Académique Documents

Professionnel Documents

Culture Documents

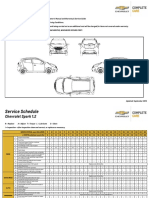

Maintenance Schedule: Air Cooling RRRRRRRRRRRRRRRRRRR R R R R R R Water Cooling R I R

Transféré par

Jatin SharmaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Maintenance Schedule: Air Cooling RRRRRRRRRRRRRRRRRRR R R R R R R Water Cooling R I R

Transféré par

Jatin SharmaDroits d'auteur :

Formats disponibles

ABB

Maintenance schedule

The maintenance schedule applies to all air-cooled and water-cooled medium voltage drives. Please

note the maintenance items in the schedule which only apply to particular drives.

The recommended intervals for maintenance and component replacement are based on the normal

operating conditions of the drive. The drive should be checked at least every two years by qualified

personnel whose recommendations should be followed. Depending on the actual condition of the

drive, the maintenance work can be carried out before or after the recommended interval.

Years from start-up

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Air cooling

- Air filters 1 I R R R R R R R R R R R R R R R R R R R

- Cooling fan (continuous operation) 2 I I P I R I P I R I P I R I P I R I P I

- Cooling fan (redundant) A, 2 I I P I P I P I R I P I P I P I R I P I

Water cooling B

- Deionizer, microfilter and strainer 3 R I R I R I R I R I R I R I R I R I R I

- Cooling pump gasket - - - - R - - - R - - - R - - - R - - -

- Cooling pump (continuous operation) 2 I I P I R I P I R I P I R I P I R I P I

- Cooling pump (redundant) 2 I I P I P I P I R I P I P I P I R I P I

- Rubber hoses I I I I I I I I R I I I I I I I R I I I

- Plastic tubes and connectors I I I I I I I I I I I I I I I I I I I I

Aging

- DC capacitors C, 4 I I I I I I I I P I P I P I P I P I P I

- AC capacitors D, 5 I I I I I I I I I I R I I I I I I I I I

- Printed circuit boards, power supplies - - - - - - - - - - R - - - - - - - - -

- Batteries E (internal to the drive) I I R I R I R I R I R I R I R I R I R I

- UPS batteries (external to the drive) I I R I R I R I R I R I R I R I R I R I

Fuses

- Line-side fuses F I I I I I I I I R I I I I I I I R I I I

Connections and operating conditions

- Optical fibers 6 - - - - - - P - P - P - P - P - P - P -

- Cable connections, bolted connections I I I I I I I I I I I I I I I I I I I I

- Dustiness, corrosion, temperature I I I I I I I I I I I I I I I I I I I I

Improvements and spare parts

- Software, hardware upgrades 7 I - I - I - I - I - P - I - I - I - I -

- Spare parts I - I - P - I - P - I - P - I - P - I -

Measurements and tests

- Measurements with auxiliary voltage I I P I P I P I P I P I P I P I P I P I

- Insulation - - - - P - - - P - - - P - - - P - - -

- Safety circuits P P P P P P P P P P P P P P P P P P P P

3BHS351169 ZAB E01 Rev. B 1 (2)

Maintenance schedule ABB

R Replacement of the component

I Inspection (visual inspection; corrective measures, repair and/or replacement of component if needed)

P Performance of on-site work (for example, commissioning, tests, measurements)

- No action

A Applies to ACS 1000i, ACS 1000A, ACS 1000W, ACS 2000, ACS 5000A, ACS 5000W

B Applies to all water-cooled drives

C Applies to ACS 1000i, ACS 1000A, ACS 1000W, ACS 2000, ACS 5000A, ACS 5000W, ACS 6000

D Applies to ACS 1000i, ACS 1000A, ACS 1000W, ACS 2000, ACS 6000, ACS 6000c, LCI

E Applies to ACS 1000i, ACS 1000A, ACS 1000W

F Applies to ACS 2000

1 Air filters can be replaced or cleaned. The decision to replace or clean a filter depends on the condition of the filter.

2 It is recommended to replace the device after four years of operation.

3 The average lifetime of the deionizer is 2-4 years, depending mainly on the water quality. At the same time the

deionizer is changed, the microfilter should also be replaced and the strainer should be cleaned.

4 The expected lifetime of DC capacitors (self-healing) depends mainly on the ambient conditions. The recommended

intervals are based on operation with rated current and maximum permitted temperature. A capacitor should be

replaced when regularly taken measurements show a significant deviation from the rated capacitance.

5 AC capacitors (not self-healing) are used in input and output filters, and the snubber circuit of ACS 6000c and LCI.

Unlike DC capacitors, AC capacitors do not show signs of reduced capacitance over the lifetime. Measurements of

the capacitance also do not allow predicting the lifetime, which depends mainly on the ambient conditions.

