Académique Documents

Professionnel Documents

Culture Documents

Abs Filament Datasheet en

Transféré par

Vinayak Aryan0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues1 pageabs

Titre original

Abs Filament Datasheet En

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentabs

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues1 pageAbs Filament Datasheet en

Transféré par

Vinayak Aryanabs

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

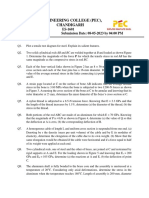

ABS PLASTIC MATERIAL PROPERTIES LIST

Physical Nominal Value Unit Test Method

Specific Gravity

-- 1.05 g/cm³ ASTM D792

23°C 1.05 g/cm³ ISO 1183

Melt Mass-Flow Rate (MFR) ASTM D1238

200°C/5.0 kg 1.4 g/10 min

220°C/10.0 kg 20 g/10 min

Melt Volume-Flow Rate (MVR) (220°C/10.0 kg) 20.0 cm³/10min ISO 1133

Mechanical Nominal Value Unit Test Method

Tensile Stress

Yield 54.0 MPa ISO 527-2/50

Break 37.0 MPa ISO 527-2/50

3.00 mm 4 45.1 MPa ASTM D638

Tensile Elongation

Break, 3.00 mm 4 25 % ASTM D638

Break 20 % ISO 527-2/50

Flexural Modulus

6.00 mm 5 2650 MPa ASTM D790

6 2200 MPa ISO 178

--

Flexural Strength

6.00 mm 5 77.5 MPa ASTM D790

6 76.0 MPa ISO 178

--

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength 20 kJ/m² ISO 179

Charpy Unnotched Impact Strength No Break ISO 179

Notched Izod Impact

23°C, 3.00 mm 205 J/m ASTM D256

23°C, 6.00 mm 175 J/m ASTM D256

-- 17 kJ/m² ISO 180/1A

Unnotched Izod Impact Strength 58 kJ/m² ISO 180/1U

Hardness Nominal Value Unit Test Method

Rockwell Hardness (R-Scale) 116 ASTM D785

Ball Indentation Hardness (H 358/30) 110 MPa ISO 2039-1

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

1.8 MPa, Unannealed 85.0 °C ASTM D648

1.8 MPa, Unannealed 88.0 °C ISO 75-2/A

1.8 MPa, Annealed 95.0 °C ASTM D648

1.8 MPa, Annealed 98.0 °C ISO 75-2/A

Vicat Softening Temperature

-- 105 °C ASTM D1525 7

-- 104 °C ISO 306/A50

-- 100 °C ISO 306/B50

Flammability Nominal Value Unit Test Method

Flame Rating (1.60 mm) HB UL 94

Processing Temperature

Nozzle Temperatur 190 to 230 °C

Vous aimerez peut-être aussi

- Hi Am Vinyak Myname Is Beyu Much Good AND AM THE BEST D2E1SI3GN WER OGT THE WORKS2 Mnully Ia The Entering ProcessDocument1 pageHi Am Vinyak Myname Is Beyu Much Good AND AM THE BEST D2E1SI3GN WER OGT THE WORKS2 Mnully Ia The Entering ProcessVinayak AryanPas encore d'évaluation

- Connecting Energies: Plastics Industry - ConnectorsDocument12 pagesConnecting Energies: Plastics Industry - ConnectorsVinayak AryanPas encore d'évaluation

- C XC DF Z C J C T DDocument2 pagesC XC DF Z C J C T DVinayak AryanPas encore d'évaluation

- WeDocument2 pagesWeVinayak AryanPas encore d'évaluation

- Torlon Design GuideDocument52 pagesTorlon Design GuideVinayak AryanPas encore d'évaluation

- GearsDocument246 pagesGearsVinayak AryanPas encore d'évaluation

- Mould CoolingDocument48 pagesMould CoolingVinayak Aryan100% (1)

- Cutting ClearanceDocument50 pagesCutting ClearanceVinayak Aryan100% (16)

- 16 CamsDocument26 pages16 CamsVinayak AryanPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Solid Mechanics IntroductionDocument25 pagesSolid Mechanics IntroductionStudy StudyPas encore d'évaluation

- Design of Reinforced Concrete Structures by Krishna RajuDocument318 pagesDesign of Reinforced Concrete Structures by Krishna Rajufgfsg75% (4)

