Académique Documents

Professionnel Documents

Culture Documents

Cable 350 MCM-Southwire

Transféré par

mariaelopez1988Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cable 350 MCM-Southwire

Transféré par

mariaelopez1988Droits d'auteur :

Formats disponibles

SPEC 44066

Machine Flexible Power

90°C Wet/90°C Dry. 600 Volts. Flexible Stranded Copper Conductor. PVC Insulation and Nylon Jacket

(THHN/THWN-2). Oil & Gasoline Resistant. Sunlight Resistant. Rated UL VW-1 and CSA FT1 & FT4 Flame Resistant.

Images not to scale. See Table 1 for Dimensions

CONSTRUCTION:

1. Conductor: 8 - 4/0 AWG: Class K,Flexible stranded bare copper 250 - 750 KCMIL: Class I, Flexible stranded bare copper

2. Insulation: Polyvinyl Chloride (PVC) with Nylon sheath

Colors: All colors available, including Green with 30% Yellow Stripe

APPLICATIONS AND FEATURES:

Southwire’s Machine Flexible Power cables are suited for use in wet and dry areas, conduits, ducts, troughs, trays, aerial

supported by a messenger, and where superior electrical properties are desired. These cables are capable of operating contin-

uously at the conductor temperature not in excess of 90°C for normal operation in wet and dry locations, 130°C for emergency

overload, and 250°C for short circuit conditions. 1/0 AWG & Larger rated for CT USE

SPECIFICATIONS:

• ASTM B3, B174, B172

• UL 83 - Type THHN/THWN-2, Oil & Gas Res I, VW-1

• UL 1063 - Machine Tool Wiring (MTW); 22 AWG - 1000 Kcmil

• UL 1685/IEEE 1202 FT4 (70,000) BTU/hr Vertical-Tray Fire Propagation and Smoke Release Test

• CSA C22.2 No. 75 - Type T90 Nylon, TWN75

• ICEA S-95-658 NEMA WC70 - Power cables rated 2000 volts or less for the distribution of electrical energy

• UL 758 - Appliance Wire:

AWM 1318/1410: AWG 8-6 AWM 1319/1411: AWG 4-2 AWM 1320/1412: AWG 1-4/0

AWM 1321/1413: Kcmil 250-500 AWM 1321/1414: Kcmil 600-1000

• CE/RoHS-2 – The CE Marking has been applied solely to express the conformance to the material restrictions

identified in the RoHS-2 (2011/65/EU) Directive.

SAMPLE PRINT LEGEND:

8AWG-1AWG

SOUTHWIRE #P# (UL) 1 AWG (42.406 mm2) CU TYPE THHN/THWN-2 600V 90(D)C DRY/90(D)C WET PRI/GRI VW-1 OR AWM [Applica-

ble Styles] OR MTW SUN RES --- (CSA) T90 NYLON OR TWN75 FT1 FT4 --- CE RoHS-2 Made in USA [SEQUENTIAL FOOTAGE MARKS]

1/0 AWG - 500 KCMIL

SOUTHWIRE #P# (UL) 500 KCMIL (253.35mm2) CU TYPE THHN/THWN-2 600V 90(D)C DRY/90(D)C WET PRI/GRI VW-1 FOR CT USE

OR AWM [Applicable Styles] OR MTW SUN RES --- (CSA) T90 NYLON OR TWN75 FT1 FT4 --- CE RoHS-2 Made in USA [SEQUENTIAL

FOOTAGE MARKS]

PACKAGING:

1 - 8 AWG: 2500’ 1/0 - 4/0 AWG: 1,000’ 250 - 750KCML 500’ Other packages and lengths available upon request.

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2019 Southwire Company, LLC. All Rights Reserved SPEC 44066_PSS DIVISION DATE: 03/17/2019 Rev:1.3.22 M

SPEC 44066

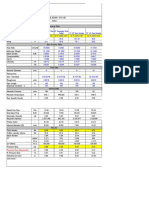

Table 1 – Weights & Measurements

Conductor

Stock Code and Colors Insul. Nylon Nominal Approx.