6 The expected lifetime of the optical fibers depends mainly on the ambient conditions. The recommended intervals are

based on operation with rated current and maximum permitted temperature. An optical fiber should be replaced when

regularly taken measurements show significant deterioration of the fiber.

7 Improvements based on further development, software modifications, and so on. When printed circuit boards must

be replaced, an upgrade of the control system should be considered as well.

2 (2) 3BHS351169 ZAB E01 Rev. B

Vous aimerez peut-être aussi

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- ABB ACS 800 PM KitsDocument2 pagesABB ACS 800 PM Kitsvenkatesan0% (1)

- VP-1200, 1000 (Eng) - SVC - Manual Ver 1.4 19.01.07Document162 pagesVP-1200, 1000 (Eng) - SVC - Manual Ver 1.4 19.01.07Daniel Guillen100% (4)

- Panasonic Sa-Akx18Document66 pagesPanasonic Sa-Akx18Francisco Assis Reis CruzPas encore d'évaluation

- GisDocument30 pagesGisAbdevil67% (3)

- Daewoo SERVICE MANUAL NO-FROST COMBI-REFRIGERATOR ERF-364 - 367 - ALL AR-EU MODELS PDFDocument56 pagesDaewoo SERVICE MANUAL NO-FROST COMBI-REFRIGERATOR ERF-364 - 367 - ALL AR-EU MODELS PDFTonpitonpi Ton PiPas encore d'évaluation

- DM 441b Tisch MultimeterDocument38 pagesDM 441b Tisch MultimeterFebriansyah IndratnoPas encore d'évaluation

- Emerson TC1369Document8 pagesEmerson TC1369Antonio OrtegaPas encore d'évaluation

- Axial Flow Fans PDFDocument66 pagesAxial Flow Fans PDFCodruţ ErașcuPas encore d'évaluation

- F10 Taps in Auto Transformers PaperDocument55 pagesF10 Taps in Auto Transformers Paperverma210Pas encore d'évaluation

- ACS2000 Preventive Maintenance WebDocument2 pagesACS2000 Preventive Maintenance Webfernandoabel01Pas encore d'évaluation

- ACS 5000 Maintenance ScheduleDocument1 pageACS 5000 Maintenance ScheduleMesafint kassiePas encore d'évaluation

- FactFile EN SP58 ACH550 ACS550 PM RS Kit RevA PDFDocument4 pagesFactFile EN SP58 ACH550 ACS550 PM RS Kit RevA PDFFarhan SattarPas encore d'évaluation

- ACS800 Maintenance Schedule - 4FPS10000223379 - Rev H PDFDocument1 pageACS800 Maintenance Schedule - 4FPS10000223379 - Rev H PDFThương NguyễnPas encore d'évaluation

- Plan de Mantenimiento Anual - ACS800Document2 pagesPlan de Mantenimiento Anual - ACS800clide_050793Pas encore d'évaluation

- ACS 600 FactDocument4 pagesACS 600 FactTemmy Candra WijayaPas encore d'évaluation

- ABB PVS800 Preventive MaintenanceDocument4 pagesABB PVS800 Preventive MaintenanceSeeths NairPas encore d'évaluation

- ACS5000 Water-Cooled Preventive Maintenance ScheduleDocument3 pagesACS5000 Water-Cooled Preventive Maintenance SchedulemlutfimaPas encore d'évaluation

- Drives Td001 en PDocument6 pagesDrives Td001 en Persanjeeb_456Pas encore d'évaluation

- Maintenance Schedule PSR Cycloconverter Ver3Document1 pageMaintenance Schedule PSR Cycloconverter Ver3IdhamtanahbaruPas encore d'évaluation

- Drives Td001 - en P Ultima VersionDocument6 pagesDrives Td001 - en P Ultima VersionCristian Yesid Pachon HernandezPas encore d'évaluation

- Preventive Maintenance Schedule ACS1000 RevBDocument3 pagesPreventive Maintenance Schedule ACS1000 RevB0502208864Pas encore d'évaluation

- Preventive Maintenance Schedule ACS2000Document2 pagesPreventive Maintenance Schedule ACS2000William Santhiago Vásquez RamosPas encore d'évaluation

- ACS800 Maintenance Schedule - 4FPS10000223379 - Rev JDocument1 pageACS800 Maintenance Schedule - 4FPS10000223379 - Rev JdicicaPas encore d'évaluation

- FactFile en SP60 SamiStar PM Kit RevADocument4 pagesFactFile en SP60 SamiStar PM Kit RevAVladimir Colombiano de SouzaPas encore d'évaluation

- Maintenance Schedule ACS800 RevFDocument2 pagesMaintenance Schedule ACS800 RevFAnonymous UihtV75Pas encore d'évaluation

- ACS580MV: Preventive Maintenance ScheduleDocument2 pagesACS580MV: Preventive Maintenance Schedulealok pratap singhPas encore d'évaluation

