Académique Documents

Professionnel Documents

Culture Documents

Bowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2

Transféré par

globalindosparepartsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2

Transféré par

globalindosparepartsDroits d'auteur :

Formats disponibles

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 1 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

BoWex®

puncture curved-tooth gear couplings types

AS, Spec.-I, Spec.-I/CD and their combinations

Type AS

Type Spec.-I

Type Spec.-I/CD

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 2 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

BoWex® curved-tooth gear couplings are flexible shaft connections. They compensate for

shaft displacements, caused by e. g. inaccuracies in production, heat expansion etc.

Table of Contents

1 Technical Data

2 Hints

2.1 Coupling Selection

2.2 General Hints

2.3 Safety and Advice Hints

2.4 General Hints to Danger

2.5 Proper Use

3 Storage

4 Assembly

4.1 Components of the Couplings

4.2 Hint Regarding the Finish Bore

4.3 Assembly of the Coupling (General)

4.4 Assembly of the Type AS

4.5 Assembly of the Type Spec.-I and Spec.-I/CD

4.6 Displacements - Alignment of the Couplings

4.7 Spares Inventory, Customer Service Addresses

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 3 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

1 Technical Data

® ®

picture 1: BoWex type AS picture 2: BoWex type Spec.-I

Table 1: dimensions type AS and Spec.-I

dimensions

pilot bore max.

[mm]

size finish bore

un- pilot d1; d2 lengthened

l1; l2 E L LH M; N D DH

bored bored l1; l2 max.

24 x - 24 26 4 56 51 2,5 36 58 50

28 x - 28 40 4 84 56 14 44 70 55

32 x - 32 40 4 84 58 13 50 84 55

45 x - 45 42 4 88 60 14 65 100 60

26

65 x 65 55 4 114 84 15 96 140 70

70 lg.

80 - 31 80 90 6 186 93 46,5 124 175 -

100 - 38 100 110 8 228 102 63 152 210 -

125 - 45 125 140 10 290 134 78 192 270 -

®

picture 3: BoWex

type Spec.-I/CD

Table 2: dimensions type Spec.-I/CD

dimensions

pilot bore finish bore

[mm]

size

un- pilot

min. max. L L1 LH E E1 l2 l1 DH D M N

bored bored

24 x - 10 24 70 73,5 51 4 7,5 26 40 58 36 20 2,5

28 x - 10 28 94,5 98 56 4 8,5 40 50,5 70 44 28 14

32 x - 12 32 94,5 - 58 4 8,5 40 50,5 84 50 27 13

45 x - 20 45 101,5 - 60 4 8,5 42 55,5 100 65 32 14

65 x 26 30 65 123 - 84 4 10 55 64 140 96 28,5 15

80 - 31 35 80 179 - 93 6 13 90 83 175 124 44 46,5

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 4 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

2 Hints

2.1 Coupling Selection

CAUTION!

! For a continuous and troublefree operation of the coupling it must be designed according to

the selection instructions (according to DIN 740 part 2) for the particular application

(see BoWex® catalogue).

If the operating conditions (performance, speed, changes at engine and machine) change,

the coupling selection must be checked again.

Please make sure that the technical data regarding torque only refers to the sleeve. The

transmissible torque of the shaft/hub connection must be checked by the orderer, and he is

responsible for the same.

For drives with endangered torsional vibration (drives with periodical load on torsional vibration) it is necessary to

make a torsional vibration calculation to ensure a perfect selection. Typical drives with endangered torsional

vibration are e. g. drives with diesel engines, piston pumps, piston compressors etc. On request KTR makes the

coupling selection and the torsional vibration calculation.

2.2 General Hints

Please read through these mounting instructions carefully before you set the coupling into operation.

Please pay special attention to the safety instructions!

The mounting instructions are part of your product. Please keep them carefully and close to the coupling.

The copyright for these mounting instructions remains with KTR Kupplungstechnik GmbH.

2.3 Safety and Advice Hints

STOP DANGER! Danger of injury to persons.

! CAUTION! Damages on the machine possible.

) ATTENTION! Pointing to important items.

2.4 General Hints of Danger

DANGER!

