Académique Documents

Professionnel Documents

Culture Documents

HEI (EJE) - Motive Steam Consumption

Transféré par

Sanjay Patel0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageThis document provides standards and equations for measuring heat exchange using steam jet ejectors. It describes how to calculate steam flow rates through nozzles using equations that consider nozzle diameter, pressure, temperature, and other factors. Flow rate curves are provided for different pressures and temperatures. The document also describes how to measure air and steam mixture flow rates by separately measuring the air and steam flow components.

Description originale:

Hei

Titre original

HEI(EJE)-Motive Steam Consumption

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides standards and equations for measuring heat exchange using steam jet ejectors. It describes how to calculate steam flow rates through nozzles using equations that consider nozzle diameter, pressure, temperature, and other factors. Flow rate curves are provided for different pressures and temperatures. The document also describes how to measure air and steam mixture flow rates by separately measuring the air and steam flow components.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageHEI (EJE) - Motive Steam Consumption

Transféré par

Sanjay PatelThis document provides standards and equations for measuring heat exchange using steam jet ejectors. It describes how to calculate steam flow rates through nozzles using equations that consider nozzle diameter, pressure, temperature, and other factors. Flow rate curves are provided for different pressures and temperatures. The document also describes how to measure air and steam mixture flow rates by separately measuring the air and steam flow components.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

STANDARDS OF THE HEAT EXCHANGE INSTITUTE, INC.

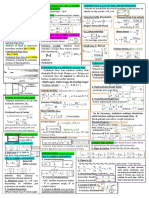

The following illustrates the use of Figures 24, 26 where:

and 27:

Ws = Steam flow rate, lb/hr

Nozzle throat diameter 0.125 in.

C = Nozzle coefficient

Barometric pressure 29.0 in. Hg

Dn = Diameter of nozzle throat, in

Differential pressure across nozzle 10.0 in. Hg

P 1 = Upstream static pressure, psia

Ambient air temperature 90°F

Vsp = Upstream specific volume, ft 31lb

Flow rate (from Figure 24) = 1143lbslhr of 70°F

air per in 2 of nozzle throat area with a nozzle coef- Using the above equation, the curves, Figures 28,

ficient of unity (c = 1.00). 29,30 and 31, have been plotted for the steam flow

rate (Ws ) on the basis of one square inch of nozzle

Nozzle throat area = 0.01221 in 2 throat area and a nozzle coefficient of 1.00 for pres-

sures from 0 to 620 psig and from saturation tem-

Temperature correction (from Figure 27) = 0.982 perature to 1000°F total temperature. Flow values

Nozzle coefficient (from Figure 26) = 0.966 taken from these curves shall be corrected by using

the proper nozzle coefficient from Figure 20. The

Actual flow rate = 1143 x 0.01227 x 0.982 x 0.966 = Reynolds number needed to determine the nozzle

13.3 lb/hr of 90°F air. coefficient from Figure 20 shall be calculated for the

Coefficient on unity = (C=1.00) prevailing test conditions by using equation (3) in

Paragraph 5.4.2 with the value for viscosity in equa-

5.4.3 Steam Tests tion (3) obtained from Figure 32.**

The quantity of steam handled by the steam jet 5.4.4 Air and Steam Mixture Tests

ejector shall be measured by means of the Heat

Exchange Institute Standard Flow Nozzles as shown The quantity of a mixture of air and steam or

in Figure 19. Critical flow shall be used. water vapor handled by the steam jet ejector shall be

determined by measuring the air flow rate, as out-

The steam flow rate through these flow nozzles lined in Paragraph 5.4.2, and measuring the steam

shall be calculated by using the following equation*: flow rate, as outlined in Paragraph 5.4.3. The air and

steam handled shall be mixed in a mixing chamber

as shown in Figure 36 before being entrained by the

W, =892.4 CD! ~ (5) ejector.

sp

* The average value ofk for steam is 1.300 and for the

critical flow testing arrangement recommend, f3 is never **Steam viscosity taken from "The Viscosity, Thermo

greater than 0.25 and in practically all cases is 0.20 or Conductivity and Prandtl Number for Air, 02' N 2' NO,

less. Using 1.3000 for k and 0.20 as an average for [3, Z' a, CO, CO2, ~O, He and Ar" by Joseph Hilsenrath and

becomes 0.4722 and substituting this value for Z' in basic Y. S. Toulaukian,ASME Transactions, Volume 76, No.6,

flow equation (2) reduces it to equation (5). August 1954, pages 967-985.