- Maintenance Schedule ACS800 2017 and Onwards Rev ADocument2 pagesMaintenance Schedule ACS800 2017 and Onwards Rev AjakkyjeryPas encore d'évaluation

- Maintenance Schedule ACS800 2016 and BeforeDocument3 pagesMaintenance Schedule ACS800 2016 and BeforeahilsergeyPas encore d'évaluation

- Panasonic - SC hc3p PC PDFDocument122 pagesPanasonic - SC hc3p PC PDFvideosonPas encore d'évaluation

- FactFile ES SP61 ACV700 PM Kit RevADocument4 pagesFactFile ES SP61 ACV700 PM Kit RevAcjroanPas encore d'évaluation

- Sentridge ABB DriveMaintenance PlanDocument2 pagesSentridge ABB DriveMaintenance Planvinoth babuPas encore d'évaluation

- Preventive Maintenance Schedule MEGADRIVE-LCIDocument2 pagesPreventive Maintenance Schedule MEGADRIVE-LCISergey PavlovPas encore d'évaluation

- A1 Ew ETf Ura LDocument23 pagesA1 Ew ETf Ura LCitoy LabadanPas encore d'évaluation

- Service Schedule for Chevrolet Spark 1.2Document3 pagesService Schedule for Chevrolet Spark 1.2SixtoPas encore d'évaluation

- 21 PDFDocument22 pages21 PDFMaltin SelmanllariPas encore d'évaluation

- SA-PMX100EG: CD Stereo SystemDocument74 pagesSA-PMX100EG: CD Stereo SystemTại TâmPas encore d'évaluation

- ACS880 PM Services Note EN 3AUA0000193491 RevA LowresDocument4 pagesACS880 PM Services Note EN 3AUA0000193491 RevA LowresThanh VuPas encore d'évaluation

- A4.1 Chiller Unit IPE31Document55 pagesA4.1 Chiller Unit IPE31ALDO DANIEL PEREZ CALLEJASPas encore d'évaluation

- Drive Preventive Maintenance PM ScheduleDocument5 pagesDrive Preventive Maintenance PM ScheduleEdisonCorderoPas encore d'évaluation

- Preventive Maintenance Kits For ABB Industrial Drives, ACS800Document2 pagesPreventive Maintenance Kits For ABB Industrial Drives, ACS800Jhon RodriguezPas encore d'évaluation

- Daewoo FR-581NT NWDocument31 pagesDaewoo FR-581NT NWguillermomartinie83% (6)

- Apache Alpine Piping Analysis ReportDocument80 pagesApache Alpine Piping Analysis ReportEdward JulianPas encore d'évaluation

- SRL 677 EvDocument81 pagesSRL 677 Evcarlos100% (1)

- Instruction Manual HZB 35 45 65Document22 pagesInstruction Manual HZB 35 45 65walleyexdaPas encore d'évaluation

- 9441 Panasonic SA-AKX18PH AKX18PN Sistema de Audio CD-USB-Bluetooth Manual de ServicioDocument66 pages9441 Panasonic SA-AKX18PH AKX18PN Sistema de Audio CD-USB-Bluetooth Manual de ServicioEduardo SierraPas encore d'évaluation

- Panasonic Sa-Pt470Document154 pagesPanasonic Sa-Pt470videoson100% (5)

- PF755 HHP Maintenance Manual - 8B5DDocument3 pagesPF755 HHP Maintenance Manual - 8B5DFranko Ney FélixPas encore d'évaluation

- Service NoteDocument2 pagesService NoteMarceloPas encore d'évaluation

- Tcp50ut50 PDFDocument97 pagesTcp50ut50 PDFDavi CaldasPas encore d'évaluation

- 1VDD300007-SafeRing-SafePlus Recommended Spare PartsDocument4 pages1VDD300007-SafeRing-SafePlus Recommended Spare PartsGary FortuinPas encore d'évaluation

- 5 Maintenance - Schedule - PVS980-58 (Mustard) PrelDocument1 page5 Maintenance - Schedule - PVS980-58 (Mustard) PrelSAEL SOLARPas encore d'évaluation

- Th46pz80ua SMDocument141 pagesTh46pz80ua SMPatrice PaulPas encore d'évaluation

- MANUALE RADIO Rfd10egDocument54 pagesMANUALE RADIO Rfd10egMadison BarocPas encore d'évaluation

- SA-AKX38PH - AKX38PN (sm-PSG1402005CE) PDFDocument70 pagesSA-AKX38PH - AKX38PN (sm-PSG1402005CE) PDFJory2005100% (2)

- Yamaha RXV1500Document125 pagesYamaha RXV1500Saeid PourfarzibPas encore d'évaluation

