Académique Documents

Professionnel Documents

Culture Documents

Methodology (TPM-Bitumen) On LH

Transféré par

vivekTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Methodology (TPM-Bitumen) On LH

Transféré par

vivekDroits d'auteur :

Formats disponibles

REGISTERED OFFICE ‘ G U R U K R I PA’ , D AT TA S Q U A R E , YAVAT M A L – 4 4 5 0 0 1 [ M A H A R A S H T R A ] I N D I A

P H . N O . 0 0 9 1 – 7 2 3 2 – 2 4 4 1 3 4 , 2 4 4 2 4 7 , 2 4 3 2 7 5 , FA X N O . 0 0 9 1 – 7 2 3 2 – 2 4 5 4 3 0

EMAIL: automark_yml@bsnl.in

C O R P O R AT E O F F I C E 1 S T F L O O R , “ S A R A F C O U R T ” O P P O S I T E YA S H WA N T S TA D I U M , D H A N T O L I ,

NAGPUR – 440012, [MAHARASHTRA], PHONE NO.: 0091-712-6603-671 TO 678,

0 0 9 1 - 7 1 2 - 6 6 1 5 7 6 8 , 2 4 6 1111 , FA X N O . : 0 0 9 1 - 7 1 2 - 6 6 0 3 - 6 7 9

ANDHRA PRADESH OFFICE H. NO. 8-4-315/6/L, SHOP NO. 68, C-BLOCK, LAXMI COMPLEX, ERRAGADDA

H Y D E R A B A D – 5 0 0 0 1 8 [ A . P. ] M O B I L E N O . 0 9 8 4 8 1 - 5 9 1 4 4

K A R N ATA K A O F F I C E M P L N O . 2 6 “ L A X M I N I L AY ” , S H A N T H A B A I , PAT E L H E G D E C O L O N Y, Y E R M E R U S C A M P

R A I C H U R [ K A R N ATA K A ] M O B I L E N O . 0 9 8 4 8 1 - 5 9 1 4 4

C H AT T I S G A R H O F F I C E S H O P N O . 11 2 , M A H A L A X M I , C L O T H M A R K E T, PA N D R I , R A I P U R – 4 9 2 0 0 4 [ C H AT T I S G A R H ]

PH. NO. 0771-4056624 MOBILE NO. 098932-97224

TA M I L N A D U O F F I C E D O O R N O . 1 7 D , K AV E R I S T R E E T, S R I N A G A R C O L O N Y, T H I R U M U L L A I VAYA L , C H E N N A I – 6 0 0 0 6 2

[ T. N . ] M O B I L E N O . 0 9 8 4 8 1 - 5 9 1 4 4 / 0 9 3 4 8 4 - 5 5 1 6 7

U T TA R P R A D E S H O F F I C E K A I L A S H P L A Z A , P L O T N O . 1 8 , S E C T O R G / L D A C O L O N Y, K A N P U R R O A D L U C K N O W [ U . P ]

G U J A R AT O F F I C E S H O P N O . 1 7 , M A H E S H WA R I PA R K S O C I E T Y, N A R O D A , A H M E D A B A D [ G U J . ] M O B . 0 9 3 7 7 7 4 3 5 5 5

RAJASTHAN OFFICE P L O T N O , A 11 9 , B A S E M E N T S H O P N O . 2 , S H YA M M I T R A M A N D A L N A G A R , O P P O S I T E V K I ,

ROAD NO. 5, JAIPUR, RAJASTHAN

PUNE OFFICE O P P. G O V E R N M E N T H O S P I TA L , D O M K H E D R O A D , WA G H O L I , P U N E – 4 1 2 2 0 7 [ M A H A R A S H T R A ]

M A D H YA P R A D E S H O F F I C E S H O P N O . 1 , S AT L A P U R , M A N D I D E E P, T E H . G O H A R G A N J , D I S T T. R A I S E N , B H O PA L [ M . P. ]

w w w. a u t o m a r k - i n d i a . c o m

METHODOLOGY TO BE ADAPTED

BY AUTOMARK INDUSTRIES (INDIA) LIMITED

FOR THERMOPLASTI C ROAD MARKING ON BITUMENOUS SURFACE

1. Plotting of points on the carriageway for centreline and edgeline markings as directed by the

Engineer / Consultants.