Size GRN- Dia (1) Count Thickness Sheath OD (2) Weight

AWG BLK BRN ORG YLW GRY YLW GRN inches strands inches mils inches lbs./MFT

8 TBA TBA TBA TBA TBA TBA TBA 0.158 168 30 5 0.227 64

6 TBA TBA TBA TBA TBA TBA TBA 0.190 273 30 5 0.26 97

4 TBA TBA TBA TBA TBA TBA 674667 0.235 413 40 6 0.332 157

2 TBA TBA TBA TBA TBA TBA TBA 0.300 665 40 6 0.412 240

1 TBA TBA TBA TBA TBA TBA TBA 0.340 836 50 7 0.454 310

1/0 TBA TBA TBA TBA TBA TBA 674668 0.400 1044 50 7 0.514 377

2/0 TBA TBA TBA TBA TBA TBA TBA 0.430 1330 50 7 0.544 468

3/0 TBA TBA TBA TBA TBA TBA TBA 0.490 1672 50 7 0.604 590

4/0 679607 ◊

TBA TBA TBA TBA 679606 TBA 0.550 2109 50 8 0.664 747

250 649414 ◊

TBA TBA TBA TBA TBA TBA 0.605 627 60 8 0.741 853

350 649415 ◊ 674662 674664 674665 674666 TBA TBA 0.670 855 60 8 0.806 1157

500 648948◊ 646978 646979 646980 646981 646982 TBA 0.858 1221 60 8 0.994 1622

600 649416 ◊

678431 678432 678434 678435 678436 TBA 0.963 1480 70 9 1.119 2025

750 649549 677721 677722 677723 677725 677726 TBA 1.094 1850 70 9 1.252 2571

All dimensions are nominal and subject to normal manufacturing tolerances

◊ Standard stock item

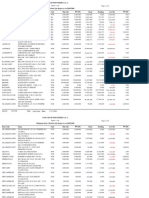

Table 2 – Electrical and Engineering Data

Min Resistance Reactance Ø Short Cir- Allowable Ampacities

Max Pull Bending DC AC XL cuit Current

Cond. Size Tension Radius @ 250C @ 900C @ 60Hz 6 Cycles 60 0C † 75 0C † 90 0C † 90 0C † †

AWG lbs. Inces Ω/MFT Ω/MFT Ω/MFT Amps Amps Amps Amps Amps

8 132 0.91 0.652 0.815 0.030 3754 40 50 55 80

6 210 1.04 0.411 0.514 0.028 5966 55 65 75 105

4 334 1.33 0.258 0.323 0.029 9491 70 85 95 140

2 531 1.65 0.162 0.203 0.028 15089 95 115 130 190

1 670 1.82 0.129 0.161 0.028 19029 110 130 145 220

1/0 845 2.06 0.102 0.128 0.028 24011 125 150 170 260

2/0 1065 2.18 0.081 0.102 0.027 30264 145 175 195 300

3/0 1342 2.42 0.064 0.081 0.027 38154 165 200 225 350

4/0 1693 2.66 0.051 0.064 0.026 48114 195 230 260 405

250 2000 2.96 0.043 0.055 0.027 56845 215 255 290 455

350 2800 3.22 0.031 0.039 0.026 79583 260 310 350 570

500 4000 3.98 0.022 0.028 0.026 113690 320 380 430 700

600 4800 5.60 0.018 0.024 0.025 136428 350 420 475 780

750 6000 6.26 0.014 0.02 0.026 170535 400 475 535 885

† Ampacities are based on Table 310.15 (B)(16) of the NEC, 2014 Edition. Allowable Ampacities of Insulated Conductors Rated Up to and Including 2000 Volts,

60ºC Through 90ºC (140ºF Through 194ºF) Not More Than Three Current-Carrying Conductors in Raceway, Cable, or Earth (Directly Buried), Based on ambient tem-

perature of 30ºC (86ºF)

† † Ampacities are based on Table 310.15 (B)(17) of the NEC, 2014 Edition. Allowable Ampacities of Single-Insulated Conductors Rated Up to and Including 2000

Volts in Free Air, Based on Ambient Temperature of 30ºC (86ºF)

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2019 Southwire Company, LLC. All Rights Reserved SPEC 44066_PSS DIVISION DATE: 03/17/2019 Rev:1.3.22 M

Vous aimerez peut-être aussi

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosPas encore d'évaluation

- 1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specDocument2 pages1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specEdgar Sierra RodriguezPas encore d'évaluation

