Académique Documents

Professionnel Documents

Culture Documents

VISTIPORT-E220 Product Information PDF

Transféré par

Goto SamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

VISTIPORT-E220 Product Information PDF

Transféré par

Goto SamDroits d'auteur :

Formats disponibles

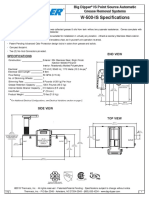

PRODUCT DATA SHEET

MODEL E220.C2

Spinning at over 2100rpm, Visiport® electrical spin windows

sling off coolant and chips for a perfect view into your

machining environment. Productivity is increased while the

need to stop and restart your machine is reduced. Operators

can view setups and milling processes behind the safety

window, eliminating the risk of bypassing machine interlocks.

The Visiport® electrical spin window installs using a unique

surface-mount method, requiring no holes so as to maintain

machine window integrity and user safety. On properly

prepared surfaces, the VHB mounting adhesive has a bonding

strength safety factor better than 20 to 1. The chemically

strengthened glass of the disc assembly helps resist

scratching. Motor assembly features integrated electronics

with reverse polarity protection, 24v brushless DC motor, and

instrument-rated bearing set. Steady state current draw

250mA (no coolant load), and 5Amp peak supply requirement.

Visiport® units work best with water-soluble coolants and light mineral oils. Made with the highest quality

components for reliable operation, it also comes with a one year limited warranty.

INSTALLATION

Visiport® spin windows may be installed in moving or fixed windows, and have a low 45mm profile compatible

with the majority of machines. Unit should be installed from vertical to 30° from vertical position. Complete

system contains the base unit, switchbox, motor assembly, small parts replacement kit, and installation

manual. For machines without the necessary 24v 5Amp circuit, an optional 120w power supply is available. All

systems require a power conduit and cabling.

FEATURES & OPTIONS

OVERALL DIAMETER 10 in (253 mm)

Sealed connection cavity with exit ports on sides and bottom. PROFILE HEIGHT 1.75 in (45 mm)

Flexible steel conduit or PUR tubing for harness routing

OVERALL LENGTH 12.375 in (315 mm)

(EO/EO2 optional).

Terminal box with mechanical on/off toggle switch. WEIGHT 4.84 lbs (2.2 kg)

Installs on glass or polycarbonate safety windows. GLASS THICKNESS .120 in (3 mm)

Drainage features for high coolant volume applications. ADHESIVE CARRIER Closed Cell Acrylic Foam

Dynamic braking to reduce inducted current.

PEEL ADHESION 20 lbs/in (3.5 N/mm)

Diamond-like Carbon (DLC) coating option for maximum

abrasion resistance. TENSILE ADHESION 140 lbs/in 2 (1.0 N/mm 2)

Light-weight aluminum construction. DYNAMIC SHEAR ADHESION 80 lbs/in2 (0.55 N/mm 2)

Mounting plate for easy installation and removal.

WWW.VISIPORT.COM 1-800-267-2120 MADE IN USA

4 3 2 1

Model E220C, P/N E220-1511-0

1.073 (27.3mm)

Ø 9.950

252.7mm

1.491 (37.9mm)

TOTAL MOUNTED HEIGHT

FOR STANDARD V CODE MOUNTING,

VISIPORT UNIT BOLTS TO AN ALUMINUM

MOUNTING PLATE BACKED WITH VHB

ADHESIVE USING 6 EACH NYLON COATED

Ø 8.500

SCREWS AGAINST AN O-RING SEAL

215.9mm

GREEN LIGHT

SPECIFICATIONS:

INDICATES

24 VOLT BRUSHLESS

24VDC AT

DC MOTOR.

MOTOR

REVERSE CURRENT

AND/OR

PROTECTED.

Model & DISC ROTATING.

4.8 AMPS MAX AT

Serial Number 50 IN OZ TORQUE.

RED LIGHT

0.3 AMP IDLE AT

INDICATES C

2100 RPM (NO LOAD).

DIAGNOSTIC

OVERLOAD PROTECTION

ERROR

TRIGGERED BY STALL.

