Académique Documents

Professionnel Documents

Culture Documents

Extracted Pages From SD NOC STR 301

Transféré par

Rudolph Rednose0 évaluation0% ont trouvé ce document utile (0 vote)

65 vues1 pageThis document provides standards for ultrasonic testing, magnetic particle inspection, and liquid penetrant inspection of welds in offshore steel structures. It specifies that ultrasonic testing of all joint types must be carried out according to AWS D1.1/D1.1M standards. It also provides details on probe types and sensitivity corrections that must be used. Any transverse imperfections detected must be evaluated according to specified standards and considered cracks. Magnetic particle and liquid penetrant inspections must follow specific ASTM or ASME standards, and acceptance criteria are provided in Table 11.1 of this document.

Description originale:

spec

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis document provides standards for ultrasonic testing, magnetic particle inspection, and liquid penetrant inspection of welds in offshore steel structures. It specifies that ultrasonic testing of all joint types must be carried out according to AWS D1.1/D1.1M standards. It also provides details on probe types and sensitivity corrections that must be used. Any transverse imperfections detected must be evaluated according to specified standards and considered cracks. Magnetic particle and liquid penetrant inspections must follow specific ASTM or ASME standards, and acceptance criteria are provided in Table 11.1 of this document.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

65 vues1 pageExtracted Pages From SD NOC STR 301

Transféré par

Rudolph RednoseThis document provides standards for ultrasonic testing, magnetic particle inspection, and liquid penetrant inspection of welds in offshore steel structures. It specifies that ultrasonic testing of all joint types must be carried out according to AWS D1.1/D1.1M standards. It also provides details on probe types and sensitivity corrections that must be used. Any transverse imperfections detected must be evaluated according to specified standards and considered cracks. Magnetic particle and liquid penetrant inspections must follow specific ASTM or ASME standards, and acceptance criteria are provided in Table 11.1 of this document.

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

LEVEL 3 – STANDARD SD-NOC-STR-301

Fabrication of Offshore Steel Structures

Rev.: 01 Effective Date: 08/2018 Page: 66 of 124

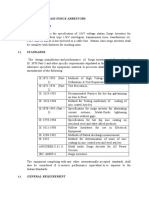

11.2.3 Ultrasonic Testing (UT)

UT shall be carried out in accordance with AWS D1.1/D1.1M/Class R for all kinds of joints. For T-

K-Y joints and tubular joints with full penetration welds (refer to paragraph 8.10 of this standard),

the “back-up weld” at the root shall also be part of the testing. However, this back-up weld shall

be evaluated as per AWS D1.1/D1.1M/Class X.

Testing according ISO 17640 testing level B with acceptance criteria according ISO 11666 Level

2 is considered as an acceptable alternate.

Prior to any UT inspection, a lamination check using 0° probe shall be performed in the vicinity of

the weld in order to verify the full coverage of the weld with transverse waves probes.

Each weld shall be evaluated using at minimum 3 probes (30°, 45°, 70°) and shall be inspected

with regards to transverse defects (typically 45° probe used longitudinally to the weld).

Prior to any inspection, the sensitivity correction shall be evaluated for each structural steel and

for each probe used.

Note: Variation in attenuation in plates, and particularly TMCP plates can often be over 8 dB,

especially with 70° probe.

Any transverse imperfection detected shall be evaluated according ISO 23279 and any

transverse planar imperfection shall be considered as crack with all the associated Non

Conformance Report, root cause analysis and corrective action implementation.

For K or ½ V bevels for butt welds, tandem technique or Phased Array inspection is mandatory

for Special Category (procedure to be submitted to Company for approval).

The UT equipment shall have been calibrated since less than one year by an independent

laboratory. The calibration certificate shall be made available to Inspector.

11.2.4 Magnetic Particle Inspection (MPI)

Procedure to be as per ASTM E709 or ASME BPVC.

Acceptance criteria shall be as per Table 11.1 of this standard.

11.2.5 Liquid Penetrant Inspection (LPI)

Procedure to be as per ASTM E165/E165M or ASME BPVC.

Acceptance criteria shall be as per Table 11.1 of this standard.

