Académique Documents

Professionnel Documents

Culture Documents

SV GB Zubh 104-123 PDF

Transféré par

Titi Mulat KusumaningrumDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SV GB Zubh 104-123 PDF

Transféré par

Titi Mulat KusumaningrumDroits d'auteur :

Formats disponibles

Busbars

and accessories

Busbars of E-Cu 57

to DIN 1759, DIN 40 500. Length: 2400 mm/bar.

Size Weight/bar

Packs of Model No. SV

mm kg

12 x 5 1.28 6 3580.000

15 x 5 1.60 6 3581.000

20 x 5 2.14 6 3582.000

25 x 5 2.67 6 3583.000

30 x 5 3.20 6 3584.000

12 x 10 2.56 6 3580.100

15 x 10 3.20 6 3581.100

20 x 10 4.27 6 3585.000

30 x 10 6.41 6 3586.000

40 x 10 8.55 3 3587.000

50 x 10 10.68 3 3588.000

60 x 10 12.82 3 3589.000

80 x 10 17.09 3 3590.000

Busbar connectors SV 9350.070

M8

For connecting busbars E-Cu; no drilling

required.

For busbars

12 x 5 to 15 x 10 mm.

Tightening torque: 10 Nm.

Material:

10

Brass. Nickel-plated surface finish. ma

x.

55

Packs Model No.

Application

of SV

Single connection 3 9350.070

SV 9320.020 SV 9320.030

M8 M8

For busbars

20 x 5 to 30 x 10 mm.

Tightening torque: 20 Nm.

Material:

Sheet steel, yellow passivated (top). 0

14

E-Cu silver plated (contact plate).

45

Packs Model No.

Application

of SV 0

11

Single connection 3 9320.020 0–

10

Baying connection* 3 9320.030

* From enclosure to enclosure

12 B

Base isolators

For configuring busbar systems with any

given bar centre distances and for

assembling PE or PEN bars.

ØC

Material:

M10

Duroplastic polyester (UP resin).

Continuous operating temperature: D D

max. 135°C. A

Technical specifications Model No. SV A B ØC D

Rated operating 3031.000 40 SW 36 32 15

1 kV 1 kV

voltage 3032.000 50 SW 50 42 19

Tensile strength 12 kN 13 kN

Torsional strength 75 Nm 90 Nm

Bending strength 6 kN 6 kN

Tightening torque 40 Nm 40 Nm

Model No. SV 3031.000 3032.000

Supply includes:

Packs of 6

104 Rittal Power distribution

Laminated copper bars

and accessories

Laminated copper bars Rittal Flexibar “S”

Length: 2000 mm/bar.

Characteristic

Configuration 1) In In In curve Installation Model No.

mm at 50 K 2) at 30 K 2) at 10 K 2)

(short-circuit type SV

resistance)

6 x 9.0 x 0.8 250 A 220 A 120 A – – 3565.000

6 x 13.0 x 0.5 200 A 150 A 110 A – – 3566.000

4 x 15.5 x 0.8 300 A 210 A 140 A – – 3567.000

6 x 15.5 x 0.8 350 A 290 A 170 A a 1 3568.000

10 x 15.5 x 0.8 450 A 350 A 190 A a 1 3569.000

5 x 20.0 x 1.0 400 A 300 A 180 A a 1 3570.000

Material: 5 x 24.0 x 1.0 450 A 370 A 230 A a 1 3571.000

Cu lamina 10 x 24.0 x 1.0 800 A 600 A 340 A b 1 3572.000

● High-purity electrolyte copper F20 5 x 32.0 x 1.0 550 A 470 A 280 A b 2/3 3573.000

Insulation 10 x 32.0 x 1.0 1000 A 800 A 460 A c 2/3 3574.000

● High-strength vinyl compound 5 x 40.0 x 1.0 800 A 600 A 340 A b 2/3 3575.000

● Expansion 370 %

● Temperature range: 10 x 40.0 x 1.0 1200 A 950 A 500 A c 2/3 3576.000

–30°C to +105°C 5 x 50.0 x 1.0 900 A 700 A 400 A b 2/3 3577.000

● Flame retardant version to UL 94-V0 10 x 50.0 x 1.0 1400 A 1000 A 600 A c 2/3 3578.000

● Dielectric strength: 20 kV/mm

10 x 63.0 x 1.0 1600 A 1240 A 715 A d 2/3 3579.000

1) Number of lamina x lamina width x lamina thickness

2) The conductor temperature of the laminated copper bar is derived from the sum total of

the ambient temperature and the temperature increase.

Example: SV 3565.000 loaded with 220 A, i.e. the temperature increases by 30 K.

Short-circuit resistance diagram At an ambient temperature of 35°C, this produces a resultant conductor temperature of

see page 119. 35°C + 30 K = 65°C.

Supply includes:

Packs of 1

Universal support Packs of Model No. SV

For the attachment of laminated copper 3 3079.000

bars from 20 x 5 to 63 x 10 mm.

Material:

Fibreglass-reinforced, thermoplastic

polyester (PBT).

Fire protection corresponding to UL 94-V0.

Supply includes:

Including screws and “U” nuts for mounting

on PS/TS mounting rails.

and accessories

Busbars

23 30

15

49

18

15

Universal holder Packs of Model No. SV

For attaching laminated copper bars from 3 sets 3079.010

40 x 5 to 100 x 10 mm.

Material:

Fibreglass-reinforced, thermoplastic Accessories:

polyester (PBT). C rails 30/15 to EN 50 024 –

Fire protection corresponding to UL 94-V0. see Cat. 30, page 980.

Supply includes:

Including screws and sliding nuts for

attaching to C rails.

Rittal Power distribution 105

Rittal SV Software

Rittal SV-Plan

Rittal SV-Plan is an innovative tool for ● Planning certainty, thanks to logical ● Integration of a CAD interface based

simple, time-saving project planning of allocation e.g. of standard commercially on Eplan View.

Rittal SV busbar systems. available power circuit-breakers to Rittal ● Project documentation with

The network-compatible, multi-lingual component adaptors. calculations, parts lists and CAD

software package includes the following ● Detailed system and product information system assembly drawing.

functions: in the form of tender texts, product ● Interfaces to all standard Windows

● Simple, menu-assisted dialogues for information, assembly instructions, CAD applications such as WinWord.

system and product selection with drawings etc. ● Compatible with Eplan 5.

planning aid. ● Integration of Rittal Power-Plan.

System requirements

Operating system: Windows 95/98, NT,

2000 or XP

RAM: 128 MB

Hard disk capacity: at least 125 MB

Supply includes

CD-ROM

Operating manual

Catalogue on CD-ROM

Language: German/English

Model No. SV 3020.100

106 Rittal Power distribution

Rittal textbook:

Busbar power distribution with Rittal

This textbook covers all applications of

busbar systems in low-voltage

installations. It refers to specific Rittal

products and includes appropriate

provisions, regulations and standards,

including selected excerpts. For the

expert, it also contains suggestions for

new approaches in project planning

and applications.

Packs of Model No. SV

Rittal Power-Plan 1 3023.000

Rittal Power-Plan permits the calculation The following calculations can be

and documentation of busbar system performed with Rittal Power-Plan:

assemblies with reference to the valid ● Testing the short-circuit resistance of

international test requirements. the entire system assembly to

Moreover, the network-compatible, multi- IEC 60 865-1 or DIN VDE 0103.

lingual software package includes ● Testing the rated current load limit of

extensive databases for D/NH fuse the busbar system to DIN 43 671.

inserts to VDE 0636 and standard ● Testing the heat loss of the entire

commercially available power circuit- system assembly, for D/NH fuse inserts

breakers (freely editable). to VDE 0636.

● Testing all data inputs for plausibility

SV software

with corresponding, clear error

messages.

● Calculations/documentation in

accordance with IEC 60 439-1 or

EN 60 439 and DIN VDE 0660

part 500.

System requirements

Operating system: Windows 95/98 or NT

RAM: 8 MB

Memory space required: 20 MB

Supply includes

CD-ROM

Operating manual

Language: German/English

Model No. SV 3020.000

Rittal Power distribution 107

Short-circuit resistance diagrams

Mini-PLS busbar support Busbar support Busbar support

up to 250 A, 3-pole up to 450 A, 3-pole up to 800 A

40 mm bar centre distance. 60 mm bar centre distance. 60 mm bar centre distance.

Rated current up to 250 A, rated Rated current up to 450 A, rated Rated current up to 800 A, rated

operating voltage up to 690 V AC, operating voltage up to 1000 V AC, operating voltage up to 1000 V AC,

50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660.

Bar accommodation 30 x 5 mm.

Basis of test: Basis of test:

VDE 0660, part 500/IEC 60 439. Basis of test: VDE 0660, part 500/IEC 60 439.

VDE 0660, part 500/IEC 60 439.

Test implemented: Test implemented:

Dynamic short-circuit resistance to Test implemented: Dynamic short-circuit resistance to

IEC 60 439. Dynamic short-circuit resistance to IEC 60 439.

IEC 60 439.

