Académique Documents

Professionnel Documents

Culture Documents

Wheel Balancing: 9. Installation of Wheel Assembly To Vehicle

Transféré par

miguel0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageThis document provides instructions for wheel balancing and installing a wheel assembly onto a vehicle. It describes how to check and adjust wheel balance using weights on both sides of the rim. It also outlines the proper procedure for attaching the wheel to the hub and tightening the nuts in a diagonal pattern to the specified torque value. Cautions are provided about tightening in stages and not overtightening drum brake models.

Description originale:

MSA5T0125A27764

Titre original

MSA5T0125A27764

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides instructions for wheel balancing and installing a wheel assembly onto a vehicle. It describes how to check and adjust wheel balance using weights on both sides of the rim. It also outlines the proper procedure for attaching the wheel to the hub and tightening the nuts in a diagonal pattern to the specified torque value. Cautions are provided about tightening in stages and not overtightening drum brake models.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

11 vues1 pageWheel Balancing: 9. Installation of Wheel Assembly To Vehicle

Transféré par

miguelThis document provides instructions for wheel balancing and installing a wheel assembly onto a vehicle. It describes how to check and adjust wheel balance using weights on both sides of the rim. It also outlines the proper procedure for attaching the wheel to the hub and tightening the nuts in a diagonal pattern to the specified torque value. Cautions are provided about tightening in stages and not overtightening drum brake models.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

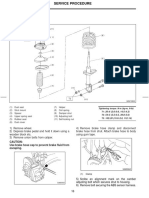

4-2 [W800] SERVICE PROCEDURE

8. Wheel Balancing

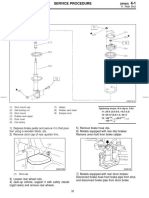

8. Wheel Balancing 9. Installation of Wheel

1) Proper wheel balance may be lost if the tire is Assembly to Vehicle

repaired or if it wears. Check the tire for dynamic 1) Attach the wheel to the hub by aligning the

balance, and repair as necessary. wheel bolt hole with the hub bolt.

2) To check for dynamic balance, use a dynamic 2) Temporarily attach the wheel nuts to the hub

balancer. Drive in the balance weight on both the bolts. (In the case of aluminum wheel, use

top and rear sides of the rim. SUBARU genuine wheel nut for aluminum wheel.)

3) Some types of balancer can cause damage to 3) Manually tighten the nuts making sure the

the wheel. Use an appropriate balancer when wheel hub hole is aligned correctly to the guide

adjusting the wheel balance. portion of hub.

4) Use genuine balance weights. 4) Tighten the wheel nuts in a diagonal selection

CAUTION: to the specified torque. Use a wheel nut wrench.

I 55 g (1.94 oz) weight used with aluminum Wheel nut tightening torque:

wheel is not available. 88±10 N·m (9±1 kg-m, 65±7 ft-lb)

I Balance weights are available for use with

any of 14- to 16-inch wheels. CAUTION:

I Tighten the wheel nuts in two or three steps

by gradually increasing the torque and working

diagonally, until the specified torque is

reached. For drum brake models, excess tight-

ening of wheel nuts may cause wheels to “jud-

der”.

I Do not depress the wrench with a foot;

Always use both hands when tightening.

I Make sure the bolt, nut and the nut seating

surface of the wheel are free from oils.

5) If a wheel is removed for replacement or for

repair of a puncture, retighten the wheel nuts to the

specified torque after running 1,000 km (600

miles).

B4M0053B

(1) Weight for aluminum wheel

(2) Weight for steel wheel

Service limit: A

Weight for steel wheel;

1.8 — 2.0 mm (0.071 — 0.079 in)

Weight for aluminum wheel;

4.5 mm (0.177 in)

34

Vous aimerez peut-être aussi

- Tugas Diferensial PDFDocument3 pagesTugas Diferensial PDFBgas StwnPas encore d'évaluation

- VDL Service ManualDocument13 pagesVDL Service ManualSergio Martín BrionesPas encore d'évaluation

- Drivers Supplement 1600Document4 pagesDrivers Supplement 1600waltPas encore d'évaluation

- MANUAL BOOK DifferentialDocument14 pagesMANUAL BOOK DifferentialHaris100% (2)

- Sisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Document59 pagesSisu Citius Series 44-49-66 74 and 84 Engines Workshop Manual 60 118Сергей ПриймакPas encore d'évaluation

- Locking Hubs: 1991 Mitsubishi MonteroDocument4 pagesLocking Hubs: 1991 Mitsubishi MonteroAnimemanuel MuñozPas encore d'évaluation