2. Scrubbing of road surface with wire brush to dislocate the dust from road surface.

3. Blowing of the dislocated dust from the surface with air-compressor.

4. Pre-marking of centreline / edgeline / Kerb line using string and chalk method.

5. Simultaneously while the above activities are being carried out, thermoplastic material is

heated in a imported oil jacketed pre-heater fitted with hydraulic stirring arrangement. The

thermoplastic material in the pre-heater is heated up to the required temperature. The

temperature is checked using a electronic temperature meter.

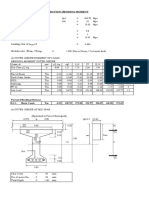

6. The machine to be used on the project:

a. Imported Hand-Push Machine: The centre lines, pedestrian crossing etc. would be marked by

imported hand-push machine in view of the traffic flow on 10 Mtr. road.

7. The molten thermoplastic material is transferred from the pre-heater to our thermoplastic road-

marking machine.

8. Temperature of the material is maintained in the applicator machine.

9. The material is screeded out from the machine through the heated shoe at a thickness of 2.5mm.

Drop on glass beads at a quantity of 300 gms/m² [including wastages due to wind pressure] are

dispensed on the surface of this screeded thermoplastic marking. The dispensing of glass beads

is irrespective of speed due to chain drive mechanism.

10. The carriageway with marking completed is opened for traffic after required drying time of

application and proper setting of thermoplastic material.

11. The pedestrian marking would be done by hand-push manual machine. When the application cannot

be done using the machines, approved manual methods shall be used e.g. for Arrows etc .

12. Following quality checks are carried out and recorded during marking each day:

a. Temperature of material during application by digital temperature meter – Every batch of

material applied.

b. Thickness of material applied – Once in a day

c. Quantity of drop on glass beads being applied – Once in a day

d. Embedment of drop on glass beads by using magnifying glass – 2 times.

e. Nighttime reflectivity with Imported Reflectometer – Daily.

From Lines to Signs ……… Road Safety is Always in sight

Vous aimerez peut-être aussi

- STS130Document252 pagesSTS130MaestroColicus0% (1)

- Parts Manual Yb4411Document467 pagesParts Manual Yb4411shinichie50% (2)

- Smartdek Design ManualDocument48 pagesSmartdek Design ManualranddyPas encore d'évaluation

- Manila RPLLDocument25 pagesManila RPLLnzcruiserPas encore d'évaluation

- Ne MapDocument700 pagesNe MapRonald KendallPas encore d'évaluation

- How To Upload Long Text Into SAP Using Excel Sheet and SAVE - TEXT Function Module - ABAP Development - SCN WikiDocument4 pagesHow To Upload Long Text Into SAP Using Excel Sheet and SAVE - TEXT Function Module - ABAP Development - SCN WikiAnonymous IFxmRW7Pas encore d'évaluation

- JG Summit Petrochemical processes overviewDocument39 pagesJG Summit Petrochemical processes overviewYasmin Yvonne De ChavezPas encore d'évaluation

- WiiiDocument19 pagesWiiiDavid van TeeselingPas encore d'évaluation

- Key Officials: Board of TrusteesDocument2 pagesKey Officials: Board of TrusteesZamboanga City Sate Polytechnic CollegePas encore d'évaluation

- Maint. M GR (PLNG) Panipatxt N 2 3 6 5 1 7 4 2 - 7 8 8 7 2 S I K Dergc@Io CL - Co.Inp Anipatxtn 2 3 5 7 1 7 4 2 7 8 7 5 7 M A U R Yasl@IoclDocument47 pagesMaint. M GR (PLNG) Panipatxt N 2 3 6 5 1 7 4 2 - 7 8 8 7 2 S I K Dergc@Io CL - Co.Inp Anipatxtn 2 3 5 7 1 7 4 2 7 8 7 5 7 M A U R Yasl@IoclCharandeep KapoorPas encore d'évaluation

- Parts Manual: FadalDocument19 pagesParts Manual: FadalSilvia_282008roPas encore d'évaluation

- Curriculum Vitae: Personal InformationDocument3 pagesCurriculum Vitae: Personal InformationJessa MartinezPas encore d'évaluation