MESSAGE

RESET BY SWITCH ON

12.375 BULKHEAD ASSEMBLY.

314.3mm DYNAMIC BRAKING ON

POWER OFF OF UNIT

7.400

188.0mm

6.300

O-RING 160.0mm

GROOVE

MOUNTING PLATE

W/VHB ADHESIVE CARRIER

FLEX (STEEL BRAID OVER PTFE)

TUBING SET WITH WIRE HARNESS;

SPECIFY LENGTH ON ORDER. GROUNDING

REFERENCE PRICE SHEET. SCREW

B

DRAINS

1/2 - 20

H FITTING

TERMINAL BOX

(BULKHEAD ASSEMBLY) ALTERNATE EXIT PORT

2.775 0.900 (22.9mm) FITTING LOCATIONS

2.840

MATERIAL PROVIDED: OPERATORS SIDE (70.5mm) 1.150 (29.2mm)

(72.2mm)

(DRY SIDE)

1. BASE ASSEMBLY STRAIN RELIEF SET SCREW

VHB ADHESIVE RING WORK PIECE SIDE

2. MOUNTING PLATE BUSHING (WET SIDE)

3. TERMINAL BOX

4. TOOL KIT OPERATION & MAINTENANCE:

INCL. HUB CAP WRENCH & SMALL PARTS BAG.

1. VISIPORT SHOULD BE WIRED SO THAT IT

IS ON WHEN MACHINE IS ON.

1/2 - 20 2. BE SURE THAT DISC IS ROTATING BEFORE A

POLYURETHANE (PUR) TUBING SET COOLANT IS TURNED ON.

MOD FITTING

WITH WIRE HARNESS; 3. THE VISIPORT WORKS BEST WITH WATER

5F5MOD1

SPECIFY LENGTH ON ORDER. SOLUBLE COOLANTS.

1.875

REFERENCE PRICE SHEET. 4. CLEAN WITH 50% WATER/50% ISOPROPYL

(47.6mm) Ø 2.000 SWITCH:

Visiport®

MFR

(50.8mm) ALCOHOL SOUTION.

CENTER OFF

5. STALL CONDITION: CHECK FREE ROTATION OF DISC.

Model E220C

TITLE

POWER CABLE REMOVE CHIPS BEFORE RE-SETTING UNIT. REMOVE

DISC TO REACHED JAMMED CHIPS IF NECESSARY. DWG. NO. REV

220C8002 A

SHEET 1 OF 1

Model: Type Size Motor Fittings Mounting P/N: 1xxx = C2D

Contact Visiport for

other configuration

options:

x5xx = H, 5F5MOD1

www.visiport.com

E 220 C H V E220 - 1 5 1 1 - 0

xx1x = V

Electric 8" / 20-cm 5 Amp 24 VDC Flex Mounting Plate xxx1 = TRM

w/VHB Adhesive

0 = w/o DLC

//SALES/VPO-TCS-40203A1.PDF

Vous aimerez peut-être aussi

- Tomas Catalogo PDFDocument55 pagesTomas Catalogo PDFLily ParadaPas encore d'évaluation

- Technical Specification Sailor N163S Power Supply PDFDocument1 pageTechnical Specification Sailor N163S Power Supply PDFseamec2Pas encore d'évaluation

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosPas encore d'évaluation

- PDS176 2019 9 LeeIMHChekValve558LCSeriesInsertDocument2 pagesPDS176 2019 9 LeeIMHChekValve558LCSeriesInsertOmri AgaiPas encore d'évaluation

- SG400Document2 pagesSG400jet.hePas encore d'évaluation

- K-45-101 Print ABDocument4 pagesK-45-101 Print ABEDUARDO100% (1)

- Ps 001222Document16 pagesPs 001222Lassané KINDOPas encore d'évaluation

- Weda Brochure 60 HZDocument8 pagesWeda Brochure 60 HZedilfreddyzPas encore d'évaluation

