Académique Documents

Professionnel Documents

Culture Documents

FISA 502 Extraction by Skidder

Transféré par

fmacaetanoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FISA 502 Extraction by Skidder

Transféré par

fmacaetanoDroits d'auteur :

Formats disponibles

DRIVING THE SKIDDER FURTHER READING

❏ 25 Do not drive if vision is obscured. Tractor units in tree work FISA501

Extraction by forwarder FISA503

❏ 26 Ensure that the stabilisers and butt plate (if fitted) are Extraction by cable crane FISA504

raised before driving off. Mechanical harvesting FISA603

Mechanical roadside processing FISA605

❏ 27 Do not allow ropes or chokers to trail on the ground Emergency planning FISA802

when the tractor is moving. Electricity at work: Forestry FISA804

Training and certification FISA805

❏ 28 Drop the load before crossing any ground which is rough Managing Public Safety on Harvesting FC forestry@apsgroup.co.uk

enough to affect the tractor and load stability.

First aid at work: Your questions answered INDG214

Managing health and safety in forestry INDG294

❏ 29 Avoid turning uphill on side slopes.

Don’t lose your hearing INDG363

STACKING

A Simple Guide to PUWER INDG291

These publications are available from the FISA and HSE websites.

Extraction

❏

❏

30 Stacks of timber should always be made and maintained

in a stable condition.

31 Where there is to be additional manual handling the

NOTES by skidder

height of the stacked timber should not exceed about

1m. So far as is reasonably practicable, avoid stack

heights above 2m.

❏ 32 Take special care in areas frequented by the public. Where

appropriate, although not a substitute for safe stacking, a

prohibition (‘Do not climb on timber stacks’) sign Name:

conforming to the Health and Safety (Safety Signs and

Signals) Regulations 1996 should be displayed, and/or the Checklist verified by:

stacking site enclosed with hazard warning tape.

Date:

SKIDDING UNIT MAINTENANCE

❏ 33 Carry out maintenance in accordance with the Further information

manufacturer’s handbook which should be available. This guide is produced by the Forest Industry Safety Accord (FISA)

59 George Street, Edinburgh, EH2 2JG Tel: 0131 240 1410

❏ 34 Keep a maintenance record. Fax: 0131 240 1411 Email: info@ukfisa.com

Copies of this guide and all other FISA priced and free publications

❏

Image courtesy of Forestry Commission Picture Library

35 Check ropes, pulleys and chokering equipment for

damage or abnormal wear. are available by mail order from the FISA office or through the FISA

website www.ukfisa.com. From here you will also be able to access

❏ 36 Check the winch/clambunk structure for distortion, a wide range of additional forestry safety information including

cracks and damage. frequently updated safety alerts.

This guide sets out evidence of good practice for a specific forestry task.

❏ 37 Check all external nuts, bolts and linkages for security.

Deviation from the guide should only be considered after a full risk

assessment has been undertaken by competent persons. Health and

❏ 38 Ensure all defects are promptly reported and repaired or

safety obligations MUST be met at all times.

replaced.

THINK SAFE / STAY SAFE

This publication is based on guidance previously published by HSE

in AFAG502 Extraction by skidder, which was withdrawn in 2013.

For more general information about health and safety, please visit

the Health and Safety Executive website www.hse.gov.uk

FISA Safety Guide 502

FISA502 Reprinted 03/13

INTRODUCTION ❏ 7 Make sure sheaves, rollers and other equipment for guiding ❏ 16 Ensure that stabilisers and adjustable butt plates (if

ropes is compatible with the dimension of the rope and kept fitted) are in the lowered position and correctly

This leaflet covers the use of a wire, rope, hydratong or clambunk in a serviceable condition to avoid damaging wire ropes. positioned and adjusted. Make allowance for some

skidder for timber extraction in forestry and other tree work. rearward movement as the hauling rope is tensioned.

❏ 8 Hauling ropes must be securely fastened to the winding

You can use this leaflet, along with the manufacturer’s handbook, drum. At least three full turns should remain on the drums ❏ 17 When facing down a slope, lower the log-rolling blade (if

as part of the risk assessment process to help identify the at all times. fitted). Pull the winch rope out smoothly. Attach the chokers

controls to put in place when extracting timber by skidder. securely near the end of the poles keeping the shortest

❏ 9 All ropes should be terminated in a suitable way such as practicable length between the poles and the winch rope.

