Académique Documents

Professionnel Documents

Culture Documents

Lesson Plan: Veer Surendra Sai University of Technology

Transféré par

santhi saranya0 évaluation0% ont trouvé ce document utile (0 vote)

8 vues2 pagesLesson 1526630034

Titre original

Lesson 1526630034

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentLesson 1526630034

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

8 vues2 pagesLesson Plan: Veer Surendra Sai University of Technology

Transféré par

santhi saranyaLesson 1526630034

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

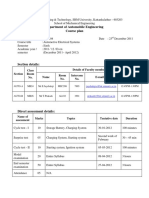

VEER SURENDRA SAI UNIVERSITY OF TECHNOLOGY

LESSON PLAN

Semester >>5th Year >> 2016 Contact Hours per week >>4

(B.Tech)

Branch >>

Sub: Metal Total Credit >>4

Forming Processes Mechanical Engineering

TEACHER Dr.Pragyan Paramita Mohanty

Period July 2016- Dec 2016

Recommended Text book:

books >>

Text Books:

1. Manufacturing Technology, P. N. Rao Vol. 3 3rd Edition, TMH Publication

2. Manufacturing Engineering and Technology, S. Kalpakian, S. Schimid, Pearson

Publication

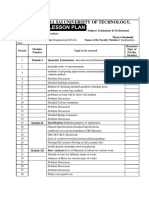

Sl. Lecture No. Topics to be covered No. of Classes

No.

MODULE-1 10

1 Lecture-01 Introduction: Principle of plastic deformation and yield criteria,

Lecture-02 Fundamental of hot and cold working processes, Effect of

2

strain rate on forming process.

3 Lecture-03 Forging: Open die forging, Drop forging

4 Lecture-04 Press forging

5 Lecture-05 Load estimation in forging

6 Lecture-06 Forging design, allowances

7 Lecture-07 Die design for drop forging

8 Lecture-08 Design of flash and gutter

9 Lecture-09 Upset forging die design

10 Lecture-10 Forging defects and inspection.

MODULE-2

11 Lecture-11 Rolling: Principle of rolling

12 Lecture-12 Rolling stand arrangement, Rolling load calculation 10

Lecture-13 Roll passes, Flat rolling, Pipe rolling

13

14 Lecture-14 Defects in rolled products.

15 Lecture-15 Extrusion: Forward and backward extrusion

16 Lecture-16 Hydrostatic Extrusion, Extrusion Forging

Lecture-17 Load estimation in extrusion, Extrusion of tubes

17

18 Lecture-18 Calculation of force in hot extrusion,

19 Lecture-19 Effect of Extrusion Variables

20 Lecture-20 Extrusion Defects.

MODULE-3

20 Lecture-21 Drawing: Wire drawing, Rod and tube drawing 10

21 Lecture-22 Drawing forces, Drawing defects.

22 Lecture-23 Sheet Metal Forming and bending: Sheet metal working-

23 Lecture-24 Shearing, blanking piercing,

24 Lecture-25 Deep drawing operation.

25 Lecture 27 Die design for sheet metal operations

Lecture 28 Progressive and compound die

26

27 Lecture 29 Strippers, stops, strip layout.

28 Lecture 28 Principle of bending, Spring back effect

29 Lecture 29 Coining.

MODULE-4

30 Lecture 30 Advanced forming processes: High energy rate forming, 10

Lecture 31 Explosive forming, electro hydro forming, electromagnetic

31

forming,

32 Lecture-32 Rubber die forming.

Lecture-33 Powder Metallurgy Forming Process: Method of Powder

33

production, Powder characteristic analysis

34 Lecture-34 Powder annealing, Precompaction studies

35 Lecture 35 Cold compaction Studies, Sintering and sintering atmosphere,

36 Lecture-36 Post sintering operations (coining, infiltration, hot forging etc.)

37 Lecture-37 Hot and cold iso-static pressing,

38 Lecture-38 Properties of P/M products and applications.

39 Lecture-39 Properties of P/M products and applications.

Signature of Teacher

Vous aimerez peut-être aussi

- Pipeline and Energy Plant Piping: Design and TechnologyD'EverandPipeline and Energy Plant Piping: Design and TechnologyÉvaluation : 5 sur 5 étoiles5/5 (2)

- Credits Total Marks: Sathyabama Institute of Science and TechnologyDocument1 pageCredits Total Marks: Sathyabama Institute of Science and TechnologyGiridharan RuPas encore d'évaluation

