Académique Documents

Professionnel Documents

Culture Documents

Mini USB (AXJ4) Connectors: Discontinued

Transféré par

Renata LouhDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mini USB (AXJ4) Connectors: Discontinued

Transféré par

Renata LouhDroits d'auteur :

Formats disponibles

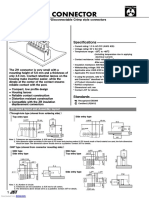

AXJ4 Discontinued

MINIATURE INTERFACE

CONNECTOR COMPLIANT

Mini USB (AXJ4)

WITH USB 2.0/ON-THE-GO CONNECTORS

FEATURES APPLICATIONS

1. Compliant with USB 2.0-OTG 1. DSC, PMP, DVC, IC recorders

(Transmission speed: 480 Mbps) 2. Mobile phones, PDA, smart phones

2. 7.7 mm deep space-saving size 3. Compact PC peripherals (e.g.

Since the depth is 7.7 mm, the occupied external HDD, memory card readers)

space is approx. 4. Game machines

15% smaller than competing standard

connectors (depth: approx 9.0 mm).

3. Reinforced fixing strength between

the body and shell

The high strength allows for the forcible

Compliance with RoHS Directive insertion of a plug.

ORDERING INFORMATION

Interface connectors

AXJ 4 1 1 1 0 G

4: Mini USB connectors

<Receptacle>

1: 5 contacts receptacle

(Compliant with the Mini USB standard)

<Composition>

3: Mini B right angle type

6: Mini AB right angle type

<Mounting type>

1: Standard, with suction tape

<Terminal and Retention fitting>

1: Terminal portion: SMD,

Retention fitting portion: SMD,

Positioning bosses: Provided

<Flange shape>

0: Without flange

<Package>

G: Embossed tape packaging

PRODUCT TYPES

Packing quantity

Positioning

Type Terminal shape Flange Part number Inner carton

bosses Outer carton

(Embossed)

Mini B

5 contacts receptacle AXJ413110G

Right angle type Terminal position: SMD

(Compliant with the Provided Without flange 1,200 6,000

Mini AB Clips (retention fitting): SMD

Mini USB standard) AXJ416110G

Right angle type

Matsushita Electric Works, Ltd. http://www.mew.co.jp/ac/e/

AXJ4

SPECIFICATIONS

1. Characteristics

Item Specifications Conditions

Rated current 1.0A

Rated voltage 30V DC/AC

EIA-364-23

Contact resistance Max. 50mΩ

(Inductive resistance to wire is not included)

Electrical EIA-364-21

Insulation resistance Min. 100MΩ

characteristics Using 100V DC megger

100V AC (Dielectric breakdown must not occur during a 1 min. EIA-364-20

Breakdown voltage

application) Detection current: 1mA

EIA-364-30

Electrostatic capacity Max. 2pF (Measure it between the adjacent terminals of the unmated

connector at a frequency of 1 kHz.)

Composite insertion Max. 35N

Mechanical force (initial) {3.57kgf} EIA-364-13

characteristics Composite removal Insert and remove a plug at a speed of 12.5 mm/min.

Min. 7N {0.714kgf}

force (initial)

Ambient temperature –55°C to 85°C No freezing or condensation in low temperatures

Storage temperature –55°C to 85°C (–40°C to 50°C for packaging materials) No freezing or condensation in low temperatures

EIA-364-28

Discontinuity: Max. 1µs Apply vibration in three directions including the mating axis

Vibration resistance Contact resistance: Max. 50mΩ that are perpendicular to one another for 15 minutes

Appearance: No abnormality respectively with a 100 mA DC current applied.

Interface connectors

Cord length: 100mm Fix the cord end.

EIA-364-27

Acceleration: 294m/s2(30G)

Discontinuity: Max. 1µs

Duration: 11 ms,

Impact resistance Contact resistance: Max. 50mΩ

Application directions: 6 surfaces (X, Y, and Z directions)

Appearance: No abnormality

Number of applications: 3 times respectively (Total: 18 times)

Cord length: 100mm Fix the cord end.