- 035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15Document6 pages035 - 319 - Technical Manual - Mechanical Units Bar End Commands - Campagnolo - Rev00 - 05 - 15theteamofthedragonflyPas encore d'évaluation

- Rear Toe Inspection/Adjustment Turning Angle InspectionDocument1 pageRear Toe Inspection/Adjustment Turning Angle InspectionsoftallPas encore d'évaluation

- Section 6-2Document80 pagesSection 6-2Raidul WafiPas encore d'évaluation

- Bcdi Prod Specialty Marine InstallDocument2 pagesBcdi Prod Specialty Marine InstallEUROTANK MARITIMEPas encore d'évaluation

- RTS TG M78Document9 pagesRTS TG M78woosah1234Pas encore d'évaluation

- 5G Timing BeltDocument10 pages5G Timing Beltraúl_palomo_10% (1)

- 11 2E 后悬架Document15 pages11 2E 后悬架Alexander cesar neyra sotoPas encore d'évaluation

- York Trailer Service ManualDocument17 pagesYork Trailer Service ManualPraveen Kumar RPas encore d'évaluation

- Boxxer Race Tuning GuideDocument11 pagesBoxxer Race Tuning GuideJorge Eduardo Jaramillo CortesPas encore d'évaluation

- E92 M3 Chassis & Suspension - SMDocument16 pagesE92 M3 Chassis & Suspension - SMAlbert HangsingPas encore d'évaluation

- Suspension Front Wheel AlignmentDocument4 pagesSuspension Front Wheel AlignmentC TMPas encore d'évaluation

- Pre-Starting Checks: Avertissement DangerDocument2 pagesPre-Starting Checks: Avertissement DangerAquino ArviPas encore d'évaluation

- WHEEL DEFECTS & WHEEL SHELLING (Soft Copy) - 0Document17 pagesWHEEL DEFECTS & WHEEL SHELLING (Soft Copy) - 0mehrotraprashant06Pas encore d'évaluation

- Wheel AlignmentDocument3 pagesWheel AlignmentDidier ÁlvarezPas encore d'évaluation

- Manutenzione CatenaDocument22 pagesManutenzione CatenaRosa TorrePas encore d'évaluation

- SPL U Joint Service Guide PDFDocument2 pagesSPL U Joint Service Guide PDFLeonardo PeñalozaPas encore d'évaluation

- Chapter 3 Chassis TiggoDocument69 pagesChapter 3 Chassis TiggoyermainPas encore d'évaluation

- ISUZUDocument188 pagesISUZUDblogic GatesPas encore d'évaluation

- TSE Installation Manual Rev5Document2 pagesTSE Installation Manual Rev5eyya 007Pas encore d'évaluation

- Overhaul: 1. Remove Oil Pump CoverDocument3 pagesOverhaul: 1. Remove Oil Pump CoverIslam AttiaPas encore d'évaluation

- Sram Spectro-S7 PDFDocument7 pagesSram Spectro-S7 PDFciohaniPas encore d'évaluation

- Lug Nut Torque: Requirements & MaintenanceDocument5 pagesLug Nut Torque: Requirements & MaintenanceSupriyanto AntokPas encore d'évaluation

- Balancing of Grinding WheelsDocument5 pagesBalancing of Grinding WheelsRashidah Muhd100% (1)

- Drive Axle PDFDocument12 pagesDrive Axle PDFnamduong368Pas encore d'évaluation

- Bearing Adjustment QRMPlusDocument1 pageBearing Adjustment QRMPlusJancPas encore d'évaluation

- Levas Luv DmaxDocument5 pagesLevas Luv DmaxSamuel da SilvaPas encore d'évaluation

- Rear Derailleur: Dealer's ManualDocument20 pagesRear Derailleur: Dealer's Manualnadeem javedPas encore d'évaluation

- Wheel Alignment Theory Operation PDFDocument5 pagesWheel Alignment Theory Operation PDFOskars ŠtālsPas encore d'évaluation

- GW491QE Petrol Engine Service Manual ClutchDocument4 pagesGW491QE Petrol Engine Service Manual ClutchAlbert BriceñoPas encore d'évaluation

- Design of Bevel and Worm Gear: Machine Element IIDocument60 pagesDesign of Bevel and Worm Gear: Machine Element IIkibromgidey12Pas encore d'évaluation

- Service Manual Yamaha Scorpio Chapter 6 ChasisDocument50 pagesService Manual Yamaha Scorpio Chapter 6 Chasisjolang46Pas encore d'évaluation