This document is proprietary to North Oil Company and contains confidential information which may not be reproduced, stored, disclosed or transmitted to any

third party, without the prior written consent of North Oil Company.

The information contained in this document does not substitute for the laws and regulations applicable in Qatar.

Printed versions of this document are uncontrolled, check CMS for latest version.

Vous aimerez peut-être aussi

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- General Requirements For Ultrasonic ExaminationsDocument11 pagesGeneral Requirements For Ultrasonic ExaminationsmaheshPas encore d'évaluation

- Electromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysDocument4 pagesElectromagnetic (Eddy-Current) Examination of Seamless and Welded Tubular Products, Austenitic Stainless Steel and Similar AlloysMaxPas encore d'évaluation

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- E243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesE243-13 Standard Practice For Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesudomPas encore d'évaluation

- Straight Beam Ultrasonic Examination of Rolled Steel Structural ShapesDocument3 pagesStraight Beam Ultrasonic Examination of Rolled Steel Structural ShapesMaxPas encore d'évaluation

- Ac Operated Automatic TR Unit WithDocument15 pagesAc Operated Automatic TR Unit WithTech1Pas encore d'évaluation

- Electromagnetic (Eddy Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie TemperatureDocument3 pagesElectromagnetic (Eddy Current) Examination of Type F-Continuously Welded (CW) Ferromagnetic Pipe and Tubing Above The Curie Temperaturefredy lopezPas encore d'évaluation

- Ut-Pro of PlatesDocument2 pagesUt-Pro of PlatesSajid ShaikhPas encore d'évaluation

- Amendmend TS 14 01 14Document17 pagesAmendmend TS 14 01 14Prakash BeheraPas encore d'évaluation

- Eddy Current in Aerospace PDFDocument7 pagesEddy Current in Aerospace PDFAllwynPas encore d'évaluation

- E243 13 PDFDocument6 pagesE243 13 PDFDaniel Mauricio Prieto ValderramaPas encore d'évaluation

- Fuller Roller Mill Lever - UT Inspection ProcedureDocument5 pagesFuller Roller Mill Lever - UT Inspection ProcedurealexisPas encore d'évaluation

- Electromagnetic (Eddy-Current) Examination of Copper Redraw Rod For Electrical PurposesDocument4 pagesElectromagnetic (Eddy-Current) Examination of Copper Redraw Rod For Electrical PurposessanthakumarPas encore d'évaluation

- ASTM A435-A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesDocument3 pagesASTM A435-A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesRaul SebastiamPas encore d'évaluation

- ASTM A435 A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel Plates PDFDocument3 pagesASTM A435 A435M-17 Standard Specification For Straight-Beam Ultrasonic Examination of Steel Plates PDFEdwinMauricioMacabeoPas encore d'évaluation

- Astm E570Document7 pagesAstm E570陳明書Pas encore d'évaluation

- Astm A609 A609m 12Document4 pagesAstm A609 A609m 12SITASPas encore d'évaluation

- TCST11110R0 Pilot CablesDocument25 pagesTCST11110R0 Pilot CablesshabeerPas encore d'évaluation

- GaAs MMIC Space Qualification PDFDocument3 pagesGaAs MMIC Space Qualification PDFDavid LopezPas encore d'évaluation

- Post Tensioning ManualDocument11 pagesPost Tensioning Manualimzee25100% (7)

- NORSOK U CR 006r1 - Subsea Production Control UmbilicalDocument14 pagesNORSOK U CR 006r1 - Subsea Production Control UmbilicalNils Antoine FreundPas encore d'évaluation

- Flux Leakage Examination of Ferromagnetic Steel Tubular ProductsDocument7 pagesFlux Leakage Examination of Ferromagnetic Steel Tubular ProductsAnbarasan PerumalPas encore d'évaluation

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocument15 pagesAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDEPas encore d'évaluation

- Cathodic Protection Drawings SP-1136Document4 pagesCathodic Protection Drawings SP-1136anuprajoshPas encore d'évaluation