STOP With assembly, operation and maintenance of the coupling it has to be made sure that the

entire drive train is protected against unintentional engagement. You can be seriously hurt

by rotating parts. Please make absolutely sure to read through and observe the following

safety instructions.

• All operations on and with the coupling have to be performed taking into account "safety first".

• Please make sure to disengage the power pack before you perform your work.

• Protect the power pack against unintentional engagement, e. g. by providing hints at the place of engagement

or removing the fuse for current supply.

• Do not touch the operation area of the coupling as long as it is in operation.

• Please protect the coupling against unintentional touch. Please provide for the necessary protection devices

and caps.

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 5 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

2 Hints

2.5 Proper Use

You may only assemble, operate and maintain the coupling if you

• have carefully read through the mounting instructions and understood them

• had technical training

• are authorized to do so by your company

The coupling may only be used in accordance with the technical data (see table 1 and 2 in chapter 1).

Unauthorized modifications on the coupling design are not admissible. We do not take any warranty for resulting

damages. To further develop the product we reserve the right for technical modifications.

The BoWex® described in here corresponds to the technical status at the time of printing of these mounting

instructions.

3 Storage

The coupling hubs are supplied in preserved condition and can be stored at a dry and roofed place for 6 - 9

months.

The features of the coupling sleeves remain unchanged for up to 5 years in case of favourable stock conditions.

CAUTION!

! The storage rooms may not include any ozone-generating devices, like e. g. fluorescent

light sources, mercury-vapour lamps or electrical high-voltage appliances.

Humid storage rooms are not suitable.

Please make sure that there is no condensation. The best relative air humidity is under 65%.

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 6 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

Basically the coupling is supplied in individual parts. Before assembly the coupling has to be controlled for

completeness.

4.1 Components of the Couplings

Components of BoWex® type AS

Component Quantity Designation

1 2 hub

2 1 sleeve AS

3 2 stop ring

4 2 circlip DIN 472

setscrew

6 2

DIN EN ISO 4029

®

picture 4: BoWex type AS

Components of BoWex® type Spec.-I

Component Quantity Designation

1 2 hub

2 1 spec. sleeve I

3 1 stop ring

4 1 circlip DIN 472

snap ring DIN 7993/

5 1

circlip DIN 472

setscrew

6 2

DIN EN ISO 4029

®

picture 5: BoWex type Spec.-I

Components of BoWex® type Spec.-I/CD

Component Quantity Designation

1 1 hub

1e 1 hub CD

2 1 spec. sleeve I

3 1 stop ring

4 1 circlip DIN 472

snap ring DIN 7993/

5 1

circlip DIN 472

setscrew

6 3

DIN EN ISO 4029

®

picture 6: BoWex type Spec.-I/CD

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 7 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

4.2 Hint Regarding the Finish Bore

DANGER!

STOP The maximum permissible bore diameters d (see

table 1 and 2 in chapter 1 - Technical Data) must not be

exceeded. If these figures are disregarded, the coupling

may tear. Rotating particles may cause serious danger.

• Hub bores (steel hubs) machined by the customer have to

observe concentric running or axial running, respectively

(see picture 7).

• Please make absolutely sure to observe the figures for dmax.

• Carefully align the hubs when the finish bores are brought

in.

• Please use a setscrew according to DIN EN ISO 4029 with a

cup point or an end plate to fasten the hubs axially.

picture 7: concentric running

and axial running

CAUTION!

! The orderer is responsible for all subsequently made machinings to unbored or pilot bored

and to finish machined coupling parts and spare parts. KTR does not assume any warranty

claims resulting from insufficient refinish.

Table 3: setscrews DIN EN ISO 4029

BoWex® size 24 28 32 45 65 80 100 125

dimension G M5 M8 M8 M8 M10 M10 M12 M16

tightening torque TA [Nm] 2 10 10 10 17 17 40 80

4.3 Assembly of the Coupling (General)

)

ATTENTION!

We recommend to check bores, shaft, keyway and feather key for dimensional accuracy

before assembly.

Heating the hubs slightly (approx. 80 °C) allows for an easier installation onto the shaft.

DANGER!

STOP Touching the heated hubs causes burns.

We would recommend to wear safety gloves.

CAUTION!

! For the assembly please make sure that the distance dimension E or E1 (see table 1 and 2)

is kept to ensure that the sleeve can be moved axially.