40

Vous aimerez peut-être aussi

- BTE2222 Thermal Science Lab ExperimentsDocument31 pagesBTE2222 Thermal Science Lab ExperimentsFirdaus ZainuddinPas encore d'évaluation

- HEI (EJE) - Critical Air FlowDocument1 pageHEI (EJE) - Critical Air FlowSanjay PatelPas encore d'évaluation

- Vapor Pressure and Evaporation Coefficient GlycerolDocument4 pagesVapor Pressure and Evaporation Coefficient GlycerolCelrose FernandezPas encore d'évaluation

- Experimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985Document3 pagesExperimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985donyaPas encore d'évaluation

- Problem Sheet 1 Basics and TemperatureDocument4 pagesProblem Sheet 1 Basics and TemperatureS DPas encore d'évaluation

- Psychometry Air Conditioning EditDocument33 pagesPsychometry Air Conditioning EditlewisPas encore d'évaluation

- P 303 AnsDocument4 pagesP 303 AnsDiptoPas encore d'évaluation

- Abl12e 09Document2 pagesAbl12e 09jlcheefei9258Pas encore d'évaluation

- AT Question BankDocument3 pagesAT Question BankShubham Vijay JadhavPas encore d'évaluation

- Steam Vent Rate CalculationDocument3 pagesSteam Vent Rate Calculationshoaib705Pas encore d'évaluation

- Chapter 6 - Gas Well PerformanceDocument43 pagesChapter 6 - Gas Well PerformanceNur Syaffiqa Mohamad RuzlanPas encore d'évaluation

- Problem #1Document1 pageProblem #1T.r.PrasannaPas encore d'évaluation

- Atrium Natural Smoke CalculationsDocument5 pagesAtrium Natural Smoke CalculationsRamiAl-fuqahaPas encore d'évaluation

- Assignment 1Document2 pagesAssignment 1Fredrik UlvinPas encore d'évaluation

- ACR-News: Masterclass: Psychometrics - Part 28Document5 pagesACR-News: Masterclass: Psychometrics - Part 28streamtPas encore d'évaluation

- Mine VentilationDocument24 pagesMine VentilationJose Mari DichosonPas encore d'évaluation

- Assignment 05Document2 pagesAssignment 05Raj KothiyaPas encore d'évaluation

- Me 333Document2 pagesMe 333Sandeep Prabakaran100% (1)

- T5a Airconditioning Tutorial Solutions 1 To 3 202223-1Document7 pagesT5a Airconditioning Tutorial Solutions 1 To 3 202223-1victorigamiPas encore d'évaluation

- Psycrometric ProcessDocument33 pagesPsycrometric Processmdalt9180Pas encore d'évaluation

- What Is Compression RatioDocument3 pagesWhat Is Compression RatiovasanthavananPas encore d'évaluation

- Condenser ProblemsDocument12 pagesCondenser ProblemsJagdeesh R100% (1)

- EXPERIMENT 1 ThrottlingDocument8 pagesEXPERIMENT 1 ThrottlingJaphet MmariPas encore d'évaluation

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDocument27 pagesCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenPas encore d'évaluation

- QuestionsDocument3 pagesQuestionsVinoth BillaPas encore d'évaluation

- Specific Heat RatioDocument5 pagesSpecific Heat RatioPaolo QuinteroPas encore d'évaluation

- 2018PGMETE08-Assignment 5Document7 pages2018PGMETE08-Assignment 5Rahul KumarPas encore d'évaluation