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnarePas encore d'évaluation

- SPEC83013 600 Volt UndergroundDocument3 pagesSPEC83013 600 Volt Undergroundakib javedPas encore d'évaluation

- RhinoDocument2 pagesRhinoValeria Rendon NoyolaPas encore d'évaluation

- PS Board ITP FileDocument6 pagesPS Board ITP FileGanesan SPas encore d'évaluation

- Beam Loading:: 2ND/3RD 4Th FloorDocument14 pagesBeam Loading:: 2ND/3RD 4Th FloorAly Arquillano JrPas encore d'évaluation

- Armor X 3C XHHW-2 Power 3GND 600V 2017 - CCDocument2 pagesArmor X 3C XHHW-2 Power 3GND 600V 2017 - CCpglv0210Pas encore d'évaluation

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoPas encore d'évaluation

- Standarisasi KabelDocument44 pagesStandarisasi Kabeladzan isaacPas encore d'évaluation

- Technical - Spec SkirtDocument25 pagesTechnical - Spec SkirtStructures ProductionPas encore d'évaluation

- Nodo A D Elemento AB BA BC CB CD DC DF FEM Dist TR Dist TR Dist TR Dist TR Dist TR Dist B CDocument1 pageNodo A D Elemento AB BA BC CB CD DC DF FEM Dist TR Dist TR Dist TR Dist TR Dist TR Dist B CCristian LopezPas encore d'évaluation

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesPas encore d'évaluation

- Polycab Price List October 2021Document6 pagesPolycab Price List October 2021Kevin MaldePas encore d'évaluation

- Moq20 05 09Document6 pagesMoq20 05 09vassim123Pas encore d'évaluation

- Welding Flanges: Price ScheduleDocument3 pagesWelding Flanges: Price ScheduleLatif RadwanPas encore d'évaluation

- BL AlanodipDocument46 pagesBL AlanodipAly Arquillano JrPas encore d'évaluation

- Flanges Price List - 2018 - PDFDocument3 pagesFlanges Price List - 2018 - PDFsithulibraPas encore d'évaluation

- 2 KV AL Cable Datasheet - Priority CablesDocument1 page2 KV AL Cable Datasheet - Priority CablesVipin KhandelwalPas encore d'évaluation

- Price List 22042013 National CablesDocument8 pagesPrice List 22042013 National CablesSukhirthan SenthilkumarPas encore d'évaluation

- Sr. No. Particular Tie BeamDocument12 pagesSr. No. Particular Tie BeamHarsh BhavsarPas encore d'évaluation

- Nitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGDocument29 pagesNitrogen Calculations: WHP 2689 Psi Anp Psi ID in SGNaveen GuptaPas encore d'évaluation

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesPas encore d'évaluation

- Water Environment Federation-Clarifier Design - WEF Manual of Practice No. FD-8-McGraw-Hill Professional (2005)Document75 pagesWater Environment Federation-Clarifier Design - WEF Manual of Practice No. FD-8-McGraw-Hill Professional (2005)K Divakara RaoPas encore d'évaluation

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouPas encore d'évaluation

- U.S. Tsubaki Bs/Din Roller ChainDocument6 pagesU.S. Tsubaki Bs/Din Roller ChainAnandhi ChidambaramPas encore d'évaluation

- Pupuk 7 RacikanDocument10 pagesPupuk 7 RacikanDimar KahuripanPas encore d'évaluation

- Anixter SPEC-44020 DLO-Cable PDFDocument3 pagesAnixter SPEC-44020 DLO-Cable PDFJoon LeePas encore d'évaluation

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateJohan F. MonroyPas encore d'évaluation

- Drift TableDocument3 pagesDrift TableRolly Hillz SochimPas encore d'évaluation

- KJIN Rockbreaker BrochureDocument8 pagesKJIN Rockbreaker BrochureRC SPARESPas encore d'évaluation

- Drop Voltage Calculation Project Tit Date RevisionDocument40 pagesDrop Voltage Calculation Project Tit Date Revisiongawe bitaPas encore d'évaluation

- 1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesDocument5 pages1N2970-1N3015B, 1N3993-1N4000A: 10 Watt Zener DiodesAndres GalvezPas encore d'évaluation

