Académique Documents

Professionnel Documents

Culture Documents

Item Stop Kiln NAR2 Vib

Transféré par

Safrin SangiaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Item Stop Kiln NAR2 Vib

Transféré par

Safrin SangiaDroits d'auteur :

Formats disponibles

KILN SHUT DOWN FOR RE-ACTIVATING SLC CHANGE OVER GATE (COG)

Stop tgl 11 Juni 12 jam 04'28 krn ID Fan High Vibration, lgsg repair COG SLC (idle selama 2 hr) feed to feed, heating jam 20'00 tgl 12/6/12

No Item Deskripsi Keterangan PIC Status

1 444-PH1 Repair COG SLC and ILC Ganti roller Taufik

Ganti/repair mekanikal seal Taufik

Modifikasi limit switch Switch diletakkan agak jauh sehingga Enjang

tidak cepat rusak karena kepanasan

2 444-FN1/2 Water blaster Tidak perlu terlalu bersih SI Produksi

Sand blasting Kodari

3 444-PH1 Cleaning Ujung kiln & riser duct dari lt 3 sampai lt 5 SI Produksi

4 454- PF1 Check & adjust gap rotor Taufik

5 484-PF1 Check & adjust gap rotor Taufik

6 L64-RM1 Check & repair thermocouple bearing roller Roller 1, 2 & 3 Ruslan

7 474-CC1 Check tipping valve Flange flapper valve 474-FV6 Taufik

8 494-PN1 Check link DB Taufik

9 474-FN2 Check bearing Fix bearing abnnormal Made/Bambang

10 454-FV1 Install water spray untuk mendorong & mendinginkan Taufik/Enjang

material dlm bunker

11 474-CV1/2 Check/repair link Taufik

12 464-2K1 Check probe analyser Ruslan

13 454-PF1/2 Review logic remote ke local Untuk switch dr local ke remote harus Muchlas

start ID Fan & blower

14 4D4-PP1 Install selector untuk pengisian dust ke C/M dr CCR Made/Muchlas

15 4D4-PP1 Ganti bearing FK Pump dust bin Taufik

16 444-PH1 Tambah poke hole akses cleaning Lt 5 utara/selatan (4" diameter) SI Prod/Taufik

17 444-PH1 Reposisi sampler hot meal SLC lt.6 (agak ke selatan) SI Prod/Taufik

18 444-PH1 Check/tambah poke hole akses Cardox Lt. 4 dan lt.4,5 SI Prod/Taufik

19 L64-RM1 Repair seal rocker arm High false air Taufik

20 464-KL1 Check main motor Amper deviasi tinggi Enjang

21 L64-FN1 Clean up blade Kadang-kadang high vibration SI Prod

22 L64-WF1 Starvation indikator abnormal Switch ke angkat SI Prod/Ruslan

23 494-BF1 casing byk tambalan & Delta P tinggi Taufik

24 474-FA8/9 V-belt slip Taufik

25 444-PH1 Man hole byk yang susah dibuka lt 6 R/D, lt 7 C4 SLC Taufik

26 474-RC1 Pondasi HRB banyak yang retak Perlu dicor Kodari

27 L3C-MW1 Gate pengarah material keropos Taufik

28 484-BL1 Reducer rembes Taufik

29 434-SG3 Repair sambungan air slide Bocor Taufik

30 L3C-RE1 Seal reducer harrow bocor Taufik

31 434-BE1 Ganti seal liquid coupling Sisi timur Taufik

32 L64-RM1 Oli roller#2 kosong Nambah oli & check seal roller Taufik

33 464-KL1 Las/pasang rip pd tyre yg crack Made

34 474-CC1 Cleaning aterial di atas grate plate Jam 20'00 crew Pak Dir ada yg masuk Sudirmanto

NAR2 KILN SHUT DOWN FOR CLEANING ILC ID FAN (HIGH VIBRATION)