- ImageDocument1 pageImagejaiswal_anurag2832Pas encore d'évaluation

- LPPRDocument12 pagesLPPRAlbino Luis Mondadori AfonsoPas encore d'évaluation

- Ga Sale14041798 10 - 01Document1 pageGa Sale14041798 10 - 01mahesh_eilPas encore d'évaluation

- Interface: Register RegisterDocument26 pagesInterface: Register RegisterPolitik Itu KejamPas encore d'évaluation

- Orçamento Do Veículo: Obs: Coifa CaixaDocument1 pageOrçamento Do Veículo: Obs: Coifa CaixaAntonio GoncalvesPas encore d'évaluation

- f.40 - Tower MKD Tc-50 ModelDocument1 pagef.40 - Tower MKD Tc-50 ModelAnil MarturiPas encore d'évaluation

- Commercial Park Layout and Testing RegimeDocument1 pageCommercial Park Layout and Testing RegimemawejosephPas encore d'évaluation

- Inspections MapsDocument8 pagesInspections MapscrushspreadPas encore d'évaluation

- Instructions Essec Masterinmanagement e Businessstrat e Business Winter2024Document70 pagesInstructions Essec Masterinmanagement e Businessstrat e Business Winter2024Syed KhizarPas encore d'évaluation

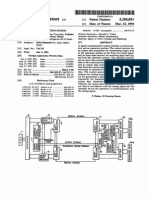

- United States Patent (19) : Bass Et A1Document70 pagesUnited States Patent (19) : Bass Et A1scolem26Pas encore d'évaluation

- Revenue Regulations Implementing Disability Act Tax BenefitsDocument23 pagesRevenue Regulations Implementing Disability Act Tax BenefitsKathylene GomezPas encore d'évaluation

- BengalDocument2 pagesBengalRashedul IslamPas encore d'évaluation

- State Electrical Schedule 05-14Document4 pagesState Electrical Schedule 05-14api-178722618Pas encore d'évaluation

- RTC-Branch 40, Silay City: Calendar of CasesDocument2 pagesRTC-Branch 40, Silay City: Calendar of CasesBobby AdamsPas encore d'évaluation

- S Det FR CancelledDocument2 pagesS Det FR CancelledrajeshbantaPas encore d'évaluation

- TREMIX CONCRETE FLOORING METHODOLOGYDocument37 pagesTREMIX CONCRETE FLOORING METHODOLOGYthinkwinPas encore d'évaluation

- part tower lightDocument2 pagespart tower lightSilvia GosalPas encore d'évaluation

- Alexan MuseumDocument1 pageAlexan MuseumHouston ChroniclePas encore d'évaluation

- Steven Mccaul Juvenile 3Document3 pagesSteven Mccaul Juvenile 3api-251591949Pas encore d'évaluation

- T-Pad IS703CDocument5 pagesT-Pad IS703CKajal SarkarPas encore d'évaluation

- Production Process of Amul LassiDocument6 pagesProduction Process of Amul LassiManeesh ThapaPas encore d'évaluation

- f.39 - Tower MKD Tb-50 ModelDocument1 pagef.39 - Tower MKD Tb-50 ModelAnil MarturiPas encore d'évaluation

- MOSIS Acceptance Test Results for 0.18um TechnologyDocument2 pagesMOSIS Acceptance Test Results for 0.18um TechnologyPraveen VsPas encore d'évaluation

- HRM Case Study: How Cavin Kare Overcame Bureaucracy and Improved Productivity Through Performance ManagementDocument7 pagesHRM Case Study: How Cavin Kare Overcame Bureaucracy and Improved Productivity Through Performance ManagementSuvhrajeet ChakrabortyPas encore d'évaluation

- OutplacementDocument1 pageOutplacementSoftExWorldwidePas encore d'évaluation

- Sweet desserts and healthy treats for Lima's young professionalsDocument8 pagesSweet desserts and healthy treats for Lima's young professionalsDamariz VargasPas encore d'évaluation

- Ald-2i 315-091464-13 PDFDocument4 pagesAld-2i 315-091464-13 PDFogautierPas encore d'évaluation

- Progress Report 2Document1 pageProgress Report 2api-246421172Pas encore d'évaluation