Disregarding this hint may cause damage on the coupling.

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 8 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

4.4 Assembly of the Type AS

• Push the hubs with stop ring and circlip onto the shafts of the driving side and the driven side

(see picture 8).

• Fasten the hubs by tightening the setscrews DIN EN ISO 4029 with cup point or an end plate.

• Put the coupling sleeve onto the toothing of a coupling hub (see picture 9).

• Move the power packs in axial direction until the dimension E is achieved (see picture 10).

• If the power packs are already firmly assembled, axial movement of the hubs on the shafts allows for adjusting

the dimension E.

• Put the circlips in the keyways of the coupling sleeves in order to protect the sleeve against axial displacement

(see picture 11).

picture 8 picture 9

picture 10 picture 11

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 9 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

4.5 Assembly of the Type Spec.-I and Spec.-I/CD

• Push one hub and one hub with stop ring and circlips onto the shafts of the driving side and the driven side

(see picture 12).

• Fasten the hubs by tightening the setscrews DIN EN ISO 4029 with cup point or an end plate.

• Insert the the snap ring or circlip (component 5) into the sleeves (see picture 13).

• Put the coupling sleeve onto the toothing of the coupling hub with the circlip and the stop ring pushed onto the

hub collar (see picture 14).

• Protect the coupling sleeve against axial displacement by inserting the circlips into the ring keyways of the

coupling sleeves (see picture 15).

• Move the power packs in axial direction until the dimension E or E1 is achieved (see picture 16).

• If the power packs are already firmly assembled, axial movement of the hubs on the shafts allows for adjusting

the dimension E.

picture 12 picture 13

picture 14 picture 15

picture 16

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 10 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

4.6 Displacements - Alignment of the Couplings

The displacement figures shown in table 4 offer sufficient safety to compensate for environmental influences like,

for example, heat expansion or lowering of foundation.

CAUTION!

! In order to ensure a long lifetime of the coupling, the shaft ends must be aligned accurately.

Please absolutely observe the indicated displacement figures (see table 4). If these figures

are exceeded, the coupling is damaged.

The exacter the alignment of the coupling, the higher is its lifetime.

Please note:

• The displacement figures mentioned in table 4 are maximum figures which must not arise in parallel. If radial

and angular displacement arises at the same time, the permissible radial displacements of the coupling halves

have to be reduced as follows:

ΔKr

ΔKrperm = ΔKr − • ΔWw

2ΔKw

ΔWw = angular shaft displacement

• The displacement figures mentioned are general figures that apply up to an ambient temperature of 80 °C,

ensuring a sufficient service life of the BoWex® coupling.

Displacement figures between the speeds indicated have to be interpolated accordingly. If necessary, please

ask about the displacement for the corresponding coupling type.

• Please check with a dial gauge, ruler or feeler whether the permissible displacement figures of table 4 can be

observed.

angular displacements radial displacements axial displacements radial and angular

displacements

picture 17: displacements

Example for the misalignment

combinations given in picture 18: picture 18:

combinations of

displacement

Example 1:

ΔKr = 30 %

ΔKw = 70 %

Example 2:

ΔKr = 60 %

ΔKw = 40 %

ΔKtotal = ΔKr + ΔKw ≤ 100 %

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

KTR Kupplungstechnik BoWex® KTR-N 40115 EN

GmbH Operating-/Assembly Instructions sheet: 11 of 11

D-48407 Rheine Type AS, Spec.-I and Spec.-I/CD edition: 2

4 Assembly

4.6 Displacements - Alignment of the Couplings

Table 4: Displacement figures

coupling size 24 28 32 45 65 80 100 125

max. axial displacement ΔKa [mm] ±1 ±1 ±1 ±1 ±1 ±1 ±1 ±1

max. radial displacement

0,35 0,35 0,35 0,40 0,45 0,45 0,45 0,45

with n=1500 1/min ΔKr [mm]

max. radial displacment

0,23 0,23 0,23 0,25 0,28 0,28 0,28 0,28

with n=3000 1/min ΔKr [mm]

ΔKw max. angular displacement

0,9 0,9 0,9 0,9 0,7 0,6 0,6 0,4

with n=1500 1/min [degree]

ΔKw max. angular displacement

0,6 0,6 0,6 0,6 0,5 0,4 0,4 0,3

with n=3000 1/min [degree]

4.7 Spares Inventory, Customer Service Addresses

A basic requirement to guarantee the operational readiness of the coupling is a stock of the most important spare

parts on site.