SV 9600.000 SV 3000.000 (3-pole)

40

SV 3066.000 SV 3050.000 (2-pole)

100

SV 3064.000 (4-pole)

35 100

95

lp short-circuit current [kA]

95 a

30 90

90 b

85

25

85 c

80

20 d

80

lp short-circuit current [kA]

75

lp short-circuit current [kA]

15 75

70

70

10 65

50 100 150 200 250 300 350 400

65

Busbar support spacing [mm] 60

60

55

55

50

50

45

e

Busbar support 40

45

up to 360 A, 3-pole 35

40 f

40 mm bar centre distance. 35

g

Rated current up to 360 A, rated 30

200 300 400 500 600

operating voltage up to 1000 V AC, 30

Busbar support spacing [mm] 200 300 400 500 600

50/60 Hz to VDE 0660.

Busbar support spacing [mm]

Calculation basis:

VDE 0103/IEC 60 865.

Busbar E-Cu Rated current

Curve

(mm) (A)

SV 9350.000

75 12 x 5 210 g

a

70 12 x 10 340 f

65 b 15 x 3 187 f

60 15 x 4 210 f

lp short-circuit current [kA]

c

55

15 x 5 260 f

50

16 x 3 198 f

16 x 4 225 f

45

16 x 5 280 f

40

d 16 x 8 397 e

35

20 x 5 319 e

30

20 x 10 497 c

25

25 x 5 384 d

20

150 200 250 300 350 400 30 x 5 447 b

Busbar support spacing [mm] 30 x 10 800 a

Busbar E-Cu Rated current

Curve Busbar Rated

(mm) up to (A)

E-Cu current Curve

12 x 5 210 d mm (inches) (A)

12 x 10 340 b 9.53 x 25.40 (3/8 x 1˝) 599 a

15 x 5 260 c 6.35 x 25.40 (1/4 x 1˝) 449 d

15 x 10 360 a 4.76 x 25.40 (3/16 x 1˝) 349 d

3.18 x 25.40 (1/8 x 1˝) 299 d

9.53 x 19.05 (3/8 x 3/4˝) 449 a

6.35 x 12.70 (1/4 x 1/2˝) 249 f

108 Rittal Power distribution

PLS busbar supports Busbar support Busbar support

up to 800 A, 3-pole up to 1250 A, 3-pole up to 2500 A, 3-pole

60 mm bar centre distance. 100 mm bar centre distance. 150 mm bar centre distance.

Rated current up to 800 A, rated Rated current up to 1250 A, rated Rated current up to 2500 A, rated

operating voltage up to 1000 V AC, operating voltage up to 1000 V AC, operating voltage up to 1000 V AC,

50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660.

Bar accommodation 3 x 2 x 80 x 10 mm.

Basis of test: Basis of test:

VDE 0660, part 500/IEC 60 439. VDE 0660, part 500/IEC 60 439. Basis of test:

VDE 0660, part 500/IEC 60 439.

Test implemented: Test implemented:

Dynamic short-circuit resistance to Dynamic short-circuit resistance to Test implemented:

IEC 60 439. IEC 60 439. Dynamic short-circuit resistance to

IEC 60 439.

SV 3500.000 SV 3073.000

60 110

SV 3055.000

a 160

105

55

100

150

lp short-circuit current [kA]

95

50

b 140

90

lp short-circuit current [kA]

45 85

130

80

lp short-circuit current [kA]

40

75 120

d

70

35 110

65

c

30 60 100

200 300 400 500 600

Busbar support spacing [mm]

25 90

20 Busbar E-Cu Rated current 80

Curve 150 200 300 400 500 600 700 800

(mm) up to (A)

Busbar support spacing [mm]

15 30 x 10 800 d

40 x 10 850 c

10

0 100 200 300 400 500 600 50 x 10 1000 b

Busbar support spacing [mm] 60 x 10 1250 a

PLS busbar support Busbar support Busbar support

up to 1600 A, 3-pole up to 1600 A, 3-pole up to 3000 A, 3-pole

60 mm bar centre distance. 185 mm bar centre distance. 150 mm bar centre distance.

Rated current up to 1600 A, rated Rated current up to 1600 A, rated Rated current up to 3000 A, rated

operating voltage up to 1000 V AC, operating voltage up to 1000 V AC, operating voltage up to 1000 V AC,

50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660. 50/60 Hz to VDE 0660.

Bar accommodation 3 x 2 x 100 x 10 mm.

Basis of test: Basis of test:

VDE 0660, part 500/IEC 60 439. VDE 0660, part 500/IEC 60 439. Basis of test:

Short-circuit

VDE 0660, part 500/IEC 60 439.

resistance

Test implemented: Test implemented:

diagrams

Dynamic short-circuit resistance to Dynamic short-circuit resistance to Test implemented:

IEC 60 439. IEC 60 439. Dynamic short-circuit resistance to

IEC 60 439.

SV 3510.000 SV 3052.000

80 160

SV 3057.000

160

150

70 a

lp short-circuit current [kA]

140 150

60 130

b

lp short-circuit current [kA]

140

120

lp short-circuit current [kA]

50

110 130

c

100

40 120

90

30 110

80

200 400 600 800 1000

20 Busbar support spacing [mm] 100

10 Busbar E-Cu Rated current 90

0 100 200 300 400 500 600 Curve

(mm) up to (A)

Busbar support spacing [mm] 80

50 x 10 1000 c 150 200 300 400 500 600 700 800

60 x 10 1250 b Busbar support spacing [mm]

80 x 10 1600 a

Rittal Power distribution 109

Overview

Power circuit-breakers / starter combinations

Mini-PLS component adaptors 12 A/25 A 40 mm Mini-PLS component adaptors 40 A/100 A 40 mm

Page 22 Page 24

Make/model Model No. SV Accessories

Moeller Make/model Model No. SV

Model No.

PKM0... 9614.100 9615.100 SV

PKZM0-... 9614.100 9615.100

PKZM0-...T 9614.100 9615.100 Moeller

PKZM0-../E-10-D 9614.100 9615.100 NZM 1 9629.000 – –

PKZM0-../0.-. 9614.100 9615.100 PKZ2/ZM-... 9627.000 9628.000 –

PKZM0-../S00-11 9614.100 9615.100 PKZ2/ZM-...-8 9627.000 9628.000 –

PKZM0-../SE00-11 9614.100 9615.100 PKZ2/ZM-.../SE1A/11 9628.000 – –

PKZ2/ZM-... PKZ2/ZM-.../S 9628.000 – –

(max. 25 A) 9625.000 9626.000 PKZ2/SE1A/11 9628.000 – –

PKZ2/ZM-...-8 PKZ2/S 9628.000 – –

(max. 25 A) 9625.000 9626.000 PKZM4-...

PKZM0-.../E01-G-W 9629.010 – (max. 40 A) 9617.000 – –

PKZM0-.../.-..-W 9629.010 – PKZM4-... 9629.000 – 9320.120

PKZM0-.../.-..WMF 9629.030 – Siemens

PKZM4-...

(max. 25 A) 9615.000 – S2

3RV1. 31-4..10

Siemens (max. 40 A) 9617.000 – –

S0 3RV1. 31-4..10 9629.000 – 9320.120

3RA11 20...2.-0... 9614.1001) – 3RW30 3.-1AB..

3RA12 20-....-... 9629.020 – (max. 40 A) 9617.000 – –

3RV1. 21-...1. 9614.100 9615.100 3RW30 3.-1AB.. 9629.000 – 9320.120

3RW30 2.-1AB.. 9614.100 9615.100 S3

S00 3RV1. 4.-4..10 9629.000 – 9320.120

3RA11 10...1.-1... 9614.1001) – 3RW30 4.-1AB.. 9629.000 – 9320.120

3RA12 10-...-... 9629.010 – ABB

3RV10 11-..A1. 9614.100 9615.100

3RW30 1.-1CB.4 9614.100 9615.100 MS450-..

S00 Cage Clamp (max. 40 A) 9617.000 – –

RV10 11-..A20 9614.110 – MS450-.. 9629.000 – 9320.120

S2 MS451-..

3RV1. 31-4..10 (max. 40 A) 9617.000 – –

(max. 25 A) 9615.000 – MS451-.. 9629.000 – 9320.120

3RW30 3.-1AB.. MS495-.. 9629.000 – 9320.120

(max. 25 A) 9615.000 – MS496-.. 9629.000 – 9320.120

MS497-.. 9629.000 – 9320.120

ABB Sace

MS25-TM-.. 9614.000 9615.000 LNA 32 9629.000 – –

MS116-.. 9614.100 9615.100 LNA 63 9629.000 – –

MS225-.. 9614.000 9615.000 LNA 100 9629.000 – –

MS325-.. 9614.000 9615.000 Tmax

MS450-.. T1 9629.000 – –

(max. 25 A) 9615.000 – T2 9629.000 – –

MS451-.. AEG

(max. 25 A) 9615.000 –

Mbs100 9629.000 – 9320.120

AEG

Allen Bradley

Mbs25 9614.100 9615.100

Mbs28 9614.000 9615.000 140M-F8.-...

(max. 40 A) 9616.000 9617.000 –

Allen Bradley 140-CMN-.... 9629.000 – 9320.120

103-...R 9614.100 9615.100 Merlin Gerin

107-...R 9629.010 –

140M-...-... 9614.100 9615.100 Compact NS 80H-MA 9629.000 – –

140-MN-... 9614.100 9615.100 Telemecanique

190-M1-... 9615.1001) – GK3-EF..

190-M2-... 9615.1001) – (max. 40 A) 9628.000 – –

Telemecanique GK3-EF.. 9629.000 – 9320.120

GK3-EF.. GV3-M...