- SEO Optimized Title for Tower Structure DrawingDocument1 pageSEO Optimized Title for Tower Structure DrawingAnil MarturiPas encore d'évaluation

- HK Mk.23 SOCOM Pistol User ManualDocument48 pagesHK Mk.23 SOCOM Pistol User ManualGasMaskBobPas encore d'évaluation

- Steven Mccaul Juvenile 1Document2 pagesSteven Mccaul Juvenile 1api-251591949Pas encore d'évaluation

- Cash Flow2Document28 pagesCash Flow2Yhon Eddy Vilca PeraltaPas encore d'évaluation

- Tugas Besar SPTK - 1Document10 pagesTugas Besar SPTK - 1BagasPas encore d'évaluation

- Subject to Jurisdiction of Courts in MumbaiDocument1 pageSubject to Jurisdiction of Courts in MumbaiLucky ChougalePas encore d'évaluation

- University of Delhi MBE Part-II Exam 2011 ResultsDocument4 pagesUniversity of Delhi MBE Part-II Exam 2011 ResultsRajesh GuptaPas encore d'évaluation

- 1/16 Scale Models - Special Sets: PZ - Kpfw. VI, Tiger I, Ausf.E (SD - Kfz. 181) - Early VersionDocument5 pages1/16 Scale Models - Special Sets: PZ - Kpfw. VI, Tiger I, Ausf.E (SD - Kfz. 181) - Early VersionsharkmouthPas encore d'évaluation

- S-010-Rencana Struktur Kolom & Balok LT - Atap.dwg PDFDocument1 pageS-010-Rencana Struktur Kolom & Balok LT - Atap.dwg PDFArsitek RumahPas encore d'évaluation

- Pricelist Bulan Januari CV Unggal PTI Ersada: Type Spesifikasi Harga (Idr) PromoDocument2 pagesPricelist Bulan Januari CV Unggal PTI Ersada: Type Spesifikasi Harga (Idr) Promosekar ayuPas encore d'évaluation

- How To Build PM ProgramDocument21 pagesHow To Build PM ProgramishoneyPas encore d'évaluation

- 40 KMDocument6 pages40 KMPetre LacatusuPas encore d'évaluation

- Surat It Company NameDocument23 pagesSurat It Company NameParmar NileshPas encore d'évaluation

- PD 14770 Famome1Document6 pagesPD 14770 Famome1zamplerrPas encore d'évaluation

- GP Presentation LEONIDocument21 pagesGP Presentation LEONIعلي اسامة عدلي ابراهيمPas encore d'évaluation

- All WinnerDocument1 pageAll WinnerDivertopPas encore d'évaluation

- 28 Agust 2016 Ibu Titin PDFDocument1 page28 Agust 2016 Ibu Titin PDFMaman HelmanaPas encore d'évaluation

- Computer Integrated ConstructionD'EverandComputer Integrated ConstructionH. WagterPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 412Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 412vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 416Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 416vivekPas encore d'évaluation

- Stress Check Rare MaxDocument1 pageStress Check Rare MaxvivekPas encore d'évaluation

- EROWDocument138 pagesEROWvivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 421Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 421vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 234Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 234vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 20Document1 pageDesign of 15m Span Superstructure Re - 20vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 415Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 415vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 387Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 387vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 233Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 233vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 17Document1 pageDesign of 15m Span Superstructure Re - 17VivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 119Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 119vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 19Document1 pageDesign of 15m Span Superstructure Re - 19vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 379Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 379vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 232Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 232vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 231Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 231vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 19Document1 pageDesign of 15m Span Superstructure Re - 19vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 230Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 230vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 10Document1 pageDesign of 15m Span Superstructure Re - 10vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 18Document1 pageDesign of 15m Span Superstructure Re - 18vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 5Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 5vivekPas encore d'évaluation

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 4Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 4vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 20Document1 pageDesign of 15m Span Superstructure Re - 20vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 62Document1 pageDesign of 15m Span Superstructure Re - 62vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 63Document1 pageDesign of 15m Span Superstructure Re - 63vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 64 PDFDocument1 pageDesign of 15m Span Superstructure Re - 64 PDFvivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 4Document1 pageDesign of 15m Span Superstructure Re - 4vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Design of 15m Span Superstructure Re - 3Document1 pageDesign of 15m Span Superstructure Re - 3vivekPas encore d'évaluation