- Trim and StabilityDocument8 pagesTrim and StabilityAsh ganPas encore d'évaluation

- Ra Bill 3 GGS2Document18 pagesRa Bill 3 GGS2rohitPas encore d'évaluation

- Importadora C.M., C.A.: Lista de PreciosDocument2 pagesImportadora C.M., C.A.: Lista de PreciosJuan J GonzalezPas encore d'évaluation

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesPas encore d'évaluation

- 5 Marla House Detail Estimation 2017Document5 pages5 Marla House Detail Estimation 2017El ChapoPas encore d'évaluation

- Polycab Cables PricelistDocument6 pagesPolycab Cables PricelistRakhee SinhaPas encore d'évaluation

- Direct Online Starters (DOL) : Type HP KW Overload Relay Amp Range Unit Price (RS.)Document2 pagesDirect Online Starters (DOL) : Type HP KW Overload Relay Amp Range Unit Price (RS.)ThilinaPas encore d'évaluation

- Problem 1: Differential Vaporization at T 229 FDocument16 pagesProblem 1: Differential Vaporization at T 229 Fperiya salehPas encore d'évaluation

- Codi de Zener SMDDocument6 pagesCodi de Zener SMDartola14Pas encore d'évaluation

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraPas encore d'évaluation

- ABB Price Book 278Document1 pageABB Price Book 278EliasPas encore d'évaluation

- PL Final de Fisa Chiile 20-02Document3 pagesPL Final de Fisa Chiile 20-02Marcel GallardoPas encore d'évaluation

- BL Restificar 3fDocument20 pagesBL Restificar 3fAly Arquillano JrPas encore d'évaluation

- Building EstimationDocument22 pagesBuilding EstimationchanakyaPas encore d'évaluation

- Nodo A D Nodo A D Elemento AB BA BC CB CD DC Elemento AB BA BC CB CD DC DF DF FEM FEM Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist B C B CDocument1 pageNodo A D Nodo A D Elemento AB BA BC CB CD DC Elemento AB BA BC CB CD DC DF DF FEM FEM Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist TR TR Dist Dist B C B CCristian LopezPas encore d'évaluation

- 1N4728 (A) - 1N4764 (A) : 1 Watt Zener DiodesDocument4 pages1N4728 (A) - 1N4764 (A) : 1 Watt Zener DiodesadarshPas encore d'évaluation

- Common SSR For The Year 2019-20 (For All AP Power Utilities)Document48 pagesCommon SSR For The Year 2019-20 (For All AP Power Utilities)SIVA NAGA SUDHEER SIDDANIPas encore d'évaluation

- Alp Prof Price BRK DWN Per MTR at 122Document1 pageAlp Prof Price BRK DWN Per MTR at 122nagesh raoPas encore d'évaluation

- 1121 PDFDocument1 page1121 PDFCristian LopezPas encore d'évaluation

- Acsr TW PDFDocument5 pagesAcsr TW PDFJavier Soza DazaPas encore d'évaluation

- 2 Old Evaps LB and ELB Series PDFDocument28 pages2 Old Evaps LB and ELB Series PDFPreeti gulatiPas encore d'évaluation

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07Pas encore d'évaluation

- HSN Summary of September 2021Document4 pagesHSN Summary of September 2021AmitPas encore d'évaluation

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezPas encore d'évaluation

- CSTR Data Sets 1 - 3Document11 pagesCSTR Data Sets 1 - 3brittanyPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Failure Analysis of A Half Shaft of A Formula SAE Racing Car PDFDocument7 pagesFailure Analysis of A Half Shaft of A Formula SAE Racing Car PDFhayyanadmaPas encore d'évaluation

- 2021-Flexural Behavior of Post-Tensioned Concrete BeamsDocument17 pages2021-Flexural Behavior of Post-Tensioned Concrete BeamsNhung VũPas encore d'évaluation

- Hitachi Flexible Cable 2011Document48 pagesHitachi Flexible Cable 2011Denar PurnamaPas encore d'évaluation

- Distribution Transformers in PakistanDocument25 pagesDistribution Transformers in PakistanMuhammadShakeelBhattiPas encore d'évaluation