Contact addresses of the KTR partners for spare parts and orders can be obtained from the KTR homepage

under www.ktr.com.

Schutzvermerk Gezeichnet: 25.02.10 Pz Ersatz für: KTR-N vom 17.12.99

ISO 16016 beachten. Geprüft: 05.03.10 Pz Ersetzt durch:

Vous aimerez peut-être aussi

- Connector Harness CaterpillarDocument90 pagesConnector Harness Caterpillarglobalindospareparts100% (1)

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiPas encore d'évaluation

- The Photoshop CS6 Book 2013 PDFDocument212 pagesThe Photoshop CS6 Book 2013 PDFglobalindosparepartsPas encore d'évaluation

- Caterpillar - Steering Selenoid 785Document4 pagesCaterpillar - Steering Selenoid 785globalindosparepartsPas encore d'évaluation

- Cable TrenchDocument57 pagesCable TrenchHari Krishna AaryanPas encore d'évaluation

- ThaiREC Checklist-Barge Inspection Questionnaire GasDocument18 pagesThaiREC Checklist-Barge Inspection Questionnaire Gasเปีย วันชัย สวนทอง100% (1)

- Actual Crankshaft Manufacturer: Inhouse: Raw Material Production + CNC MachiningDocument16 pagesActual Crankshaft Manufacturer: Inhouse: Raw Material Production + CNC Machiningglobalindospareparts100% (1)

- Berg Manual CPP Contr Pitch PropellerDocument290 pagesBerg Manual CPP Contr Pitch PropellerКонстантин СкворцовPas encore d'évaluation

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberD'EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberÉvaluation : 5 sur 5 étoiles5/5 (1)

- C831/PRO8432WT Illustrated Spare Parts ManualDocument19 pagesC831/PRO8432WT Illustrated Spare Parts ManualLarry LinchPas encore d'évaluation

- HLX5 Kataloğu - 2016Document22 pagesHLX5 Kataloğu - 2016Alma100% (1)

- Catalogo Productos Cat Fuente+Segura+2008-2009Document548 pagesCatalogo Productos Cat Fuente+Segura+2008-2009Juan G. Gonzalez F.100% (1)

- Fuel Feed Pump ApplicationDocument144 pagesFuel Feed Pump ApplicationglobalindosparepartsPas encore d'évaluation

- Welding ProceduresDocument11 pagesWelding ProceduresnamasralPas encore d'évaluation

- Lista de Peças de Reposição: R902268922 Desenho: Número Do MaterialDocument46 pagesLista de Peças de Reposição: R902268922 Desenho: Número Do MaterialMarcus PereiraPas encore d'évaluation

- ROTEX Flex Coupling GR Instruction ManualDocument21 pagesROTEX Flex Coupling GR Instruction ManualIzzi Al-AkbarPas encore d'évaluation

- ISO 14583-01 - Hexalobular Socket Pan Head ScrewsDocument8 pagesISO 14583-01 - Hexalobular Socket Pan Head ScrewsGuillermo TorresPas encore d'évaluation

- Ads 2200 2700 PDFDocument17 pagesAds 2200 2700 PDFPaul Albu100% (1)

- Bowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6Document21 pagesBowex-Elastic: KTR-N Sheet: Edition: 40113 EN 1 of 21 6влад камрPas encore d'évaluation

- Instruccionesaacoples KTRDocument16 pagesInstruccionesaacoples KTRDênis DáyolPas encore d'évaluation

- Acoplamiento Bowex (Triturador) Instrucciones de MontajeDocument15 pagesAcoplamiento Bowex (Triturador) Instrucciones de MontajeNoePas encore d'évaluation

- Brother P-Touch PT-2420PC Parts List PDFDocument16 pagesBrother P-Touch PT-2420PC Parts List PDFMaxim100Pas encore d'évaluation

