Académique Documents

Professionnel Documents

Culture Documents

PTW For Hot Work: Pakistan EPCL PVC Expansion Project

Transféré par

Muhammad Rafique0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pagenm

Titre original

Hot

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentnm

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues1 pagePTW For Hot Work: Pakistan EPCL PVC Expansion Project

Transféré par

Muhammad Rafiquenm

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

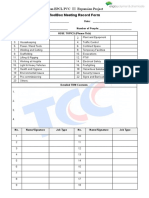

Pakistan EPCL PVC Ⅲ Expansion Project

PTW for Hot Work

PTW No.: T18B10–HSSE-PTW-HW-

Company Applicant

Unit/Location Supervisor

Valid Time From (date) (time) to (date) (time)

Type of Hot Work Area Temporary hot work area Fixed hot work area

Work Description

No. Check List Confirmation N/A

1 Work is wearing essential PPEs required for work.

2 Welding or heating equipments are certified, and in safe working order.

3 Hot job area is cordoned off and tagged at the ground floor.

4 Proper ventillation and escape routes are available

5 Wind velocity is low and not strong enough to carry sparks away.

6 Check explosivity (LEL) in the area and confirmed there is no gas leakage.

7 Electrical wires and hoses etc. will not become obstacles, and shall be smoothed out.

Electric welding circuit wire should be connected to the weldment, and earth wire shall not

8

pass through or overlap with other equipment or electrical conductors.

9 Clear up inflammables around the hot work area, or take proper fire prevention measure.

10 Gas cylinders are vertically secured with chains and take sun proof measures.

Gas cylinder is located at least 20 ft. away from the hot job point to avoid any sparks

11

falling on it. Also, gas leads from cylinder to torch are in good condition.

The cylinder shall be equipped with a cap and an anti-seismic ring when transported in a specific

12

vehicle or a cart. All the flammable gas cylinders should be equipped with anti-backfire valves.

13 Inspected fire extinguisher is placed at work place.

14 Water hose available at hot job location.

15 Hose pipes of gas cutting kit are in good condition, soap test of gas cylinder is conducted.

16 For hot job at ground, all drains & manholes within 10 ft. of the work place are adequately covered.

For hot job at heights, all drains & manholes within 30 ft. of the work place are adequately

17

covered. The area may be increased depending upon the wind direction etc.

Scaffolding is properly installed & wooden planks are firmly placed, wetted with water & safe for the

18

job. If planks are not wetted, then protect them with fire resistant cloth or metal sheet.

19 No painting to be done in the job area till the completion of the job.

Spark prevention measures, such as a fire blanket or a fire pan, shall be taken for working

20 at heights (above 1.8m). Enclosure should be sufficient to retain all the welding spatters

falling on gas flanges, valves, fittings or instrument cable trays.

21 Supervisor shall be on site all the time. Name of fire watcher ( )

22 Welder/Fabricator is certified and documented.

23 Safety and technology disclosure has been done.

Subcontractor TCC Professional

Subcontractor HSSE Supervisor TCC HSSE Engineer

Representative of Executor Engineer

Note: Any violation of approved regulations and procedures will possibly cause serious incident or accident!

TCC will strictly punish personnel and subcontractor with violation.

Vous aimerez peut-être aussi

- HOT Job ChecklistDocument1 pageHOT Job ChecklistAyoun Ul HaquePas encore d'évaluation

- Hotwork Implementation Verification Checklist Rev 5Document3 pagesHotwork Implementation Verification Checklist Rev 5anjangandak2932100% (1)

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- Scope of WorkDocument24 pagesScope of WorkGijo GeorgePas encore d'évaluation

- HOT WORK PERMIT SAFETYDocument1 pageHOT WORK PERMIT SAFETYwlyPas encore d'évaluation

- Hot Work Procedure, WHSPRO-010 CMDocument3 pagesHot Work Procedure, WHSPRO-010 CMmyo lwinPas encore d'évaluation

- Hot Work Procedure 2021Document8 pagesHot Work Procedure 2021Wan Ahmad FaaizunPas encore d'évaluation