- Yamaha rx-v477 htr-4067 SM PDFDocument143 pagesYamaha rx-v477 htr-4067 SM PDFLeonardo Tafur100% (1)

- Saakx 18 PHDocument68 pagesSaakx 18 PHKarina GonzalezPas encore d'évaluation

- Ideal Electric - SABH100 Manual PDFDocument88 pagesIdeal Electric - SABH100 Manual PDFjose machadoPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Abb Isomax s3-s8 Circuit Breaker DatasheetDocument53 pagesAbb Isomax s3-s8 Circuit Breaker DatasheetElson Peringattu GeorgePas encore d'évaluation

- Danfoss 5016Document61 pagesDanfoss 5016tatasrbaPas encore d'évaluation

- Demand Side Management: Internship Report OnDocument41 pagesDemand Side Management: Internship Report Onsyed asifullaPas encore d'évaluation

- 3VL CatalogueDocument6 pages3VL CatalogueKevin DucusinPas encore d'évaluation

- TM11-2648 Vibrator Pack PP-68 U, 1945Document43 pagesTM11-2648 Vibrator Pack PP-68 U, 1945david_graves_okstatePas encore d'évaluation

- Tom Upto Gate 2010 Ies2009Document298 pagesTom Upto Gate 2010 Ies2009NiteshRaiPas encore d'évaluation

- ABB ZX2 KatalogDocument112 pagesABB ZX2 KatalogarozmanPas encore d'évaluation

- Power Factor Correction GuideDocument16 pagesPower Factor Correction GuidePurduePete1980Pas encore d'évaluation

- 4.1 General Device Data: 4.1.1 Analog InputsDocument4 pages4.1 General Device Data: 4.1.1 Analog InputsEbrahim ArzaniPas encore d'évaluation

- Design Criteria ElectricalDocument38 pagesDesign Criteria ElectricalPramod B.Wankhade100% (4)

- Technical Manual For Float Cum Boost Battery Charger (S1A02)Document8 pagesTechnical Manual For Float Cum Boost Battery Charger (S1A02)DEEPAKPas encore d'évaluation

- Inelectra - Protección Contra Descargas Eléctricas Atmosféricas PDFDocument32 pagesInelectra - Protección Contra Descargas Eléctricas Atmosféricas PDFgilbertomjcPas encore d'évaluation

- ETAP-product DescriptionDocument38 pagesETAP-product DescriptionManohar PotnuruPas encore d'évaluation

- IEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Document65 pagesIEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Alex PAPas encore d'évaluation

- Improvement of Power Quality in Wind Energy Conversion SystemsDocument11 pagesImprovement of Power Quality in Wind Energy Conversion SystemsIJRASETPublicationsPas encore d'évaluation

- WECON LX3V Product Wiring DiagramDocument2 pagesWECON LX3V Product Wiring DiagramAhmed AbdelazimPas encore d'évaluation

- Integrating Wind Energy in ERCOTDocument27 pagesIntegrating Wind Energy in ERCOTsupering143Pas encore d'évaluation

- 202011231810195795final MVVNL SoP Manual - UploadDocument13 pages202011231810195795final MVVNL SoP Manual - UploadAman singhPas encore d'évaluation

- 402-91-EL-LIS-00003 Rev A1Document3 pages402-91-EL-LIS-00003 Rev A1Krishnan KrishPas encore d'évaluation

- Time Schedule (S Curve) for 150kV Ampel Substation Construction ProjectDocument153 pagesTime Schedule (S Curve) for 150kV Ampel Substation Construction Projectindra squarefacePas encore d'évaluation

- Electrical Panel Types and FunctionsDocument13 pagesElectrical Panel Types and FunctionsShamim MollaPas encore d'évaluation

- 1.5-77 (Class I) : Highest Capacity Factor in Its ClassDocument8 pages1.5-77 (Class I) : Highest Capacity Factor in Its ClassCamio HormazabalPas encore d'évaluation

- Analisa Sistem Tenaga Dengan MatlabDocument10 pagesAnalisa Sistem Tenaga Dengan MatlabSony AdyatamaPas encore d'évaluation

- DC Power SupplyDocument8 pagesDC Power Supplyweaam raedPas encore d'évaluation

- Understanding natural circulation in boilersDocument5 pagesUnderstanding natural circulation in boilerssugumar100% (1)

- A New Method of Maximum Power Point Tracking For DFIG Based Wind TurbineDocument7 pagesA New Method of Maximum Power Point Tracking For DFIG Based Wind Turbinebalaji06202Pas encore d'évaluation

- 1KD EduDocument5 pages1KD EduMakokha Mumelo100% (1)

- Utility Scale Electrical Energy Storage Systems: Julio C. RimadaDocument12 pagesUtility Scale Electrical Energy Storage Systems: Julio C. RimadaJulio Cesar Rimada HerreraPas encore d'évaluation