Académique Documents

Professionnel Documents

Culture Documents

Insulation Ashrae

Transféré par

Sameeh Kaddoura0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues1 pageInsulation Ashrae

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentInsulation Ashrae

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues1 pageInsulation Ashrae

Transféré par

Sameeh KaddouraInsulation Ashrae

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Insulation for Mechanical Systems

permesbility thickness, and quality ofthe mastic aplication. Also,

some mastics may not be compatible with cerain insulation types.

For this reason always consult the insulation manufacture fr tec

‘ommendations on the correct type of vapor retarder to use in the

pplication, Weather bacrcr maslics are nol vapor retarder matics

and should nat be used for below-amiient applications unless they

also have a low vapor permeability or ae used in conjunction with

separate vapor retarder.

[Below-ambient piping and equipment in general, and below:

fering applications in particule, are the most demanding appli-

cations for an insulation vapor relarder. Even though extremely

Jow-permeance [<0.3 np(s-m-Pa)] vapor retarder materials exist it

is extemely difficult to achieve a perfec barter in system that is

field installed and includes numerous joints and penetrations. It

follows that adequate system design, proper insulation an jacket

ing material selection, and eareful workmanship are all equally

important

Tr pipes operating at below-ambient temperatures, it is recom

‘mended that every 4.5 t06 lineal m, ora every fitting, «vapor stop

{also called vapor dam) be installed. Should a leak'ovcur in the

‘vapor retard, a vapor stop isolates vapor intrusion o that pipe ins

Jation section and thereby prevents vapor and condensed water

intrusion into the adjacent section(s) of pipe insulation or adjacent

fitting insulation, A vapor stop is made by applying a Vapacretarde|

mastic Hberally tothe pipe surface, for 75 mm along its lengi>

cent to the end of the pipe insulation section. After installing th

pipe insulation section, the mastic is then applied liberally othe end|

ofthe pipe insulation. Using a glass fiber or polyester sim allows

visual confiemasion thatthe mastic is thick enough, For illustations

of vapor stops, see MICA's (2011) National Commercial and Indus-

trial Insulation Standards.

‘Air-Handling Systems. Vapor retarders for equipment and duct

{ngulation take various forms. Because ofthe relatively less severe

and demanding conditions in arshandling systems located in condi

tioned spaces (because oftheir higher operating temperatures and|

lower indoor ambient humidity), current vapor retarder material

have been shown to adequately meet these performance require-

‘ments. In general, moisture problems are not often encountered if

insulation design is adequate for the application, and some low

permeability insulation materials are used without separate vapor

retarders For fberplass duct wrap and duct board, a lamination of

sluminum foil, scrim, and kraft paper (FSK) has long been the

vaterial of ehoice, although flexible vinyl and other white or black

facings are occasionally used. All ofthese facings can be procured|

separately in oll form, and used oa any ‘ype of insulation, ASTM

Standard C1136, type is atypical specification for factory-applied|

vapor retarder on duct insulation (except flexible duct) Flexible

(flex) ducting typically incorporates a plastic fm o il lamination

that contains a metalized substrate as a vapor-etarding component,

For outdoor ducts, laminate jacketing, manufacturer rated to have a

low vapor permeance (0.3 ngi(s-m*-Pa] and for outdoor wse, can

be installed over the previously mentioned types of duct insulation

using’ compatible tape fo closures, to provide protection from both|

weather exposure and vapor intrusion tothe duc insulation

“Application-specific pressur-senstive tapes or mastic are typ

‘cally used to Seal joins, As in aay cold system where a vapor|

relarder is required, design, selection of materials, and workman

ship mast be propery addressed, The insulation manufacturer's =~

‘ommendations shouldbe followed,

INSTALLATION

Pipe Insulation

‘Small pipes canbe insulated wth cylindrical alfseetions of rigid

insulation or with preformed flexible material. Larger pipes can be|

insulated with flexible material or with curve, flat segmented, of

23.13

cylindrical hal, hid, or quarter sections of rigid insulation Fitings

(Galves, tees, erosses, and elbows) use preformed fitting insulation,

fabricated Sting insultion, individual pieces eut from sectional

straight-pipe insulation, or insulting cements. Fitting insulations

should always be equal in thermal performance to the pipe insula-

‘Securing Methods. The method of securing varies withthe type

of insulation, size of pipe, form and weight of insulation, ané type

ofjacketng (Le, feld-o factory-applied. Insulation with factory-

applied jacketing can be secured on small piping by securing the

overlapping jacket, which usually includes a integral sealing tape

‘Additional tape around the circumference may be necessary. Large

piping may zequite supplemental witing or banding. Insulation on

large piping requiring separate jacketing is wired or banded in place,

and the jackets cemented wired, o banded, depending on he type

Flexible closed-cell materials require no jacket for most applica-

tions and are applied using specially formulated contact adhesives,

Tasulating Pipe Hangers. AIT piping is held in place by hangers

and supports. Seleetion and treatment of pipe hangers and supports

can significantly affect thermal performance ofan insulation sytem,

Thus, tis important thatthe piping engineer and insalation specifier

coordinate during project design to ensure that correct hangers are

‘used and sufficient physical space is maintained to allow forthe

required thickness of insulation

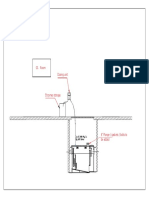

‘A pica ring or ine size hangers illustrated in Figure 6A. This

pS type of hanger is commonly used on above-ambient lines at mod:

crate temperature. However, it provides a thermal short circuit

‘through the insulation, and the penetration is difficult to seal effec

lively against water vapor, so i isnot recommended for below-

ambient applications,

Pipe shoes (Figure 6B) are used for hot piping of lage diameter

(Qigh mass) and where significant pipe movement is expected. The

design allows for pipe movement without damage tothe insulation or

the finish, The design is not recommended for below-ambientappli=

cations because of the thermal short circuit and dilficuly ia vapor

sealing.