- Assignment 1Document4 pagesAssignment 1TanmayPas encore d'évaluation

- Negative Skin Friction in Piles and Design DecisionsDocument10 pagesNegative Skin Friction in Piles and Design DecisionsZaher J. YazejiPas encore d'évaluation

- Mechanical and Failure Characteristics of Shear Keys On Immersed Tunnel Segment Joints Under Differential SettlementsDocument6 pagesMechanical and Failure Characteristics of Shear Keys On Immersed Tunnel Segment Joints Under Differential SettlementskanomasiPas encore d'évaluation

- Simulation of Spring: Date: Martes, 25 de Agosto de 2020 Designer: Solidworks Study Name: Resorte 1 Analysis TypeDocument10 pagesSimulation of Spring: Date: Martes, 25 de Agosto de 2020 Designer: Solidworks Study Name: Resorte 1 Analysis TypeIván D. ArdilaPas encore d'évaluation

- KIT Zugversuche Study V19 190115Document32 pagesKIT Zugversuche Study V19 190115Abdullah tahaPas encore d'évaluation

- Problem Sheet - 1 (Theories of Failure & Factor of Safety)Document2 pagesProblem Sheet - 1 (Theories of Failure & Factor of Safety)S D100% (1)

- Topic 3 World Wide Attenuation RelationshipDocument6 pagesTopic 3 World Wide Attenuation RelationshipGleanna NiedoPas encore d'évaluation

- The Rising Symbol of Western China, Raffles City by Ir. Penny CheungDocument34 pagesThe Rising Symbol of Western China, Raffles City by Ir. Penny CheungPTchongPas encore d'évaluation

- The Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KDocument15 pagesThe Modular Ratio in Reinforced Concrete Design (Manuscript) - A.KMohan ManickamPas encore d'évaluation

- Design For Snapfit Revi-10 PDFDocument26 pagesDesign For Snapfit Revi-10 PDFDmitry ShelestPas encore d'évaluation

- Machine DesignDocument69 pagesMachine DesignSushant TiwariPas encore d'évaluation

- Lecture 2 ELFPDocument47 pagesLecture 2 ELFPrizwan ghafoorPas encore d'évaluation

- Geotechnical Engineering by C Venkatramaiah PDFDocument1 pageGeotechnical Engineering by C Venkatramaiah PDFraghu_chandra_3Pas encore d'évaluation

- PPTDocument16 pagesPPTVasthadu Vasu KannahPas encore d'évaluation

- Tear Test - Determination of Tear Energy andDocument23 pagesTear Test - Determination of Tear Energy andVikram KulriaPas encore d'évaluation

- Ductile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringDocument7 pagesDuctile-Brittle Transition Temperature and Impact Energy Tests - Yena EngineeringKASHFI UDDINPas encore d'évaluation

- R16 DMM 1 SyllubusDocument2 pagesR16 DMM 1 SyllubusRameshMagantiPas encore d'évaluation

- Spring Back EffectDocument9 pagesSpring Back EffectRahul DevPas encore d'évaluation

- L3S3. Endogenic Processes (Crustal Deformation)Document25 pagesL3S3. Endogenic Processes (Crustal Deformation)Sichayra GamotiaPas encore d'évaluation

- Mitesh PatelDocument25 pagesMitesh PatelDevashish Joshi100% (1)

- Lessons Learned From A Failure of Geosynthetics-Reinforced Segmental Retaining WallDocument10 pagesLessons Learned From A Failure of Geosynthetics-Reinforced Segmental Retaining WallRenugopalPas encore d'évaluation

- Pressure Meter TestDocument6 pagesPressure Meter TestAve de GuzmanPas encore d'évaluation

- Experiment 2 Torsion Testing: Aim of The ExperimentDocument8 pagesExperiment 2 Torsion Testing: Aim of The ExperimentMadhavPas encore d'évaluation

- CHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Document68 pagesCHANGES in AISC's SEISMIC PROVISIONS: AISC 341-05 To AISC 341-10Anonymous 7MdZQn167% (3)

- Soil Details: Enter Both Length and WidthDocument5 pagesSoil Details: Enter Both Length and WidthDiana CristinaPas encore d'évaluation

- Engineering Design II: Springs I - IntroductionDocument46 pagesEngineering Design II: Springs I - IntroductionSean ChanPas encore d'évaluation