250 hours

Contact resistance: Max. 50mΩ

Heat resistance Withstand voltage: 100V AC dielectric breakdown must not EIA-364-17

(mated) occur during a one-minute application. Temperature: 85±2°C

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

96 hours

Contact resistance: Max. 50mΩ

Environmental Low temperature Withstand voltage: 100V AC dielectric breakdown must not

characteristics Temperature: –55±2°C

resistance (mated) occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

7 cycles

Contact resistance: Max. 50mΩ

Humidity resistance Withstand voltage: 100V AC dielectric breakdown must not

EIA-364-31 Method III

(mated) occur during a one-minute application.

Insulation resistance: Min. 100MΩ

Appearance: No abnormality

10 cycles

Sequence

Contact resistance: Max. 50mΩ

1. –55±3°C, 30 minutes

Temperature cycle test Withstand voltage: 100V AC dielectric breakdown must not

2. ~, Max. 5 minutes

(mated) occur during a one-minute application.

3. 85±2°C, 30 minutes

Insulation resistance: Min. 100MΩ

4. ~, Max. 5 minutes

Appearance: No abnormality

Bath temperature: 35±2°C

48 hours

Saltwater spray Saltwater concentration: 5±1%

Contact resistance: Max. 100mΩ

resistance (mated) Wash the connector with water at room temperature after the

Appearance: No abnormality

test, and then dry it at room temperature.

96 hours Temperature :40±2°C

Hydrogen sulfide Contact resistance: Max. 100mΩ Humidity: 75 to 80%

Appearance: No abnormality Gas concentration: 3±1ppm

Soldering Reflow soldering Peak temperature: Max. 260°C

temperature 300±10°C: Max. 5 s

resistance Manual soldering

350±10°C: Max. 3 s

2. Material and surface treatment

Part name Material Surface treatment

Resin-molding portion Heat-resistant resin (UL94V-0) —

Contact portion: Ni plating on base, Au plating on surface

Contact Copper alloy

Metal parts Terminal portion: Ni plating on base, Sn plating on surface

Shell Copper alloy Ni plating on base, Sn plating on surface

Pickup tape Heat-resistant resin —

Matsushita Electric Works, Ltd. http://www.mew.co.jp/ac/e/

AXJ4

mm General tolerance: ±0.3

DIMENSIONS

1. Mini B Right angle type

AXJ413110G Recommended PC board pattern

(TOP VIEW)

3.20

0.80±0.15

0.25 0.95±0.05 dia. (hole)

3.2±0.05

2.7±0.1

0.8±0.05

3.70

0.4±0.05 2.0±0.1

7.70

2.5±0.1

1.40±0.1

7.50±0.1

7.5±0.1

2.90

5.3±0.1

4×1.20

7.70

9.90

1.00±0.1

PC board edge

4.4±0.05

8.9±0.1

0.07

Terminal No.1 6.90 Terminal No.5

With a plug inserted:

4.40

3.10

3.95

3.95

Including the projection of the spring

in the shell contact section

5.95

0.80

0.80 dia.

4.40

5.87

Interface connectors

2. Mini AB Right angle type mm General tolerance: ±0.3

AXJ416110G

Recommended PC board pattern

(TOP VIEW)

3.20

0.80±0.15

0.95±0.05 dia. (hole)

0.25 3.2±0.05

2.7±0.1

0.8±0.05

0.4±0.05 2.0±0.1

3.70

2.5±0.1

7.70

1.40±0.1

7.50±0.1

7.5±0.1

2.90

5.3±0.1

4×1.20

7.70

1.00±0.1

9.90

PC board edge

4.4±0.05

8.9±0.1

Terminal No.1 6.90 Terminal No.5

0.07

With a plug inserted:

1.93

4.40

3.10

3.95

3.95

Including the projection of the spring

in the shell contact section

5.95

0.80

0.80 dia.

4.40

5.32

EMBOSSED TAPE DIMENSIONS (unit: mm)

• Tape dimensions (Conforming to JIS C 0806-3 1999) • Reel dimensions (Conforming to EIAJ ET-7200B)

24.0±0.3

11.5 25.4±1

1.75

Taping reel

Top cover tape

4.0

Pull out direction

2.0

Embossed carrier tape

380 dia.

Embossed mounting-hole

12.0

1.5 dia.