No Item Deskripsi Keterangan PIC Status

1 464-KL1 - Repair wearing ring Made

- Clean up Rhino burner safety orang kerja di cooler Si Prod

- Las shell kiln metet 32 Made

2 444-PH1 - Cleaning riser duct dari Lt#5 Si Prod

- Sounding Cyclone Preheater Safety reason Si Prod

3 474-CC1 - Check replaceable lip comp#2 & 3 Utara high fall through Slamet

- Check grate plate Slamet

- Clean up material di atas grate plate Sudirmanto

4 494-PN1 - Check link & rel sisi utara -selatan & Rel dudukan rel kendor Made

5 474-CV1/2 - Check link Slamet

6 444-FN1 Water blaster & sand blasting blade Unbalance vibration after reducing KF (Thermal shock) Si Prod/Kodari

7 444-FN2 Water blaster Si Produksi

8 L64 - RM1 Check termocouple Roller#3 (TI5) Ruslan

9 474-FAB casing bolong/tipis Tambal yang bolong dan tipis sebelah atas Slamet

(446-FNH)

10 474-Fa8 Casing bolong/tipis Tambal yang bolong dan tipis sebelah selatan Slamet

11 V94-BC1 Rubber skirt sudah aus Utara-Selatan sudah aus ,material tumpah Agung

12 494-PN2 Check sprocket/alignment Roller sering patah boltnya Slamet

13 L3C-RE1 seal reducer harrow bocor oil leakage Slamet

14 474 -CC1 Drive#1 Roller traction macet di compt.#1 Made

15 474 -CC1 Kiln hood Refractory rontok/hot spot (sisi utara) Sudirmanto

16 444 - PH1 Riser duct Refractory rontok/hot spot sisi selatan lt#4 Sudirmanto

17 434 -BE1 Reducer/Fluid coupling Oil leakage Slamet

18 464- KT1 Kiln thrust roller oil filter oil leakage Made

19 L34 -BC2 Chute di bawah BC mepet di dekat lantai Bolong/tumpahan meterial Slamet

20 L64 -WF1 Check inside&scavangernya Noise Slamet

21 L64 -SR1 Check bearing Noise Slamet

22 4D4- PG1 sambungan AS ocor antara PG1 dan SG1 Slamet

23 4D4 -RF1 Seal free bearing bocor Ganti bearing Slamet Done

24 494 -PN1 Lubang grease buntu 7 roller sisi utara (ada tanda) Mukri

Vous aimerez peut-être aussi

- Item Stop Kiln NAR2Document13 pagesItem Stop Kiln NAR2Safrin SangiaPas encore d'évaluation

- NAR2 KSD Items Jan11Document1 pageNAR2 KSD Items Jan11Safrin SangiaPas encore d'évaluation

- NAR2 Kiln Shut Down Items: NO Hac Code Description of Activity PIC Mechanical - Adi SantosaDocument4 pagesNAR2 Kiln Shut Down Items: NO Hac Code Description of Activity PIC Mechanical - Adi SantosaSafrin SangiaPas encore d'évaluation

- Item Stop Kiln NAR1 6 Feb 2013Document7 pagesItem Stop Kiln NAR1 6 Feb 2013Safrin SangiaPas encore d'évaluation

- Item Stop Kiln NAR1Document7 pagesItem Stop Kiln NAR1Safrin SangiaPas encore d'évaluation

- Action Plan 2021Document48 pagesAction Plan 2021Nanda SalsabilaPas encore d'évaluation

- PLC Io ListDocument4 pagesPLC Io ListVaibhav ShrivastavPas encore d'évaluation

- CLD1609-DA-586054-05-RL-002 Rev.1 LISTADO DE REPUESTOS CAPITALDocument3 pagesCLD1609-DA-586054-05-RL-002 Rev.1 LISTADO DE REPUESTOS CAPITALkevinzzzxd1Pas encore d'évaluation

- Lha 00 1836Document10 pagesLha 00 1836eug_manu8Pas encore d'évaluation

- RepairParts WriteUPDocument3 pagesRepairParts WriteUPSehar KhanPas encore d'évaluation

- SN11145T SECTION 5 SPARE PARTS Print FriendlyDocument12 pagesSN11145T SECTION 5 SPARE PARTS Print Friendlyrig602.mechanicPas encore d'évaluation