- 2014 RMB Tech Manual Rev Apr 8Document71 pages2014 RMB Tech Manual Rev Apr 8muzPas encore d'évaluation

- Spring Grinding Guide: Page 1 of 13Document13 pagesSpring Grinding Guide: Page 1 of 13fatinPas encore d'évaluation

- Practical Task 2-3Document6 pagesPractical Task 2-3Hanif OhsemPas encore d'évaluation

- Normativa Técnica Salvadoreña de AccesibilidadDocument2 pagesNormativa Técnica Salvadoreña de AccesibilidadmattkidoPas encore d'évaluation

- Dokumen - Tips - Engine Mechanical DaihatsuDocument33 pagesDokumen - Tips - Engine Mechanical DaihatsuJovie GrohlPas encore d'évaluation

- Petter AC1 MarineDocument33 pagesPetter AC1 Marinesergiozed0% (1)

- Showa 47u Front ForkDocument27 pagesShowa 47u Front ForkToine Van Den Brandt100% (1)

- Kayaba Forks Workshop Manual - Off-Road-Eng-61e529a6c44f0Document64 pagesKayaba Forks Workshop Manual - Off-Road-Eng-61e529a6c44f0Aleš ZaverlaPas encore d'évaluation

- Quad Bike Steering PDFDocument4 pagesQuad Bike Steering PDFSunnySinghPas encore d'évaluation

- 章林奉 Camioneta JMCDocument43 pages章林奉 Camioneta JMCRusonegroPas encore d'évaluation

- Wheel Alignment Theory OperationDocument5 pagesWheel Alignment Theory OperationToua YajPas encore d'évaluation

- Chapter 3Document39 pagesChapter 3amiranurul50% (2)

- Module 2 - CouplingsDocument18 pagesModule 2 - CouplingsthandonksPas encore d'évaluation

- 4 Wheel and Tire-N900 Series JMCDocument12 pages4 Wheel and Tire-N900 Series JMCRusonegroPas encore d'évaluation

- Fitting & Acc PDFDocument663 pagesFitting & Acc PDFUncorrectableNamePas encore d'évaluation

- Tomei Manual EnglishDocument5 pagesTomei Manual EnglishMuaiyad AL-baluchi100% (1)

- Fitting & Acc.Document595 pagesFitting & Acc.jarekPas encore d'évaluation

- Group 10 TransmissionDocument54 pagesGroup 10 TransmissionDado OgamePas encore d'évaluation

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellPas encore d'évaluation

- WishboneDocument14 pagesWishboneSapana Kudake SK0% (1)

- Heating, Ventilation & Air ConditioningDocument95 pagesHeating, Ventilation & Air ConditioningmiguelPas encore d'évaluation

- Steering SystemDocument23 pagesSteering SystemmiguelPas encore d'évaluation

- Sportage: Workshop ManualDocument67 pagesSportage: Workshop ManualmiguelPas encore d'évaluation

- Defogger: SectionDocument38 pagesDefogger: SectionmiguelPas encore d'évaluation

- Manual Transaxle System - M6CF3-1 - 1.6LDocument26 pagesManual Transaxle System - M6CF3-1 - 1.6LmiguelPas encore d'évaluation

- Door and Related PartsDocument1 pageDoor and Related PartsmiguelPas encore d'évaluation

- Replacement of Rear DOJ and BJ Boots: A: RemovalDocument2 pagesReplacement of Rear DOJ and BJ Boots: A: RemovalmiguelPas encore d'évaluation

- Rear Drive Shaft AssemblyDocument1 pageRear Drive Shaft AssemblymiguelPas encore d'évaluation

- Oil Pump: A: RemovalDocument5 pagesOil Pump: A: RemovalmiguelPas encore d'évaluation

- Rear StabilizerDocument2 pagesRear StabilizermiguelPas encore d'évaluation

- Front Crossmember: B: InspectionDocument2 pagesFront Crossmember: B: InspectionmiguelPas encore d'évaluation

- Front Strut: A: RemovalDocument4 pagesFront Strut: A: RemovalmiguelPas encore d'évaluation

- Front Transverse Link: A: RemovalDocument3 pagesFront Transverse Link: A: RemovalmiguelPas encore d'évaluation

- Propeller Shaft: A: On-Car ServiceDocument3 pagesPropeller Shaft: A: On-Car ServicemiguelPas encore d'évaluation

- Rear Differential Mounting SystemDocument1 pageRear Differential Mounting SystemmiguelPas encore d'évaluation