(max. 25 A) 9626.000 – (max. 40 A) 9628.000 – –

GV2-.... 9614.100 9615.100 GV3-M... 9629.000 – 9320.120

GV2-M..K1.. 9614.100 9615.100

GV2-M..K2.. 9629.010 –

GV2-P..D2.. 9629.030 –

GV2-P..D1.. 9615.1001) –

GV3-M... 9626.000 –

LD1-L.030

(max. 25 A) 9615.100 –

LH4-N1....7 9614.100 9615.100

LH4-N2....7 9629.010 –

1) Support rail must be offset

110 Rittal Power distribution

40 mm

Mini-PLS quick-fit component adaptors 25 A Multi-functional component adaptor 40 A

40 mm 40 mm

(32 A) Component adaptor 100 A

Page 23 Page 31

Make/model Model No. SV For bar thickness

Moeller Make/model 5 mm 10 mm

PKM0... 9619.000 Model No. SV Model No. SV

PKZM0-... 9619.000 Allen Bradley

PKZM0-...T 9619.000 140M-F8.-... (max. 40 A) 9350.2001) 9350.2101)

PKZM0-../S00-11 9620.000 140-CMN-... 9350.420 9350.430

PKZM0-../SE00-11 9620.000

Merlin Gerin

Siemens

Compact NS 80H-MA 9350.420 9350.430

S0

3RA11 20...2.-0... 9622.000 Telemecanique

3RV1. 21-...1. 9622.000 GK3-EF.. 9350.420 9350.430

ABB GV3-M... 9350.420 9350.430

1) The bottom support rails is eliminated

MS25-TM-.. 9622.000

AEG

Mbs25 9618.000

Allen Bradley

Multi-functional component adaptor 12 A/25 A 40 mm

140M-...-... 9620.000

Page 28/29

General Electric

SFKO1 9618.000 For bar thickness Accessories

Schiele Make/model 5 mm 10 mm

Model No. Model No. Model No.

MSU-K 9618.000 SV SV SV

Telemecanique Moeller

GV2-LE 9621.000 PKM0... 9350.100 9350.110 –

GV2-M 9621.000 PKZM0-... 9350.100 9350.110 –

GV2-P 9622.000 PKZM0-...T 9350.100 9350.110 –

PKZM0-../0.-. 9350.100 9350.110 –

PKM0.../E01-G-W 9350.280 9350.290 –

PKZM0-../E-10-D 9350.100 9350.110 –

Multi-functional component adaptor 40 A PKZM0-../S00-11 9350.100 9350.110 9320.140

40 mm

Component adaptor 100 A PKZM0-../SE00-11 9350.100 9350.110 9320.140

Page 31 PKZM0-.../.-..-W 9350.280 9350.290 –

For bar thickness PKZM0-.../.-..-WMF 9350.3201) 9350.3301) –

Make/model 5 mm 10 mm Siemens

Model No. SV Model No. SV S0

Moeller 3RA11 20-...2.-0... 9350.100 9350.110 9320.140

3RA12 20-....-... 9350.300 9350.310 –

NZM 1 9350.420 9350.430 3RV1. 21-...1. 9350.100 9350.110 –

PKZM4-... (max. 40 A) 9350.340 9350.350 3RW30 2.-1AB.. 9350.100 9350.110 –

PKZM4-... 9350.420 9350.430 S00

Siemens 3RA11 10...1.-1... 9350.100 9350.110 9320.140

S2 3RA12 10-....-... 9350.2802) 9350.2902) 9320.140

3RV1. 31-4..10 (max. 40 A) 9350.340 9350.350 3RV10 11-..A1. 9350.100 9350.110 –

3RV1. 31-4..10 9350.420 9350.430 3RW30 1.-1CB.4 9350.100 9350.110 –

Power circuit-

3RW30 3.-1AB.. (max. 40 A) 9350.340 9350.350 S00 Cage Clamp

3RW30 3.-1AB.. 9350.420 9350.430 3RV10 11-..A20 9350.080 9350.090 –

Overview

breakers

S3 ABB

3RV1. 4.-4..10 9350.420 9350.430 MS116-.. 9350.100 9350.110 –

3RW30 4.-1AB.. 9350.420 9350.430

AEG

ABB

Mbs25 9350.100 9350.110 –

DLA..-30 9350.2002) 9350.2102)

MS25-TM-.. 9350.2001) 9350.2101) Allen Bradley

MS225-.. 9350.2001) 9350.2101) 103-...R 9350.100 9350.110 –

MS325-.. 9350.2001) 9350.2101) 107-...R 9350.280 9350.290 –

MS450-.. (max. 40 A) 9350.340 9350.350 140M-...-... 9350.100 9350.110 –

MS450-.. 9350.420 9350.430 140-MN-... 9350.100 9350.110 –

MS451-.. (max. 40 A) 9350.340 9350.350 190-M1-... 9350.260 9350.270 –

MS451-.. 9350.420 9350.430 190-M2-... 9350.260 9350.270 –

MS495-.. 9350.420 9350.430 Telemecanique

MS496-.. 9350.420 9350.430

MS497-.. 9350.420 9350.430 GV2-.... 9350.100 9350.110 –

Sace GV2-M..K1.. 9350.100 9350.110 –

LNA 32/63/100 9350.420 9350.430 GV2-M..K2.. 9350.280 9350.290 –

GV2-P..D1.. 9350.260 9350.270 –

AEG GV2-P..D2.. 9350.3201) 9350.3301) –

Mbs28 9350.2001) 9350.2101) LD1-L.030 (max. 25 A) 9350.100 9350.110 –

Mbs100 9350.420 9350.430 LH4-N1....7 9350.100 9350.110 –

1) The bottom support rails is eliminated LH4-N2....7 9350.280 9350.290 –

2) The top support rails is eliminated 1) Moeller: The bottom support rails is eliminated

Telemecanique: The upper support rail is offset at a distance of

For additional component types, please refer to the column 125 mm from the lower supp. rail (supp. rail centre-to-centre spac.)

opposite (top of page) 2) Support rail must be offset

Rittal Power distribution 111

Overview

Power circuit-breakers / starter combinations

Multi-functional component adaptor 12 A/25 A 60 mm

Page 50/51

For bar thickness Accessories

Make/model 5 mm 10 mm

Model No. Model No. Model No.

SV SV SV

Moeller

PKM0... 9320.180 9320.190 –

PKZM0-... 9320.180 9320.190 –

PKZM0-...T 9320.180 9320.190 –

PKZM0-../0.-. 9320.180 9320.190 –

PKZM0.../E01-G-W 9320.380 9320.390 –

PKZM0-../E-10-D 9320.180 9320.190 –

PKZM0-../S00-11 9320.180 9320.190 9320.140

PKZM0-../SE00-11 9320.200 9320.210 –

PKZM0-.../.-..-W 9320.380 9320.390 –

PKZM0-.../.-..WMF 9320.4201) 9320.4301) –

Siemens

S0

3RA11 20-...2.-0... 9320.180 9320.190 9320.140

3RA12 20-....-... 9320.400 9320.410 –

3RV1. 21-...1. 9320.180 9320.190 –

3RW30 2.-1AB.. 9320.180 9320.190 –

S00

3RA11 10...1.-1... 9320.180 9320.190 9320.140

3RA12 10-....-... 9320.3801) 9320.3901) 9320.140 Multi-functional component adaptor 40 A 60 mm

3RV10 11-..A1. 9320.180 9320.190 –

Page 53

3RW30 1.-1CB.4 9320.180 9320.190 –

S00 Cage Clamp For bar thickness

3RV10 11-..A20 9320.160 9320.170 – 5 mm 10 mm

Make/model

ABB Model No. Model No.

MS116-.. 9320.180 9320.190 – SV SV

AEG Moeller

Mbs25 9320.180 9320.190 – PKZM4-...

(max. 40 A) 9320.460 9320.470

Allen Bradley

Siemens

103-...R 9320.180 9320.190 –

107-...R 9320.380 9320.390 – S2

140M-...-... 9320.180 9320.190 – 3RV1. 31-4..10

140-MN-... 9320.180 9320.190 – (max. 40 A) 9320.460 9320.470

190-M1-... 9320.440 9320.450 – 3RW30 3.-1AB..

190-M2-... 9320.440 9320.450 – (max. 40 A) 9320.460 9320.470

Telemecanique ABB

GV2-.... 9320.180 9320.190 – MS25-TM-.. 9320.3001) 9320.3101)

GV2-M..K1.. 9320.180 9320.190 – MS225-.. 9320.3001) 9320.3101)

GV2-M..K2.. 9320.380 9320.390 – MS325-.. 9320.3001) 9320.3101)

GV2-P..D1.. 9320.440 9320.450 – MS450-..

GV2-P..D2.. 9320.4202) 9320.4302) – (max. 40 A) 9320.460 9320.470

LD1-L.030 MS451-..

(max. 25 A) 9320.180 9320.190 – (max. 40 A) 9320.460 9320.470

LH4-N1....7 9320.180 9320.190 – DLA..-30 9320.3002) 9320.3102)

LH4-N2....7 9320.380 9320.390 – AEG

1) The bottom support rails is eliminated Mbs28 9320.3001) 9320.3101)

2) The upper support rail is offset at a distance of 125 mm from

Allen Bradley

the lower support rail (support rail centre-to-centre spacing) 140M-F8.-...