Matsushita Electric Works, Ltd. http://www.mew.co.jp/ac/e/

AXJ4

NOTES

1. Use of a cover is recommended 4. Since excessive force on the

when using this device in order to terminals will cause deformation and

prevent scraps, dust, dirt, etc., from the integrity of the soldering will be

getting inside of the receptacle. lost during reflow soldering, avoid

2. PC board design dropping or rough handling of the

Please refer to the recommended PC product.

board pattern to ensure the strength of 5. PC board warpage should be

soldered portion of terminals. controlled less than 0.03mm to entire

3. Soldering length of the connector.

1) Manual soldering 6. Repeated bending of terminals and

• Please set up temperature and applied holding parts can result in terminals

time of soldering iron as indicated in breaking.

specification sheet. 7. Regarding after soldering

• Please use soldering iron after connectors on PC boards

confirming removal of dispersed solder • After mounting connectors on PC

flux on the contact surface by use of boards, do not apply excessive loads to

magnifying glass after each soldering. the connector by piling up the boards.

• Please properly clean soldeing iron. • Please do not add the force to the

2) Reflow soldering connector during assembled connector

• Screen printing is recommended for on PC board.

Interface connectors

cream solder printing. 8. This connector has metal shell for

• Screen thickness of 0.15mm is preventing EMI, when designing an

recommended for cream solder printing. enclosure the followings should be

• When applying different thickness of considered. Guide for plug entrance

screen, please consult us. should be arranged in order to prevent

• Depending upon size of connector, self distorted insertions. Provide a cover

alignments may not be expected. to reinforce the metal shell portions of

Please pay attention to align terminals the receptacle.

and soldered pads. 9. We recommend the use of a

• The following diagram shows the purified-water-based solution for

recommended reflow soldering cleaning the PC board. If you use an

temperature profile. alcohol-based solution, the surface of

Temperature

the molded part may be whitened. In

Max. 260°C

Maximum temperature addition, please carefully monitor the

200°C contamination degree of the solution

Pre-heating

150 to 175°C to prevent the solution from re-

60 to 120 second

Max. 70 sec

contaminating the connector

Time

contacts.

10. Others

• The temperature measured on the PC To prevent insulation deterioration of PC

board surface near connector terminals. board after soldering, please avoid

• After reflow soldering, in case of PC adhesion coating agent to terminals in

board surface the reverse side using case of coating.

reflow soldering, for example an adhesive

and so on connector of fixed disposition. For other details, please verify with

3) Rework of soldering portion the product specification sheets.

• Rework is one time.

• In case of soldering rework of bridges.

Please use a flat-head soldering iron and

don’t use supplementary solder flux.

• Please use the soldering iron under

specification’s temperature

Matsushita Electric Works, Ltd. http://www.mew.co.jp/ac/e/

Vous aimerez peut-être aussi

- Video and Camcorder Servicing and TechnologyD'EverandVideo and Camcorder Servicing and TechnologyÉvaluation : 4 sur 5 étoiles4/5 (1)

- Features: Narrow Pitch Connectors (0.4mm Pitch)Document11 pagesFeatures: Narrow Pitch Connectors (0.4mm Pitch)Jhonn arcilaPas encore d'évaluation

- 716m Scf12 c02 RectoDocument2 pages716m Scf12 c02 Rectogerardo jimenez lopezPas encore d'évaluation

- 7-16 DIN Male Connector For 7/8" Coaxial Cable, OMNI FIT Standard, O-Ring SealingDocument2 pages7-16 DIN Male Connector For 7/8" Coaxial Cable, OMNI FIT Standard, O-Ring SealingLuciano Silvério LeitePas encore d'évaluation

- Con Eng f4sDocument13 pagesCon Eng f4scristian.rodriguezPas encore d'évaluation

- Micro-USB ConnectorsDocument4 pagesMicro-USB ConnectorsTonpitonpi Ton PiPas encore d'évaluation

- Leaf Limit Switch CatalogDocument19 pagesLeaf Limit Switch Catalogbrian sPas encore d'évaluation

- Leoni Sealine: Cable Type: 9Y (ST) CH 4X2X0.6/1.2-100 Li GN FRNCDocument2 pagesLeoni Sealine: Cable Type: 9Y (ST) CH 4X2X0.6/1.2-100 Li GN FRNCLeodoletaPas encore d'évaluation

- Phoenix Contact 1757064 enDocument6 pagesPhoenix Contact 1757064 enDGPas encore d'évaluation

