Académique Documents

Professionnel Documents

Culture Documents

660 Gallon Tank

Transféré par

leeconner3Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

660 Gallon Tank

Transféré par

leeconner3Droits d'auteur :

Formats disponibles

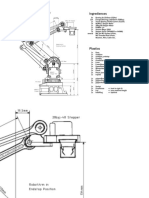

ITEM P/N DESCRIPTION QTY

FRONT & 6 1 H42375J HEAD ,0.353M/0.375Nx42 OD SA516-70 SE 2:1 JOGGLE 2

11

BACKSIDE 2 A10131-300X-SL SHELL BURNT 0.375 CS SA516-70 95.25 X 42.00 OD 1

3 S100343-21 MANWAY 12.00 X 16.00 X 6.000 X 1.000 RNG CS SA106C C/W 300# CLOSURE 1

4 S102949 RFSO ASY, 4" 300# S80 (.337" WALL) 7.34 LG SA105 ANSI B16.5/ SA106-B 2

5 F603000H CPLG 3.000 NPT SA105 ANSI B16.11 3000# HALF 1

1 PV019

6 F101000 WELD FLG 1.000 NPT CS SA181-70 FLAT 255 4

SPOT XRAY PER UW-11(a)(5)(b)

7 F100250 WELD FLG 0.250 NPT CS SA181-70 FLAT 251 1

8 S102114 SKIRT ASSEMBLY, 7GA X 35.50"OD A1011CS-B 1

3/8 8.1 S100066 SKIRT 7GA A1011CS-B 12.000 X 35.50 OD W/8.000 CLR 1

PV017

3/8 8.2 S102021 SKIRT CLIP, 7GA A1011CS-B x 3.000 x 4.000 x 3.000 LG 4

3" TO SHELL 9 A10131-300X-NP NAME PLATE FOR A10131-300X A1011CS-B 1

10 64-784-H LIFT LUG 0.500 A36 3.48 X 8.71 FOR 36-72" TANKS 2

11 S101972 LIFT LUG 0.500 SA105 3.000 X 4.875 PHOENIX 2-900-LUG SMALL SERIES 2

5

PV017 PV019

4

10 SKIRT SEAM SPOT XRAY PER UW-11(b)

25.00"

3/8

n42.00" OD PV017

3/8

24.00" 11 PIPE TO SHELL

120.00+0/-2.00

TYP 5/8 MIN INT PROJ

7 12.00" 4

6

PV017

q q

PLUG 4 PLCS

25.00" 3/8

PV017 TOP & PV017

3/16 6 1/4

1" NPT AND SMALLER BOTTOM 45° FLG TO PIPE

0.688" X 1.500" SLOT 11

4 PLCS EQ SPACED PV017

ON 38.00 B.C. 5/16

9 TYP LIFT LUGS

6 10

2

3

1/2

10 PV017 **SHELL CUT SIZE IS REFERENCE ONLY

1/2 **CPLG & FITTING 0.50 EXT PROJ TYP

25.00" MW TO SHELL 3 (1.00)" **HEAD THICKNESS SHOWN IS SPECIFIED MINIMUM

1.375 MIN INT PROJ **RADIUS INSIDE PROJECTED EDGES OF NOZZLES 1/8” MIN

6.00" **SEE PAGE 2 FOR FINISH

12.00" TYP 4 **FLANGE BOLT HOLES STRADDLE TANK C/L EXCEPT AS NOTED

6 8.06" **ALL DIMS IN INCHES UNLESS NOTED OTHERWISE

**IMPACT TEST EXEMPT PER UG 20(f)

TOP VIEW

TRUE ORIENTATION 42" X 120" 300# VERTICAL AIR RECEIVER

4 NOTES

20.00" IF YES THEN

PV017

1/4 REF TRAVELER REQUIRED

Yes FIXTURE REQUIRED

No FIXTURE #

6" WELD 8 PLCS 1 11.94" REF

RELEASED TO PRODUCTION TOLERANCES ARE PER EN1370

DESIGN & CALCULATIONS COMPLY WITH

STEEL FAB STANDARD TOLERANCES

SALES ORDER# ASME CODE SECTION VIII, DIV1.

