Slabs

The development of voided slab is similar to that of solid slabs. In decks where the maximum stress on the top and

bottom fibers is less than the permissible limit, it is cost effective to create side cantilevers and to remove material from

the center of wide slabs, creating effectively a voided ribbed slab.

Criteria for making Voided Slab

Center to center spacing of voids shall not be less than the total depth of slab.

Ratio of void to the total depth of slab shall not exceed 75%.

The thickness of the concrete above the voids where cables are not located shall not be less than 200 mm.

The thickness of the concrete below voids where cables are located shall have 75mm minimum clear cover

measured from outside of sheathing.

The thickness of web shall not be less than 200 mm plus diameter of duct hole. Where cables cross within the

web, suitable thickness over the above value shall be made.

III. GRILLAGE ANALOGY METHOD

The grillage analogy method is a computer-oriented technique and is being used in the analysis and design of bridges.

With the use of computer facilitates, the investigation of several load cases can be done in very short time as compared to

manual methods. The method consists of rigidly connected beams at discrete nodes i.e. idealizing the slab by an

equivalent grillage. The deformations at the two ends of a beam element are related to the bending and torsional moments

through their bending and torsional stiffness.

Idealization, as number of longitudinal and transverse beam elements in a single horizontal plane, rigidly interconnected

at nodes. Transverse beams may be orthogonal or skewed with respect to the longitudinal beams, so that skew, curved,

tapering or irregular slabs can be analyzed by this method.

In a simple grillage analysis, each beam is allotted a flexural stiffness in the vertical plane and a torsional stiffness.

Vertical loads are applied only at the nodes. Computer software is used to determine the displacements (rotations about

the two horizontal axes and the vertical displacement) at each node and the forces (bending moments, torsional moments

and vertical shear forces) in the beams connected to each node.

Software’s like STAAD Pro or SAP2000 can be used for grillage analogy modeling method.

Following points give a summary of the guidelines to convert an actual bridge deck into a grid for grillage analysis:

Grid lines are placed along the center line of the existing beams, if any and along the center line of left over slab, as

in the case of T-girder decking.

Longitudinal grid lines at either edge be placed at 0.3D from the edge for slab bridges, where D is the depth of the

deck.

Grid lines should be placed along lines joining bearings.

A minimum of five grid lines are generally adopted in each direction.

Grid lines are ordinarily taken at right angles.

Grid lines in general should coincide with the CG of the section. Some shift, if it simplifies the idealization, can be

made.

Over continuous supports, closer transverse grids may be adopted. This is so because the change is more depending

upon the bending moment profile.

For better results, the side ratios i.e. the ratio of the grid spacing in the longitudinal and transverse directions should

preferably lie between 1.0 to 2.0.

General steps for grillage analogy method:

1. Idealization of physical slab into equivalent grillage.

2. Evaluation of equivalent elastic inertias of members of grillage.

3. Application and transfer of loads to various nodes of grillage.

4. Determination of force responses and design envelopes and

5. Interpretation of results.

All Rights Reserved, @IJAREST-2016

106

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

IV. DESCRIPTION OF BRIDGE SUPER STRUCTURE

A simply supported two lane span of 25m solid and voided slab is considered. Railing, footpath, crash barrier, lane

dimensions are considered as per IRC: 5-1998. Voids dimensions are considered as per IRC SP: 64-2005. The bridge

superstructure with 2 lane carriageway of 7.5 m width with footpath with prestressed solid slab is taken. On two side of

carriage way crash-barrier with 0.45 m width and footpath with 1.5m width and parapet with 0.3m width provided.

CROSS SECTION OF SLAB

Figure 1. Cross Section of 25m Solid Slab

Figure 2. Cross Section of 25m Voided Slab

ELEVATION OF SLAB

Figure 3. Elevation of Slab

Table 1. Dimension of Slab Type Superstructure

Solid slab Voided slab

Span (M) 25m 25m

Depth (M) 1.2 1.2

Width (M) 8.4 8.4

Void Diameter(M) - 0.6

No. Of Void - 8

Area (M2) 10.08 7.818

LOADS

The following loads are considered:

1) Dead load: The dead load includes self-weight of the slab type superstructure.