- Manufacturing Technology 2Document2 pagesManufacturing Technology 2Jeremaiah HaylingPas encore d'évaluation

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaPas encore d'évaluation

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologystarboyPas encore d'évaluation

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyPratik VishwakarmaPas encore d'évaluation

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaPas encore d'évaluation

- Iare - MP - Lecture NotesDocument47 pagesIare - MP - Lecture NotesMayank SharmaPas encore d'évaluation

- Gujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IIDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IITemp WorkPas encore d'évaluation

- Manufacturing ProcessDocument127 pagesManufacturing ProcesssathwikPas encore d'évaluation

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PPas encore d'évaluation

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringDocument49 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaPas encore d'évaluation

- BMP - ExtrusionDocument24 pagesBMP - Extrusionmantra2010Pas encore d'évaluation

- BMP - Metal WorkingDocument17 pagesBMP - Metal Workingmantra2010Pas encore d'évaluation

- BMP PDFDocument17 pagesBMP PDFmantra2010Pas encore d'évaluation

- BMP - Other Welding ProcessesDocument76 pagesBMP - Other Welding Processessujay nayakPas encore d'évaluation

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghPas encore d'évaluation

- B.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesDocument1 pageB.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesAmin FarukiPas encore d'évaluation

- MEC207Document4 pagesMEC207Senthil Muthu Kumar TPas encore d'évaluation

- BMP - CastingDocument217 pagesBMP - Castingmantra2010Pas encore d'évaluation

- BMP - RollingDocument46 pagesBMP - Rollingmantra2010Pas encore d'évaluation

- R PT Instruction PlanDocument6 pagesR PT Instruction PlanVipin KumarPas encore d'évaluation

- MP366 Modern Manufacturing ConceptsDocument2 pagesMP366 Modern Manufacturing ConceptsDr. Mubarak AliPas encore d'évaluation

- Introduction To The CourseDocument23 pagesIntroduction To The Coursemosab1234056Pas encore d'évaluation

- Manufacturing ProcessesDocument136 pagesManufacturing ProcessesArijit GhoshPas encore d'évaluation

- PP-I Syllabus (SH2019)Document2 pagesPP-I Syllabus (SH2019)Vishwa RohindPas encore d'évaluation

- Manufacturing Process - IIIDocument1 pageManufacturing Process - IIIRing MasterPas encore d'évaluation

- BMP - Powder MetallurgyDocument71 pagesBMP - Powder Metallurgymantra2010Pas encore d'évaluation

- BMP - Electric Arc WeldingDocument91 pagesBMP - Electric Arc Weldingsujay nayakPas encore d'évaluation

- 3140204Document3 pages3140204vikas raiPas encore d'évaluation

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantPas encore d'évaluation

- MTECH Manufacturing EnggDocument10 pagesMTECH Manufacturing EnggSudhir KumarPas encore d'évaluation

- MME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, JaipurDocument2 pagesMME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, Jaipurraghav dhamaniPas encore d'évaluation

- BMP - DrawingDocument22 pagesBMP - Drawingmantra2010Pas encore d'évaluation

- Elective 7Document1 pageElective 7Other StuffPas encore d'évaluation

- RTM Nagpur University Syllabus (Theory)Document5 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarPas encore d'évaluation

- Fatigue of WeldmentsDocument222 pagesFatigue of WeldmentsAjay MenonPas encore d'évaluation

- FINAL MCW-17ME35A - Notes PDFDocument108 pagesFINAL MCW-17ME35A - Notes PDFAMOGHPas encore d'évaluation

- Course Handout (BMP)Document4 pagesCourse Handout (BMP)058-Somyajit RayPas encore d'évaluation

- ME2201 Manufacturing Technology-IDocument9 pagesME2201 Manufacturing Technology-IHiru Purushothaman HirudayanathanPas encore d'évaluation

- Computer Integrated Manufacturing 05 63xxDocument97 pagesComputer Integrated Manufacturing 05 63xxAnonymous mcFvPwzXPas encore d'évaluation

- Me 8392 - Manufacturing Technology: 14. Course OutcomesDocument6 pagesMe 8392 - Manufacturing Technology: 14. Course OutcomesERKATHIRPas encore d'évaluation

- Me5251 Manufacturing Processes SyllabusDocument2 pagesMe5251 Manufacturing Processes SyllabusYogeswaranPas encore d'évaluation