UNLESS OTHERWISE SPECIFIED

LATEST EDITION

RELEASE DATE: QTY:

8.1 ENG. APP'L / DATE

8.2 NB/SERIAL# A10131 @ 300 PSI SAB - 12/8/2009

QCM. APP'L / DATE

6 8.2 ---

JP-1/8/2009

HEAD THK: .353" MIN C.A.: MAT'L SA516-70 EFF 100 %

8.00" -- A.I. VERIFICATION / DATE

REF PV017 SHELL THK: .375" NOM C.A.: MAT'L SA516-70 EFF 85 % BQ-1/9/2009

3/16

CONT UP SIDES NAT'L BD: YES STAMP " U " SAMUEL PRESSURE VESSEL GROUP

FRONT VIEW ~F

REV DATE DESCRIPTION ENG QCM AI/DATE VOLUME: 660 APPROX GAL

MAWP 300 PSI AT 400 OAKVILLE, ONT LEBANON, VA

TRUE ELEVATION 5 7/23/18 REVISED NP POSITION MH BW BQ 7/24/18 MDMT -20 ~F AT 300 PSI

DRAWN BY: P/N PAGE REV.

SHIPPING WEIGHT: 2045 LBS TEST: HYDRO KRG

6 10/12/18 LIFT LUG WERE 64-784-H, UPDATED TO DIVISIONAL WELD PROCEDURES MG BW BQ 10/15/18

BQ 1/11/19

AT 390

---

PSI

DATE: 11/14/2012 A10131-300X PAGE

1 OF 2

7

7 1/10/19 MANWAY WAS S1003436 MH BW CRN: E2202.6 TEST: PNEU AT PSI

SF-FRM-EN1450 REV 0 12/17/2015

FINISH SPECIFICATION SHIPPING AND PACKAGING WELD JOINT DETAILS

ALL TANKS REQUIRE:

INTERIOR AND EXTERIOR TO BE FREE OF WELD

SPATTER, DRY INTERIOR AFTER HYDROTEST, VACUUM GENERAL NOTES

INTERIOR FREE OF LOOSE PARTICLES, CLEAN & WASH PLUG ALL UNPLUGGED OPENINGS WITH PLASTIC PLUGS AFTER PAINTING

EXTERIOR FOR FINISHING BUILD SKID SO THAT TANK DOES NOT EXTEND BEYOND EDGES OF SKID

USE FOAM UNDER BANDS. SHRINK WRAP PLASTIC PLUGS TO NOZZLES.

PRE-ASSEMBLY SURFACE PREP:

REFER TO SHOP ORDER - SHIPPING WORK GUIDELINES, FOR ADDITIONAL

INSTRUCTIONS (IF APPLICABLE)

PACKAGING MATERIALS

POST-ASSEMBLY SURFACE PREP: REFER TO PALLET DRAWING ____________

PALLET SIZE ___ X ___ COLOR CODE: _________

STACK PER PALLET DRAWING USING CARDBOARD, BANDS, FOAM, AND

SHRINK WRAP AS APPLICABLE

EXTERIOR FINISH: ADDITIONAL SHIPPING INSTRUCTIONS

PAINT EXT STD GRAY PRIMER (P100004)

INTERIOR FINISH:

DOCUMENTATION

** DO NOT PAINT SEALING SURFACES OF FLANGES **

ADDITIONAL NOTES:

DESIGN & CALCULATIONS COMPLY WITH

ASME CODE SECTION VIII, DIV1.

LATEST EDITION

OUTSIDE SERVICE VERIFICATION A10131 @ 300 PSI

ENG. APP'L / DATE

SAB - 12/8/2009

WHEN PRODUCT IS SHIPPED DIRECT TO CUSTOMER FROM VENDOR, QCM. APP'L / DATE

OUTSIDE VENDOR SHALL SIGN OFF INDICATING ACCEPTANCE OF JP-1/8/2009

A.I. VERIFICATION / DATE

ALL CRITERIA ON FINISH SPECIFICATIONS. FINISH SPECIFICATIONS BQ-1/9/2009

SHALL BE SIGNED BY VENDOR & RETURNED TO STEEL FAB AFTER

SAMUEL PRESSURE VESSEL GROUP

JOB IS COMPLETE.

OAKVILLE, ONT. LEBANON, VA

PAGE REV.