2) SIDL: Weight of crash barrier, parapet and wearing coat is considered in SIDL.

3) Live Load: IRC loading for two lane bridges are considered, which are as follows:

One lane of Class-70R wheel loading

Two lane of class-A loading

4) Load Combination: Following load combinations are carried out and worst effect is considered in the analysis.

DL + SIDL + LL (Maximum of Class 70R, Class A)

All Rights Reserved, @IJAREST-2016

107

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

Figure 4. Grid Mesh (25m Span, 30° Degree Curvature)

Figure 5. Live Load (Class 70R)

Figure 6. Live Load (Class A)

V. ANALYSIS RESULTS

The results are collected for a 25m span with varying degree of curvature (15° to 60° at 15° increment). Results are taken

for DL + SIDL + LL (Max.). The values of maximum B.M., S.F., and displacement are collected for entire Section of

which maximum B.M. and displacement occurs at mid span, maximum S.F. at edge near supports.

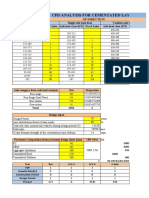

Table 2. Max. Bending Moment of Solid and Voided Slab (T.M)

25m Span Degree Of Curvature

15° Degree 30° Degree 45° Degree 60° Degree

Solid Slab 2652.61 3097.36 3673.15 4432.66

Voided Slab 2253.92 2630.58 3117.61 3759.14

All Rights Reserved, @IJAREST-2016

108

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

MAX. BENDING MOMENT (25M SPAN)

BENDING MOMENT (T.M)

5000.00

4500.00

4000.00

3500.00

3000.00

2500.00

2000.00

1500.00

1000.00

500.00

0.00

15 DEGREE 30 DEGREE 45 DEGREE 60 DEGREE

Solid Slab 2652.60 3097.36 3673.15 4432.66

Voided Slab 2253.92 2630.58 3117.61 3759.14

DEGREE OF CURVATURE

Figure 7. Max. Bending Moment of Solid and Voided Slab (25m Span)

Table 3. Max. Shear Force of Solid and Voided Slab (T/M width)

25m Span Degree Of Curvature

15° Degree 30° Degree 45° Degree 60° Degree

Solid Slab 79.31 97.93 119.57 149.68

Voided Slab 68.39 84.02 102.17 126.17

MAX. SHEAR FORCE (25M SPAN)

160.00

140.00

SHEAR FORCE (T/M)

120.00

100.00

80.00

60.00

40.00

20.00

0.00

15 DEGREE 30 DEGREE 45 DEGREE 60 DEGREE

Solid Slab 79.31 97.93 119.57 149.68

Voided Slab 68.39 84.02 102.17 126.17

DEGREE OF CURVATURE

Figure 8. Max. Shear Force of Solid and Voided Slab (T/M width)

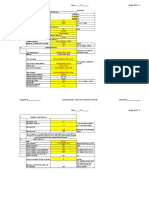

Table 4. Max. Displacement of Solid and Voided Slab (M)

25m Span Degree Of Curvature

15° Degree 30° Degree 45° Degree 60° Degree

Solid Slab 0.089 0.129 0.192 0.294

Voided Slab 0.076 0.109 0.163 0.250

All Rights Reserved, @IJAREST-2016

109

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

MAX. DISPLACEMENT (25M SPAN)

0.350

DISPLACEMENT (M)

0.300

0.250

0.200

0.150

0.100

0.050

0.000

15 DEGREE 30 DEGREE 45 DEGREE 60 DEGREE

Solid Slab 0.089 0.129 0.192 0.294

Voided Slab 0.076 0.109 0.163 0.250

DEGREE OF CURVATURE

Figure 9. Max. Displacement (25m Span)

VI. CONCLUSION

Eight Models were prepared for solid slab and voided slab keeping the same material properties with varying degree of

curvature from 15° to 60° at 15° increment for different load conditions and load combinations. Loads, load

combinations and end conditions were applied to the models as per IRC specifications. STAAD Pro Software was used

for the analysis. The conclusions obtained from the present study are shown in tables and graphs above and can be

described as below.