- 45 - 37295 - EE218 - 2012 - 4 - 2 - 1 - EE 218 Sheets and SolutionsDocument20 pages45 - 37295 - EE218 - 2012 - 4 - 2 - 1 - EE 218 Sheets and Solutionsmaz alvitPas encore d'évaluation

- Tid 001 PDFDocument3 pagesTid 001 PDFJorge Kovach AlvaradoPas encore d'évaluation

- Diesel SpraysDocument5 pagesDiesel SpraysSohaib Ur-rehmanPas encore d'évaluation

- Thermodynamics Lab Report H111J UnitDocument14 pagesThermodynamics Lab Report H111J UnitKarim AbdallahPas encore d'évaluation

- 4.1.3 Step-by-Step CalculationDocument11 pages4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Fluid Mechanics AssignmentDocument11 pagesFluid Mechanics AssignmentAgnibha BanerjeePas encore d'évaluation

- Experiment-1: Pressure-Temperature Relationship For SteamDocument8 pagesExperiment-1: Pressure-Temperature Relationship For Steamknowledge About EverythingPas encore d'évaluation

- Sensor ProblemsDocument20 pagesSensor ProblemsSalih AbbasPas encore d'évaluation

- 7 MCE 211-The Carnot CycleDocument8 pages7 MCE 211-The Carnot CycleAhmed Al-ayatPas encore d'évaluation

- Lab 4Document13 pagesLab 4Dilshad S FaisalPas encore d'évaluation

- Assignment 1 ATDDocument4 pagesAssignment 1 ATDPrashant Singh0% (1)

- ME1310Document5 pagesME1310Uday BagadePas encore d'évaluation

- Heat and Mass TransferDocument28 pagesHeat and Mass TransfersureshkumarPas encore d'évaluation

- Te MJ07Document4 pagesTe MJ07Anonymous ijGnA6CWEaPas encore d'évaluation

- شيتات تربوDocument15 pagesشيتات تربومحمد عفيفىPas encore d'évaluation

- Process Control Instrumentation Technology 8th Edition Solutions ManualDocument8 pagesProcess Control Instrumentation Technology 8th Edition Solutions ManualMona Ibrahim100% (1)

- Assignment 4 Reciprocating Air CompressorsDocument8 pagesAssignment 4 Reciprocating Air CompressorsAkshay A KumarPas encore d'évaluation

- 08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Document3 pages08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Senthil AnnaunivPas encore d'évaluation

- Presentation ORCDocument21 pagesPresentation ORCstanlnleybudukaPas encore d'évaluation

- Chapter 5 Gas Well PerformanceDocument41 pagesChapter 5 Gas Well PerformanceJagathisswary SatthiPas encore d'évaluation

- Experiment-1: Pressure-Temperature Relationship For SteamDocument7 pagesExperiment-1: Pressure-Temperature Relationship For SteamNTOBEKO GASAPas encore d'évaluation

- AT1 (3rd) MAY2011Document3 pagesAT1 (3rd) MAY2011transendencePas encore d'évaluation

- MTTE 012 Mtech RAC Set 01Document3 pagesMTTE 012 Mtech RAC Set 01Vinod yadavPas encore d'évaluation

- Axial Flow Compressors and Fans - DixDocument4 pagesAxial Flow Compressors and Fans - DixYanganani SindeloPas encore d'évaluation

- Cam 05 Calculation Tcm48-705084Document16 pagesCam 05 Calculation Tcm48-705084Bao Kim100% (1)

- Applied Thermodynamics EME-401 PDFDocument6 pagesApplied Thermodynamics EME-401 PDFRohit GrewalPas encore d'évaluation

- Chapter 1 - Properties of Humid Air - 2017 - Air Conditioning System DesignDocument28 pagesChapter 1 - Properties of Humid Air - 2017 - Air Conditioning System Designsasha.zach1024Pas encore d'évaluation

- Assignment 04Document16 pagesAssignment 04Pritam SahPas encore d'évaluation

- Propulsion Homework Exercises A 12-08Document11 pagesPropulsion Homework Exercises A 12-08jgolloberPas encore d'évaluation