(max. 40 A) 9320.3001) 9320.3101)

1) The bottom support rails is eliminated

2) The top support rails is eliminated

112 Rittal Power distribution

60 mm

Component adaptor 63 A 60 mm

Page 56/57

For bar thickness

Make/model 5 mm 10 mm

Model No. SV Model No. SV

Moeller

PKZ2/S 3046.000 3047.000

PKZ2/SE1A/11 3046.000 3047.000

PKZ2/ZM-.../S 3046.000 3047.000

PKZ2/ZM-.../SE1A/11 3046.000 3047.000

PKZM0-../0-SD 3048.0001) 3049.0001)

PKZM0../00(A)-SD 3048.0001) 3049.0001)

PKZM0-../E-10-SD 3048.0001) 3049.0001)

PKZM0-../E-10-G-SD 3048.0001) 3049.0001)

PKZM4-... 3036.000 3037.000

PKZM4-... 3445.000 3445.000

Siemens

S2

3RV1. 31-4..10 3036.000 3037.000

3RV1. 31-4..10 3445.000 3445.000

3RW30 3.-1AB.. 3036.000 3037.000

3RW30 3.-1AB.. 3445.000 3445.000

S3

3RV1. 4.-4..10 (max. 63 A) 3067.000 3068.000

3RW30 4.-1AB.. (max. 63 A) 3067.000 3068.000

Component adaptor 50 A 60 mm ABB

Page 54/55 MS25-TM-.. 3445.000 3445.000

For bar thickness MS25-TM-.. 3446.000 3446.000

Make/model MS225-.. 3445.000 3445.000

5 mm 10 mm MS225-.. 3446.000 3446.000

Model No. SV Model No. SV MS325-.. 3445.000 3445.000

Moeller MS325-.. 3446.000 3446.000

PKZ2/ZM-... 3544.000 3545.000 MS450-.. 3036.000 3037.000

PKZ2/ZM-...-8 3544.000 3545.000 MS450-.. 3445.000 3445.000

PKZM0-.../.-..WMF 3042.0001) 3043.0001) MS451-.. 3036.000 3037.000

Siemens MS451-.. 3445.000 3445.000

MS495-.. (max. 63 A) 3067.000 3068.000

S2 MS496-.. (max. 63 A) 3067.000 3068.000

3RA11 30-...3.-0... 3040.0002) 3041.0002) MS497-.. (max. 63 A) 3067.000 3068.000

3RV10 31-.... 3069.000 3070.000

AEG

ABB

Mbs28 3445.000 3445.000

MS25-TM-.. 3540.000 3541.000 Mbs28 3446.000 3446.000

MS225-.. 3540.000 3541.000

MS325-.. 3540.000 3541.000 Allen Bradley

AEG 140M-F8.-... 3445.000 3445.000

140M-F8.-... 3446.000 3446.000

Mbs28 3540.000 3541.000

Telemecanique

Allen Bradley

GK3-EF.. (max. 63 A) 3067.000 3068.000

140M-F8.-... 3540.000 3541.000 GV3-M... (max. 63 A) 3067.000 3068.000

Power circuit-

Telemecanique LD1-L.030 3067.000 3068.000

GV2-P..D2.. 3042.0002) 3043.0002) LD4-L..30 3067.000 3068.000 Overview

1) One support rail is eliminated

brakers

1) The bottom support rails must be offset

2) One support rail must be offset

Current carrying capacity Conversion factors

of insulated PVC cables at an ambient temperature of +40°C, for the load capacity of cables (DIN EN 60 204-1:1998-11)

installation type E (DIN EN 60 204-1:1998-11) Ambient temperature (°C) Factor

Nominal cross-section (mm2) Current capacity (A) 30 1.15

1.5 16 35 1.08

2.5 22 40 1.00

4 30 45 0.91

6 37 50 0.82

10 52 55 0.71

16 70 60 0.58

25 88

35 114

Rittal Power distribution 113

Technical information

NH isolators, size 000 Electronic fuse monitoring NH fused isolators, sizes 00 to 3

● Thanks to a specially developed ● No separate auxiliary voltage required. ● The cable outlet – top or bottom – is

locking mechanism, the fuse inserts ● Automatic activation following fault selected directly during assembly on

are easily and quickly installed and rectification. the same device. The switch cover unit

rewired. ● Reliable functioning, thanks to surge- is simply rotated through 180°

● A special switching aid pre-stresses proof microelectronics. (sizes 1 to 3).

the lyre contact when the isolator lid is ● Readily accessible connector facilitates ● Reliable isolated or off-load position of

closed. This means that the fuse insert service-friendly connection of the signal the switch cover unit, thanks to the

slides reliably into its final position tracks. integral multi-function key.

without damaging the contact. ● Rapid response behaviour in the event of ● Switch locking can be achieved via the

● Micro-switches for monitoring the lid a fault. installation of padlocks in the closed

position are readily integrated on the and isolated position.

Electronic fuse monitoring may be used in

right and left. ● For inspection purposes, there are

50/60 Hz three-phase circuits ranging from

● The unit can be protected from viewing windows with integral holes in

400 V AC to 690 V AC. The auxiliary

unauthorised switching via the readily the switch cover unit or sliding viewing

voltage required for operation is obtained

accessible sealing device on the front windows.

from the mains voltage (supply end) via live

of the unit. ● Simple external/internal mounting of

puller lugs. Consequently, this function is

● The spaciously designed viewing microswitches to indicate the switch

only available with the mains voltage

window of the isolator lid allows easy position of the NH unit (lid unit).

connected and the isolator lid closed. If

monitoring of the fuse insert indicators.

one or more of the NH fuse inserts is

● Test holes drilled in the viewing window

switched due to a malfunction, an error

allow direct measurement access to

signal is generated. Evaluation is achieved

the contact parts of the fuse inserts.

by comparing the voltage on the puller lugs

with the NH fuse inserts used (differential

voltage ≥ 75 V). In the event of a fault, a

corresponding signal message for further

processing is provided via the separate

relay contacts. Additionally, malfunctions

are visually indicated by a red LED

display, whilst a green LED indicates that

the system is operational.

NH isolator, sizes 00 to 3

● Easy assembly with removable push-in

isolator lid and top mounted contact 13

hazard protection cover. Function 11

● Two-part contact hazard protection block 12

14

cover plate with service-friendly central

unlocking facility allows connection in

accordance with BGV-A2 (VBG 4),

LED LED

even whilst the supply end is live.

● Apart from its protective function, the

design of the NH on-load isolator

facilitates the activation and

deactivation of electrical equipment Electromechanical fuse monitoring

and system components. The connection clamps of the floating

● The units may be actuated whilst live switch contacts which serve as indicators

(see table, “Technical specifications” are arranged on the top of the isolator

page 115). base. This arrangement guarantees

● Micro-switches to indicate the Material:

extremely simple installation. The isolator

switching position of the isolator lid are lids can be removed without disconnecting NH isolators

easily installed via snap-mounting on any pilot wires, in the same way as NH

the left and right. Size Sizes 000/00/1/2/3

isolators without fuse monitoring. Unlike an

● The viewing window integrated into the electronic monitor, this system operates Fibreglass-reinforced

lid unit has test holes which can be Isolator lid

without auxiliary power, yet still performs polyamide

opened by sliding the viewing window, the same functions.

for direct measurement access to the Contact

Fibreglass-reinforced

contact parts of the fuse inserts hazard

polyamide

(see photograph). protection

Isolator Fibreglass-reinforced

chassis polyamide

Wiring diagram Contact

Silver-plated hard copper

L1 L2 L3 22 21 13 14 tracks

NH fused isolators

1 L1 3 L2 5 L3 22 13

Size Sizes 00/1/2/3

21 14

Fibreglass-reinforced

Cover

polyamide

2 T1 4 T2 6 T3

Strip

Duroplastic polyester

chassis

Contact

Silver-plated hard copper

tracks

114 Rittal Power distribution

NH isolators

Technical specifications

to VDE 0660, part 107/IEC 60 947-3

Size

000 000/00 1 2 3

(NH fuse inserts to DIN 43 620)

Rated operating current Ie 100 A 160 A 250 A 400 A 630 A

Conventional thermal current Ith 160 A1) 160 A 250 A 400 A 630 A

Rated operating voltage Ue AC 690 V AC 690 V

Rated insulation voltage Ui 690 V 800 V

Rated surge voltage resistance Uimp 6 kV 8 kV

Conditional rated short-circuit current when

80 kA 50 kA 50 kA 50 kA 50 kA

protected with fuses

AC-22B AC-22B AC-22B AC-22B AC-22B

400 V

Rated breaking capacity to Ie = 100 A Ie = 160 A Ie = 250 A Ie = 400 A Ie = 630 A

VDE 0660, part 107/ AC-21B AC-22B AC-21B AC-21B AC-21B

690 V

IEC 60 947-3 Ie = 100 A Ie = 160 A Ie = 250 A Ie = 400 A Ie = 630 A

(utilisation category) DC-21B DC-21B DC-21B DC-21B DC-21B

440 V2)

Ie = 100 A Ie = 160 A Ie = 250 A Ie = 400 A Ie = 630 A

Mechanical life (switching cycles) 2000 1600 1000 600 600

Permissible ambient temperature –25°C to +55°C

Fire protection corresponding to UL 94-V0

Pv max./fuse insert 7.5 W (9 W1)) 12 W 23 W 34 W 48 W

1) For 95 mm2 connection cross-section (95 mm2 connection pieces available on request).