This leaflet does not cover: splicing, soft eye loops or swaging – do not use knots.

❏ 18 Organise the chokering system to allow the load to be

• the safety requirements when working within the risk zone of a ❏ 10 Check daily for visual signs of rope deterioration such as freely winched in, avoiding obstructions (see Figure 3).

harvester or processor (see FISA leaflet 605 Mechanical excessive wear, broken wires or strands, distortions and

roadside processing); corrosion. Repair or replace broken or damaged ropes

without delay.

• the safety requirements when the machine is fitted with a loader

(see FISA leaflet 503 Extraction by forwarder paragraphs 11-23).

❏ 11 Replace all ropes when their nominal diameter falls below

You must also assess the effect of the site and the weather as 90% of the original.

well as following this guidance. Figure 3: Organised chokering

❏ 12 Broken or badly frayed ropes must be joined by adequate

All operators must have had appropriate training in how to splicing or be replaced. Knots greatly reduce the strength ❏ 19 If the load becomes snagged, stop winching. Do not

operate the machine and how to carry out the tasks required (see of the ropes and must not be used. continue to pull, release the tension on the rope and take

FISA leaflet 805 Training and certification). appropriate action to free the load.

CHOKERING EQUIPMENT ❏ 20 Ensure the load is winched up close to the butt plate or

This leaflet must be read in conjunction with FISA leaflet 501

Tractor units in tree work. the notched drawbar.

❏ 13 Firmly attach all connections for captive chokers to the

wire rope. Ensure all terminal connections are firmly ❏ 21 When operating on side slopes with a double drum

GENERAL ADVICE attached before use. winch, haul in the load on the upper drum first to

improve the tractor stability.

❏ 1 Do not operate a skidding unit if any part of the machine or CHOKERING AND WINCHING

the tree can come within one tree length + the vicinity zone ❏ 22 Operate the winch controls only from the designated

(down to a minimum distance of 15 m) of energised ❏ 14 Park the tractor in a stable position where it is as level as position as specified in the instruction manual. Where

overhead power lines. The vicinity zone will vary between possible (see Figure 1). winches are operated by lanyard or other remote means,

1m and 5m depending on line voltages (see FISA leaflet operators should stand to one side of the line of pull, to

804 Electricity at work: Forestry). the higher side if on a side slope and outside the risk

zone of where the machine could tip over.

❏ 2 The skidding unit must be equipped with ropes and

components in a serviceable condition and which meet the ❏ 23 Stop work when anyone comes within a distance equal to

manufacturer’s recommended specification. twice the length of the load and hauling rope (see Figure 4).

❏ 3 Winches and tongs must be compatible with the tractor to twice this distance

which they are to be fitted, and attached according to the

manufacturer’s instructions.

❏ 4 If operating the winch from inside the tractor unit, then

suitable operator protection, eg mesh screens, must be

fitted to either the tractor or the top of the winch unit.

Figure 1: Retention of supporting branches

WIRE ROPES

❏ 15 Position the rear of the tractor to face the load (see Figure 2).

❏ 5 A Test Certificate must accompany the winch ropes when Avoid excessive side hauling. Use a re-direct pulley if required.

they are purchased and this must be retained.

❏ 6 The rope size and lay of the ropes used must be to the

❏ 24 Do not work within the bight of a slack hauling rope.

winch manufacturer’s recommendations. Never attempt to

join ropes of different diameters. Figure 4: Safety zone

Figure 2: Tractor facing load

Vous aimerez peut-être aussi

- FISA 104 FencingDocument2 pagesFISA 104 Fencingblair mcfarlanePas encore d'évaluation

- Using Petrol-Driven Chainsaws: FISA Safety Guide 301Document2 pagesUsing Petrol-Driven Chainsaws: FISA Safety Guide 301Garden GrillPas encore d'évaluation

- Wood Chippers: FISA Safety Guide 604Document2 pagesWood Chippers: FISA Safety Guide 604Garden GrillPas encore d'évaluation

- Chainsaw Snedding: FISA Safety Guide 303Document2 pagesChainsaw Snedding: FISA Safety Guide 303Garden GrillPas encore d'évaluation

- FISA 705 Steep Slope WorkingDocument2 pagesFISA 705 Steep Slope WorkingGarden GrillPas encore d'évaluation

- FISA 704 Excavators in Tree WorkDocument4 pagesFISA 704 Excavators in Tree Workjames.clancyPas encore d'évaluation