- Arms Part ListDocument4 pagesArms Part ListHaris MunirPas encore d'évaluation

- ROCKY Tools Part List-SamsonDocument17 pagesROCKY Tools Part List-SamsonPabloRuizOlivaPas encore d'évaluation

- Wilkins 420 Parts BreakdownDocument2 pagesWilkins 420 Parts Breakdownboytest2000Pas encore d'évaluation

- Couplings &bearingsDocument22 pagesCouplings &bearingsanilPas encore d'évaluation

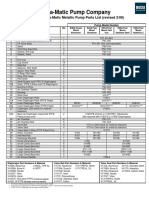

- Versa-Matic Pump Company: Model E4, Elima-Matic Metallic Pump Parts List (Revised 2/08)Document4 pagesVersa-Matic Pump Company: Model E4, Elima-Matic Metallic Pump Parts List (Revised 2/08)Sakahi SharmaPas encore d'évaluation

- Oilfield Equipment Inspection RequestDocument2 pagesOilfield Equipment Inspection Requestvinsensius rasaPas encore d'évaluation

- Hydraulic Circuit, EDM 2000Document2 pagesHydraulic Circuit, EDM 2000frfgfPas encore d'évaluation

- Appendix A List of EquipmentDocument2 pagesAppendix A List of EquipmentFlexatherm HOPas encore d'évaluation

- VM 1 1 - 2 Metalen - Handleiding - en PDFDocument21 pagesVM 1 1 - 2 Metalen - Handleiding - en PDFchmatias3Pas encore d'évaluation

- Blackmer Part List XL2BDocument2 pagesBlackmer Part List XL2Bjuan davidPas encore d'évaluation

- K229-0C-MR-4300-401-A5016-0001 - 2X (Install Manual)Document1 315 pagesK229-0C-MR-4300-401-A5016-0001 - 2X (Install Manual)Mohamed SamirPas encore d'évaluation

- TK Series Gear OperatorsDocument2 pagesTK Series Gear OperatorsdharmendrabholePas encore d'évaluation

- Benin WRP - WELDING DETAILS FOR NDT - 02.03.2022Document4 pagesBenin WRP - WELDING DETAILS FOR NDT - 02.03.2022Charles OnyecherePas encore d'évaluation

- 08-1218 H16330 Submittal DrawingsDocument6 pages08-1218 H16330 Submittal DrawingsLeomar JimenezPas encore d'évaluation

- Pemakaian DI DO BCUDocument20 pagesPemakaian DI DO BCUantodamanikPas encore d'évaluation

- Generator maintenance and testing activitiesDocument16 pagesGenerator maintenance and testing activitiesJayPrakash YadavPas encore d'évaluation

- Part & Consumable ReportDocument6 pagesPart & Consumable ReportGuruh SuprayitnoPas encore d'évaluation

- Running Hours For Month of AugustDocument4 pagesRunning Hours For Month of AugustSung Ki JymPas encore d'évaluation

- LK PC PLDocument308 pagesLK PC PLANDERSON G HERRERA DPas encore d'évaluation

- Blackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NDocument2 pagesBlackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NJuan David Triana SalazarPas encore d'évaluation

- AsbriDocument6 pagesAsbriAshraf moghalPas encore d'évaluation

- 200 Tem ControlDocument3 pages200 Tem Controlrobson lopes bezerraPas encore d'évaluation

- 54 Identifier Loa/Ptw NameDocument6 pages54 Identifier Loa/Ptw Nameloli2323Pas encore d'évaluation

- 11.3.2 Critical Sparepart & Inventory List - Kazo JaxDocument11 pages11.3.2 Critical Sparepart & Inventory List - Kazo JaxJOHAN SIAHAANPas encore d'évaluation

- BB TubtimDocument35 pagesBB TubtimBudiPas encore d'évaluation

- Al Yasat Asset SurveyDocument14 pagesAl Yasat Asset Surveyabisankar333Pas encore d'évaluation

- Bomba de AguaDocument5 pagesBomba de Aguajuan riveraPas encore d'évaluation

- Items For Indigenization PDFDocument41 pagesItems For Indigenization PDFAnonymous CDxMwF2ofPas encore d'évaluation