- Metal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveDocument3 pagesMetal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveB. selvababuPas encore d'évaluation

- Production TechnologyDocument5 pagesProduction TechnologyAparnaa MoorthyPas encore d'évaluation

- Lesson Plan AMC and AWPDocument3 pagesLesson Plan AMC and AWPupenderPas encore d'évaluation

- ME104 Manufacturing Process: Suggested ReadingsDocument1 pageME104 Manufacturing Process: Suggested ReadingsAditya KumarPas encore d'évaluation

- Br20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesDocument2 pagesBr20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesBashu Dev SanjelPas encore d'évaluation

- ME6302-SCAD-MSM-by WWW - LearnEngineering.inDocument130 pagesME6302-SCAD-MSM-by WWW - LearnEngineering.inKKPas encore d'évaluation

- 5 MPDocument3 pages5 MPASIST MechPas encore d'évaluation

- PDFDocument4 pagesPDFGeorge CamachoPas encore d'évaluation

- B.E. Mech (Sandwich) PDFDocument11 pagesB.E. Mech (Sandwich) PDFNAGA PRASANTHPas encore d'évaluation

- Manufacturing Processes LabDocument53 pagesManufacturing Processes LabUjjwal kecPas encore d'évaluation

- 03 UG ME Sem3 R2019Document12 pages03 UG ME Sem3 R2019சற்குணத்தமிழன் செPas encore d'évaluation

- Structure Final MechanicalDocument26 pagesStructure Final MechanicalSalokhaRaj RedevelopmentPas encore d'évaluation

- Production Technology Course OutDocument5 pagesProduction Technology Course Outmurjass85Pas encore d'évaluation

- Metal Forming Technology 1601913164Document12 pagesMetal Forming Technology 1601913164jesssepinkman03Pas encore d'évaluation

- Complete ReportDocument61 pagesComplete ReportMr KoolPas encore d'évaluation

- Fundamental Aspects of Dislocation Interactions: Low-Energy Dislocation Structures IIID'EverandFundamental Aspects of Dislocation Interactions: Low-Energy Dislocation Structures IIIG. KostorzPas encore d'évaluation

- BT1001 Biology For Engineers1Document3 pagesBT1001 Biology For Engineers1santhi saranyaPas encore d'évaluation

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaPas encore d'évaluation

- Btech Vi Sem 15ce347eDocument2 pagesBtech Vi Sem 15ce347esanthi saranyaPas encore d'évaluation

- Introduction To Biochemical Principles 2013 2014Document4 pagesIntroduction To Biochemical Principles 2013 2014santhi saranyaPas encore d'évaluation

- Course Code: CH1106 Course Title: Introduction To Biochemical Principles Semester: Course Time: Jan - MayDocument4 pagesCourse Code: CH1106 Course Title: Introduction To Biochemical Principles Semester: Course Time: Jan - Maysanthi saranyaPas encore d'évaluation

- Btech VI Sem 15ce347e PDFDocument3 pagesBtech VI Sem 15ce347e PDFsanthi saranyaPas encore d'évaluation

- BT1001 Biology For Engineers PDFDocument2 pagesBT1001 Biology For Engineers PDFsanthi saranyaPas encore d'évaluation

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaPas encore d'évaluation

- Department of Automobile Engineering Course PlanDocument4 pagesDepartment of Automobile Engineering Course Plansanthi saranyaPas encore d'évaluation

- BT1001 Biology For Engineers 2 PDFDocument2 pagesBT1001 Biology For Engineers 2 PDFsanthi saranyaPas encore d'évaluation

- Lesson1499214383 PDFDocument2 pagesLesson1499214383 PDFsanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaPas encore d'évaluation

- Ar 15201 Building Materials Ii (3-0-0-0) CR-03Document3 pagesAr 15201 Building Materials Ii (3-0-0-0) CR-03santhi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla: Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla: Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Ar 15203 History of Architecture I (3-0-0-0) CR-03Document2 pagesAr 15203 History of Architecture I (3-0-0-0) CR-03santhi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument2 pagesVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDocument2 pagesLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla: Quantity Estimation: Introduction, Definitions & Terms UsedDocument2 pagesVeer Surendra Sai University of Technology, Burla: Quantity Estimation: Introduction, Definitions & Terms Usedsanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDocument2 pagesLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaPas encore d'évaluation