- Nucem PrimerDocument2 pagesNucem PrimerJohn O ReillyPas encore d'évaluation

- Firestopping Standard Details Guide 14mbDocument76 pagesFirestopping Standard Details Guide 14mbJohn TrimmPas encore d'évaluation

- A Review Paper On "Utilization of Fly Ash, Rice Husk Ash and Plastic Waste in Paver Blocks"Document4 pagesA Review Paper On "Utilization of Fly Ash, Rice Husk Ash and Plastic Waste in Paver Blocks"Aragorn RingsPas encore d'évaluation

- Konversi Tensile ModulusDocument2 pagesKonversi Tensile ModulussuryohandokoPas encore d'évaluation

- Durability of Hollow Blocks With Shredded Plastics As AdditiveDocument39 pagesDurability of Hollow Blocks With Shredded Plastics As AdditiveJay ArPas encore d'évaluation

- ASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)Document1 pageASLH-D (S) B 48 NZDSF (A20SA 53 - 7,3) : Optical Ground Wire (OPGW)AHMED YOUSEFPas encore d'évaluation

- Engineering Materials and Their Properties: Jayant JainDocument18 pagesEngineering Materials and Their Properties: Jayant JainSatyaprakash KanaujiyaPas encore d'évaluation

- The Effect of The Excess Titanium Content On The MDocument10 pagesThe Effect of The Excess Titanium Content On The MBaljeet SinghPas encore d'évaluation

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehPas encore d'évaluation

- Pacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelDocument1 pagePacific Paint (Boysen) Philippines, Inc., - Two-Component Epoxy Based Coatings - BOYSEN - Sup - ® - Sup - Epoxy EnamelJojo CalimlimPas encore d'évaluation

- Lesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008Document37 pagesLesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008akmeez100% (1)

- 31.TDS MIXO Fast NNDocument2 pages31.TDS MIXO Fast NNmohamed ragabPas encore d'évaluation

- Bill of QuantitiesDocument18 pagesBill of QuantitiesELMERPas encore d'évaluation

- Porosity in Al Castings - Additonal For Moulding WMDocument75 pagesPorosity in Al Castings - Additonal For Moulding WMAlejandro Jose Garcia FernandezPas encore d'évaluation

- 6 PPDDocument2 pages6 PPDLantika Arinamurti RivayantiPas encore d'évaluation

- Welding Consumables For Hardox and WeldoxDocument4 pagesWelding Consumables For Hardox and WeldoxFilipe Cordeiro100% (1)

- CE 415 - CMaT - Module 1 - Lesson 2Document12 pagesCE 415 - CMaT - Module 1 - Lesson 2Enzo Ivan TILANDOCAPas encore d'évaluation

- Grain Refinement of Aluminum Casting Alloys : G.K. Sigworth and T.A. Kuhn, Alcoa Primary MetalsDocument8 pagesGrain Refinement of Aluminum Casting Alloys : G.K. Sigworth and T.A. Kuhn, Alcoa Primary MetalsRamzi BEN AHMEDPas encore d'évaluation

- Pds - Sunshades Instrument CoverDocument2 pagesPds - Sunshades Instrument CoverAntonio LantiguaPas encore d'évaluation

- 008 Alloy Tool SteelDocument66 pages008 Alloy Tool SteelAbdelfattah MoheyeldinPas encore d'évaluation

- Kayu Indah Terang PDFDocument1 pageKayu Indah Terang PDFAchmatAfipudinPas encore d'évaluation

- TURKEYTRIB18 Oral Presentations WordDocument263 pagesTURKEYTRIB18 Oral Presentations WordAdarsh ByadgiPas encore d'évaluation

- TDS Y381h 2021 enDocument1 pageTDS Y381h 2021 enChu ChuPas encore d'évaluation

- Me136p Exp2 Tensile Test of Reinforcing Steel BarsDocument15 pagesMe136p Exp2 Tensile Test of Reinforcing Steel BarsJohn Henry SalvadoPas encore d'évaluation

- MBrace Fibre PDFDocument4 pagesMBrace Fibre PDFFrancois-Pas encore d'évaluation

- What Are The Innovations in The Production of Medical Implants or ProsthesesDocument5 pagesWhat Are The Innovations in The Production of Medical Implants or ProsthesesJoyce Ann de RosasPas encore d'évaluation