2) With population of phases L and L .

1 3

Fuse monitoring

Technical specifications Electromechanical fuse monitoring Electronic fuse monitoring

AC 24 V to AC 690 V (50/60 Hz)

Rated operating voltage Ue AC 400 V to AC 690 V (50/60 Hz)

DC 24 V to DC 250 V

Rated surge voltage resistance Uimp 6 kV 6 kV

Response time <2s < 0.5 s

1 normally closed contact, 1 normally closed contact,

Auxiliary contacts

1 normally open contact 1 normally open contact, bounce-free

Load capacity of auxiliary contacts 1.5 A 2A

Permissible ambient temperature –25°C to +55°C –25°C to +55°C

“I” switch dial position (operational) 1 green LED (operational)

Displays

“0” switch dial position (error message) 1 red LED (error message)

Connection of auxiliary contacts Terminal up to 1.5 mm 2 4-pole connector up to 1.5 mm2

NH fuse inserts with contacted, live puller lugs

information

Technical

NH fused isolators

Technical specifications

to VDE 0660, part 107/IEC 60 947-3

Size

00 1 2 3

(NH fuse inserts to DIN 43 620)

Rated operating current Ie 160 A 250 A 400 A 630 A

Conventional thermal current Ith 160 A 250 A 400 A 630 A

Rated operating voltage Ue AC 690 V

Rated insulation voltage Ui 800 V

Rated surge voltage resistance Uimp 8 kV

Conditional rated short-circuit current when

50 kA 50 kA 50 kA 50 kA

protected with fuses

Rated breaking capacity to AC-22B AC-22B AC-22B AC-22B

400 V

VDE 0660, part 107/ Ie = 160 A Ie = 250 A Ie = 400 A Ie = 630 A

IEC 60 947-3 AC-21B AC-21B AC-21B AC-21B

(utilisation category) 690 V

Ie = 160 A Ie = 250 A Ie = 400 A Ie = 630 A

Mechanical life (switching cycles) 1600 1000 1000 1000

Permissible ambient temperature –25°C to +55°C

Fire protection corresponding to UL 94-V0

Pv max./fuse insert 12 W 23 W 34 W 48 W

Rittal Power distribution 115

Technical information

Use of semi-conductor fuses in Semi-conductor fuses type aR/gR/gRL Minimum

Rittal NH switchgear connection cross- Reduction factor

The overload and short-circuit protection IN Operating Heat loss section (Cu) for rated current

Size [W]

of semi-conductor components places [A] category [mm2]

very high demands on the fuse inserts, 00 25 gR 6 4 1.00

due to the time pattern for effective

protection of the defective or damaged 00 35 gR 9 6 1.00

sub-circuit. Because semi-conductor 00 50 gR 12 10 0.87

components have a low thermal capacity, 00 63 gR 15 16 0.87

the integral disconnect value (I2t value) of

00 80 aR 19 25 0.85

the semi-conductor fuse inserts type aR,

gR or gRL must match the integral limit 00 100 aR 21 35 0.85

value of the semi-conductor cell being 00 125 aR 26 50 0.80

protected. Consequently, the tripping 00 160 aR 34 70 0.75

characteristic of the fuse inserts must be

very fast, and overvoltage during the 1 160 gR 24 70 1.00

disconnection process (switching or arc 1 200 gR 27 95 1.00

voltage) must be as minimal as possible. 1 250 gR 30 120 1.00

Compared with fuse inserts for cable

and line protection and transformer 2 250 aR 105 120 0.77

protection, the particular features of 2 315 aR 120 185 0.75

semi-conductor fuse inserts produce a 2 450 aR 140 2 x (30 x 5) 0.75

comparatively high heat loss. The high

3 150 gR 40 70 0.90

heat loss is dissipated to the environment

in the form of thermal energy. Because 3 200 gR 55 95 0.90

NH switchgear only has a limited 3 250 gR 72 120 0.88

capacity to dissipate thermal energy to 3 350 gR 95 240 0.81

the environment, the maximum heat loss

(Pv max./fuse insert) is listed in the 3 500 gR 130 2 x 150 0.76

technical specifications of the NH

switchgear. If the values exceed the heat

loss specified by the manufacturer, the

rated current should be reduced in

accordance with the table opposite, or

the minimum connection cross-section

increased accordingly to encourage heat

dissipation.

116 Rittal Power distribution

Rittal NH bus-mounting on-load Size SIBA IN Pv Pvperm. Operating Reduction

isolators – UL-approved NH Part no. [A] [W] [W] category factor

Product certifications and approvals are 000 20 477 34. 16 3.2 7.5 gRL 1.00

key pre-requisites for the global

acceptance of industrial products. For 000 20 477 34. 20 3.6 7.5 gRL 1.00

this reason, Rittal consistently promotes 000 20 477 34. 25 4.2 7.5 gRL 1.00

international product approvals. The 000 20 477 34. 35 5.2 7.5 gRL 1.00

benefit to customers of UL recognition of

000 20 477 34. 40 5.6 7.5 gRL 1.00

NH bus-mounting on-load isolators,

sizes 000 to 3, is impressively 000 20 477 34. 50 6.5 7.5 gRL 1.00

demonstrated by the safety of Rittal SV 000 20 477 34. 63 7.6 7.5 gRL 1.00

system components. Approval involves 000 20 477 34. 80 8.8 7.5 gRL 0.95

testing a variety of factors, including

response under short-circuit conditions, 00 20 477 34. 16 3.2 10 gRL 1

temperature rise at rated current, 00 20 477 34. 20 3.6 10 gRL 1

dielectric strength, and general 00 20 477 34. 25 4.2 10 gRL 1

mechanical strength of the devices.

Under the UL approvals, Rittal NH bus- 00 20 477 34. 35 5.2 10 gRL 1

mounting on-load isolators are classified 00 20 477 34. 40 5.6 10 gRL 1

strictly as fuse-carriers for NH fuse inserts 00 20 477 34. 50 6.5 10 gRL 1

without a load switching function.

00 20 477 34. 63 7.6 10 gRL 1

UL-approved NH fuse inserts with fusing

recommendations, as shown in the table 00 20 477 34. 80 8.8 10 gRL 1

opposite, are likewise available on the 00 20 477 34. 100 10.5 10 gRL 0.98

market. These are combined semi- 00 20 477 34. 125 12 10 gRL 0.94

conductor and line protection fuses.

1 20 211 34. 63 8 22 gRL 1

information

Thanks to the gRL combination, these NH

fuse inserts boast lower heat losses than 1 20 211 34. 80 9.5 22 gRL 1 Technical

conventional gR semi-conductor fuses. 1 20 211 34. 100 12 22 gRL 1

1 20 211 34. 125 12.6 22 gRL 1

1 20 211 34. 160 23 22 gRL 0.98

1 20 211 34. 200 27 22 gRL 0.93

1 20 211 34. 250 33 22 gRL 0.86

1 20 211 34. 315 44 22 gRL 0.78

2 20 212 34. 160 23 33 gRL 1

2 20 212 34. 200 27 33 gRL 1

2 20 212 34. 250 30 33 gRL 1

2 20 212 34. 315 40 33 gRL 0.94

2 20 212 34. 350 43 33 gRL 0.92

2 20 212 34. 400 48 33 gRL 0.88

2 20 212 34. 450 50 33 gRL 0.86

2 20 212 34. 500 63 33 gRL 0.81

Rittal Power distribution 117

Technical information

Assembly and function

of bus-mounting fuse bases

For clamping screw fastening For snap-on mounting Material:

● Bus-mounting fuse base

Support part: Support part: Fibreglass-reinforced, thermoplastic

Electrical threaded base with integral Electrical threaded base with integral cable polyester (PBT).

cable outlet terminals. On the bottom are outlet terminals. The contact plates which Continuous operating temperature:

the contact plates with integral screw supply the infeed to the base are arranged max. 140°C.

terminals which are used to supply the on the underside, with integral spring- Fire protection corresponding to

component with power. Components D II loaded foot pieces for snap-on mounting UL 94-V0.

and D III are fitted with D screw fitting with a bar thickness of 5 or 10 mm. The ● Contact hazard protection cover

inserts to DIN 49 516. The D 02 bus- D bus-mounting fuse bases are fitted with Talcum-reinforced polypropylene.

mounting fuse base is prepared for gauge rings to DIN 49 362. The D 02 Continuous operating temperature:

D socket fitting inserts to DIN 49 523. bus-mounting fuse base is prepared for max. 100°C.

The contact hazard protection covers are D socket fitting inserts to DIN 49 523. Fire protection corresponding to

attached using the plug-type system. The contact hazard protection covers are UL 94-V0.

attached using the plug-type system.

Benefits: Specifications:

● Reliable-contact, shake-proof Benefits: D 02 – DIN 49 524

connection or fastening to the busbars ● Reliable-contact connection or D II – DIN 49 510/49 326

with infinitely adjustable screw attachment to the busbars, thanks to D III – DIN 49 510/49 327

terminals. special spring-loaded foot pieces.