- E215-16 Práctica Estándar para La Estandarización de Equipos y El Examen Electromagnético de Tubos de Aleación de Aluminio Sin Costura1Document11 pagesE215-16 Práctica Estándar para La Estandarización de Equipos y El Examen Electromagnético de Tubos de Aleación de Aluminio Sin Costura1fredy lopezPas encore d'évaluation

- Astm PS138 - 03 PDFDocument11 pagesAstm PS138 - 03 PDFShoyeeb AhmedPas encore d'évaluation

- Annexure III Scope of Work and Special ConditionsDocument7 pagesAnnexure III Scope of Work and Special Conditionsraj1508Pas encore d'évaluation

- Attachment #05 Propose 100mV Polarization For Cathodic Protection of Steel PilesDocument4 pagesAttachment #05 Propose 100mV Polarization For Cathodic Protection of Steel PilesArun SudarshanPas encore d'évaluation

- La TSDocument23 pagesLa TSanirban 007Pas encore d'évaluation

- Astor Accreditation Certificate 2022 (Id 1361648)Document6 pagesAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84Pas encore d'évaluation

- Astm 578Document5 pagesAstm 578ASWANTH T S100% (1)

- AAAC Test Report 95mmDocument14 pagesAAAC Test Report 95mmnigerluvPas encore d'évaluation

- 11Kv Voltage Class Surge ArrestorsDocument16 pages11Kv Voltage Class Surge ArrestorsSandip AhirePas encore d'évaluation

- BLDC SPEC - 0021 - 2005 (Rev.2) PDFDocument18 pagesBLDC SPEC - 0021 - 2005 (Rev.2) PDFdivisional electrical enggPas encore d'évaluation

- UT ProcedureDocument14 pagesUT Procedureshifa0% (1)

- ASTM E208-20 Drop Weight TestDocument13 pagesASTM E208-20 Drop Weight TestBalaPas encore d'évaluation

- E243-97 EC Copper TubesDocument6 pagesE243-97 EC Copper TubesveluPas encore d'évaluation

- CL NG 6460 002 023 Checklist For CT Rev00Document3 pagesCL NG 6460 002 023 Checklist For CT Rev00Santhosh Kumar VinayagamPas encore d'évaluation

- IP46 - Guide To Use BAPCO WPS & Welding ProceduresDocument4 pagesIP46 - Guide To Use BAPCO WPS & Welding ProceduressajiPas encore d'évaluation

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Abs Rule NDT Plan - 12-1100Document2 pagesAbs Rule NDT Plan - 12-1100fuaz100% (1)

- STL Guide For Short CircuitDocument9 pagesSTL Guide For Short CircuitMohammed ShoaibPas encore d'évaluation

- Astm e 309Document5 pagesAstm e 309김경은Pas encore d'évaluation

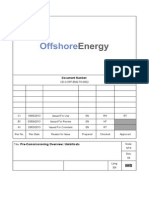

- OE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1Document16 pagesOE CORP ENG TN 0002 Pre Commissioning Overview Umbilicals Rev C1hatakerobot100% (1)

- Switchyard ErectionDocument56 pagesSwitchyard Erectiondilleh100% (1)

- Acsr Canna 933 Tip Test Raporu PDFDocument13 pagesAcsr Canna 933 Tip Test Raporu PDFelsayedPas encore d'évaluation

- Technical Specification For Aac / Acsr ConductorsDocument8 pagesTechnical Specification For Aac / Acsr ConductorsDeepeshMaliPas encore d'évaluation

- E215-16 Standard Practice For Standardizing Equipment and Electromagnetic Examination of Seamless Aluminum-Alloy TubeDocument11 pagesE215-16 Standard Practice For Standardizing Equipment and Electromagnetic Examination of Seamless Aluminum-Alloy TubeudomPas encore d'évaluation

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaPas encore d'évaluation

- Wtm-058 Ut Procedure Aws d1.5 (2010)Document9 pagesWtm-058 Ut Procedure Aws d1.5 (2010)Wisüttisäk Peäröön0% (1)

- Wave Trap Tech SpecsDocument13 pagesWave Trap Tech SpecsPrashant gaur100% (1)