- Spec Sheet - Crane PlumbingDocument2 pagesSpec Sheet - Crane PlumbingJohn Enrick ManuelPas encore d'évaluation

- 9617 Pressure SwitchDocument4 pages9617 Pressure SwitchargaPas encore d'évaluation

- Prestige Wireless DiffusersDocument22 pagesPrestige Wireless Diffuserssauc 5Pas encore d'évaluation

- Product Data Sheet Damcos BRC 250 en 60334Document4 pagesProduct Data Sheet Damcos BRC 250 en 60334Конструкторский отдел РосНефтеГазИнструментPas encore d'évaluation

- 1DB 10881 enDocument1 page1DB 10881 enFreddy MormontoyPas encore d'évaluation

- PDS168 2019 4 LeeIMHChekValve855LC2SeriesInsertDocument2 pagesPDS168 2019 4 LeeIMHChekValve855LC2SeriesInsertOmri AgaiPas encore d'évaluation

- Rotary Drilling Hoses & SwivelsDocument8 pagesRotary Drilling Hoses & SwivelsRaina GhobadiPas encore d'évaluation

- Pressure Sensor M5091 PDFDocument2 pagesPressure Sensor M5091 PDFeajPas encore d'évaluation

- O.Block Aquahi) Ii: Self INGDocument2 pagesO.Block Aquahi) Ii: Self INGMujeeb MohammedPas encore d'évaluation

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocument2 pagesZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediPas encore d'évaluation

- 95 Standard Body Series Ignition Switches: Product DatasheetDocument1 page95 Standard Body Series Ignition Switches: Product Datasheetgowrav_hassanPas encore d'évaluation

- Dyna-102 New PDFDocument4 pagesDyna-102 New PDFZar MtzPas encore d'évaluation

- Up400rdii YaskawaDocument2 pagesUp400rdii Yaskawadina auliaPas encore d'évaluation

- Dyna-102 New PDFDocument4 pagesDyna-102 New PDFmichaeltibochePas encore d'évaluation

- Submittal Data Information: KV Series Vertical Close Coupled PumpsDocument3 pagesSubmittal Data Information: KV Series Vertical Close Coupled PumpsSneyder MontoyaPas encore d'évaluation

- W 500 Is SpecDocument2 pagesW 500 Is SpecdjukalPas encore d'évaluation

- EDZ Series LED Apron LightsDocument2 pagesEDZ Series LED Apron Lightscamedih539Pas encore d'évaluation

- AVTRON 2705CE Pub5128 RevbDocument2 pagesAVTRON 2705CE Pub5128 Revbzqgjxwcc5wPas encore d'évaluation

- Blue-Thunder Serie: The Power of BlueDocument2 pagesBlue-Thunder Serie: The Power of BlueBenjamin Musa ダPas encore d'évaluation

- Pib2000 225 D4Document7 pagesPib2000 225 D4CarlosPas encore d'évaluation

- Hoja Técnica Asco 2000 - Modelo 2500 - 100 KW - V2Document2 pagesHoja Técnica Asco 2000 - Modelo 2500 - 100 KW - V2Hernán Peñafiel ReaPas encore d'évaluation

- Accessories: Elbow / Grs - Guide Rail Systems: Product FeaturesDocument2 pagesAccessories: Elbow / Grs - Guide Rail Systems: Product FeaturessagbvnPas encore d'évaluation

- John Crane Type 32 SealDocument4 pagesJohn Crane Type 32 SealhichamPas encore d'évaluation

- Pull-Safe PS-P (Polybutylene Terephthalate (PBT) .Polycarbonate (PC) )Document2 pagesPull-Safe PS-P (Polybutylene Terephthalate (PBT) .Polycarbonate (PC) )mathan_aePas encore d'évaluation

- Suntech Multi 280WDocument2 pagesSuntech Multi 280WAlok ChaudharyPas encore d'évaluation

- Datasheet - Pulling Energy 560wDocument2 pagesDatasheet - Pulling Energy 560wjoao.oliveira22Pas encore d'évaluation