● Assembly benefits and service ● Secure positioning on the busbar, thanks

friendliness thanks to direct screw to a special functional element for

fastening of the components onto automatic latching and manual

pre-assembled or existing busbar unlocking.

systems. This eliminates the time ● Safety is ensured by the Rittal Contact-

consuming work of adjustment and Plus system. The contact plate system

alignment. effectively separates electrical

● Time-saving dismantling of the bus- contacting from mechanical connection.

mounting fuse bases, even whilst the ● Time-saving dismantling of the bus-

busbar system is live. mounting fuse base by simply unlocking

● Optimum cable routing on the outlet the latching component, even with live

side, thanks to adequate recesses on busbar systems.

the body of the base. ● Optimum cable routing on the outlet

● A high level of contact reliability and side, thanks to adequate recesses on

prevention of contact heat and scorch the body of the base.

points, thanks to the use of contact ● The contact plate system with surface

plates. The fuse inserts do not make contact ensures a high level of contact

direct contact with the busbars. This stability for the fuse inserts and prevents

prevents the possibility of the busbars contact heat and scorch points. The fuse

being destroyed by contact arc, should inserts do not make direct contact with

the fuse screw cap be inadequately the busbars. This prevents the possibility

tightened or loosened as a result of of the busbars being destroyed by

vibration. contact arc, should the fuse screw cap

● Special contact plate technology be inadequately tightened or loosened

permits direct, final contact of the as a result of vibration.

components on the busbars during ● The Rittal contact plate system ensures

assembly. Consequently, with the Rittal final fastening and secure contact of the

system, final attachment and contact 3-pin base on the supply busbar, even

is not determined by screw-fastening without the fuse inserts in place.

of the fuse inserts.

118 Rittal Power distribution

Laminated copper bars

Rittal Flexibar “S”

Short-circuit resistance diagram The quotients of l/a can be used to

Basis of test: determine the permissible short-circuit

VDE 0660 part 500/IEC 60 439-1. current Ip by using curves a to d. The

Test implemented: prescribed installation type must be taken

Dynamic short-circuit resistance to into account.

IEC 60 439-1.

The dimensions for the support spacing (I)

and for the centre-to-centre spacing (a)

must be within the specified min./max.

limits.

Type of assembly with universal

support SV 3079.000 90

80

Ip short-circuit current (kA)

d

70

1 2

c

60

b

50

a

l

40

30

1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9

a a

x

Support spacing (l)

X=

Centre-to-centre spacing (a)

3

Support Centre-to-centre

Curve spacing (l) mm spacing (a) mm

min. max. min. max.

l

a 150 300 34 60

b 150 350 42 85

a

c 200 400 51 85

d 200 450 81 100

Angular connectors for

Rittal PLS 800 A/1600 A

The Rittal PLS busbar system provides the

optimum basis for busbar assemblies in a

horizontal or vertical direction. If the

enclosures in a switchgear system are to

be positioned at an angle to one another,

this can be achieved with special angular

information

connectors. Where required, these can be

Technical

customised to suit the particular situation.

For details on prices and delivery times,

please contact Rittal.

PLS corner connector PLS corner connector

1600 A, 90° 1600 A, 270°

Rittal Power distribution 119

Technical information

Rated currents of busbars E-Cu should not be more than 40°C; an average Example:

(DIN 43 671) of 35°C maximum is recommended. For a bare Cu bar 30 x 10 mm (E-Cu

DIN 43 671 specifies the continuous F30), DIN 43 617 specifies a continuous

For the continuous temperatures specified

currents of busbars at an ambient current of IN65 = 573 A. The correction

in the table, an emission level of 0.4

temperature of 35°C and an average factor diagram for square cross-sections

applies, equivalent to an oxidating copper

busbar temperature of 65°C. The indicates a correction factor k2 = 1.29 at

bar. In modern busbar systems – built into

continuous currents specified in the an air temperature of 35°C and a busbar

enclosures with a protection category of

following table may be adjusted to temperature of 85°C. Thanks to the

IP 54 and above – a more favourable

alternative operating temperatures using favourable emission level, the continuous

emission level can be assumed. The lower

a correction factor (k2). current is increased by a further 6 – 10 %.

emission level facilitates an additional

In this example, a mean value of 8 % is

For safe operation with thermal reserve, increase in continuous currents compared

used. Compared with the table figure

it is desirable to limit the busbar with the figures in DIN 43 671, irrespective

from DIN 43 671, the Rittal rated current

temperature to a maximum of 85°C. of the specified air and busbar

specification for a Cu bar 30 x 10 mm is:

However, the decisive factor is the lowest temperature. Experience has shown an

permissible continuous temperature of increase in the continuous current of

the components which directly contact 6 – 10 % compared with the table figures IN85 = IN65 · k2 · 8 %

the busbar system (fuse bases, outgoing for bare copper bars, and 60 % for = 573 A · 1.29 · 1.08

cables etc.). The ambient air temperature surface-oxidised copper bars. IN85 = 800 A

of the busbars or the busbar system

Continuous currents for busbars

Made from E-Cu with square cross-section in indoor locations at 35°C air temperature

and 65°C bar temperature, vertical position or horizontal position of the bar width.

Width Cross- Weight Material Continuous current in A Correction factor diagram

x section 1) 2) to DIN 43671

thickness AC current DC current +

AC current 2.2 0

up to 60 Hz 16 Hz 10

2.0 20

Bare Coated Bare Coated 30

1.8

mm mm2 bar bar bar bar 40

12 x 2 23.5 0.209 108 123 108 123

Ambient temperature [°C]

1.6 50

15 x 2 29.5 0.262 128 148 128 148 1.4

60

Factor k2

15 x 3 44.5 0.396 162 187 162 187

1.2

20 x 2 39.5 0.351 162 189 162 189

20 x 3 59.5 0.529 204 237 204 237 1.0

20 x 5 99.1 0.882 274 319 274 320 0.8

20 x 10 199.0 1.770 427 497 428 499

0.6

25 x 3 74.5 0.663 245 287 245 287

25 x 5 124.0 1.110 327 384 327 384 0.4

50 60 70 80 90 100 110 120

30 x 3 89.5 0.796 285 337 286 337

Busbar temperature [°C]

30 x 5 149.0 1.330 379 447 380 448

E-Cu

30 x 10 299.0 2.660 573 676 579 683

F30

40 x 3 119.0 1.060 366 435 367 436

40 x 5 199.0 1.770 482 573 484 576

40 x 10 399.0 3.550 715 850 728 865 Correction factor diagram

for PLS

50 x 5 249.0 2.220 583 697 588 703

50 x 10 499.0 4.440 852 1020 875 1050

2.0 0

60 x 5 299.0 2.660 688 826 696 836

10

60 x 10 599.0 5.330 985 1180 1020 1230 1.8 20

80 x 5 399.0 3.550 885 1070 902 1090 30

1.6

80 x 10 799.0 7.110 1240 1500 1310 1590 40

Ambient temperature [°C]

1) Calculated with a density of 8.9 kg/dm 3

1.4 50

2) Reference basis for the continuous current levels (figures taken from DIN 43 671)

60

Factor k2

1.2

70

Rittal PLS current load Basic rated current 1.0

According to DIN 43 671, the correction PLS special WS 50/60 Hz

factor k2 (correction factor diagram) is bars

for 35/75°C for 35/65°C 0.8

used to correct the basic rated current

with reference to the existing E-Cu 800 A 800 A 684 A

0.6

temperatures of the ambient air and the E-Cu 1600 A 1600 A 1368 A

busbar. In accordance with DIN 43 671, 0.4

the load figures of the Rittal PLS special

bars have been determined on the basis 50 60 70 80 90 100 110

of measurement trials, as follows: Busbar temperature [°C]

120 Rittal Power distribution

Calculation of heat loss in busbars Note: and the corresponding length of the

The heat loss of busbars can be The rated current specified for a busbar conductor system in the installation or

calculated using the following equation, configuration is the maximum permissible distributor are known. By contrast, the

provided the AC current resistance is current which this busbar is able to resistance of conductor systems –

known: conduct on its entire length. Often, the heat particularly the AC current resistance of

loss calculated with this rated current does busbar arrangements – cannot simply be

not represent a realistic value. taken from a document or determined

yourself. For this reason, and in order to

IB2 · r · l Depending on the spatial division of the

obtain comparable results when

Pv = power supply (or supplies) and outlets,

1000 determining heat losses, the following

busbars conduct graduated “operating

table shows the resistance values in

currents”. Therefore, it is expedient for heat

mΩ/m for the most common cross-

Pv:[W] heat loss loss to be calculated directly section by

sections of copper busbars.