- CL-NG-6460-002-023 Checklist For CT Rev01Document5 pagesCL-NG-6460-002-023 Checklist For CT Rev01sachin francisPas encore d'évaluation

- QA-NDT-12 ET DNV Classification Note 7Document13 pagesQA-NDT-12 ET DNV Classification Note 7Colin-James Lowe100% (1)

- Specification of Lightening ArrestersDocument12 pagesSpecification of Lightening ArrestersS BalasubramaniamPas encore d'évaluation

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument5 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForahmedPas encore d'évaluation

- Anode Spec. SampleDocument10 pagesAnode Spec. Samplezaidi562Pas encore d'évaluation

- VCB PanelsDocument17 pagesVCB PanelsSenthil Prasadh100% (1)

- Demo 6 Indication CompareDocument23 pagesDemo 6 Indication CompareRudolph RednosePas encore d'évaluation

- Sketch Specimen: Approved by NDT Level Iii Prepareded by Specimen No: Name: Reviewed by Name: NameDocument1 pageSketch Specimen: Approved by NDT Level Iii Prepareded by Specimen No: Name: Reviewed by Name: NameRudolph RednosePas encore d'évaluation

- Chứng chỉ nguồn - D2984Document4 pagesChứng chỉ nguồn - D2984Rudolph RednosePas encore d'évaluation

- Salman Hse Green Banding Exercise: BSP Contract Ref: C181824 Competitive Feed and Proposal Development For Salman ProjectDocument3 pagesSalman Hse Green Banding Exercise: BSP Contract Ref: C181824 Competitive Feed and Proposal Development For Salman ProjectRudolph RednosePas encore d'évaluation

- PAUT Demo Indication SummaryDocument1 pagePAUT Demo Indication SummaryRudolph Rednose100% (1)

- AcsaDocument1 pageAcsaRudolph RednosePas encore d'évaluation

- Session 9 - QatarDocument11 pagesSession 9 - QatarRudolph RednosePas encore d'évaluation

- Flawless Project Delivery: Ken Ede Apr 2016Document10 pagesFlawless Project Delivery: Ken Ede Apr 2016Rudolph RednosePas encore d'évaluation

- Linac NDT Services Limited: Radiographic Report (Lsf2)Document1 pageLinac NDT Services Limited: Radiographic Report (Lsf2)Rudolph RednosePas encore d'évaluation

- Linac NDT Services Limited: Radiographic Report (Lsf2)Document1 pageLinac NDT Services Limited: Radiographic Report (Lsf2)Rudolph RednosePas encore d'évaluation

- FBI Strategy Pillars PDFDocument1 pageFBI Strategy Pillars PDFRudolph RednosePas encore d'évaluation

- Extracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsDocument1 pageExtracted Pages From ASME B31.8-2018 Gas Transmission and Distribution Piping SystemsRudolph RednosePas encore d'évaluation

- CTRL + D: Need To Copy A Shape? Select It and Press CTRL+DDocument1 pageCTRL + D: Need To Copy A Shape? Select It and Press CTRL+DRudolph RednosePas encore d'évaluation

- Demo SUMDocument27 pagesDemo SUMRudolph RednosePas encore d'évaluation

- ChartDocument9 pagesChartRudolph RednosePas encore d'évaluation

- Additional Required by Spec (DNV-OS-F101 Appendix D, Subsection H)Document1 pageAdditional Required by Spec (DNV-OS-F101 Appendix D, Subsection H)Rudolph RednosePas encore d'évaluation

- Piping PAUT ReportDocument21 pagesPiping PAUT ReportRudolph Rednose100% (2)

- Calibration Block - Stock Checked.Document1 pageCalibration Block - Stock Checked.Rudolph RednosePas encore d'évaluation

- Piping RT ReportDocument1 pagePiping RT ReportRudolph RednosePas encore d'évaluation

- Travel PlanDocument1 pageTravel PlanRudolph RednosePas encore d'évaluation

- Minimum Number of Films For Each Pipe SzeDocument5 pagesMinimum Number of Films For Each Pipe SzeRudolph RednosePas encore d'évaluation