- Pressure Switch Directional Valves: InstallationDocument2 pagesPressure Switch Directional Valves: InstallationEliud Rodriguez100% (1)

- EW2025R Series Worklamp ProductDataSheet ECCO A4Document1 pageEW2025R Series Worklamp ProductDataSheet ECCO A4Nelson SobaPas encore d'évaluation

- Manhole Monitor PLUSSpec Sheet 2206 BDocument2 pagesManhole Monitor PLUSSpec Sheet 2206 BTri NguyenPas encore d'évaluation

- VST 20 HF 220Document6 pagesVST 20 HF 22018EE25 - G.Sharan KrishnanPas encore d'évaluation

- INTERCAMBIADOR DE CALOR DE PLACAS PARKER SERIE OAW CoolersDocument7 pagesINTERCAMBIADOR DE CALOR DE PLACAS PARKER SERIE OAW CoolersDaniel MarPas encore d'évaluation

- 64-2103 Tweco Pistolas WeldskillDocument6 pages64-2103 Tweco Pistolas WeldskillcarlosPas encore d'évaluation

- ZENITH English Brochure V1Document8 pagesZENITH English Brochure V1SoultechLovePas encore d'évaluation

- CS-Datasheet-HiKu6 - CS6R-MS - v1.9C5 - EN (Black Frame 12y)Document2 pagesCS-Datasheet-HiKu6 - CS6R-MS - v1.9C5 - EN (Black Frame 12y)Ghinet MariusPas encore d'évaluation

- Datasheet Canadian CS3W-435... 465MSDocument2 pagesDatasheet Canadian CS3W-435... 465MSFernando VieiraPas encore d'évaluation

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 pagesTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedPas encore d'évaluation

- Kohler Veil K-20704Document2 pagesKohler Veil K-20704Enak CenirPas encore d'évaluation

- Super High Power Mono Perc ModuleDocument2 pagesSuper High Power Mono Perc ModulerodrigoPas encore d'évaluation

- Care222 Mercury Free Far Uv C ExcimerDocument4 pagesCare222 Mercury Free Far Uv C Excimersanjeev kumar0% (1)

- K-20705-0 Spec INDIA Kohler enDocument2 pagesK-20705-0 Spec INDIA Kohler enkamal kanthPas encore d'évaluation

- Model - SMD: Air Pressure SwitchesDocument2 pagesModel - SMD: Air Pressure SwitchesRig 25 Sr. ElectricianPas encore d'évaluation

- 590w BifacialDocument2 pages590w BifacialNaqash AhmedPas encore d'évaluation

- ACI Thermistor NTC 20KDocument2 pagesACI Thermistor NTC 20KSantiago J. ramos jrPas encore d'évaluation

- Automatic Wall-Mounted Soap Dispenser: Technical DataDocument1 pageAutomatic Wall-Mounted Soap Dispenser: Technical Datashivap341995Pas encore d'évaluation

- New 015 2012 HyDocument1 pageNew 015 2012 HyРома БлошенкоPas encore d'évaluation

- WACT Hydraulic ActuatorDocument12 pagesWACT Hydraulic Actuatorjhonyblaze1984Pas encore d'évaluation

- Printed Electronic enDocument6 pagesPrinted Electronic enilker YILMAZPas encore d'évaluation

- Nexans - 19 33kV Three CoreDocument5 pagesNexans - 19 33kV Three CoreRonit KayasthaPas encore d'évaluation

- Mitutoyo - Suwmiarki Elektroniczne 300 MM - E12045 - 2019 ENDocument4 pagesMitutoyo - Suwmiarki Elektroniczne 300 MM - E12045 - 2019 END.T.Pas encore d'évaluation

- BY268, BY269: Vishay SemiconductorsDocument4 pagesBY268, BY269: Vishay SemiconductorsGenesisPas encore d'évaluation