- 1 HotworkDocument1 page1 Hotworkchariot1729Pas encore d'évaluation

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- Hot Work ChecklistDocument1 pageHot Work ChecklistloganathanPas encore d'évaluation

- Ace Hot Work Permit Application Form PDFDocument3 pagesAce Hot Work Permit Application Form PDFkevin100% (1)

- Safety Work PermitDocument36 pagesSafety Work PermitAshwani Dogra100% (1)

- PRL SOW-HP Steam Line ModificationDocument3 pagesPRL SOW-HP Steam Line ModificationM Waqas HabibPas encore d'évaluation

- Execution of Tie-Ins Without A Plant ShutdownDocument3 pagesExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianPas encore d'évaluation

- Permit Work System SafetyDocument36 pagesPermit Work System SafetyDipin RajPas encore d'évaluation

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Hot Tap PipingDocument21 pagesHot Tap PipingRachel FloresPas encore d'évaluation

- Hot Work Permit To WorkDocument3 pagesHot Work Permit To WorkMorris M.Pas encore d'évaluation

- National Safety Council Permit To Work SystemDocument13 pagesNational Safety Council Permit To Work SystemAnilPas encore d'évaluation

- Reformer RepairDocument11 pagesReformer RepairNishant Kumar ThakurPas encore d'évaluation

- Work Permit SystemDocument38 pagesWork Permit SystemNaveen Meena50% (2)

- Shandong TIEJUN Electric Power Engineering Company Limited Letter of Award to Larsen & Toubro for Cuddalore Power Plant ProjectDocument20 pagesShandong TIEJUN Electric Power Engineering Company Limited Letter of Award to Larsen & Toubro for Cuddalore Power Plant ProjectVijay RajPas encore d'évaluation

- Hot Work Permit PolicyDocument3 pagesHot Work Permit PolicyRodrigo ZapataPas encore d'évaluation

- Taping and Chilled Water Pipe InstallationDocument13 pagesTaping and Chilled Water Pipe InstallationProject enghvacPas encore d'évaluation

- Safety Method Statement for Welding PipeworkDocument22 pagesSafety Method Statement for Welding PipeworkCobbinah MarkPas encore d'évaluation

- HSE guide section on hot tapping safetyDocument4 pagesHSE guide section on hot tapping safetyabhisheknharanghat100% (1)

- 53 TS Fire Protection System For 400kV R1 010108Document95 pages53 TS Fire Protection System For 400kV R1 010108girish_motiyani100% (3)

- Hot Work Permits: Corporate Environment Safety & HealthDocument17 pagesHot Work Permits: Corporate Environment Safety & HealthBv Rao100% (1)

- Installation of Auxiliary Steam Boiler PackageDocument10 pagesInstallation of Auxiliary Steam Boiler Packagesharif339Pas encore d'évaluation

- Requirements in Executing A Hot Tap - ION PRODocument25 pagesRequirements in Executing A Hot Tap - ION PROHous BoukadoPas encore d'évaluation

- Checklist For High Risk Work - Hot WorkDocument8 pagesChecklist For High Risk Work - Hot WorkSalsabilla Putri anggrainiPas encore d'évaluation

- 06_170914_TBX12_HotworksDocument2 pages06_170914_TBX12_HotworksJason LeonardPas encore d'évaluation

- Work Permit SystemDocument5 pagesWork Permit SystemSuresh PasumarthiPas encore d'évaluation

- Method Statement For Hot TappingDocument13 pagesMethod Statement For Hot TappingAmb Patrick OghatePas encore d'évaluation

- Hot Work PermitDocument18 pagesHot Work PermitMuneeb Ur RehmanPas encore d'évaluation

- Fire Protection Pipes Method StatementDocument16 pagesFire Protection Pipes Method StatementAbdul Hakkim80% (5)

- ICT Permit To Work Application - Rev 2021Document2 pagesICT Permit To Work Application - Rev 2021Fatma AlSuwaidiPas encore d'évaluation

- CAT-08 Hot Work and Safe Work-EnglishDocument23 pagesCAT-08 Hot Work and Safe Work-EnglishDanPas encore d'évaluation