IB: [A] operating current section using these actual currents.

r: [mΩ/m] AC current resistance of the

In order to calculate the heat loss in

busbar

accordance with the above formula, in

I: [m] length of busbar which IB flows

individual cases it can be assumed that the

through

rated current of a circuit and/or the

“operating currents” of the busbar sections

Alternating current resistance of busbars

Strand Resistance per 1 m of busbar system

dimensions 2) in mΩ/m 1)

I III II II II III III III

1 main conductor 3 main conductors 3 x 2 main conductors 3 x 3 main conductors

mm rGS rWS rGS rWS rGS rWS rGS rWS

1 2 3 4 5 6 7 8 9

1 12 x 2 0.871 0.871 2.613 2.613

2 15 x 2 0.697 0.697 2.091 2.091

3 15 x 3 0.464 0.464 1.392 1.392

4 20 x 2 0.523 0.523 1.569 1.569

5 20 x 3 0.348 0.348 1.044 1.044

6 20 x 5 0.209 0.209 0.627 0.627

7 20 x 10 0.105 0.106 0.315 0.318 0.158 0.160

8 25 x 3 0.279 0.279 0.837 0.837 0.419 0.419

9 25 x 5 0.167 0.167 0.501 0.501 0.251 0.254

10 30 x 3 0.348 0.348 1.044 1.044 0.522 0.527

11 30 x 5 0.139 0.140 0.417 0.421 0.209 0.211

12 30 x 10 0.070 0.071 0.210 0.214 0.105 0.109

13 40 x 3 0.174 0.174 0.522 0.522 0.261 0.266

14 40 x 5 0.105 0.106 0.315 0.318 0.158 0.163

information

15 40 x 10 0.052 0.054 0.156 0.162 0.078 0.084 0.052 0.061 Technical

16 50 x 5 0.084 0.086 0.252 0.257 0.126 0.132 0.084 0.092

18 60 x 5 0.070 0.071 0.210 0.214 0.105 0.112 0,070 0.079

19 60 x 10 0.035 0.037 0.105 0.112 0.053 0.062 0.035 0.047

20 80 x 5 0.052 0.054 0.156 0.162 0.078 0.087 0.052 0.062

21 80 x 10 0.026 0.029 0.078 0.087 0.039 0.049 0.026 0.039

22 100 x 5 0.042 0.045 0.126 0.134 0.063 0.072 0.042 0.053

23 100 x 10 0.021 0.024 0.063 0.072 0.032 0.042 0.021 0.033

24 120 x 10 0.017 0.020 0.051 0.060 0.026 0.036 0.017 0.028

Key to symbols:

rGS Total resistance of busbar system when used for DC current in mΩ/m

rWS Total resistance of busbar system when used for AC current in mΩ/m

1) The resistance figures are based on an assumed average conductor temperature of

65°C (ambient temperature + self-heating) and a specific resistance

of

2

P = 20.9 mΩ · mm

m

2) Dimensions match those of standard DIN 43 671

Rittal Power distribution 121

Technical information

Connection of busbars to The possible torques of the screws used In the case of screw-fastened busbars, a

DIN 43 673, part 1 are sufficient for safe electrical connection weakening of the conductor material

DIN 43 673 sets out the guidelines for of busbars which are slightly height-offset. occurs as a result of drilling the hole.

connections with busbars whose rated Plate clamps are not suitable for such However, this does not have a

current is specified in DIN 43 671. applications. They are only used for disadvantageous effect, since the

The relevant parameters are the hole connecting laminated flat copper bars. In resultant weak point is compensated by

diameter, the number of holes and their the case of solid copper brackets, the the conductive screw material. Moreover,

position, and the size of the connection possible tightening torques are not at the connection point there are two

screws. Busbar connection to DIN 43 673 sufficient to compensate for a possible bar busbars on top of one another, i.e. the

is used, for example, for shipping splits offset (shown in an exaggerated form in busbar thickness is doubled. The

between two enclosure units or for Figure 1b). Punctiform contact (due to the weakening of the material caused by the

connecting two systems which cross. bar offset) cannot be reliably rectified by a drilled hole is fully compensated.

plate clamp. Due to the cross-section taper

Shipping splits are often connected with In addition to the correct size of the hole

occurring at the transition point, this will

Cu brackets. The Cu bracket is packed and the screw used, the Cu busbars must

result in an impermissible temperature rise.

above the two busbars being connected. also have an adequate overlap. Slots

Optimum contact is achieved if the DIN 43 673 contains guidelines on the are permissible on one side of the

busbar and bracket are screw-fastened arrangement of the holes. Depending on connection. Figure 3 shows the valid

as per the guidelines in DIN 43 673. the busbar width, there may be one or figures for dimensions b, d, e1 and e2.

more holes and various drill hole patterns.

Figure 1:

Bracket connection

a) Firmly screw-fastened

b) With plate clamp

(Not permissible in this form)

Figure 2:

Screw connection

122 Rittal Power distribution

Figure 3:

Hole patterns and holes to DIN 43 673

Bar widths 12 to 50 25 to 60 60 80 to 100

Shape 1) 1 2 3 4

Ø 13.5

b

2

b

2

Ø 13.5

e3

b

e3

b

b

Drilled holes in the bar

2

b

2

b

d

d

e1 e2 e1

ends (drilling pattern) e2 e1

e2 e1

80

Nominal width

d e1 d e1 e2 e1 e2 e3 e1 e2 e3

b

12 5.5 6 – – – – – – – – –

15 6.6 7.5 – – – – – – – – –

20 9.0 10 – – – – – – – – –

25 11 12.5 11 12.5 30 – – – – – –

Hole size

30 11 15 11 15 30 – – – – – –

40 13.5 20 13.5 20 40 – – – – – –

50 13.5 25 13.5 20 40 – – – – – –

60 – – 13.5 20 40 17 26 26 – – –

80 – – – – – – – – 20 40 40

100 – – – – – – – – 20 40 50

Permissible deviations for hole-centre distances ± 0.3 mm

1) Shape designations 1 – 4 match DIN 46 206, part 2 – Flat-type screw terminal

Figure 4:

Examples of busbar screw connections

Longitudinal connections

e1 e2 e1

e1 e2 e1

e1 e2 e1

e1 e1

b

b

b

b

Angular connections

e1

e1

e1

e2

e1

information

e2

e1

Technical

e1

b

e2

e1

e1

b b

T-connections

e1

e1

e1

e2

e1

e2

e1

e1

e2

e1

b

e1

b b

Dimensions b, d, e1 and e2 as shown in the table.

Slots are permissible in the end of a bar or end of a bar stack.

Rittal Power distribution 123

Vous aimerez peut-être aussi

- Indoor Cable GlandDocument1 pageIndoor Cable GlandChandra Sekhar BoyinaPas encore d'évaluation

- Cutsheet Helios 80C LED Highbay FLIDocument6 pagesCutsheet Helios 80C LED Highbay FLIMunck CranesPas encore d'évaluation

- Application: Slip-On Outdoor TerminationDocument2 pagesApplication: Slip-On Outdoor Terminationlatif100% (1)

- Standard Tables For Wind Moment ConnectionDocument18 pagesStandard Tables For Wind Moment ConnectionAce LowPas encore d'évaluation

- Price ListDocument2 pagesPrice ListAshan Udaya PushpakumaraPas encore d'évaluation

- CNC Insert ToolingDocument55 pagesCNC Insert Toolingtranviet25Pas encore d'évaluation

- Limited and Float InstallationDocument2 pagesLimited and Float InstallationGoran PetrovicPas encore d'évaluation

- NIC Components NATK SeriesDocument4 pagesNIC Components NATK SeriesNICCompPas encore d'évaluation

- 10wfloodilluminator AP CL AeDocument5 pages10wfloodilluminator AP CL AeYingcheng TangPas encore d'évaluation

- Linergy Terminal BlocksDocument6 pagesLinergy Terminal Blocksjby1970Pas encore d'évaluation

- Series CatalogueDocument13 pagesSeries Catalogueatul vermaPas encore d'évaluation

- Nama Barang, Toko, No TelponDocument9 pagesNama Barang, Toko, No Telpontutun financePas encore d'évaluation

- Licad86061000009 F46Document1 pageLicad86061000009 F46Sakeel WagirkhanPas encore d'évaluation

- Work Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyDocument2 pagesWork Document T 34.2 Tightening Torques For Screw Connections Used For SILUMIN Parts VC General AssemblyLetacio OliveiraPas encore d'évaluation

- Super Welding CablesDocument1 pageSuper Welding CablesNarasimha Rao JaggarapuPas encore d'évaluation

- Faktur Penjualan DefaultDocument1 pageFaktur Penjualan DefaultAku CylennPas encore d'évaluation

- PTFE Single Core: BS 3G 210 Type BDocument1 pagePTFE Single Core: BS 3G 210 Type BSKYhabiaPas encore d'évaluation

- Cuadro de Carga 1Document9 pagesCuadro de Carga 1pablo andres berrios jaraPas encore d'évaluation

- Trimming DataDocument27 pagesTrimming DatagouthamShetty DPas encore d'évaluation

- Design of Rectangular Column Section by Limit-State MethodDocument44 pagesDesign of Rectangular Column Section by Limit-State Methodsridhar100% (1)

- Elephant Foot Ferrules: 36.1 General InformationDocument8 pagesElephant Foot Ferrules: 36.1 General InformationlowelPas encore d'évaluation

- MATERIAL List-Injection SubstationDocument21 pagesMATERIAL List-Injection Substation030160645100% (5)

- Blind Bolt-Metric-Tech-DataDocument4 pagesBlind Bolt-Metric-Tech-Dataantun.tankosicPas encore d'évaluation

- C44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingDocument8 pagesC44A, 400 - 1,500 VDC/250 - 630 VAC, For General Purpose & SnubbingRaphael Santos do NascimentoPas encore d'évaluation

- Cotacao GM - 35615 PDFDocument1 pageCotacao GM - 35615 PDFGercio Gilberto MandlatePas encore d'évaluation

- SY Control CablesDocument3 pagesSY Control Cablesganasaii3882Pas encore d'évaluation

- 1031.5 - Thru-Bolt PRO Approved TDSDocument8 pages1031.5 - Thru-Bolt PRO Approved TDShexensohnPas encore d'évaluation

- Beryl (Radial Thru-Hole) LL SeriesDocument2 pagesBeryl (Radial Thru-Hole) LL Seriesester853Pas encore d'évaluation