- Reference Jica-Chodai Scouring Manual in ThailandDocument175 pagesReference Jica-Chodai Scouring Manual in ThailandSeptinurriandianiPas encore d'évaluation

- Saep 1116Document5 pagesSaep 1116Anonymous 4IpmN7OnPas encore d'évaluation

- DPM Engineering WorksDocument34 pagesDPM Engineering WorksAkash SinghPas encore d'évaluation

- Carbon Nanotube: Properties and ApplicationsDocument22 pagesCarbon Nanotube: Properties and ApplicationsmanuPas encore d'évaluation

- Waste To Energy: A Possibility For Puerto Rico, 5-2007Document57 pagesWaste To Energy: A Possibility For Puerto Rico, 5-2007Detlef LoyPas encore d'évaluation

- TR 541 2Document78 pagesTR 541 2Omar Marghani SalmaPas encore d'évaluation

- How To Start Building With CobDocument16 pagesHow To Start Building With CobRoy Huntley100% (3)

- Index of Revisions Rev. Description And/Or Revised SheetsDocument17 pagesIndex of Revisions Rev. Description And/Or Revised Sheetsfabio.henriquePas encore d'évaluation

- Example Pump CalcsDocument4 pagesExample Pump CalcsSourav ChattopadhyayPas encore d'évaluation

- Garrita National High SchoolDocument5 pagesGarrita National High SchoolAxle Rose CastroPas encore d'évaluation

- Plan Holders ReportDocument8 pagesPlan Holders ReportSusan KunklePas encore d'évaluation

- SeaCom System Manual Rev 0401Document149 pagesSeaCom System Manual Rev 0401maselo100% (1)

- Hercules Engines c2 90d Engine Service ManualDocument7 pagesHercules Engines c2 90d Engine Service ManualRicardoPas encore d'évaluation

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDocument59 pagesMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanPas encore d'évaluation

- 2019 Centennial ClassDocument291 pages2019 Centennial ClassGerman Vega0% (2)

- Transformer Design and Optimization A Literature Survey PDFDocument26 pagesTransformer Design and Optimization A Literature Survey PDFRushikesh MaliPas encore d'évaluation

- In ThoseDocument2 pagesIn ThoseanggiePas encore d'évaluation

- Inside A Gamma SterilizerDocument5 pagesInside A Gamma SterilizerckanesanPas encore d'évaluation

- ASTM D445-Viscoz Cinematica PDFDocument9 pagesASTM D445-Viscoz Cinematica PDFCorina StanculescuPas encore d'évaluation

- MAWS301 Datasheet B210396EN-C LowResDocument2 pagesMAWS301 Datasheet B210396EN-C LowResmumapaduriiiPas encore d'évaluation

- Voice Recognition Using MatlabDocument10 pagesVoice Recognition Using MatlabSneha Muralidharan100% (1)

- Lesson Plan - Revit Intro Lesson OverviewDocument56 pagesLesson Plan - Revit Intro Lesson Overviewlingga123Pas encore d'évaluation

- Jovan Marjanovic Theory of Gravity MachinesDocument10 pagesJovan Marjanovic Theory of Gravity MachinesWilhelm HartmanPas encore d'évaluation

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- C-Zone SDN BHD: Price List Effective 10 AUG 2019Document2 pagesC-Zone SDN BHD: Price List Effective 10 AUG 2019Cikgu AlPas encore d'évaluation

- Astm D 3241 - 02 - RdmyndetmdjbDocument13 pagesAstm D 3241 - 02 - RdmyndetmdjbSamuel EduardoPas encore d'évaluation

- GRE Sentence CompletionDocument3 pagesGRE Sentence Completionapi-3699142Pas encore d'évaluation

- MP-20x Datasheet 1Document2 pagesMP-20x Datasheet 1Francisco MoragaPas encore d'évaluation

- Licensing Electrical Cables JointersDocument17 pagesLicensing Electrical Cables Jointersraedkaissi5096100% (2)

- Tuning SU CarbsDocument49 pagesTuning SU CarbsVictor PetrosckiPas encore d'évaluation