- HSE - Use of Winches in Directional Felling and TakedownDocument4 pagesHSE - Use of Winches in Directional Felling and Takedowndonnyars1979Pas encore d'évaluation

- Cirular Saw Hse 601Document4 pagesCirular Saw Hse 601adeptsafetyPas encore d'évaluation

- R09 IND560x D1Z1 SI ML GlobalDocument22 pagesR09 IND560x D1Z1 SI ML GlobalHebert FirmoPas encore d'évaluation

- Afag401 (2013) PDFDocument11 pagesAfag401 (2013) PDFrshamsuldoshPas encore d'évaluation

- Manual Marantz SR4600Document41 pagesManual Marantz SR4600stuff LifePas encore d'évaluation

- TM 9-2350-247-10 M548a1 NSN 2350-01-096-9356 and M548a3 NSN 2350-01-369-6081Document640 pagesTM 9-2350-247-10 M548a1 NSN 2350-01-096-9356 and M548a3 NSN 2350-01-369-6081AdvocatePas encore d'évaluation

- Fall Protection PresentationDocument47 pagesFall Protection PresentationAz CorkerPas encore d'évaluation

- User's Guide: P R X 5 1 2 MDocument32 pagesUser's Guide: P R X 5 1 2 MTheo RoscaPas encore d'évaluation

- Venice f32Document122 pagesVenice f32Nutthawut SemsamrarnPas encore d'évaluation

- Adc GP 001Document8 pagesAdc GP 001Lisa3000Pas encore d'évaluation

- Plant Hazard ReportDocument3 pagesPlant Hazard Reportsaham cuanPas encore d'évaluation

- Daedong Service ManualDocument402 pagesDaedong Service ManualFrançois Charrière100% (2)

- Tadano TM 1800 PDFDocument151 pagesTadano TM 1800 PDFharoun100% (1)

- Safe Use of Agricultural Mowers: HSE Information SheetDocument3 pagesSafe Use of Agricultural Mowers: HSE Information SheetjPas encore d'évaluation

- Instructions: Dx100 OptionsDocument29 pagesInstructions: Dx100 OptionsTran LePas encore d'évaluation

- 2010 Arctic Cat 450 H1, 700 H1, 550 H1, 1000 H2 Mud Pro, Thundercat Operator's ManualDocument100 pages2010 Arctic Cat 450 H1, 700 H1, 550 H1, 1000 H2 Mud Pro, Thundercat Operator's ManualTindaro PelleritiPas encore d'évaluation

- CS530es03 040110Document36 pagesCS530es03 040110MikeRaufeisenPas encore d'évaluation

- Model SR3001 User Guide: AV Surround ReceiverDocument41 pagesModel SR3001 User Guide: AV Surround ReceiverpvelancsicsPas encore d'évaluation

- Marantz SR8001 AV Surround Receiver Amplifier User ManualDocument79 pagesMarantz SR8001 AV Surround Receiver Amplifier User Manualtrevor5409Pas encore d'évaluation

- Safe Work Practice: Title General Application Protective MechanismsDocument1 pageSafe Work Practice: Title General Application Protective MechanismsandidipayadnyaPas encore d'évaluation

- Poulan 2900 Type 1 Owner's ManualDocument13 pagesPoulan 2900 Type 1 Owner's ManualKipper KreminPas encore d'évaluation

- TM 9 2350 277 20 1Document859 pagesTM 9 2350 277 20 1SiPas encore d'évaluation

- Manual Taller Telescopica MFDocument781 pagesManual Taller Telescopica MFManuelAguilarPas encore d'évaluation

- VigasI Floor System Interior Catalogo2Document40 pagesVigasI Floor System Interior Catalogo2ricardo coutinhoPas encore d'évaluation

- User S Manual: Version 1.0 October 2005Document18 pagesUser S Manual: Version 1.0 October 2005Ali KhanPas encore d'évaluation

- CD Player: English Français EspañolDocument38 pagesCD Player: English Français EspañolpanfokPas encore d'évaluation

- Shindaiwa Models 300S, 360, 377, CHAIN SAW: Owner'S/Operator'S ManualDocument36 pagesShindaiwa Models 300S, 360, 377, CHAIN SAW: Owner'S/Operator'S Manualnistorgeorge632Pas encore d'évaluation

- ES7001 User Manual U enDocument25 pagesES7001 User Manual U enErnesto TrujilloPas encore d'évaluation