- Tire Rotation: Caution: When Rotating Tires, Replace Unevenly Worn or Damaged Tires With New OnesDocument2 pagesTire Rotation: Caution: When Rotating Tires, Replace Unevenly Worn or Damaged Tires With New OnesmiguelPas encore d'évaluation

- Application Table 6. Wheel BalanceDocument1 pageApplication Table 6. Wheel BalancemiguelPas encore d'évaluation

- Msa5t0128a34681 PDFDocument2 pagesMsa5t0128a34681 PDFmiguelPas encore d'évaluation

- Select Monitor Function Mode: 3. Trouble Codes Are DisplayedDocument2 pagesSelect Monitor Function Mode: 3. Trouble Codes Are DisplayedmiguelPas encore d'évaluation

- MSA5T0128A34678Document1 pageMSA5T0128A34678miguelPas encore d'évaluation

- Electrical Components Location: A: EngineDocument13 pagesElectrical Components Location: A: EnginemiguelPas encore d'évaluation

- Front Wiper and Washer: 2. Headlight RelayDocument4 pagesFront Wiper and Washer: 2. Headlight RelaymiguelPas encore d'évaluation

- Oil Cooler (AT Vehicles Only) : A: RemovalDocument2 pagesOil Cooler (AT Vehicles Only) : A: RemovalmiguelPas encore d'évaluation

- Rear Strut: A: RemovalDocument3 pagesRear Strut: A: RemovalmiguelPas encore d'évaluation

- MSA5T0125A27743Document1 pageMSA5T0125A27743miguelPas encore d'évaluation

- General Diagnostic Table: Malfunction of Parts Other Than Those Listed Is Also Possible.Document2 pagesGeneral Diagnostic Table: Malfunction of Parts Other Than Those Listed Is Also Possible.miguelPas encore d'évaluation

- Engine Coolant Temperature Sensor: A: Removal and InstallationDocument1 pageEngine Coolant Temperature Sensor: A: Removal and InstallationmiguelPas encore d'évaluation

- Manual JacDocument235 pagesManual Jacmiguel100% (8)

- MSA5T0126A27919Document1 pageMSA5T0126A27919miguelPas encore d'évaluation

- Introduction To AccountingDocument36 pagesIntroduction To AccountingRajnikant PatelPas encore d'évaluation

- F5 - LTM TrainingDocument9 pagesF5 - LTM TrainingAliPas encore d'évaluation

- New Car Info PDFDocument1 pageNew Car Info PDFSelwyn GullinPas encore d'évaluation

- Mosaic Charter School TIS Update 12202019Document73 pagesMosaic Charter School TIS Update 12202019Brandon AtchleyPas encore d'évaluation

- ISC 2008 Computer Science Paper 1 TheoryDocument8 pagesISC 2008 Computer Science Paper 1 TheoryShadowerPas encore d'évaluation

- Marc-André Ter Stegen PES 2021 StatsDocument1 pageMarc-André Ter Stegen PES 2021 StatsSom VasnaPas encore d'évaluation

- UNIT 2 - ConnectivityDocument41 pagesUNIT 2 - ConnectivityZain BuhariPas encore d'évaluation

- GTAG 1 2nd EditionDocument36 pagesGTAG 1 2nd EditionChristen Castillo100% (2)

- AbDocument8 pagesAbSehar BanoPas encore d'évaluation

- Asia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Document21 pagesAsia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 65 / April 2, 2020Donnie HavierPas encore d'évaluation

- Pace 349 ScheduleDocument3 pagesPace 349 Schedulesaxman011100% (1)

- Vigi Module Selection PDFDocument1 pageVigi Module Selection PDFrt1973Pas encore d'évaluation

- Manual On Power System ProtectionDocument393 pagesManual On Power System ProtectionSakthi Murugan88% (17)

- Pay Policy and Salary ScalesDocument22 pagesPay Policy and Salary ScalesGodwin MendezPas encore d'évaluation

- Links To GoodnessDocument194 pagesLinks To GoodnessKevin Itwaru0% (3)

- Comparison of The Gasification Performance in The Downdraftfixed-Bedgasifier Fed by Different Feedstocks Rice Husk, Sawdust, and Their MixtureDocument8 pagesComparison of The Gasification Performance in The Downdraftfixed-Bedgasifier Fed by Different Feedstocks Rice Husk, Sawdust, and Their MixturechaniefPas encore d'évaluation

- 0601 FortecstarDocument3 pages0601 FortecstarAlexander WiesePas encore d'évaluation