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoPas encore d'évaluation

- OHS Work PermitsDocument17 pagesOHS Work PermitsNadaPas encore d'évaluation

- Q & Hse BriefingDocument2 pagesQ & Hse BriefingTony ChengPas encore d'évaluation

- WorkpermitDocument26 pagesWorkpermitsupahing supahingPas encore d'évaluation

- 7418 Fls Hot Work ProgramDocument3 pages7418 Fls Hot Work ProgramAli AlahmaPas encore d'évaluation

- CUMC Hot Work Permit ProceduresDocument6 pagesCUMC Hot Work Permit ProceduresMairaj UddinPas encore d'évaluation

- PTW Training PackageDocument39 pagesPTW Training PackageMoucha JustdoitPas encore d'évaluation

- Safety Code For Gas Cutting & Gas WeldingDocument15 pagesSafety Code For Gas Cutting & Gas WeldingCh UdayPas encore d'évaluation

- Concrete Risk PDFDocument32 pagesConcrete Risk PDFkrissregionPas encore d'évaluation

- 2.safety and Security Regulation UpdatedDocument36 pages2.safety and Security Regulation Updatedrashad mPas encore d'évaluation

- Indian Oil Corporation Limited Panipat Refinery: (Refineries Division)Document11 pagesIndian Oil Corporation Limited Panipat Refinery: (Refineries Division)Priyanshu JhaPas encore d'évaluation

- Job Procedure 01 For HT PANELSDocument7 pagesJob Procedure 01 For HT PANELSSoumik Kar100% (1)

- Method Statement For Heat Exchanger Revise1Document19 pagesMethod Statement For Heat Exchanger Revise1DanielLeePas encore d'évaluation

- Risk Assessment Method Statement Documents: April 2007Document11 pagesRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahPas encore d'évaluation

- Overhauling Boiler Parts NTPC Lara STPPDocument97 pagesOverhauling Boiler Parts NTPC Lara STPPRAMAN SHARMAPas encore d'évaluation

- Safety - Form-SAF019-HotWorkPermitDocument5 pagesSafety - Form-SAF019-HotWorkPermitEdwin MofokengPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsD'EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionD'EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Maqsood Khan Civil Supervisor Contact and ProfileDocument2 pagesMaqsood Khan Civil Supervisor Contact and ProfileMuhammad RafiquePas encore d'évaluation

- Block MasoneryDocument2 pagesBlock MasoneryMuhammad RafiquePas encore d'évaluation

- Engr Sarmad CV (ShutDown)Document5 pagesEngr Sarmad CV (ShutDown)Muhammad RafiquePas encore d'évaluation

- 脚手架验收检查清单checklist for scaffold inspection and acceptanceDocument2 pages脚手架验收检查清单checklist for scaffold inspection and acceptanceMuhammad RafiquePas encore d'évaluation

- Violation of Mr. Shakeel Ahmed 14Document1 pageViolation of Mr. Shakeel Ahmed 14Muhammad RafiquePas encore d'évaluation

- 班前会ToolBox Meeting Record FormDocument1 page班前会ToolBox Meeting Record FormMuhammad RafiquePas encore d'évaluation

- AssigmentDocument8 pagesAssigmentMuhammad Rafique0% (1)

- EN 540 Class Problem (BBS)Document2 pagesEN 540 Class Problem (BBS)Muhammad RafiquePas encore d'évaluation

- Sop 1Document3 pagesSop 1Muhammad RafiquePas encore d'évaluation

- 4397Document33 pages4397Muhammad RafiquePas encore d'évaluation

- Resume of Shakeel AhmedDocument1 pageResume of Shakeel AhmedMuhammad RafiquePas encore d'évaluation

- Weekly HSE Inspection Report 20190409Document5 pagesWeekly HSE Inspection Report 20190409Muhammad RafiquePas encore d'évaluation

- Reflecting on UPHSD's Mission, Vision, and Core ValuesDocument3 pagesReflecting on UPHSD's Mission, Vision, and Core ValuesBia N Cz100% (1)