- Ae180nxt03 13 Eng PDFDocument2 pagesAe180nxt03 13 Eng PDFnormPas encore d'évaluation

- CSD - 33KV (E) 3C X 300 SQ - MM 2xwy - BestDocument1 pageCSD - 33KV (E) 3C X 300 SQ - MM 2xwy - Bestshivam dwivediPas encore d'évaluation

- 189ET INSTRUM RE-vY (ST) Y 6X1 MM2 BK-JJlap HitamDocument1 page189ET INSTRUM RE-vY (ST) Y 6X1 MM2 BK-JJlap Hitamchakrapani vagish chandra pandeyPas encore d'évaluation

- Technical Features: 7-16 DIN Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingDocument2 pagesTechnical Features: 7-16 DIN Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingLuciano Silvério LeitePas encore d'évaluation

- Connector Connector: ZH Connector ZH ConnectorDocument3 pagesConnector Connector: ZH Connector ZH ConnectorGreenoceanPas encore d'évaluation

- N Female Connector For 7/8" Coaxial Cable, OMNI FIT Standard, O-Ring SealingDocument2 pagesN Female Connector For 7/8" Coaxial Cable, OMNI FIT Standard, O-Ring SealingLuciano Silvério LeitePas encore d'évaluation

- Conector 7/16 Din Macho 1/2" Superflex (L) .Document2 pagesConector 7/16 Din Macho 1/2" Superflex (L) .SIMON S. FLORES G.Pas encore d'évaluation

- Pepwave Ant 101Document1 pagePepwave Ant 101StartPas encore d'évaluation

- Phoenix Contact 1009166 enDocument6 pagesPhoenix Contact 1009166 enDGPas encore d'évaluation

- PCB Terminal Block - GMKDS 1,5/ 2 - 1717020: Key Commercial DataDocument8 pagesPCB Terminal Block - GMKDS 1,5/ 2 - 1717020: Key Commercial DatalukaPas encore d'évaluation

- Page 10Document1 pagePage 10Autor AutorPas encore d'évaluation

- D 2 MiniDocument1 pageD 2 MiniSteve Diego Alberto GarcÃa BarriosPas encore d'évaluation

- Roseta Optica FTB-501Document1 pageRoseta Optica FTB-501Sergio Quintero GuzmanPas encore d'évaluation

- 0.4mm, 0.5mm, 1mm Pitch, 1.2mm Above The Board, Flexible Printed Circuit & Flexible Flat Cable ZIF ConnectorsDocument16 pages0.4mm, 0.5mm, 1mm Pitch, 1.2mm Above The Board, Flexible Printed Circuit & Flexible Flat Cable ZIF ConnectorsAbdul HameedPas encore d'évaluation

- Mb-0301-4e DX07 PlugDocument4 pagesMb-0301-4e DX07 PlugSHYAM THILLAINATHANPas encore d'évaluation

- Schedule of Technical Data Instrument Cable BS EN 50288-7: Tcu/Xlpe/Os/Swa/Pvc 300/500 VDocument1 pageSchedule of Technical Data Instrument Cable BS EN 50288-7: Tcu/Xlpe/Os/Swa/Pvc 300/500 VIntanPas encore d'évaluation

- Phoenix Contact 1757048 enDocument16 pagesPhoenix Contact 1757048 enDGPas encore d'évaluation

- 9-1375055-2 Product SpecificationDocument3 pages9-1375055-2 Product SpecificationLê TrungPas encore d'évaluation

- 2006-8035 Eng TdsDocument6 pages2006-8035 Eng TdsAPPas encore d'évaluation

- Connector Selection GuidDocument24 pagesConnector Selection Guidvelanvasanth31Pas encore d'évaluation

- Stepcraft CNC - QTN1 PDFDocument3 pagesStepcraft CNC - QTN1 PDFA SPas encore d'évaluation

- Fuji Digital Sound Detector: FSB 8DDocument2 pagesFuji Digital Sound Detector: FSB 8DMar WilkPas encore d'évaluation

- I.C.T Online Jet Dispensing MachineDocument4 pagesI.C.T Online Jet Dispensing MachineLouis ChewPas encore d'évaluation

- Emdoor Info. Rugged Tablet PC EM-I10J-1Document2 pagesEmdoor Info. Rugged Tablet PC EM-I10J-1Mohsin MakkiPas encore d'évaluation