- RD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSDocument17 pagesRD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSInsan AzizPas encore d'évaluation

- WarrantyDocument4 pagesWarrantyMauricio GarcíaPas encore d'évaluation

- Report No P.O Hac Area Description HAC Tp/OpDocument2 pagesReport No P.O Hac Area Description HAC Tp/OpSadia HasanPas encore d'évaluation

- RAPID BLEEDING HYDRAULIC EXHAUSTDocument6 pagesRAPID BLEEDING HYDRAULIC EXHAUSTdipepejPas encore d'évaluation

- Heat Exchangers: WO# PE# Equipment Description WO# DescriptionDocument2 pagesHeat Exchangers: WO# PE# Equipment Description WO# DescriptionBeantickPas encore d'évaluation

- SC430 - Scrubber-Dryer - Parts Lists DiagramsDocument18 pagesSC430 - Scrubber-Dryer - Parts Lists DiagramsDimitris ThanasopoulosPas encore d'évaluation

- Annexure-1 Bill of Materials for 415V 4000A, 2500A & 1600A NSPBDDocument1 pageAnnexure-1 Bill of Materials for 415V 4000A, 2500A & 1600A NSPBDsanjayprakash1979Pas encore d'évaluation

- HVAC ComparisonDocument283 pagesHVAC Comparisonmilindskulkarni2005@yahoo.co.in100% (1)

- Fans-Blowers Detail MillwideDocument7 pagesFans-Blowers Detail MillwidePankaj PandeyPas encore d'évaluation

- Maintaining Power Supply for PT. Truba Jaga Cita Shutdown ProjectDocument6 pagesMaintaining Power Supply for PT. Truba Jaga Cita Shutdown Projectkurniawan DhenyPas encore d'évaluation

- List of Equipment To Be Included in AmendmentDocument10 pagesList of Equipment To Be Included in AmendmentElfawizzyPas encore d'évaluation

- Commercial Offer for HDPE Pipes Electrical Panel SupplyDocument4 pagesCommercial Offer for HDPE Pipes Electrical Panel SupplyKapila Dhammika EdirisinghePas encore d'évaluation

- unitor CO2 hoses diagramDocument9 pagesunitor CO2 hoses diagramPrasad BangaruPas encore d'évaluation

- K229-0c-Mr-4300-401-A0104-0001 - 4X (Equip List)Document2 pagesK229-0c-Mr-4300-401-A0104-0001 - 4X (Equip List)Mohamed SamirPas encore d'évaluation

- Loop Drawing DataDocument9 pagesLoop Drawing DataAbarajithan RajendranPas encore d'évaluation

- Parts ListDocument1 pageParts ListWiwy TransmitPas encore d'évaluation

- Hydraulic equipment components listDocument1 pageHydraulic equipment components listJhon Henry Silvestre BazanPas encore d'évaluation

- Torque Specs 230413001Document19 pagesTorque Specs 230413001Fabio Medeiros DiverPas encore d'évaluation

- Material Handover ConfirmationDocument3 pagesMaterial Handover ConfirmationrejeshPas encore d'évaluation

- 01-03 A A4Document3 pages01-03 A A4Mohammed ShoaibPas encore d'évaluation

- Circulating Fluidized Bed Boilers: Design and OperationsD'EverandCirculating Fluidized Bed Boilers: Design and OperationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Drying-out instructions for refractory materialsDocument8 pagesDrying-out instructions for refractory materialsSafrin SangiaPas encore d'évaluation

- Safety Working Time LimitsDocument1 pageSafety Working Time LimitsSafrin SangiaPas encore d'évaluation

- Actions From Cilacap Burn Fatality ReportDocument3 pagesActions From Cilacap Burn Fatality ReportSafrin SangiaPas encore d'évaluation

- Pricing Policy FinalDocument32 pagesPricing Policy FinalSafrin SangiaPas encore d'évaluation

- Eric Olsen Visit in Indonesia 20160119Document11 pagesEric Olsen Visit in Indonesia 20160119Safrin SangiaPas encore d'évaluation