- A Modern Course in Statistical PhysicsD'EverandA Modern Course in Statistical PhysicsÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Groundwater HydrologyDocument83 pagesGroundwater Hydrologydixn__100% (1)

- AVCO Orifice PlatesDocument3 pagesAVCO Orifice PlatestmharishPas encore d'évaluation

- Closed Feed Water HeatersDocument56 pagesClosed Feed Water HeatersAnudeep ChittluriPas encore d'évaluation

- Back Pressure Calculation 1 PDFDocument2 pagesBack Pressure Calculation 1 PDFRanu Januar100% (6)

- Module 3 - Fluid Pressure Regimes - UpdatedDocument14 pagesModule 3 - Fluid Pressure Regimes - UpdatedKd FaPas encore d'évaluation

- Lab Report 123Document9 pagesLab Report 123Falcon Tech0% (1)

- Selection of Taper Roller BearingsDocument5 pagesSelection of Taper Roller BearingsJai SharmaPas encore d'évaluation

- Water Footprints of Some Select Crops in Pakistan PDFDocument61 pagesWater Footprints of Some Select Crops in Pakistan PDFEnviro_Pak100% (2)

- Rising MainDocument2 pagesRising MainJitesh KumarPas encore d'évaluation

- Toaz - Info Sample Problem Part 9 Mech Fluid PRDocument10 pagesToaz - Info Sample Problem Part 9 Mech Fluid PRChristian Castle SpiritPas encore d'évaluation

- Boundary Layer SuctionDocument2 pagesBoundary Layer Suctionengineer bilalPas encore d'évaluation

- Tubes With InsertionDocument23 pagesTubes With InsertionDenys TsybulskiyPas encore d'évaluation

- S L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryDocument4 pagesS L Dixon Fluid Mechanics and Thermodynamics of TurbomachineryAbel AziePas encore d'évaluation

- ME2134cheatsheet PDFDocument1 pageME2134cheatsheet PDFbenPas encore d'évaluation

- Applied AerodynamicsDocument23 pagesApplied AerodynamicsAfiorPas encore d'évaluation

- DAE Mechanical Technology 3rd Year PDFDocument116 pagesDAE Mechanical Technology 3rd Year PDFShahid JehanPas encore d'évaluation

- Guidelines On Compressor Sizing and SelectionDocument35 pagesGuidelines On Compressor Sizing and SelectionIan LuyaoPas encore d'évaluation

- Exam On Pumps and Pipe NetworksDocument10 pagesExam On Pumps and Pipe Networksm_abdelgawadPas encore d'évaluation

- Modul Fizik F5 2023 (Answers)Document25 pagesModul Fizik F5 2023 (Answers)nyshahidaPas encore d'évaluation

- Hysys PrintDocument41 pagesHysys PrintLucas WalkerPas encore d'évaluation

- C410 963 A RA-635784 001 D: LegendsDocument1 pageC410 963 A RA-635784 001 D: LegendsmuthuvelaaPas encore d'évaluation

- ManometersDocument16 pagesManometersYuva RajaPas encore d'évaluation

- Lattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015 PDFDocument12 pagesLattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015 PDFSofian SalmaniPas encore d'évaluation

- Presentation On Bernoulli's EquationDocument41 pagesPresentation On Bernoulli's EquationDerek Stampone100% (2)

- Price Schedule 18T-Q-1430-FernasDocument2 pagesPrice Schedule 18T-Q-1430-FernasTASNEEMPas encore d'évaluation

- Slaughterhouse Waste Water TreatmentDocument16 pagesSlaughterhouse Waste Water TreatmentAleem AhmedPas encore d'évaluation

- Septic Tank Purpose - FunctionDocument35 pagesSeptic Tank Purpose - FunctionMasnun Rahman100% (2)

- Bill Nye Water Cycle Ws With BlanksDocument1 pageBill Nye Water Cycle Ws With BlanksairdogfatPas encore d'évaluation

- Hydraulic FluidsDocument29 pagesHydraulic FluidsRhea TalibPas encore d'évaluation

- HPM CatalogDocument8 pagesHPM CatalogNaser JahangiriPas encore d'évaluation