Académique Documents

Professionnel Documents

Culture Documents

NDT and Welding Map Suction Scrubber V-101a-B

Transféré par

Haris Hutama0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageNdt and Welding Map Suction Scrubber v-101a-b

Titre original

Ndt and Welding Map Suction Scrubber v-101a-b

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentNdt and Welding Map Suction Scrubber v-101a-b

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageNDT and Welding Map Suction Scrubber V-101a-B

Transféré par

Haris HutamaNdt and Welding Map Suction Scrubber v-101a-b

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

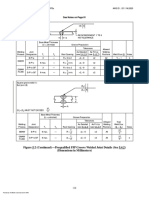

NO.

COMPONENT DESCRIPTION MATERIAL METHOD EXTENT NDE AFTER WPS

OF NDE PWHT

1 LS-01, CS-01, Long Seam, Circum Seam SA 516 70 RT 100% NA TEP-WPS-ASME-003

CS-02 TEP-WPS-ASME-024

TEP-WPS-ASME-025

2 NxJ1 Butt Joint SA 106 B, SA 105 MT/PT 100% NA TEP-WPS-ASME-003

Nozzle Pipe to Flange TEP-WPS-ASME-024

TEP-WPS-ASME-025

3 NxJ2 Welding Joint Nozzle Pipe/ SA 106 B, SA 516 70, SA MT/PT 100% NA TEP-WPS-ASME-024

Coupling to Shell/ Head 105 TEP-WPS-ASME-025

4 NxJ3 Welding Joint Reinforcement SA 516 70 MT/PT 100% NA TEP-WPS-ASME-024

Pad to Shell/ Head TEP-WPS-ASME-025

5 CS-03, LS-02 Circum Seam of skirt to bottom SA 516 70 MT/PT 100% NA TEP-WPS-ASME-003

head, Long Seam of skirt TEP-WPS-ASME-024

TEP-WPS-ASME-025

6 Others - Internal and external SA 516 70 MT/PT 100% NA TEP-WPS-ASME-024

attachment welds TEP-WPS-ASME-025

- Welding joint of lifting

device

7 Earthing Lug Welding joint Earting Lug to SS316, SA 516 70 - - - TEP-WPS-ASME-009

Leg

8 - - All temporary attachment SA 516 70, SA 105, SA 106 MT/PT 100% NA -

and arc strikes (after B

Grinding)

Client: HS COMPRESSION & PROSSESS Pte. Ltd

Project Name: PENGADAAN 2 UNIT KOMPRESSOR SCREW GAS

DI AREA SEMBAKUNG TARAKAN FIELD

Doc No.: -

NDT AND WELDING MAP FOR SUCTION

SCRUBBER (V-101A/B)

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Reaction PaperDocument4 pagesReaction PaperDaryl EstantePas encore d'évaluation

- Welding Basics - An Introduction To Practical & Ornamental WeldingDocument364 pagesWelding Basics - An Introduction To Practical & Ornamental Weldingmclade01100% (1)

- Chapter 6 - WeldingDocument20 pagesChapter 6 - WeldingDipayan DasPas encore d'évaluation

- Signed Off - SMAW11 - q1 - m5 - Welding Fillet Weld On Carbon Steel PLate - v3Document101 pagesSigned Off - SMAW11 - q1 - m5 - Welding Fillet Weld On Carbon Steel PLate - v3Christian Jake Respicio100% (1)

- Welding MythsDocument176 pagesWelding MythsAnonymous 1BdR0EQgbu100% (2)

- Pressure Vessel Manual-M.asgaRZADEGANDocument79 pagesPressure Vessel Manual-M.asgaRZADEGANH BPas encore d'évaluation

- CBT Questions For PipingDocument41 pagesCBT Questions For PipingarulselvamPas encore d'évaluation

- Zoki Zavarivanje PDFDocument46 pagesZoki Zavarivanje PDFDejanPas encore d'évaluation

- SMAW12 Quarter 1 Module 1Document60 pagesSMAW12 Quarter 1 Module 1Ronald Michael Poblete GlobioPas encore d'évaluation

- Tutorial Sheet Drawing II - IOEDocument47 pagesTutorial Sheet Drawing II - IOEwatif99884Pas encore d'évaluation

- me8361-MT 1 LabmanualDocument37 pagesme8361-MT 1 LabmanualHOD ITPas encore d'évaluation

- Esbm5a 1B310 S AaDocument28 pagesEsbm5a 1B310 S AaAlanevh AlanevhPas encore d'évaluation

- Types of Weld in Fillet Joints: Weld Carbon Steel Plates in Flat Position (1F)Document12 pagesTypes of Weld in Fillet Joints: Weld Carbon Steel Plates in Flat Position (1F)Sweni De GraciaPas encore d'évaluation

- Q2-02, Smaw Teacher's Made LMTDocument6 pagesQ2-02, Smaw Teacher's Made LMTFelix MilanPas encore d'évaluation

- Joint B-P1aDocument1 pageJoint B-P1akapsarcPas encore d'évaluation

- Section 2Document31 pagesSection 2Mohd Farid OsmanPas encore d'évaluation

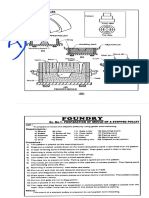

- Foundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyDocument4 pagesFoundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyAtshayaPas encore d'évaluation

- Welding SymbolsDocument49 pagesWelding SymbolsManiPas encore d'évaluation

- CBLM Smaw NC Ii PipeDocument40 pagesCBLM Smaw NC Ii PipeRyanM.PradelPas encore d'évaluation

- Airframe and Aero Engine Lab FinalDocument25 pagesAirframe and Aero Engine Lab FinalAravind Phoenix50% (2)

- Unit WI04: Welding Joints, Positions and Symbols: Session 3Document22 pagesUnit WI04: Welding Joints, Positions and Symbols: Session 3danPas encore d'évaluation

- Acceptable Weld ProfilesDocument9 pagesAcceptable Weld ProfilesDominic Apollo Robles100% (1)

- SECTION 05 36 00 Composite Metal DeckingDocument9 pagesSECTION 05 36 00 Composite Metal DeckingJuanPaoloYbañezPas encore d'évaluation

- Welder Visual Inspection HandbookDocument77 pagesWelder Visual Inspection HandbookfaizalzolPas encore d'évaluation

- 1614327061096-Objective Questions On Workshop Trade Theory MWT-04Document15 pages1614327061096-Objective Questions On Workshop Trade Theory MWT-04Pâtâñ ShâkéèrPas encore d'évaluation

- PDF Chapter 1 MEC 218 Welding Overview Student ResourceDocument9 pagesPDF Chapter 1 MEC 218 Welding Overview Student ResourceShamsudeen Abubakar SodangiPas encore d'évaluation

- Welding Is ADocument19 pagesWelding Is AAnthony ValinPas encore d'évaluation

- Laboratory Manual: II Year B. Tech II-Semester Mechanical EngineeringDocument48 pagesLaboratory Manual: II Year B. Tech II-Semester Mechanical EngineeringNaga KiranPas encore d'évaluation

- 12 - SMAW W 2 - Types of Fillet JointDocument12 pages12 - SMAW W 2 - Types of Fillet JointNelPalalonPas encore d'évaluation

- WeldDocument4 pagesWeldDineshkumar SPas encore d'évaluation