DRAWN BY: P/N

____________________________ ______________ KRG

SIGNED DATE DATE: 11/14/2012 A10131-300X PAGE

2 OF 2

7

SF-FRM-EN1450 REV 0 12/17/2015

Vous aimerez peut-être aussi

- A Simple Method For The Selection of Axial Fan Blade ProfilesDocument7 pagesA Simple Method For The Selection of Axial Fan Blade ProfilesVigiiPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Aluminum Bulk Carrier SuperstructureDocument142 pagesAluminum Bulk Carrier SuperstructureCésar VenegasPas encore d'évaluation

- IME - Bolted Flanged Joints Methods & PracticesDocument188 pagesIME - Bolted Flanged Joints Methods & PracticesHeviiPas encore d'évaluation

- European Standard Norme Européenne Europäische NormDocument13 pagesEuropean Standard Norme Européenne Europäische NormTsrinivasanTPas encore d'évaluation

- Protem Catalogue EDocument112 pagesProtem Catalogue EemadnaguibPas encore d'évaluation

- Aluminium VesselsDocument106 pagesAluminium VesselsThomas BryanPas encore d'évaluation

- Supplementary Notes For Hobbymat MD65 2nd EdnDocument7 pagesSupplementary Notes For Hobbymat MD65 2nd EdnAndrew Mazurkiewicz100% (2)

- Dean RA Pump ManualsDocument23 pagesDean RA Pump ManualscoltonPas encore d'évaluation

- AMICON - Butterfly ValvesDocument16 pagesAMICON - Butterfly ValvesAnees OlasserilPas encore d'évaluation

- DIN Flange Summary ChartDocument1 pageDIN Flange Summary ChartARNOUXPas encore d'évaluation

- DNV Noise and VibrationDocument14 pagesDNV Noise and VibrationΡαφαηλ Καμ.Pas encore d'évaluation

- Catalogo Chute TelescopicoDocument4 pagesCatalogo Chute TelescopicoIgor San Martín PeñalozaPas encore d'évaluation

- C7-1 ADocument79 pagesC7-1 AAnonymous 24lnhhPas encore d'évaluation

- ASME B31.1-2001-12 Table 121.5Document1 pageASME B31.1-2001-12 Table 121.5karim hilalPas encore d'évaluation

- Robot GeometryDocument2 pagesRobot Geometryjuan alberto II selenius portPas encore d'évaluation

- O SPC07 PDFDocument124 pagesO SPC07 PDFdenisonocPas encore d'évaluation

- Décembre 1995: Boutique AFNOR Pour: Solios Carbone Client 8319200 Commande N-20100112-383554-TA Le 12/1/2010 16:25Document42 pagesDécembre 1995: Boutique AFNOR Pour: Solios Carbone Client 8319200 Commande N-20100112-383554-TA Le 12/1/2010 16:25Mahesh Kumar Bandari100% (1)

- SM-J110F PCB LayoutDocument2 pagesSM-J110F PCB LayoutJhonn arcila0% (1)

- Trinidad & Tobago - 62.01 - Petroleum Act & RegsDocument160 pagesTrinidad & Tobago - 62.01 - Petroleum Act & RegsOilmanGH100% (1)

- 15.cat c2 0809 Int ScreenDocument618 pages15.cat c2 0809 Int ScreenOzren Djuric100% (1)

- 9736 1 3 - Im-Clm1,2,3-En-10 03Document87 pages9736 1 3 - Im-Clm1,2,3-En-10 03Jeremy ShanePas encore d'évaluation

- Co-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIDocument2 pagesCo-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIHmd MokhtariPas encore d'évaluation

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices Pipingraobabar21Pas encore d'évaluation

- LPG - Dispenser, Base TrainingDocument30 pagesLPG - Dispenser, Base TrainingPaco MorenoPas encore d'évaluation

- Ti en 001Document397 pagesTi en 001benjapb92Pas encore d'évaluation

- PAS-JBG-400-D-002 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2050B Rev BDocument8 pagesPAS-JBG-400-D-002 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2050B Rev BElias EliasPas encore d'évaluation

- DesignhandbookDocument178 pagesDesignhandbookmuktikantaPas encore d'évaluation

- Seamless Stainless Tubes For Hydraulic and Instrumentation SystemsDocument10 pagesSeamless Stainless Tubes For Hydraulic and Instrumentation Systemsfezzeh kabiri kenariPas encore d'évaluation

- ARaymond EDS Catalog 2018 WebDocument124 pagesARaymond EDS Catalog 2018 WebFidrian Eko Wahyudi100% (1)

- 1405 - Vallourec - Express - Brochure - V7LR - 2Document4 pages1405 - Vallourec - Express - Brochure - V7LR - 2sajithv78Pas encore d'évaluation