A better solution isto use clevis hangers Figure 6C), which are

sized oll clearance forthe specified thickness of inslation, and

avoid the short circuit assovated with ring hangers and pipe shoes.

Shields (or saddles) spread the load from the pipe ts contents, and

‘the insulation material over an area sufficient to suppor the system

without significantly compressing the insulation material. Table 10

provides guidance on sheet metal sade lengths for glass fiber pipe

insulation. For pipe sizes above 80 mm, itis recommended tat high-

compressive-stength inserts (e.g, foam, high-density fiberglass,

calcium silicate) be used. Table 11° gives recommended saddle

lengths for 32 ken polyisocyunurate foam insulation. Prinsulated

sadles are availabe, Note that wood blocks have poor thermal con-

ductivity and are not recommended, especialy for cold pipe systems.

‘When the goal is avoiding compression of low-compressve-

strength insulation products, ts recommended to use highstrength

6 Insulating Pipe Hangers

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Microsoft Word - AppH-DefenitionsArabicDocument7 pagesMicrosoft Word - AppH-DefenitionsArabicSameeh KaddouraPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Load Calculation For HvacDocument1 pageLoad Calculation For HvacSameeh KaddouraPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Microsoft Word - AppE-ShadingDocument5 pagesMicrosoft Word - AppE-ShadingSameeh KaddouraPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- List of Mechanical Drawings: DWG No. Title Scale RevDocument1 pageList of Mechanical Drawings: DWG No. Title Scale RevSameeh KaddouraPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Action Plan For Ielts Self Study Students Book General Training Module Isbn 0521615283 9780Document14 pagesAction Plan For Ielts Self Study Students Book General Training Module Isbn 0521615283 9780Sameeh KaddouraPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Liner Slot Diffuser - 2 Slots 300lpsDocument1 pageLiner Slot Diffuser - 2 Slots 300lpsSameeh KaddouraPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- CELEX 32011R0327 en TXTDocument14 pagesCELEX 32011R0327 en TXTSameeh KaddouraPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- NK 100-400/395 EUP 50 HZ: Company Name: Created By: Phone: DateDocument3 pagesNK 100-400/395 EUP 50 HZ: Company Name: Created By: Phone: DateSameeh KaddouraPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Victaulic Piping Guide PDFDocument8 pagesVictaulic Piping Guide PDFkumar123rajuPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- MSA Booklet - March 2018Document50 pagesMSA Booklet - March 2018Agnel StanleyPas encore d'évaluation

- Grease Interc-01-Model PDFDocument1 pageGrease Interc-01-Model PDFSameeh KaddouraPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Weather - WikipediaDocument10 pagesWeather - WikipediaSameeh KaddouraPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Dancing Dry Deck FountainsDocument1 pageDancing Dry Deck FountainsSameeh KaddouraPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Design Weather Parameters & MshgsDocument1 pageDesign Weather Parameters & MshgsSameeh KaddouraPas encore d'évaluation

- Talk To A Domain Expert:: Hurry - Once It's Sold This Opportunity Will BeDocument2 pagesTalk To A Domain Expert:: Hurry - Once It's Sold This Opportunity Will BeSameeh KaddouraPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Design Weather Parameters & MshgsDocument1 pageDesign Weather Parameters & MshgsSameeh KaddouraPas encore d'évaluation

- Attachment 3 - Correlator DatasheetDocument4 pagesAttachment 3 - Correlator DatasheetSameeh KaddouraPas encore d'évaluation

- Correlator DatasheetDocument4 pagesCorrelator DatasheetSameeh KaddouraPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Goool - de - WikipediaDocument2 pagesGoool - de - WikipediaSameeh KaddouraPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Engineering Portfolios Value Use and ExamplesDocument9 pagesEngineering Portfolios Value Use and ExamplesSameeh KaddouraPas encore d'évaluation

- Correlator DatasheetDocument4 pagesCorrelator DatasheetSameeh KaddouraPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- M 0004 RevDocument1 pageM 0004 RevSameeh KaddouraPas encore d'évaluation

- Vocab by TopicDocument6 pagesVocab by TopicSameeh KaddouraPas encore d'évaluation

- Mastering Writing Task2Document52 pagesMastering Writing Task2Sameeh KaddouraPas encore d'évaluation

- Option 1 Reference Location Flow Cooling Load Quantity Type Remarks L/s TON CH-01 Roof 23 200 7 ScrollDocument9 pagesOption 1 Reference Location Flow Cooling Load Quantity Type Remarks L/s TON CH-01 Roof 23 200 7 ScrollSameeh KaddouraPas encore d'évaluation

- TOEFL Vocabulary PDFDocument15 pagesTOEFL Vocabulary PDFDivya S KumarPas encore d'évaluation

- Writing Task Two Course PackDocument54 pagesWriting Task Two Course PackRavi DasPas encore d'évaluation

- TOEFL Writing Ibt PDFDocument18 pagesTOEFL Writing Ibt PDFMina MinawyPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)