1. As per above graph it has been concluded that the bending moment, shear force and displacement of slab type

superstructure is increase with increasing in degree of curvature.

2. Bending moment, shear force and displacement of voided slab is lower than solid slab.

3. Due to voids self-weight of voided slab decrease about 23% than solid slab.

4. Max. Bending moment and displacement obtain at center of span length.

5. Max. Shear force obtain at outer edge of curvature near the support.

6. Max. Displacement obtain at center span outer edge of curvature.

7. Due to increasing in span and degree of curvature bending moment shear force and displacement is increase.

8. For 25m span voided slab is better than solid slab in term of bending moment, shear force, displacement, self-weight.

9. The benefit for grillage analysis is that it is easy to use and comprehend.

REFERENCES

1. Saifee Bhagat and Dr. K. B. Parikh, “Comparative Study of Voided Flat Plate Slab and Solid Flat Plate Slab”

International Journal of Innovative Research & Development (IJIRD) Vol. 3 Issue 3, March-2014.

2. Shaimaa Tariq Sakin, “Punching Shear in Voided Slab” International Institute for Science Technology and

Education (IISTE) Vol. 6, No.10, 2014.

3. Saifee Bhagat and Dr. K. B. Parikh, “Parametric Study of R.C.C Voided and Solid Flat Plate Slab using SAP 2000”

IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) Vol. 11, Issue 2 Ver. VI, Mar- Apr. 2014.

4. Mulesh K. Pathak, “Performance of RCC Box type Superstructure in Curved bridges” International Journal of

Scientific & Engineering Research, Vol. 5, Issue 1, January-2014.

5. Amit Saxena and Dr. Savita Maru, “Comparative Study of the Analysis and Design of T-Beam Girder and Box

Girder Superstructure” IJREAT International Journal of Research in Engineering & Advanced Technology, Vol. 1,

Issue 2, April-May, 2013.

6. B.Vaignan and Dr. B.S.R.K Prasad, “Analysis Of Voided Deck Slab And Cellular Deck Slab Using Midas Civil”

International Journal of Engineering Research & Technology (IJERT) Vol. 3 Issue 9, September- 2014.

7. Singh Shailendra, Jain Utkarsh, Nimoriya Manish Kumar, Faraz Md. Islamuddin, “A Comparative Study Of Simply

Supported And Continuous R.C.C. Slab Bridges” International Journal of Engineering Research and General

Science, Volume 3, Issue 3, ISSN 2091-2730, May-June, 2015.

8. R.Shreedhar, Spurti Mamadapur, “Analysis of T-beam Bridge Using Finite Element Method” International Journal

of Engineering and Innovative Technology (IJEIT), Volume 2, Issue 3, ISSN: 2277-3754, September 2012.

9. R.Shreedhar, Rashmi Kharde, “Comparative study of Grillage method and Finite Element Method of RCC Bridge

Deck” International Journal of Scientific & Engineering Research Volume 4, Issue 2, ISSN 2229-5518, February-

2013.

10. Baidarb Akht, Leslie G Jaege, M. S. Cheung, Aftab A. Muft, “The State Of The Art in Analysis of Cellular and

Voided Slab Bridges” National Research Council of Canada.

11. Mohsen A. lssa and Rajan Sen, “Service, Post-cracking and Ultimate Response of Continuous Post-Tensioned

Voided Slab Bridges” ACI Structural Journal.

All Rights Reserved, @IJAREST-2016

110

International Journal of Advance Research in Engineering, Science & Technology (IJAREST)

Volume 3, Issue 3, March 2016, e-ISSN: 2393-9877, print-ISSN: 2394-2444

12. C.S. Surana and R. Agrawal, “Griliage Analogy in Bridge Deck Analysis” Narosa Publishing House, New Delhi.

13. Edmund C.Hambly, “Bridge Deck behavior”

14. N. Krishna Raju (2002) “Prestressed Concrete”, 8th edition, TATA McGraw-Hill Publishing Company Limited,

New Delhi.

15. IRC: 6-2000, Standard Specification and Code of Practice for Road Bridge, Section II, Loads and Stresses, Indian

Road Congress, New Delhi.