- ResumeDocument5 pagesResumeSaeed SiriPas encore d'évaluation

- 7 C's of Business LetterDocument3 pages7 C's of Business LetterGladys Forte100% (2)

- CHEE319 Tutorial 4 SolnDocument13 pagesCHEE319 Tutorial 4 SolnyeshiduPas encore d'évaluation

- Running Head:: Describe The Uses of Waiting Line AnalysesDocument6 pagesRunning Head:: Describe The Uses of Waiting Line AnalysesHenry AnubiPas encore d'évaluation

- Super-Critical BoilerDocument32 pagesSuper-Critical BoilerAshvani Shukla100% (2)

- HWXX 6516DS1 VTM PDFDocument1 pageHWXX 6516DS1 VTM PDFDmitriiSpiridonovPas encore d'évaluation

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- Calculating Molar MassDocument5 pagesCalculating Molar MassTracy LingPas encore d'évaluation

- Mock PPT 2023 TietDocument22 pagesMock PPT 2023 Tiettsai42zigPas encore d'évaluation

- Comparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDocument6 pagesComparison of Waste-Water Treatment Using Activated Carbon and Fullers Earth - A Case StudyDEVESH SINGH100% (1)

- CD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesDocument26 pagesCD1 ISO/IEC 17000 Conformity Assessment - Vocabulary and General PrinciplesMAC CONSULTORESPas encore d'évaluation

- Employees' Job Satisfaction and Organizational Performance A Case of KSRTCDocument4 pagesEmployees' Job Satisfaction and Organizational Performance A Case of KSRTCEditor IJTSRDPas encore d'évaluation

- MST 2 ReviewerDocument4 pagesMST 2 ReviewerAizha NarioPas encore d'évaluation

- Advanced Scan I21no2Document29 pagesAdvanced Scan I21no2Jaiber SosaPas encore d'évaluation

- Alside Brochure - Zen Windows The TriangleDocument13 pagesAlside Brochure - Zen Windows The TriangleZenWindowsTheTrianglePas encore d'évaluation

- Final Term Quiz 2 On Cost of Production Report - Average CostingDocument4 pagesFinal Term Quiz 2 On Cost of Production Report - Average CostingYhenuel Josh LucasPas encore d'évaluation

- Overhead Water Tank Structural AnalysisDocument28 pagesOverhead Water Tank Structural Analysiscollins unanka100% (3)

- Pricelist Hardware Jayacom Disember 2018Document2 pagesPricelist Hardware Jayacom Disember 2018ContempGamelan PerformingGroupPas encore d'évaluation

- Main Sulci & Fissures: Cerebral FissureDocument17 pagesMain Sulci & Fissures: Cerebral FissureNagbhushan BmPas encore d'évaluation

- G String v5 User ManualDocument53 pagesG String v5 User ManualFarid MawardiPas encore d'évaluation

- Designers' Guide To Eurocode 7 Geothechnical DesignDocument213 pagesDesigners' Guide To Eurocode 7 Geothechnical DesignJoão Gamboias100% (9)

- Lab 01 - HCV and LCV by Gas CalorimeterDocument6 pagesLab 01 - HCV and LCV by Gas CalorimeterTakreem SindhuPas encore d'évaluation

- Section 3.4: Buffer Overflow Attack: Defense TechniquesDocument26 pagesSection 3.4: Buffer Overflow Attack: Defense TechniquesAdeenPas encore d'évaluation

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- MA4850 Supply Chain & Logistics ManagementDocument21 pagesMA4850 Supply Chain & Logistics ManagementQy LeePas encore d'évaluation

- Whirlpool FL 5064 (ET)Document8 pagesWhirlpool FL 5064 (ET)long_kongo100% (1)

- AsdfgDocument2 pagesAsdfgTejendra PachhaiPas encore d'évaluation

- Holacracy FinalDocument24 pagesHolacracy FinalShakil Reddy BhimavarapuPas encore d'évaluation

- Mohammad Abu-Radi ResumeDocument4 pagesMohammad Abu-Radi ResumeMohammad Abu-RadiPas encore d'évaluation