- BN-DS-M01 Saddles For Horizontal VesselsDocument3 pagesBN-DS-M01 Saddles For Horizontal VesselsGabriel TravassosPas encore d'évaluation

- 4 Presentation Tenaris Premium Connection Design Sucker RodDocument24 pages4 Presentation Tenaris Premium Connection Design Sucker RodzhiqianxuPas encore d'évaluation

- Babbitt Bearing Design IntroDocument4 pagesBabbitt Bearing Design IntroBrandonPas encore d'évaluation

- Hydraulic Boom 1093 - Model TR-14 NewDocument377 pagesHydraulic Boom 1093 - Model TR-14 NewSidney OlivieiraPas encore d'évaluation

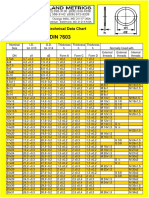

- Din 7603 - 1Document3 pagesDin 7603 - 1emre taşPas encore d'évaluation

- Vegetable Line BrochureDocument21 pagesVegetable Line BrochureAndrea HernandezPas encore d'évaluation

- Airide DGDocument84 pagesAiride DGforosdzPas encore d'évaluation

- Flange Design: Welding UnitsDocument0 pageFlange Design: Welding Unitsabhi1648665Pas encore d'évaluation

- VTP-VTPF - Ols 97891918Document30 pagesVTP-VTPF - Ols 97891918Hitesh Gajera100% (1)

- Table 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsDocument2 pagesTable 8-4. Entering and Tightening Clearances, In. Conventional ASTM A325 and A490 BoltsMiguelRagasPas encore d'évaluation

- Instrument Tie-In Engeneering Dossier Field Mounted Light TP-750-0063 (750-G23.1)Document8 pagesInstrument Tie-In Engeneering Dossier Field Mounted Light TP-750-0063 (750-G23.1)missoum mohamedPas encore d'évaluation

- Gears FundamentalDocument24 pagesGears FundamentalVIMAL APas encore d'évaluation

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDocument6 pagesTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDPas encore d'évaluation

- Rathod 2015Document9 pagesRathod 2015manasikarthikPas encore d'évaluation

- ManualDocument1 195 pagesManualDejan DrumacPas encore d'évaluation

- Tuberia PVCDocument154 pagesTuberia PVCEduard GatuellasPas encore d'évaluation

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDocument4 pagesIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyPas encore d'évaluation

- Plain Bearings Made From Engineering PlasticsDocument44 pagesPlain Bearings Made From Engineering PlasticsJani LahdelmaPas encore d'évaluation

- Machine Design Databook, Second Edition: Abstract: This Book Provides The Formulas and Data You Need To Solve Even TheDocument7 pagesMachine Design Databook, Second Edition: Abstract: This Book Provides The Formulas and Data You Need To Solve Even TheMichael AngeloPas encore d'évaluation

- Forming Shoulder DesignDocument8 pagesForming Shoulder DesignIndra100% (1)

- Piping Design StandardDocument16 pagesPiping Design StandardHướng PhạmPas encore d'évaluation

- HydrotransportDocument3 pagesHydrotransportMehrdad HosseinzadehPas encore d'évaluation

- Balon CompleteCatalogDocument106 pagesBalon CompleteCatalogJemmyPas encore d'évaluation

- Process Industry Practices Vessels: Pip Vedbi003 Vessels For Bulk Solids Data SheetDocument7 pagesProcess Industry Practices Vessels: Pip Vedbi003 Vessels For Bulk Solids Data Sheetmsaldivar177Pas encore d'évaluation

- Gear Box No Load Run Test ReportDocument1 pageGear Box No Load Run Test ReportPRABHUDAYAL SHARMAPas encore d'évaluation

- Internal Gear Pumps: Series QXDocument32 pagesInternal Gear Pumps: Series QXfadhlidzilPas encore d'évaluation

- Jacketed Ball Valves LeafletDocument2 pagesJacketed Ball Valves LeafletSherif EltoukhiPas encore d'évaluation

- NS50 Aerox R Water PumpDocument1 pageNS50 Aerox R Water PumptsimposthomasPas encore d'évaluation

- Septic Tank Design ComputationDocument1 pageSeptic Tank Design ComputationEngilbert AragonPas encore d'évaluation

- Patent Pervious ConcreteDocument28 pagesPatent Pervious ConcreteChong Ting ShengPas encore d'évaluation

- Delphi Mt88 Engine Control ModuleDocument2 pagesDelphi Mt88 Engine Control ModuleAngelJosePas encore d'évaluation