- WCN SyllabusDocument3 pagesWCN SyllabusSeshendra KumarPas encore d'évaluation

- Solution Manual For Labor Relations Development Structure Process 12th Edition Fossum 0077862473 9780077862473Document16 pagesSolution Manual For Labor Relations Development Structure Process 12th Edition Fossum 0077862473 9780077862473savannahzavalaxodtfznisq100% (27)

- KR 10 Scara: The Compact Robot For Low PayloadsDocument4 pagesKR 10 Scara: The Compact Robot For Low PayloadsBogdan123Pas encore d'évaluation

- Guide To Downloading and Installing The WebMethods Free Trial Version - Wiki - CommunitiesDocument19 pagesGuide To Downloading and Installing The WebMethods Free Trial Version - Wiki - CommunitiesHieu NguyenPas encore d'évaluation

- Parts Price ListDocument5 325 pagesParts Price ListAlva100% (1)

- Bit2203 Advanced Object-Oriented Programming Lectures Sep 2021Document250 pagesBit2203 Advanced Object-Oriented Programming Lectures Sep 2021Agnes MathekaPas encore d'évaluation

- High-Rise Climb V0.6a Smokeydots PDFDocument10 pagesHigh-Rise Climb V0.6a Smokeydots PDFHer Lan OPas encore d'évaluation

- Uploading, Sharing, and Image Hosting PlatformsDocument12 pagesUploading, Sharing, and Image Hosting Platformsmarry janePas encore d'évaluation

- Salumber ProjectDocument103 pagesSalumber ProjectVandhana RajasekaranPas encore d'évaluation

- BSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Document4 pagesBSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Mmc MixPas encore d'évaluation

- BCCA Semester New Syllabus Direction 2016-17 PDFDocument76 pagesBCCA Semester New Syllabus Direction 2016-17 PDFChetana Gorakh100% (1)

- SummaryDocument50 pagesSummarygirjesh kumarPas encore d'évaluation

- Dinner Theater Business PlanDocument21 pagesDinner Theater Business PlanBhumika KariaPas encore d'évaluation

- House Rules: How to Decorate for Every Home, Style, and BudgetD'EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetPas encore d'évaluation

- Crochet Impkins: Over a million possible combinations! Yes, really!D'EverandCrochet Impkins: Over a million possible combinations! Yes, really!Évaluation : 4.5 sur 5 étoiles4.5/5 (10)

- The Martha Manual: How to Do (Almost) EverythingD'EverandThe Martha Manual: How to Do (Almost) EverythingÉvaluation : 4 sur 5 étoiles4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiD'Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiÉvaluation : 5 sur 5 étoiles5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsD'EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsPas encore d'évaluation

- Edward's Menagerie: Dogs: 50 canine crochet patternsD'EverandEdward's Menagerie: Dogs: 50 canine crochet patternsÉvaluation : 3 sur 5 étoiles3/5 (5)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiD'EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiÉvaluation : 4 sur 5 étoiles4/5 (3)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldD'EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldÉvaluation : 4.5 sur 5 étoiles4.5/5 (30)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestD'EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestÉvaluation : 4 sur 5 étoiles4/5 (28)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsD'EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersD'EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsD'EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsPas encore d'évaluation

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)D'EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Pas encore d'évaluation

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeD'EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeÉvaluation : 5 sur 5 étoiles5/5 (1)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerD'EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerÉvaluation : 4.5 sur 5 étoiles4.5/5 (54)

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreD'EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreÉvaluation : 4 sur 5 étoiles4/5 (6)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesD'Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesPas encore d'évaluation

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsD'EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Modern Embroidery: A Book of Stitches to Unleash CreativityD'EverandModern Embroidery: A Book of Stitches to Unleash CreativityPas encore d'évaluation

- Supersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleD'EverandSupersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleÉvaluation : 5 sur 5 étoiles5/5 (2)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsD'EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsÉvaluation : 4 sur 5 étoiles4/5 (5)

- Funny Amigurumi: 16 Creatures & Their Accessories to CrochetD'EverandFunny Amigurumi: 16 Creatures & Their Accessories to CrochetÉvaluation : 5 sur 5 étoiles5/5 (1)

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearD'EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesD'EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesÉvaluation : 5 sur 5 étoiles5/5 (3)

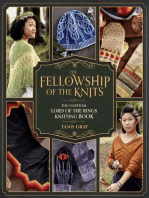

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookD'EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsD'EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsPas encore d'évaluation

- Textiles Transformed: Thread and thrift with reclaimed textilesD'EverandTextiles Transformed: Thread and thrift with reclaimed textilesPas encore d'évaluation

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtD'EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtPas encore d'évaluation