16. IRC: 21-2000, “Standard Specifications and Code of Practice for Road Bridges, Section III, Cement Concrete (Plain

and Reinforced)”, The Indian Roads Congress, New Delhi, India, 2000.

17. IRC: 5-1998, Standard Specifications and Code of Practice for Road Bridges, Section 1 General Features of Design,

New Delhi.

18. IRC: 38, For Horizontal Curve, Indian Road Congress, New Delhi.

19. IRC: SP 64-2005, Guidelines for the analysis and design of Cast-in-place voided slab superstructure.

All Rights Reserved, @IJAREST-2016

111

Vous aimerez peut-être aussi

- Filipino Construction TermsDocument3 pagesFilipino Construction Termspaul2reebok71% (21)

- Flexural Fatigue Performance of ECC Link Slabs For Bridge Deck ApplicationsDocument14 pagesFlexural Fatigue Performance of ECC Link Slabs For Bridge Deck ApplicationsankitPas encore d'évaluation

- Stetter: MCI 70 N Control System Ver 3.0Document2 pagesStetter: MCI 70 N Control System Ver 3.0DEBU SASMALPas encore d'évaluation

- Study The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadDocument4 pagesStudy The Effect of Different Load Combination That Will Lead To The Failure of The Structure and Hence Design For The Critical Combination of LoadEditor IJTSRDPas encore d'évaluation

- Analysis of Slab Culvert Bridges Using ConventionaDocument7 pagesAnalysis of Slab Culvert Bridges Using Conventionajeeva anandPas encore d'évaluation

- Loc-1 - Up Traffic On DownDocument14 pagesLoc-1 - Up Traffic On DownPriyanka YadavPas encore d'évaluation

- A Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD Pro ReviewDocument12 pagesA Study On Design and Analysis of Precast Box For Road Bridge Construction Using STAAD Pro ReviewEditor IJTSRDPas encore d'évaluation

- Detailed Analysis of Pre-Cast Box Segment and Thrust Bed and Thrust Wall Using Staad ProDocument6 pagesDetailed Analysis of Pre-Cast Box Segment and Thrust Bed and Thrust Wall Using Staad ProIJRASETPublicationsPas encore d'évaluation

- FounDocument18 pagesFounSisay GashaPas encore d'évaluation

- CC PDFDocument4 pagesCC PDFRanjan Kumar SahooPas encore d'évaluation

- Analysis of Multi-Column Pier of Bridge Using STAAD - Pro Under Static and Dynamic LoadingDocument14 pagesAnalysis of Multi-Column Pier of Bridge Using STAAD - Pro Under Static and Dynamic LoadingBHUSHAN SANTOSH POHARKARPas encore d'évaluation

- Brdige Engineering Presentation Final1 2 1Document49 pagesBrdige Engineering Presentation Final1 2 1Nhorwin Jay TadeoPas encore d'évaluation

- Study On Seismic Analysis of High-Rise Building by Using SoftwareDocument9 pagesStudy On Seismic Analysis of High-Rise Building by Using SoftwaremonaliPas encore d'évaluation

- A Comparative Study On T-Beam Girder and Box Girder Bridges For Different Skew AnglesDocument6 pagesA Comparative Study On T-Beam Girder and Box Girder Bridges For Different Skew AnglesVikramPas encore d'évaluation

- Comment - Draft - Comp Girder-26.34-R6Document61 pagesComment - Draft - Comp Girder-26.34-R6Nilay GandhiPas encore d'évaluation

- Elastomercic Bearing DN (14+872 MNB)Document19 pagesElastomercic Bearing DN (14+872 MNB)Ankur ChauhanPas encore d'évaluation

- Comparison Design Result of RCC Building Using Staad and Etabs SoftwareDocument6 pagesComparison Design Result of RCC Building Using Staad and Etabs SoftwarearjunPas encore d'évaluation

- Encon: Quality Assurance PlanDocument1 pageEncon: Quality Assurance PlanRaj DhuriPas encore d'évaluation