- A Basic Guide of Arc Welding Electrodes: by Bruce BauerleinDocument4 pagesA Basic Guide of Arc Welding Electrodes: by Bruce BauerleinRajeev KhantwalPas encore d'évaluation

- Silo Fluidizer Mini Disk: Mini Fluidizing Disk Keeps Material Moving in Tight CurvaturesDocument2 pagesSilo Fluidizer Mini Disk: Mini Fluidizing Disk Keeps Material Moving in Tight Curvaturesseeralan_1986Pas encore d'évaluation

- ECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Document12 pagesECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Er Dipak PatelPas encore d'évaluation

- Bucky PaperDocument22 pagesBucky PaperShreyashkumar ZingadePas encore d'évaluation

- Distillation Column Case StudyDocument26 pagesDistillation Column Case Studysachin2010Pas encore d'évaluation

- Ecg524 - Term PaperDocument11 pagesEcg524 - Term PaperamierulPas encore d'évaluation

- 1 s2.0 S2590048X22001030 MainDocument17 pages1 s2.0 S2590048X22001030 MainJeff DatinguinooPas encore d'évaluation

- Safety Data Sheet: Hydrocarbons, C10, Aromatics, 1% NaphthaleneDocument15 pagesSafety Data Sheet: Hydrocarbons, C10, Aromatics, 1% NaphthalenebogodavidPas encore d'évaluation

- Sample Quotation For Plumbing WorkDocument1 pageSample Quotation For Plumbing WorkIzat Malaya100% (1)

- Recent Advances in Graphene-Based Nanocomposites For Automotive and Off-Highway Vehicle ApplicationsDocument34 pagesRecent Advances in Graphene-Based Nanocomposites For Automotive and Off-Highway Vehicle ApplicationsAg PradhiPas encore d'évaluation

- Slab Comflor60Document6 pagesSlab Comflor60ihpeterPas encore d'évaluation

- Astm A105, A105mDocument5 pagesAstm A105, A105mMike Dukas0% (1)

- Berutox FE 18 EP: Technical Product InformationDocument1 pageBerutox FE 18 EP: Technical Product InformationMauricio SánchezPas encore d'évaluation

- UPSC IES Weightage For ECEDocument4 pagesUPSC IES Weightage For ECEPriyaKumar0% (1)

- Database of Embodied Energy and Water Values For MaterialsDocument3 pagesDatabase of Embodied Energy and Water Values For MaterialsMax Yanac TelleriaPas encore d'évaluation

- If P 100N T1 T2 58: Design CodesDocument1 pageIf P 100N T1 T2 58: Design CodesserePas encore d'évaluation

- Skoda Kodiaq - Brief Instructions EnglishDocument36 pagesSkoda Kodiaq - Brief Instructions EnglishMario Redsocial100% (1)

- FCI - ST80-SeriesDocument12 pagesFCI - ST80-Seriesabdulkidwai2009Pas encore d'évaluation

- Uec 3 & Uec3 MPC Manual440-12100Document40 pagesUec 3 & Uec3 MPC Manual440-12100Periyasamy Chellaiah50% (2)

- Jotun Facade New 21 - tcm132 91545Document5 pagesJotun Facade New 21 - tcm132 91545dnytan12345Pas encore d'évaluation

- Combustion and Explosion Characteristics of Dusts GESTIS-DUST-EX - Edition 2-2001Document22 pagesCombustion and Explosion Characteristics of Dusts GESTIS-DUST-EX - Edition 2-2001micaziv4786Pas encore d'évaluation

- Steven Thomas ResumeDocument1 pageSteven Thomas ResumestevenmthomasPas encore d'évaluation

- SPE-68789-MS One PetroDocument5 pagesSPE-68789-MS One PetroAlex ZamanPas encore d'évaluation

- 2012 Rekomendasi Pengangkutan Limbah B3Document75 pages2012 Rekomendasi Pengangkutan Limbah B3yordan abdulPas encore d'évaluation

- Lei 2011Document8 pagesLei 2011Zakaria TabiaPas encore d'évaluation

- Assesment of Textile Dyeing Units and ZLD at Tirupur - CPCB PDFDocument87 pagesAssesment of Textile Dyeing Units and ZLD at Tirupur - CPCB PDFVishal Duggal100% (1)

- Approved: Materials Engineering SpecificationDocument2 pagesApproved: Materials Engineering SpecificationRonald AraujoPas encore d'évaluation