- Olrl 602Document4 pagesOlrl 602alejandro perezPas encore d'évaluation

- Pulley SKFDocument84 pagesPulley SKFNguyễn NhẫnPas encore d'évaluation

- Minex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5Document20 pagesMinex - S Permanent Magnetic Coupling: KTR-N Sheet: Edition: 46510 EN 1 of 20 5HyungTae JangPas encore d'évaluation

- Documento - MX Comp1Document10 pagesDocumento - MX Comp1Mangesh BanalePas encore d'évaluation

- Victaulic Quickvic™ SD Installation-Ready™ System: 1.0 Product DescriptionDocument9 pagesVictaulic Quickvic™ SD Installation-Ready™ System: 1.0 Product DescriptionQuynh NguyenPas encore d'évaluation

- PEGLER ValvesDocument8 pagesPEGLER Valveseng.abdullrahmanPas encore d'évaluation

- 1H18B0 - Water Accessories Booklet Rev. 2A PDFDocument258 pages1H18B0 - Water Accessories Booklet Rev. 2A PDFcnl filesPas encore d'évaluation

- Cim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDocument2 pagesCim 312CR: Full Bore Ball Valve - PN 32 - Type T12 - Aluminium Butterfly Handle - DZR Brass CRDaniel B. BalmoriPas encore d'évaluation

- RN68 - 68M (RN76 - 76M and RN90 - 90M) Water Leakage at The Piston Cooling Running PipesDocument6 pagesRN68 - 68M (RN76 - 76M and RN90 - 90M) Water Leakage at The Piston Cooling Running PipescarmaPas encore d'évaluation

- Catalogo de Acoples Rotex 2Document36 pagesCatalogo de Acoples Rotex 2cmaradiagaPas encore d'évaluation

- 2213 Ca P0Document1 page2213 Ca P0Oleg ShkolnikPas encore d'évaluation

- Type 06198: Overflow ValvesDocument2 pagesType 06198: Overflow ValvesabdulfetahPas encore d'évaluation

- LTV 8X7 Series Lite OnDocument18 pagesLTV 8X7 Series Lite OnStick BohorquezPas encore d'évaluation

- DT 55 (1985-1987) DT 65 (1985-1987)Document57 pagesDT 55 (1985-1987) DT 65 (1985-1987)Antonio MatronePas encore d'évaluation

- Grundfos InstructionDocument22 pagesGrundfos InstructionSajeev NerurkarPas encore d'évaluation

- Crane Bronze StrainerDocument1 pageCrane Bronze StrainerstephenlongislandPas encore d'évaluation

- Parts Reference List: Color FAX/MFCDocument35 pagesParts Reference List: Color FAX/MFCJesse ScheckPas encore d'évaluation

- Grundfosliterature 2616Document22 pagesGrundfosliterature 2616Sal MendezPas encore d'évaluation

- Slot Diffuser: Type VSD50Document14 pagesSlot Diffuser: Type VSD50Kim Nicolas SaikiPas encore d'évaluation

- Tabla de Equivalencias de Aceros NormadosDocument1 pageTabla de Equivalencias de Aceros NormadosGASTÓN ANDRÉS BALTIERRA CARTESPas encore d'évaluation

- CylinderDocument39 pagesCylinderapi-3854910100% (1)

- Parts Reference ListDocument42 pagesParts Reference ListVladPas encore d'évaluation

- Shear ContactDocument1 pageShear ContactNkolmintag Church BroadcastPas encore d'évaluation

- Hydrapac RV-2DDocument2 pagesHydrapac RV-2DzipaalexandrePas encore d'évaluation

- Line Strainer 4005: DN 10 Up To DN 65Document3 pagesLine Strainer 4005: DN 10 Up To DN 65santhoshkrishnaPas encore d'évaluation

- Series R: 3 Piece Ball Valves With Integrated Handle DN8 - DN50 Butt Weld, Threaded, Socket Weld and Flanged VersionDocument2 pagesSeries R: 3 Piece Ball Valves With Integrated Handle DN8 - DN50 Butt Weld, Threaded, Socket Weld and Flanged VersionАртем КосовPas encore d'évaluation

- Parts Reference List: Model: DCP-L8410CDW MFC-L8610CDW/L8690CDW MFC-L8900CDW/L9570CDW MFC-L9577CDWDocument36 pagesParts Reference List: Model: DCP-L8410CDW MFC-L8610CDW/L8690CDW MFC-L8900CDW/L9570CDW MFC-L9577CDWpablo contreras100% (1)