- 1 FM Safety Section Rev BDocument26 pages1 FM Safety Section Rev BRogerPas encore d'évaluation

- IM Gauge HatchesDocument2 pagesIM Gauge HatchesqwertyPas encore d'évaluation

- 695xl Opmanual enDocument52 pages695xl Opmanual enboki11080Pas encore d'évaluation

- TM - 1 1500 204 23 10 - CHG 4Document467 pagesTM - 1 1500 204 23 10 - CHG 4vjd5wzx92xPas encore d'évaluation

- User's Guide: P R X 6 1 2 MDocument36 pagesUser's Guide: P R X 6 1 2 MHector OrozcoPas encore d'évaluation

- STIHL 017 018: Warning!Document54 pagesSTIHL 017 018: Warning!Krešimir IvanovićPas encore d'évaluation

- Marantz SR 5500 ManualDocument41 pagesMarantz SR 5500 ManualzebozeboPas encore d'évaluation

- F360se.24 GCDocument38 pagesF360se.24 GCניקולאי איןPas encore d'évaluation

- Manual Weiler GrinderDocument30 pagesManual Weiler GrinderCFCRPas encore d'évaluation

- Tractor PtoDocument5 pagesTractor PtobshariPas encore d'évaluation

- Service Instructions "P-1Nn/F" Single Pressure Compensator With Load Sense, Series F1U ControlDocument20 pagesService Instructions "P-1Nn/F" Single Pressure Compensator With Load Sense, Series F1U ControlAndre RuestaPas encore d'évaluation

- SWP00059Document1 pageSWP00059sabbahmabroukPas encore d'évaluation

- TM1574 John Deere 325, 345 Lawn & Garden Tractors Technical ManualDocument14 pagesTM1574 John Deere 325, 345 Lawn & Garden Tractors Technical Manualtteelsars0% (1)

- Behringer FCB1010 ENG Rev FDocument16 pagesBehringer FCB1010 ENG Rev FtvdwouwPas encore d'évaluation

- Devicenet SST-DN3-PCU CardDocument95 pagesDevicenet SST-DN3-PCU CardD.C ROBOMATIONPas encore d'évaluation

- Jet JWBS Band SawDocument68 pagesJet JWBS Band SawczechsixPas encore d'évaluation

- BEHRINGER QSG - BE - 0805-AAR - U-PHORIA-Series - WWDocument37 pagesBEHRINGER QSG - BE - 0805-AAR - U-PHORIA-Series - WWwhitehennaPas encore d'évaluation

- Kioti Daedong Nd80, Nd100, Nd130, Nd8d (E), Nd10d (E), Dt8d (E), Dt10d (E) Power Tillers Service ManualDocument19 pagesKioti Daedong Nd80, Nd100, Nd130, Nd8d (E), Nd10d (E), Dt8d (E), Dt10d (E) Power Tillers Service ManualLisakolyPas encore d'évaluation

- TM 1 1520 256 23Document522 pagesTM 1 1520 256 23ณัฐนนท์ คงทนPas encore d'évaluation

- CASE 9 91841 PreviewDocument41 pagesCASE 9 91841 PreviewGama SaguiPas encore d'évaluation

- 155491-1CD-R2 - DX100 Options PDFDocument566 pages155491-1CD-R2 - DX100 Options PDFAlan Portela VieiraPas encore d'évaluation

- 3408C, 3412, 3412C and 3412D High Performance Marine EnginesDocument10 pages3408C, 3412, 3412C and 3412D High Performance Marine Enginesmohd_faizal100% (1)

- Preventive Maintenance Instruction For V3F16R Drive MODULE KM870400GDocument14 pagesPreventive Maintenance Instruction For V3F16R Drive MODULE KM870400GMarta Silva VenturaPas encore d'évaluation

- John Deere 4000 Series Technical ManualDocument10 pagesJohn Deere 4000 Series Technical Manualbryan100% (51)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesD'EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Rural Safety: Machinery, Stock and General HazardsD'EverandRural Safety: Machinery, Stock and General HazardsÉvaluation : 5 sur 5 étoiles5/5 (1)

- EBM Pabst - CPAP - BlowerDocument4 pagesEBM Pabst - CPAP - BlowerlouisPas encore d'évaluation

- Material de Inspección VisualDocument27 pagesMaterial de Inspección VisualGuillermo BarragánPas encore d'évaluation