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Automatic Paint Spraying With Conveyor SystemDocument3 pagesAutomatic Paint Spraying With Conveyor Systemieee4mybusinessonlyPas encore d'évaluation

- Case Study On Plant Location and Plant Layout of Pharmaceutical IndustryDocument10 pagesCase Study On Plant Location and Plant Layout of Pharmaceutical IndustryJfjf86% (7)

- MCBDocument6 pagesMCBAnonymous ufMAGXcskMPas encore d'évaluation

- 50zpa 06pdDocument22 pages50zpa 06pdMayki Flores LópezPas encore d'évaluation

- Insulating Systems For High-Voltage Rotating MachinesDocument16 pagesInsulating Systems For High-Voltage Rotating MachinesNikulin JoelPas encore d'évaluation

- Cod.1828 - r4 Nema InputDocument306 pagesCod.1828 - r4 Nema InputidontlikeebooksPas encore d'évaluation

- 3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsDocument16 pages3M Cold Shrink Silicone Rubber Termination QT-III: InstructionsEliazer GonzalezPas encore d'évaluation

- CT - L1, L2Document9 pagesCT - L1, L2Rohna IqbalPas encore d'évaluation

- AASHTO M 320-10 Performance Graded Asphalt BinderDocument7 pagesAASHTO M 320-10 Performance Graded Asphalt BinderplavingalneemaPas encore d'évaluation

- Atrita Pulverizer Products and ServicesDocument36 pagesAtrita Pulverizer Products and ServicesYousuf AliPas encore d'évaluation

- Estimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingDocument3 pagesEstimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingNilton Santillan100% (1)

- 01 Heating PL 2017 Rs v03 Svu 5.4 FinalDocument77 pages01 Heating PL 2017 Rs v03 Svu 5.4 FinalKajak Klub DrinaPas encore d'évaluation

- Olefins Production PDFDocument64 pagesOlefins Production PDFAnonymous 0zrCNQPas encore d'évaluation

- BurnerDocument33 pagesBurnertoficPas encore d'évaluation

- Pe301, C Tech. CH.4 Melting and CleaningDocument49 pagesPe301, C Tech. CH.4 Melting and Cleaningakshatkumargarg 2K20PE09Pas encore d'évaluation

- Lennox G26 Installation InstructionsDocument31 pagesLennox G26 Installation Instructionslinkheating100% (1)

- Pocket Guide To Brick ConstructionsDocument130 pagesPocket Guide To Brick ConstructionsLeontin Leon100% (3)

- Flue Gas Cooler Brochure - 0 PDFDocument1 pageFlue Gas Cooler Brochure - 0 PDFSriram RamanujamPas encore d'évaluation

- Grade 9 Assessment Tasks: Term 2 Matter and MaterialsDocument74 pagesGrade 9 Assessment Tasks: Term 2 Matter and MaterialsSaesha MahabeerPas encore d'évaluation

- Search ResultsDocument3 pagesSearch ResultsSanjay MehtaPas encore d'évaluation

- GT h120k FipaDocument1 pageGT h120k FipaHIDRAFLUIDPas encore d'évaluation

- Nitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes RapidlyDocument14 pagesNitroglycerine, C3H5N3O9, Is An Explosive Which, On Detonation, Decomposes Rapidlyapi-25909541Pas encore d'évaluation

- Shower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDDocument4 pagesShower Tile - Over Tray Installation Guide Wet Area Solutions (Aust) Pty LTDpaulnidPas encore d'évaluation

- Tutorial 1Document4 pagesTutorial 1Kevin TanPas encore d'évaluation

- English For Industrial Machinery StudentsDocument4 pagesEnglish For Industrial Machinery StudentsDíaz YvonnePas encore d'évaluation

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaPas encore d'évaluation

- Crane Packing ListDocument2 pagesCrane Packing Listmanas3sPas encore d'évaluation

- Brazing Methods GuideDocument9 pagesBrazing Methods GuideVitorHugoPas encore d'évaluation

- Gdi Mussel Presentation 11Document37 pagesGdi Mussel Presentation 11yesim53Pas encore d'évaluation