- 1108 Brazil CantagaloDocument2 pages1108 Brazil CantagaloSafrin SangiaPas encore d'évaluation

- New CEO Award Idea SubmissionDocument21 pagesNew CEO Award Idea SubmissionSafrin SangiaPas encore d'évaluation

- AGC C-19-008 Offer For NarogongDocument1 pageAGC C-19-008 Offer For NarogongSafrin SangiaPas encore d'évaluation

- Data Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisDocument7 pagesData Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisSafrin SangiaPas encore d'évaluation

- Running Insp Sheet NewDocument20 pagesRunning Insp Sheet NewSafrin SangiaPas encore d'évaluation

- Spesification of Bag FilterDocument14 pagesSpesification of Bag FilterSafrin SangiaPas encore d'évaluation

- Patroller Development Program Overview (Rev5.3)Document9 pagesPatroller Development Program Overview (Rev5.3)Safrin SangiaPas encore d'évaluation

- Safety PauseDocument4 pagesSafety PauseSafrin SangiaPas encore d'évaluation

- Schedule Shift 2012 SEODocument10 pagesSchedule Shift 2012 SEOSafrin SangiaPas encore d'évaluation

- Learn@LH Overview 071215 VFDocument19 pagesLearn@LH Overview 071215 VFSafrin SangiaPas encore d'évaluation

- Schedule Install From ShinakawaDocument1 pageSchedule Install From ShinakawaSafrin SangiaPas encore d'évaluation

- Cost Centre Separation Rev.1Document11 pagesCost Centre Separation Rev.1Safrin SangiaPas encore d'évaluation

- Process Roadmap 2016Document10 pagesProcess Roadmap 2016Safrin SangiaPas encore d'évaluation

- Daily AFR Material QualityDocument2 pagesDaily AFR Material QualitySafrin SangiaPas encore d'évaluation

- CPOH FlyerDocument2 pagesCPOH FlyerSafrin SangiaPas encore d'évaluation

- Manager Safety Tour Duty ObservationsDocument4 pagesManager Safety Tour Duty ObservationsSafrin SangiaPas encore d'évaluation

- Process and Production Introduction and Key Activities: © 2015 LafargeholcimDocument8 pagesProcess and Production Introduction and Key Activities: © 2015 LafargeholcimSafrin SangiaPas encore d'évaluation

- Daily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Document1 pageDaily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Safrin SangiaPas encore d'évaluation

- Target 2012 KPI Manufacturing DirectorateDocument3 pagesTarget 2012 KPI Manufacturing DirectorateSafrin SangiaPas encore d'évaluation

- Daily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Document1 pageDaily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Safrin SangiaPas encore d'évaluation

- NR.473-GQ1 Replace Roof, CasingDocument8 pagesNR.473-GQ1 Replace Roof, CasingSafrin SangiaPas encore d'évaluation

- AFR Material Quality 18-Jul-2012Document2 pagesAFR Material Quality 18-Jul-2012Safrin SangiaPas encore d'évaluation

- NR.473-GQ1 Fab - and Repl. Bull NoseDocument4 pagesNR.473-GQ1 Fab - and Repl. Bull NoseSafrin SangiaPas encore d'évaluation

- Quotation Awal From DepotDocument7 pagesQuotation Awal From DepotSafrin SangiaPas encore d'évaluation

- Pt. Depot Teknik Indonesia: Pantai Indah Selatan Blok D/A Kav. No.9. PIK Jakarta 14460 Phone: Fax: +62-21-5881059Document1 pagePt. Depot Teknik Indonesia: Pantai Indah Selatan Blok D/A Kav. No.9. PIK Jakarta 14460 Phone: Fax: +62-21-5881059Safrin SangiaPas encore d'évaluation

- The Aesthetics of Interactive Music Systems: Robert RoweDocument5 pagesThe Aesthetics of Interactive Music Systems: Robert Rowesertimone0% (1)

- My Media Kit AllDocument10 pagesMy Media Kit Allapi-4725615Pas encore d'évaluation

- Superior Pipeline EquipmentsDocument68 pagesSuperior Pipeline Equipmentsaliyildizx17730Pas encore d'évaluation