- Comparative Study On Normal and Skew Bridge of PSC Box GirderDocument6 pagesComparative Study On Normal and Skew Bridge of PSC Box GirderDhananjay KumarPas encore d'évaluation

- Backup Calc For CTB and CTSB (Tuipang To Aizawl)Document4 pagesBackup Calc For CTB and CTSB (Tuipang To Aizawl)wqqwqwqwqPas encore d'évaluation

- Effect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksDocument9 pagesEffect of Skew Angle On Static Behaviour of Reinforced Concrete Slab Bridge DecksAshish RanaPas encore d'évaluation

- G+12 Design Detail ReportDocument18 pagesG+12 Design Detail ReportvinujohnpanickerPas encore d'évaluation

- Material Properties:: Main Builtup Girder Flexural CheckDocument22 pagesMaterial Properties:: Main Builtup Girder Flexural CheckDipak BorsaikiaPas encore d'évaluation

- Rate Analysis Pil and Diaphragmw AllDocument1 pageRate Analysis Pil and Diaphragmw AllManan ParikhPas encore d'évaluation

- 29+635 - (32 Deg Skew)Document27 pages29+635 - (32 Deg Skew)Praveen CyssanPas encore d'évaluation

- 2Document105 pages2Zankar R ParikhPas encore d'évaluation

- Alternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyDocument9 pagesAlternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyAnkur SrivastavaPas encore d'évaluation

- Current Notice 04122023Document88 pagesCurrent Notice 04122023soumyadeepacesPas encore d'évaluation

- Consolidation 3 Gang TestDocument8 pagesConsolidation 3 Gang TestSandeep Reddy100% (1)

- Water Tank Analysis Using STAAD PRO: Mainak GhosalDocument9 pagesWater Tank Analysis Using STAAD PRO: Mainak GhosalEr Bhavesh IngalePas encore d'évaluation

- Bhimgoda BarrageDocument2 pagesBhimgoda BarrageLuojisi CilPas encore d'évaluation

- Apsara BorderDocument15 pagesApsara BorderskumarsrPas encore d'évaluation

- Final 2 09Document1 pageFinal 2 09api-271041677Pas encore d'évaluation

- Concrete Sheet Piling Design (EN1997)Document11 pagesConcrete Sheet Piling Design (EN1997)ChuksbozmentPas encore d'évaluation

- Illustrative Worked Examples: 222 - Vehicle Collision Loads On Supports of Bridges, Flyover Supports & Foot Over BridgesDocument2 pagesIllustrative Worked Examples: 222 - Vehicle Collision Loads On Supports of Bridges, Flyover Supports & Foot Over Bridgesjatin singlaPas encore d'évaluation

- Design Exmple RC T - Beam PDFDocument29 pagesDesign Exmple RC T - Beam PDFnabinniraulaPas encore d'évaluation

- Bridge CantileverDocument9 pagesBridge CantileverPriyal vasaiwalaPas encore d'évaluation

- PART 6 Deck Slab DesignDocument6 pagesPART 6 Deck Slab Designshashi rajhansPas encore d'évaluation

- Optimization PSC Bridge An ExampleDocument13 pagesOptimization PSC Bridge An Exampleani4576Pas encore d'évaluation

- Inclined Retaining Wall RCC Design 4mDocument10 pagesInclined Retaining Wall RCC Design 4mRahul GargPas encore d'évaluation

- GT Report Open Cutting at Ch. 34 KM MizoramDocument15 pagesGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarPas encore d'évaluation

- Top Slab of Sludge Collection Tank SilcharDocument3 pagesTop Slab of Sludge Collection Tank SilcharAditya KumarPas encore d'évaluation

- S.Muthu Vel Murugan: Behaivour of Earth Quake Resisting Masonry Building As Per Is 4326:1993Document55 pagesS.Muthu Vel Murugan: Behaivour of Earth Quake Resisting Masonry Building As Per Is 4326:1993Praveenkumar ShanmugamPas encore d'évaluation

- Engineering Science and Technology, An International JournalDocument7 pagesEngineering Science and Technology, An International JournalPoun KumarPas encore d'évaluation

- A Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodDocument4 pagesA Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodEditor IJTSRDPas encore d'évaluation