- CKD Sab SVB Catalogue en Cc770a PDFDocument58 pagesCKD Sab SVB Catalogue en Cc770a PDFvanPas encore d'évaluation

- Giaonx, Bai 24 - P27-28.5. Vinh-Dat Vuong-Revised-1Document9 pagesGiaonx, Bai 24 - P27-28.5. Vinh-Dat Vuong-Revised-1Phước Trương VĩnhPas encore d'évaluation

- LSMW - Tips and TricksDocument2 pagesLSMW - Tips and TricksSiddharth ZaveriPas encore d'évaluation

- Deck Machinery PartsDocument3 pagesDeck Machinery Partsmihat jasneyPas encore d'évaluation

- Mountdebug - 2021 12 20 02 39 01Document5 pagesMountdebug - 2021 12 20 02 39 01Arturo ZaragozaPas encore d'évaluation

- Piston Mindman Mcgs-03!32!200Document9 pagesPiston Mindman Mcgs-03!32!200Micky CeceñaPas encore d'évaluation

- 2.1 System Requirement SpecificationDocument30 pages2.1 System Requirement SpecificationAtif NiazPas encore d'évaluation

- An Introduction To Control Network PDFDocument44 pagesAn Introduction To Control Network PDFsipteckPas encore d'évaluation

- Normas Iec - AstmDocument3 pagesNormas Iec - AstmGregorio Mendoza PolaresPas encore d'évaluation

- RoutersDocument4 pagesRoutersBeth RivPas encore d'évaluation

- 341-02 - AISC - Seismic Provisions Structural Steel BldgsDocument94 pages341-02 - AISC - Seismic Provisions Structural Steel BldgsMohit100% (1)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document15 pagesAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)HyungTae JangPas encore d'évaluation

- Twinact & Uniact Relief Valve Catalogue - FORT - VALEDocument32 pagesTwinact & Uniact Relief Valve Catalogue - FORT - VALEMiguel GonzálezPas encore d'évaluation

- Oracle Enterprise Manager Cloud Control 12c Cloud MGMT Workshop - D77277GC10 - 1080544 - USDocument4 pagesOracle Enterprise Manager Cloud Control 12c Cloud MGMT Workshop - D77277GC10 - 1080544 - USJinendraabhiPas encore d'évaluation

- PIPE LAYING PROJECT (Sent To Ms. Analyn) PDFDocument1 pagePIPE LAYING PROJECT (Sent To Ms. Analyn) PDFJamaica RolloPas encore d'évaluation

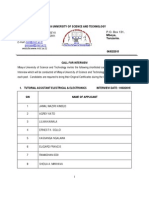

- Call For Interview Phase V - Mbeya University.Document13 pagesCall For Interview Phase V - Mbeya University.Rashid BumarwaPas encore d'évaluation

- Setup and Hold Time - Static Timing Analysis (STA) Basic (Part 3a) - VLSI ConceptsDocument3 pagesSetup and Hold Time - Static Timing Analysis (STA) Basic (Part 3a) - VLSI ConceptsRakesh KumarPas encore d'évaluation

- 84D8CDocument17 pages84D8CDWNLD USRML100% (1)

- ACCF - CSR Reconciliation-Darrang-18-08-20Document7 pagesACCF - CSR Reconciliation-Darrang-18-08-20Hunny VermaPas encore d'évaluation

- DX79TO ProductGuide01 EnglishDocument86 pagesDX79TO ProductGuide01 EnglishqwarztPas encore d'évaluation

- Fabricante de HPFF CableDocument132 pagesFabricante de HPFF Cableccrrzz100% (1)

- Arch 2-2 QuestionnairesDocument11 pagesArch 2-2 QuestionnairesGels GenovaPas encore d'évaluation

- Task 4 M5 LA3Document5 pagesTask 4 M5 LA3aristyPas encore d'évaluation

- Software Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Document16 pagesSoftware Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Karthik KeyanPas encore d'évaluation

- Caed PDF Notes I SemDocument161 pagesCaed PDF Notes I SemjovanPas encore d'évaluation

- An Introduction To Project Logistics Management: ArticleDocument9 pagesAn Introduction To Project Logistics Management: ArticleCh Tushar BhatiPas encore d'évaluation

- CommsII Problem Set 3 With AddendumDocument2 pagesCommsII Problem Set 3 With AddendumMarlon BoucaudPas encore d'évaluation

- 9701 w12 QP 23Document12 pages9701 w12 QP 23poliuytrewqPas encore d'évaluation