- Head ClearancesDocument2 pagesHead ClearancesMohan Rao0% (2)

- 2642 Ni 71350002Document56 pages2642 Ni 71350002ToudPas encore d'évaluation

- Trip BHA#12.25in TPN - DZ 20.6 (TPN-223)Document2 pagesTrip BHA#12.25in TPN - DZ 20.6 (TPN-223)Setya AminPas encore d'évaluation

- HS FWR01 000000staec - CDocument4 pagesHS FWR01 000000staec - CMarcoPas encore d'évaluation

- Cutting Data Catalogue PDFDocument138 pagesCutting Data Catalogue PDFlyxuandatbkPas encore d'évaluation

- Brother HL 2130 2132 2135 2220 ErsatzteileDocument38 pagesBrother HL 2130 2132 2135 2220 Ersatzteilemark parkinsPas encore d'évaluation

- Voith AcoplamentoDocument21 pagesVoith AcoplamentoJosé LuizPas encore d'évaluation

- 30D MS Standard Mast Limited Freelift 2-Stage: Arts ManualDocument27 pages30D MS Standard Mast Limited Freelift 2-Stage: Arts ManualХелфор УкраинаPas encore d'évaluation

- PL HL2220 HL2230 HL2240 HL2240D HL2270DW PDFDocument35 pagesPL HL2220 HL2230 HL2240 HL2240D HL2270DW PDFJosé MaríaPas encore d'évaluation

- 546 DatasheetDocument11 pages546 Datasheetwilfredo mercedesPas encore d'évaluation

- Monninghoff 546 - DatasheetDocument11 pagesMonninghoff 546 - DatasheetirfannadinePas encore d'évaluation

- Eq DF2Document1 pageEq DF2SKYhabiaPas encore d'évaluation

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILPas encore d'évaluation

- Bachofen Seria TrimodBesta Raport Exida FMEDA SILDocument26 pagesBachofen Seria TrimodBesta Raport Exida FMEDA SILannisaanugerahPas encore d'évaluation

- Parts Reference List: Model: HL-5240/5250DN/5270DN/ 5280DW/5250DNTDocument35 pagesParts Reference List: Model: HL-5240/5250DN/5270DN/ 5280DW/5250DNTlibfly18Pas encore d'évaluation

- Coupling & Flange Connections: 4 Bolt Flange - Threaded X O-Ring FaceDocument6 pagesCoupling & Flange Connections: 4 Bolt Flange - Threaded X O-Ring FaceDaniel MarPas encore d'évaluation

- 223 STARDIESEL ProductsCatalog 03 2018Document285 pages223 STARDIESEL ProductsCatalog 03 2018globalindospareparts100% (1)

- Perkins 1100 Series: Bore: 105mmDocument17 pagesPerkins 1100 Series: Bore: 105mmglobalindosparepartsPas encore d'évaluation

- PLL 1405Document4 pagesPLL 1405globalindosparepartsPas encore d'évaluation

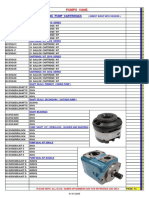

- Model VQ Vane Pump CartridgesDocument7 pagesModel VQ Vane Pump CartridgesglobalindosparepartsPas encore d'évaluation

- Deutsch Connector CatDocument48 pagesDeutsch Connector CatglobalindosparepartsPas encore d'évaluation

- PLL - 1453 VickersDocument5 pagesPLL - 1453 VickersglobalindosparepartsPas encore d'évaluation

- Axial Plug-In, Maintenance-Free, Torsionally Rigid: Bowex Fle-Pa - Dimensions/Nominal Dimension To SaeDocument2 pagesAxial Plug-In, Maintenance-Free, Torsionally Rigid: Bowex Fle-Pa - Dimensions/Nominal Dimension To SaeglobalindosparepartsPas encore d'évaluation

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDocument30 pagesDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsPas encore d'évaluation

- Ict-Leavyseal-Cat-A4-En ConnectorDocument24 pagesIct-Leavyseal-Cat-A4-En ConnectorglobalindosparepartsPas encore d'évaluation

- Bowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2Document11 pagesBowex: KTR-N Sheet: Edition: 40115 en 1 of 11 2globalindosparepartsPas encore d'évaluation

- Polymers For Transdermal Drug Delivery SystemsDocument9 pagesPolymers For Transdermal Drug Delivery SystemsAmjadRazaPas encore d'évaluation

- Ehe 07Document286 pagesEhe 07api-348272721Pas encore d'évaluation

- Practical Considerations For The Use of A Howland Current SourceDocument4 pagesPractical Considerations For The Use of A Howland Current SourceRamiShaabannnnPas encore d'évaluation

- Starboard Strategies Issue 13-MinDocument28 pagesStarboard Strategies Issue 13-MinkrishnamrutamPas encore d'évaluation

- 02 - Student Lesson 2 Pile Driving SystemDocument91 pages02 - Student Lesson 2 Pile Driving SystemdannyzuanPas encore d'évaluation

- Email TMK88065 PDFDocument3 pagesEmail TMK88065 PDFlily_ng3642Pas encore d'évaluation

- XRD ProcedureDocument2 pagesXRD Procedurepullo123Pas encore d'évaluation

- LDT9965 Dis WasherDocument70 pagesLDT9965 Dis WasherJosé Airton TirakowskiPas encore d'évaluation

- VocationalDocument2 pagesVocationalMegha RoyPas encore d'évaluation

- Parts Catalog: Paper Feed Unit Type 3800C (G568)Document23 pagesParts Catalog: Paper Feed Unit Type 3800C (G568)poldisagtPas encore d'évaluation

- Project Title: Hotel Management Software Project: PurposeDocument3 pagesProject Title: Hotel Management Software Project: PurposesuryaPas encore d'évaluation

- Retrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsDocument2 pagesRetrofit of Water Mist Catcher: WMC For L23/30 (H) and L28/32 (H) GensetsMichael GorobaoPas encore d'évaluation

- A Review Paper On Effect of Varying Welding Heat Input On Microstructure, Mech Properties and Corrosion Behaviors of Ferritic SS & Mild Steel PDFDocument5 pagesA Review Paper On Effect of Varying Welding Heat Input On Microstructure, Mech Properties and Corrosion Behaviors of Ferritic SS & Mild Steel PDFMursidil KamilPas encore d'évaluation

- On The Gaussian Error Function (1935) : Robert J. KolkerDocument4 pagesOn The Gaussian Error Function (1935) : Robert J. KolkerSanthosh KulandaiyanPas encore d'évaluation

- Scenario of Shale Gas Exploration in IndiaDocument24 pagesScenario of Shale Gas Exploration in IndiaManish TiwariPas encore d'évaluation

- Debug 1214Document3 pagesDebug 1214Pandji AsmaraPas encore d'évaluation

- Module D Exercise ModD - QB09 - EngDocument4 pagesModule D Exercise ModD - QB09 - Engapi-3812894Pas encore d'évaluation

- UAMDocument35 pagesUAMVishnu R PuthusseryPas encore d'évaluation

- EC8093 - Digital Image Processing (Ripped From Amazon Kindle Ebooks by Sai Seena) PDFDocument102 pagesEC8093 - Digital Image Processing (Ripped From Amazon Kindle Ebooks by Sai Seena) PDFSivaramakrishnan Kanagaraj0% (1)

- Lectures - Mass TransferDocument36 pagesLectures - Mass TransferaaaPas encore d'évaluation

- 11i APC Imp GuideDocument108 pages11i APC Imp GuidePrashanth ReddyPas encore d'évaluation

- L1F1Document5 pagesL1F1DanielPas encore d'évaluation

- Ncomputing VSpace Server Management Console User ManualDocument34 pagesNcomputing VSpace Server Management Console User ManualJeff IvanPas encore d'évaluation

- FD100 CatalogoDocument4 pagesFD100 CatalogoKaren VásconezPas encore d'évaluation

- Surface Condenser Eng2Document5 pagesSurface Condenser Eng2MuhammadFikriPas encore d'évaluation

- Cfw300 Manual 1Document124 pagesCfw300 Manual 1maurilioPas encore d'évaluation

- L19 External DiffusionDocument30 pagesL19 External DiffusionEga NabellaPas encore d'évaluation