- Veer Surendra Sai University of Technology, Burla Lesson PlanDocument1 pageVeer Surendra Sai University of Technology, Burla Lesson Plansanthi saranyaPas encore d'évaluation

- Pilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolDocument10 pagesPilot Implementation of The Limited Face-to-Face Class Program at Librada Avelino Elementary SchoolCher GeriPas encore d'évaluation

- List Katalog Fire Hydrant (Box)Document3 pagesList Katalog Fire Hydrant (Box)Sales1 mpicaPas encore d'évaluation

- APCO CSAA ANS2 101 1webfinalDocument38 pagesAPCO CSAA ANS2 101 1webfinalJUAN CAMILO VALENCIA VALENCIAPas encore d'évaluation

- Adiba Final Activity CousellingDocument29 pagesAdiba Final Activity Cousellingadiba KhanPas encore d'évaluation

- Surface TensisonDocument28 pagesSurface TensisonJAWAD AHMAD BURTPas encore d'évaluation

- Mds SM13CRM 110 enDocument5 pagesMds SM13CRM 110 enColinPas encore d'évaluation

- Digital Album On Prominent Social ScientistsDocument10 pagesDigital Album On Prominent Social ScientistsOliver Antony ThomasPas encore d'évaluation

- 747Document12 pages747GurdevBaines100% (3)

- Prose 2 - Lost Spring - Important QADocument5 pagesProse 2 - Lost Spring - Important QADangerous GamingPas encore d'évaluation

- 3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectDocument3 pages3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectShehbaz ThakurPas encore d'évaluation

- Etrade Bank-StatementDocument5 pagesEtrade Bank-StatementMark Galanty100% (4)

- Nassaji - Schema TheoryDocument37 pagesNassaji - Schema TheoryAtiq AslamPas encore d'évaluation

- Module 4 - Community Health AssessmentDocument8 pagesModule 4 - Community Health AssessmentSteffiPas encore d'évaluation

- Technical Data Sheet: BS-510 All Pressure Solvent CementDocument1 pageTechnical Data Sheet: BS-510 All Pressure Solvent CementBuwanah SelvaarajPas encore d'évaluation

- English 4 Q.2 Module 2Document6 pagesEnglish 4 Q.2 Module 2RjVValdezPas encore d'évaluation

- Datasheet Double Solenoid Valve DMV 12Document7 pagesDatasheet Double Solenoid Valve DMV 12flatron445Pas encore d'évaluation

- Unit 9: Cities of The World I. ObjectivesDocument4 pagesUnit 9: Cities of The World I. ObjectivesTrang Hoang NguyenPas encore d'évaluation

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocument2 pagesFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryPas encore d'évaluation

- SK AccBro CI Update - FABIA - Unpriced - SEPT 2023 AW v4Document34 pagesSK AccBro CI Update - FABIA - Unpriced - SEPT 2023 AW v4Vlad TiurinPas encore d'évaluation

- Lecture Note On Photovoltaic CellDocument1 pageLecture Note On Photovoltaic CellHaseeb NawazPas encore d'évaluation

- The Man Who Named The CloudsDocument7 pagesThe Man Who Named The Cloudsapi-302345936Pas encore d'évaluation

- Advanced Communication SystemDocument13 pagesAdvanced Communication SystemZohaib AhmadPas encore d'évaluation

- Intermed Products: International CatalogueDocument12 pagesIntermed Products: International CatalogueRicardo Bonetti TadenPas encore d'évaluation

- CCR Control System Interface HandbookDocument17 pagesCCR Control System Interface Handbooklcastrey23Pas encore d'évaluation

- Nature'S Numbers: - BasicbooksDocument39 pagesNature'S Numbers: - Basicbooksyeol pacisPas encore d'évaluation

- MMC 16101 - Positive Displacement Pump - 01Document19 pagesMMC 16101 - Positive Displacement Pump - 01HET DEDHIAPas encore d'évaluation

- D6588Document6 pagesD6588Pulak DebnathPas encore d'évaluation

- EKONET CPRS Importer 26062014Document6 pagesEKONET CPRS Importer 26062014anthony0216Pas encore d'évaluation

- Big Data Executive Survey 2019 Findings Updated 010219 1Document16 pagesBig Data Executive Survey 2019 Findings Updated 010219 1satmaniaPas encore d'évaluation

- Plaquette-Costronic en 2020Document2 pagesPlaquette-Costronic en 2020Jun OrtizPas encore d'évaluation