- Technical DataDocument19 pagesTechnical Datamustafa nasihPas encore d'évaluation

- Development Length TablesDocument1 pageDevelopment Length TablesOsama AnwarPas encore d'évaluation

- SM Series: Aluminium Electrolytic CapacitorDocument2 pagesSM Series: Aluminium Electrolytic CapacitorStuxnetPas encore d'évaluation

- SENSIQ WEIGHBEAM - bvd2453gbDocument8 pagesSENSIQ WEIGHBEAM - bvd2453gbĐào Thanh HoanPas encore d'évaluation

- SR.# Item Unit Price QTY Total Price AnnexureDocument4 pagesSR.# Item Unit Price QTY Total Price AnnexureMuhammad Saqib SwatiPas encore d'évaluation

- Multifix All Mechanical Anchor - Design GuideDocument28 pagesMultifix All Mechanical Anchor - Design GuideConstantino Ramirez (Cons)Pas encore d'évaluation

- Beryl (Radial Thru-Hole) HW SeriesDocument2 pagesBeryl (Radial Thru-Hole) HW Seriesester853Pas encore d'évaluation

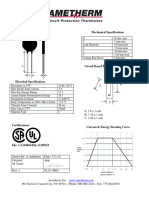

- Rhopoint Ametherm Inrush Current Limiter SL10 10003Document2 pagesRhopoint Ametherm Inrush Current Limiter SL10 10003jordanPas encore d'évaluation

- VD Quantity Chainage 2250.2450.3100Document9 pagesVD Quantity Chainage 2250.2450.3100Mohit PariharPas encore d'évaluation

- Licad86061000010 F06Document1 pageLicad86061000010 F06Sakeel WagirkhanPas encore d'évaluation

- Example - Transformed Sections Fig. 1: A y A yDocument1 pageExample - Transformed Sections Fig. 1: A y A yThabiso MotalingoanePas encore d'évaluation

- Beryl (Radial Thru-Hole) TC SeriesDocument2 pagesBeryl (Radial Thru-Hole) TC Seriesester853Pas encore d'évaluation

- Licad86061000013 L14Document1 pageLicad86061000013 L14Sakeel WagirkhanPas encore d'évaluation

- Qty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountDocument1 pageQty Particulars Bill Rate Amount Quoted Rate Amount Rate AmountNitin GandharePas encore d'évaluation

- Elec2 PDFDocument1 pageElec2 PDFNitin GandharePas encore d'évaluation

- Daftar As, Sprocket & BearingDocument3 pagesDaftar As, Sprocket & BearingdediPas encore d'évaluation

- Renk Tds Loose Oil Ring enDocument2 pagesRenk Tds Loose Oil Ring enJaime Vanegas IriartePas encore d'évaluation

- GSM 2M. CONECTORES MITAD 85 - 15dbDocument2 pagesGSM 2M. CONECTORES MITAD 85 - 15dbZeroPas encore d'évaluation

- Post TensionDocument8 pagesPost Tensionedc1312Pas encore d'évaluation

- CLA 11362651 PreviewDocument51 pagesCLA 11362651 Previewhusan shahPas encore d'évaluation

- Reach 1 Stitch Concrete BBS-JP7-JP6Document2 pagesReach 1 Stitch Concrete BBS-JP7-JP6Eticala RohithPas encore d'évaluation

- STRAD Consultants (Pte) Ltd. Project No Project: Part of StructureDocument32 pagesSTRAD Consultants (Pte) Ltd. Project No Project: Part of StructureLakmal JayashanthaPas encore d'évaluation

- Group20 2 PDFDocument26 pagesGroup20 2 PDFphuocloi82Pas encore d'évaluation

- Side LocksDocument2 pagesSide LocksVictor Villouta LunaPas encore d'évaluation

- LIMCOM SPLICE 1 - Bracing3 OKDocument3 pagesLIMCOM SPLICE 1 - Bracing3 OKmascalzonePas encore d'évaluation

- FT - 024 - 001 Zumi̇ LLC-1Document1 pageFT - 024 - 001 Zumi̇ LLC-1Levani ChubinidzePas encore d'évaluation

- Cash Flow Belanja Material & Upah CGDocument28 pagesCash Flow Belanja Material & Upah CGamara prabuPas encore d'évaluation

- Power Distribution: Laminated Copper Bars Short-Circuit Withstand Strength To IECDocument2 pagesPower Distribution: Laminated Copper Bars Short-Circuit Withstand Strength To IECKushtrim MalaPas encore d'évaluation

- Standard Girder Girder Flange 5%Document4 pagesStandard Girder Girder Flange 5%Sharyn PolleyPas encore d'évaluation

- Dismantling Joint DN350 To DN2400Document1 pageDismantling Joint DN350 To DN2400Zivadin LukicPas encore d'évaluation

- C&P WITCHLINER Insulated 3-Bolt Pipe ClampDocument1 pageC&P WITCHLINER Insulated 3-Bolt Pipe ClampAchraf BoudayaPas encore d'évaluation

- MK Pds Catalogue Ukmk467-0520-En FinalDocument46 pagesMK Pds Catalogue Ukmk467-0520-En FinalKuljinder VirdiPas encore d'évaluation

- An 2005 03 Short Circuit Behaviour of IGBT3 600 V 042-05Document5 pagesAn 2005 03 Short Circuit Behaviour of IGBT3 600 V 042-059588400913Pas encore d'évaluation

- Fi X30HL BDocument3 pagesFi X30HL BMichael MitchellPas encore d'évaluation

- C22D5-0900-1330 - I3 - 201003 Spare Part ListDocument2 pagesC22D5-0900-1330 - I3 - 201003 Spare Part ListkhanhPas encore d'évaluation

- PDFDocument50 pagesPDFAdam LiviuPas encore d'évaluation

- 7sd61 Catalog Sip E7Document26 pages7sd61 Catalog Sip E7anse1Pas encore d'évaluation

- 206 Hydraulics TROUBLESHOOTDocument19 pages206 Hydraulics TROUBLESHOOTek Joy100% (1)

- Test Report For LV PanelDocument8 pagesTest Report For LV PanelJayaprakash M PPas encore d'évaluation

- V2500 & CFM56 Difference PDFDocument5 pagesV2500 & CFM56 Difference PDFBahador100% (3)

- Switches and Sensors CatalogueDocument124 pagesSwitches and Sensors CatalogueQWEWERERPas encore d'évaluation

- Ride Control Accumulator - Test and ChargeDocument9 pagesRide Control Accumulator - Test and Chargeالبراق للتوريدات وصيانة المعداتPas encore d'évaluation

- Implementing Embedded Speed Control For Brushless DC Motors Part1Document8 pagesImplementing Embedded Speed Control For Brushless DC Motors Part1charliesteven100% (2)

- PROTEK SRS InstructionsDocument7 pagesPROTEK SRS InstructionsTom BeanPas encore d'évaluation

- MK SpecDocument2 pagesMK SpecBrandon TrocPas encore d'évaluation

- Twin Cylinder OHV BRIGGS & STRATTON PDFDocument101 pagesTwin Cylinder OHV BRIGGS & STRATTON PDFigrekqa100% (12)

- Davtron Catalog WebDocument20 pagesDavtron Catalog WebRadunPas encore d'évaluation

- Saudara Kita EnterpriseDocument3 pagesSaudara Kita EnterprisetierachumelPas encore d'évaluation

- InverterDocument31 pagesInverterĐẹp PhanPas encore d'évaluation

- 5 - Detectores Série 40000 PDFDocument3 pages5 - Detectores Série 40000 PDFNelso BedinPas encore d'évaluation

- Pansw EKG CableDocument13 pagesPansw EKG CableMaxi NoblegaPas encore d'évaluation

- Uponor Return Temperature LimiterDocument1 pageUponor Return Temperature LimiterUPOTERMPas encore d'évaluation

- Habilis Review Center 5Document8 pagesHabilis Review Center 5Al-nashreen AbdurahimPas encore d'évaluation

- 3002D HV PS User ManualDocument17 pages3002D HV PS User ManualtxescientistPas encore d'évaluation

- Moldcast Contra Cline Washington Globe & Savannah Lantern Brochure 1996Document10 pagesMoldcast Contra Cline Washington Globe & Savannah Lantern Brochure 1996Alan MastersPas encore d'évaluation

- Design and Development of An X-Ray Machine, Francisco Piernas DiazDocument40 pagesDesign and Development of An X-Ray Machine, Francisco Piernas DiazArmandinho CaveroPas encore d'évaluation

- Service PartsDocument56 pagesService PartsFredPas encore d'évaluation

- Panshul Industries ProfileDocument12 pagesPanshul Industries ProfileSunil KumarPas encore d'évaluation

- An Ek016 enDocument61 pagesAn Ek016 enАлександрPas encore d'évaluation

- MODELS YCAS0295, 0335, 0375, 0425, 0475, 0515, 0555, 0575 and YCAS0605Document68 pagesMODELS YCAS0295, 0335, 0375, 0425, 0475, 0515, 0555, 0575 and YCAS0605Nathan ArcilaPas encore d'évaluation

- Product Recommendation JCB Telescopic Handlers 506-36 Stage IIIA (5CD) (2007-2013)Document3 pagesProduct Recommendation JCB Telescopic Handlers 506-36 Stage IIIA (5CD) (2007-2013)Valmaq Prestação Serviço LdaPas encore d'évaluation