- Revised GTP Ab CableDocument1 pageRevised GTP Ab Cableer.manishnhpcPas encore d'évaluation

- DF11serie Eng Tds PDFDocument14 pagesDF11serie Eng Tds PDFviaxaPas encore d'évaluation

- SKHC 1370786Document5 pagesSKHC 1370786mars 05Pas encore d'évaluation

- NM LCF78 C03 PDFDocument2 pagesNM LCF78 C03 PDFLuciano Silvério LeitePas encore d'évaluation

- Phoenix Contact 1873210 enDocument23 pagesPhoenix Contact 1873210 enMuradPas encore d'évaluation

- Eng CS 82181 Softshell Standard Density 0508 PDFDocument98 pagesEng CS 82181 Softshell Standard Density 0508 PDFStanley ClermontPas encore d'évaluation

- Conector 7-16 Din Hembra 7/8" Cellflex.Document2 pagesConector 7-16 Din Hembra 7/8" Cellflex.SIMON S. FLORES G.Pas encore d'évaluation

- FH19C FH19SC CatalogDocument12 pagesFH19C FH19SC CatalogLinchys_88Pas encore d'évaluation

- Ik Siemens-7MF4233Document5 pagesIk Siemens-7MF4233hoapro537817Pas encore d'évaluation

- Industrial Ethernet Cat 6 Es: Leoni Special Cables GMBHDocument2 pagesIndustrial Ethernet Cat 6 Es: Leoni Special Cables GMBHLeodoletaPas encore d'évaluation

- Technical Features: N Male Connector For 1/2" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingDocument2 pagesTechnical Features: N Male Connector For 1/2" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingLuciano Silvério LeitePas encore d'évaluation

- IE PI RJ45 FH - enDocument4 pagesIE PI RJ45 FH - enklkkmklf fejkrfPas encore d'évaluation

- Con Eng A4sDocument14 pagesCon Eng A4sChuan NguyenPas encore d'évaluation

- TS-1PRX1.5MM, 2PRX1.5MM - Blue (New)Document2 pagesTS-1PRX1.5MM, 2PRX1.5MM - Blue (New)mohd darusPas encore d'évaluation

- Phoenix Contact 1011860 enDocument6 pagesPhoenix Contact 1011860 enDGPas encore d'évaluation

- Alps Alpine SPVMDocument4 pagesAlps Alpine SPVMJose Carlos SoaresPas encore d'évaluation

- Trench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 PackingDocument10 pagesTrench Gate Field-Stop, 650 V, 10 A, Low-Loss M Series IGBT Die in D7 Packingkrimo biomédicalPas encore d'évaluation

- HS212T - Full Range Horn Speaker 12 100V AUDACDocument1 pageHS212T - Full Range Horn Speaker 12 100V AUDACBambang KaryantoPas encore d'évaluation

- Single Level 5.0 MM Pitch PCB Terminal BlocksDocument2 pagesSingle Level 5.0 MM Pitch PCB Terminal BlocksDaxesh ManiyarPas encore d'évaluation

- Phoenix Contact 3244313 enDocument6 pagesPhoenix Contact 3244313 enDGPas encore d'évaluation

- Product Specification: Model NO.: 7.5inch E-Paper BDocument39 pagesProduct Specification: Model NO.: 7.5inch E-Paper BfirsttenorPas encore d'évaluation

- GT-S5250 Training Manual HWDocument43 pagesGT-S5250 Training Manual HWNayeem QureshiPas encore d'évaluation

- Technical Features: N Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingDocument2 pagesTechnical Features: N Female Connector For 7/8" Coaxial Cable, OMNI FIT™ Standard, O-Ring SealingLuciano Silvério LeitePas encore d'évaluation

- Sniffer Nano ManualDocument5 pagesSniffer Nano ManualMuhammad SalmanPas encore d'évaluation

- TS-1PR X 1.5MM (New)Document2 pagesTS-1PR X 1.5MM (New)mohd darusPas encore d'évaluation

- JST NV ConnectorDocument2 pagesJST NV ConnectorRicky CapascoPas encore d'évaluation

- Propagare - Threshold Degradation - AbateriDocument72 pagesPropagare - Threshold Degradation - AbateriAndrada AdaPas encore d'évaluation