- Catchment Area Ab Road1Document66 pagesCatchment Area Ab Road1skumarsrPas encore d'évaluation

- Cross Section Properties (All Dimensions Are in CMS)Document2 pagesCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisPas encore d'évaluation

- A General A-1: Matara Katharagama New Rail Road Development Project Design Unit Epc DivisionDocument3 pagesA General A-1: Matara Katharagama New Rail Road Development Project Design Unit Epc DivisionrasikamalPas encore d'évaluation

- Prestressed Concrete Girder Continuity ConnectionDocument6 pagesPrestressed Concrete Girder Continuity ConnectionagnayelPas encore d'évaluation

- Calculations of Pile Capacity of Pile: K EI TDocument5 pagesCalculations of Pile Capacity of Pile: K EI Tgaurav sharmaPas encore d'évaluation

- Box Culvert Design VVIMPDocument11 pagesBox Culvert Design VVIMPAshishPas encore d'évaluation

- Design Coefficientsfor Three Cell Box CulvertDocument14 pagesDesign Coefficientsfor Three Cell Box CulvertteweldePas encore d'évaluation

- Case Study Tech AbutmentDocument7 pagesCase Study Tech AbutmentGajendra BishtPas encore d'évaluation

- Design of Abutment For Major Bridge at KM 4+547 PDFDocument154 pagesDesign of Abutment For Major Bridge at KM 4+547 PDFmrinal kayalPas encore d'évaluation

- Comparative Study of RCC T-Beam Bridge byDocument32 pagesComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Pier Sheet Hollow r0Document1 pagePier Sheet Hollow r0Varun VermaPas encore d'évaluation

- FCFVFDocument4 pagesFCFVFAnonymous sfkedkymPas encore d'évaluation

- RCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Document13 pagesRCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Shivendra KumarPas encore d'évaluation

- Composite GirdersDocument268 pagesComposite GirdersdeathesPas encore d'évaluation

- Soil Data PDFDocument118 pagesSoil Data PDFKiran MahajanPas encore d'évaluation

- BR - NO.775 (1X3.00m RCC BOX) 23-08-2019-ModelDocument1 pageBR - NO.775 (1X3.00m RCC BOX) 23-08-2019-Modelgrao vakapalliPas encore d'évaluation

- Effect of Skew Angles On Longitudinal Girder and Deck Slab of Prestressed Concrete T Beam Girder BridgesDocument9 pagesEffect of Skew Angles On Longitudinal Girder and Deck Slab of Prestressed Concrete T Beam Girder BridgesIJRASETPublicationsPas encore d'évaluation

- Behavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesD'EverandBehavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesPas encore d'évaluation

- Lap Length & AnchorageDocument4 pagesLap Length & AnchorageNeha SinghPas encore d'évaluation

- What Is The Difference Between Development Length and Anchorage LengthDocument5 pagesWhat Is The Difference Between Development Length and Anchorage LengthankitPas encore d'évaluation

- PSC Box Girder (Prestressing)Document51 pagesPSC Box Girder (Prestressing)ankit100% (3)

- HDSD 1. Chay File 1.2011.REG 2. Chay File 2.devcon - Exe 3. Chay File 3.install - BatDocument1 pageHDSD 1. Chay File 1.2011.REG 2. Chay File 2.devcon - Exe 3. Chay File 3.install - BatankitPas encore d'évaluation

- SuperstructureDocument98 pagesSuperstructureankitPas encore d'évaluation

- Performa For Inspection For BridgeDocument7 pagesPerforma For Inspection For BridgeankitPas encore d'évaluation

- Steel Tables by R Agor, Birla Publications PDFDocument97 pagesSteel Tables by R Agor, Birla Publications PDFankitPas encore d'évaluation

- IRC-18 - (Prestressed Concrete Road Bridges - Post Tensioning) PDFDocument38 pagesIRC-18 - (Prestressed Concrete Road Bridges - Post Tensioning) PDFankitPas encore d'évaluation

- Steel Tables by R Agor, Birla Publications PDFDocument97 pagesSteel Tables by R Agor, Birla Publications PDFankitPas encore d'évaluation