- Development Control Rules 2014Document155 pagesDevelopment Control Rules 2014ChandraPrabhaPas encore d'évaluation

- Groovy 9 – capturing RawRequest & ResponseDocument4 pagesGroovy 9 – capturing RawRequest & ResponseSirisha ChigurupatiPas encore d'évaluation

- Delft3D-TRIANA User ManualDocument54 pagesDelft3D-TRIANA User ManualAnonymous K02EhzPas encore d'évaluation

- 013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionDocument4 pages013 - Engine - Throttle - Pedal Position Sensor - Switch A Circuit MalfunctionMortada AlsonniPas encore d'évaluation

- Data Sheet: INJECTO-COMPACT (IC) 1400/725VDocument2 pagesData Sheet: INJECTO-COMPACT (IC) 1400/725VJulian FrailePas encore d'évaluation

- Turbine Heat Rate CalculationDocument2 pagesTurbine Heat Rate Calculationkaruna34650% (2)

- IEMPOWER-2019 Conference Dates 21-23 NovDocument2 pagesIEMPOWER-2019 Conference Dates 21-23 Novknighthood4allPas encore d'évaluation

- GITAM University Industrial Training ReportDocument6 pagesGITAM University Industrial Training ReportAkash RanjanPas encore d'évaluation

- Catalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDocument336 pagesCatalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDr. Dragos CobzariuPas encore d'évaluation

- Configure Dynamic NAT and PATDocument20 pagesConfigure Dynamic NAT and PATMary Amirtha Sagayee. GPas encore d'évaluation

- Privatisation: A Formula For Provision or Perversion of Municipal Solid Waste Management?Document56 pagesPrivatisation: A Formula For Provision or Perversion of Municipal Solid Waste Management?SoniaSegerMercedesPas encore d'évaluation

- Senior Finance Accounting Manager in Memphis TN Resume Frank FreeseDocument2 pagesSenior Finance Accounting Manager in Memphis TN Resume Frank FreeseFrankFreesePas encore d'évaluation

- Latihan HitunganDocument9 pagesLatihan HitunganMuhamad FadilahPas encore d'évaluation

- Various Types of W.C and Water Supply ConnectionsDocument12 pagesVarious Types of W.C and Water Supply ConnectionsAtish Kumar100% (1)

- Desalination Plant Feed Water ArrangementsDocument11 pagesDesalination Plant Feed Water ArrangementsSooraj Surendran SugathaPas encore d'évaluation

- Acceptance Criteria Boiler (API 573)Document1 pageAcceptance Criteria Boiler (API 573)Nur Achmad BusairiPas encore d'évaluation

- Clean BotDocument26 pagesClean BotCrystal FrostPas encore d'évaluation

- GDFGDFDocument12 pagesGDFGDFAissa FaikPas encore d'évaluation

- Catalog ABB 2018Document42 pagesCatalog ABB 2018Razvan Pislaru0% (1)

- Minds, Brains, and Computers PDFDocument8 pagesMinds, Brains, and Computers PDFJorge de La BarrePas encore d'évaluation

- Electronic Patient Record Use During Ward Rounds: A Qualitative Study of Interaction Between Medical StaffDocument8 pagesElectronic Patient Record Use During Ward Rounds: A Qualitative Study of Interaction Between Medical StaffpsikubPas encore d'évaluation

- Management of Change Order Claims in the Egyptian Industrial Construction SectorDocument106 pagesManagement of Change Order Claims in the Egyptian Industrial Construction SectorhymerchmidtPas encore d'évaluation

- Microsoft Outlook QuestionDocument1 pageMicrosoft Outlook QuestionRipunjay MishraPas encore d'évaluation

- 38 69 3 PBDocument23 pages38 69 3 PBIdethzPas encore d'évaluation

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRAlba R.Pas encore d'évaluation

- Perkins 500P PDFDocument5 pagesPerkins 500P PDFsaleemPas encore d'évaluation

- WavelengthPeriodFrequency QuestionsDocument2 pagesWavelengthPeriodFrequency QuestionssalmasomaPas encore d'évaluation