- Brenda Patton Guided Reflection QuestionsDocument3 pagesBrenda Patton Guided Reflection QuestionsCameron JanzenPas encore d'évaluation

- HorticultureDocument168 pagesHorticultureagni sahanaPas encore d'évaluation

- Anil Singh Rathore: Career HighlightsDocument4 pagesAnil Singh Rathore: Career HighlightsHRD CORP CONSULTANCYPas encore d'évaluation

- Assembly Manual, Operation and Maintenance Round Vibrating Screen Model: Tav-Pvrd-120Document15 pagesAssembly Manual, Operation and Maintenance Round Vibrating Screen Model: Tav-Pvrd-120Sandro Garcia Olimpio100% (1)

- Band Structure Engineering in Gallium Sulfde NanostructuresDocument9 pagesBand Structure Engineering in Gallium Sulfde NanostructuresucimolfettaPas encore d'évaluation

- NavaDocument2 pagesNavasaikiranPas encore d'évaluation

- Boil-Off Gas CalculationsDocument14 pagesBoil-Off Gas CalculationsAlberto100% (1)

- Text 5Document7 pagesText 5santoshkumarray490Pas encore d'évaluation

- Elements, Compounds, MixturesDocument35 pagesElements, Compounds, MixturesNorviePas encore d'évaluation

- ASTM A581 A581M-95bDocument3 pagesASTM A581 A581M-95bFetenePas encore d'évaluation

- School: Grade Level: Teacher: Section Teaching Dates and Time: QuarterDocument3 pagesSchool: Grade Level: Teacher: Section Teaching Dates and Time: QuarterZeny Aquino DomingoPas encore d'évaluation

- Digital Logic DesignDocument38 pagesDigital Logic DesignAri BaderPas encore d'évaluation

- Suez Canal ReportDocument5 pagesSuez Canal ReportAnonymous Pc6LwfCPas encore d'évaluation

- Oplan Tumbler ProposalDocument3 pagesOplan Tumbler ProposalKay Tuppil ManzanillaPas encore d'évaluation

- LTE 3GPP Band13 Test Entrance CriteriaDocument130 pagesLTE 3GPP Band13 Test Entrance CriteriaBuchi Reddy0% (1)

- GEHC Service Manual CARESCAPE Monitor B850 v1 2011Document172 pagesGEHC Service Manual CARESCAPE Monitor B850 v1 2011NguyễnCảnhBắcPas encore d'évaluation

- Modeling of Conducted EMI (Model Motor Simulink Bun)Document8 pagesModeling of Conducted EMI (Model Motor Simulink Bun)Ioan ŢileaPas encore d'évaluation

- Cigarettes and AlcoholDocument1 pageCigarettes and AlcoholHye Jin KimPas encore d'évaluation

- Fermat Contest: Canadian Mathematics CompetitionDocument4 pagesFermat Contest: Canadian Mathematics Competitionสฮาบูดีน สาและPas encore d'évaluation

- Flap Designs For Flap Advancement During Implant Therapy A Systematic Review 2016 PDFDocument8 pagesFlap Designs For Flap Advancement During Implant Therapy A Systematic Review 2016 PDFRohit ShahPas encore d'évaluation

- Atlas-Complejidad Económica PDFDocument362 pagesAtlas-Complejidad Económica PDFRafael QuiñonesPas encore d'évaluation

- Beauty Therapy Thesis SampleDocument8 pagesBeauty Therapy Thesis Samplerachelvalenzuelaglendale100% (2)

- Electricity and MagnetismDocument29 pagesElectricity and MagnetismNashrul HaqPas encore d'évaluation

- Greyhound Free Patt.Document14 pagesGreyhound Free Patt.claire_garlandPas encore d'évaluation

- Fender TransformersDocument2 pagesFender TransformersVincenzo TabaccoPas encore d'évaluation

- Design and Management of Mettur Dam by Predicting Seepage Losses Using Remote SensingDocument10 pagesDesign and Management of Mettur Dam by Predicting Seepage Losses Using Remote SensingInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Agricultural Machinery in PakistanDocument19 pagesAgricultural Machinery in PakistanBadar NiaziPas encore d'évaluation

- IJETR022563Document5 pagesIJETR022563erpublicationPas encore d'évaluation

- EclipseDocument6 pagesEclipsetoncipPas encore d'évaluation