- Home ArchitectureDocument1 pageHome ArchitectureBhathiya Maneendra PilanawithanaPas encore d'évaluation

- Footing Preliminary DesignDocument12 pagesFooting Preliminary Designप्रविणअर्यालPas encore d'évaluation

- Structural Wall - AnalysisDocument16 pagesStructural Wall - AnalysiscdestudosPas encore d'évaluation

- Underpinning of Structures: MohammedabbasDocument53 pagesUnderpinning of Structures: MohammedabbasManvendra Vikram Singh50% (2)

- CM Exam Paper 2007 (Metric)Document36 pagesCM Exam Paper 2007 (Metric)naconnetPas encore d'évaluation

- Volume 2Document649 pagesVolume 2Denny Azumi ZurinairaPas encore d'évaluation

- May2012 - Renovating and Revamping Your Home PDFDocument45 pagesMay2012 - Renovating and Revamping Your Home PDFKapil RampalPas encore d'évaluation

- MBMA 2012 Deflection LimitDocument1 pageMBMA 2012 Deflection LimitHoang Duc LocPas encore d'évaluation

- Steel and Timber Design Benchmarks - EnuDocument456 pagesSteel and Timber Design Benchmarks - EnuKang'ethe GeoffreyPas encore d'évaluation

- Mix DesignDocument74 pagesMix DesignKarthikeyan m.karthiPas encore d'évaluation

- Contor Rab Saluran Drainase BandaraDocument73 pagesContor Rab Saluran Drainase Bandarabansai100% (1)

- Reo Detailing HandbookDocument201 pagesReo Detailing HandbookYuki Gitara100% (5)

- Steel Slit Shear Walls With An Efficient GeometryDocument13 pagesSteel Slit Shear Walls With An Efficient GeometryTY ZPas encore d'évaluation

- Brochure For International Webinar (RTCP) PDFDocument3 pagesBrochure For International Webinar (RTCP) PDFVishalBeheraPas encore d'évaluation

- Handout 2Document31 pagesHandout 2عبدالله عبدالحكيم عامرPas encore d'évaluation

- Equipment and Apparatus For Testing: Cement 1. Blaine Air ApparatusDocument11 pagesEquipment and Apparatus For Testing: Cement 1. Blaine Air ApparatusGabriel VergaraPas encore d'évaluation

- BED PROTECTION 10MTR 5 SPAN BRIDGE-Model PDFDocument1 pageBED PROTECTION 10MTR 5 SPAN BRIDGE-Model PDFEr Navneet JassiPas encore d'évaluation

- Reodata41 PDFDocument68 pagesReodata41 PDFMunzuara AktherPas encore d'évaluation

- PC Girder Class 10 - MistDocument264 pagesPC Girder Class 10 - MistnibirPas encore d'évaluation

- Module 3 Kani' MethodDocument7 pagesModule 3 Kani' Methodram100% (1)

- Crane BeamDocument20 pagesCrane BeamPreyash Shah100% (1)

- Shortening of Waiting Period For Closure Pour in Bridge ConstructionDocument19 pagesShortening of Waiting Period For Closure Pour in Bridge ConstructionHao LuoPas encore d'évaluation

- Chapter 5.2 - Continous Beam PDFDocument17 pagesChapter 5.2 - Continous Beam PDFfhatiha atikaPas encore d'évaluation

- Temporary Structures: Wall Form DesignDocument6 pagesTemporary Structures: Wall Form Designapi-19878202Pas encore d'évaluation

- Design One Way SlabDocument22 pagesDesign One Way Slabjohn rey toledoPas encore d'évaluation

- Concise PT PDFDocument30 pagesConcise PT PDFmathuPas encore d'évaluation

- Concrete Design DIN 1045 1 PDFDocument82 pagesConcrete Design DIN 1045 1 PDFRanjeet Kumar100% (1)

- Numerical Insights Into The Effect of ITZ and Aggregate Strength On Concrete PropertiesDocument11 pagesNumerical Insights Into The Effect of ITZ and Aggregate Strength On Concrete PropertiesAndres ForeroPas encore d'évaluation