- Strategy SnapshotDocument1 pageStrategy SnapshotRudolph RednosePas encore d'évaluation

- Steel Beam Sizes From The AISC Manual of Steel ConstructionDocument72 pagesSteel Beam Sizes From The AISC Manual of Steel ConstructionRudolph RednosePas encore d'évaluation

- Philippine Die and Mold Industry 2018: A Status Report: Alexander P. GonzalesDocument7 pagesPhilippine Die and Mold Industry 2018: A Status Report: Alexander P. GonzalesYou do it baby do it rightPas encore d'évaluation

- Certificate Course of Data AnalyticsDocument5 pagesCertificate Course of Data Analyticsnattu kakaPas encore d'évaluation

- Maths Is FunDocument10 pagesMaths Is FunLynx AdamPas encore d'évaluation

- Safety Climate in University and College Laboratories: Impact of Organizational and Individual FactorsDocument12 pagesSafety Climate in University and College Laboratories: Impact of Organizational and Individual Factorsmnazri98Pas encore d'évaluation

- Demand Forecasting TechniqesDocument29 pagesDemand Forecasting Techniqessheebakbs5144Pas encore d'évaluation

- Statistics and Probability - Solved Assignments - Semester Spring 2010Document33 pagesStatistics and Probability - Solved Assignments - Semester Spring 2010Muhammad UmairPas encore d'évaluation

- ArrzafirahDocument11 pagesArrzafirahAr-Rayyan AshPas encore d'évaluation

- Education Reforms in IsraelDocument27 pagesEducation Reforms in IsraelLuan NguyenPas encore d'évaluation

- Evironmental Impact AssessmentDocument2 pagesEvironmental Impact AssessmentAnil MarsaniPas encore d'évaluation

- Ent ProjectDocument3 pagesEnt ProjectreemPas encore d'évaluation

- Capa SopDocument23 pagesCapa SopHaroon Rasheed100% (3)

- SHRP2 - S2-R19B-RW-1 Bridges For Service Life Beyond 100 Years - Service Limit State DesignDocument521 pagesSHRP2 - S2-R19B-RW-1 Bridges For Service Life Beyond 100 Years - Service Limit State DesignKY PengPas encore d'évaluation

- Hospital Human Resource PlanningDocument23 pagesHospital Human Resource PlanningDang RajoPas encore d'évaluation

- Master Degree Thesis PaperDocument8 pagesMaster Degree Thesis Paperdwfz48q3100% (2)

- Aga A2 1104 PpsDocument2 pagesAga A2 1104 Pps조윤호Pas encore d'évaluation

- SWIS Facilitators GuideDocument32 pagesSWIS Facilitators GuideRemzije SylejmaniPas encore d'évaluation

- Tiktok Application Thesis Chapter 1-5 Edited.Document20 pagesTiktok Application Thesis Chapter 1-5 Edited.Erich Solomon CarantoPas encore d'évaluation

- AyrishDocument26 pagesAyrishlaila dennis jabalPas encore d'évaluation

- Technical Writing Essentials 1563391738. - Print PDFDocument284 pagesTechnical Writing Essentials 1563391738. - Print PDFVishnu VishnuPas encore d'évaluation

- Ethical Side of Beauty PageantDocument13 pagesEthical Side of Beauty PageantAldyn OlermoPas encore d'évaluation

- Risk Management PlanDocument5 pagesRisk Management Plannabeel aliPas encore d'évaluation

- MATH 7 LAS Q4 Week 1Document16 pagesMATH 7 LAS Q4 Week 1johnpaulnavas13Pas encore d'évaluation

- Soil InvestigationDocument18 pagesSoil InvestigationJohn Eric PinedaPas encore d'évaluation

- AIS Effectiveness Nigerian BankingDocument27 pagesAIS Effectiveness Nigerian BankinglingamrubhiniPas encore d'évaluation

- Jose Rizal University College of Liberal Arts, Criminology & EducationDocument39 pagesJose Rizal University College of Liberal Arts, Criminology & EducationRanier Factor Aguilar100% (1)

- Final Action Research ProposalDocument13 pagesFinal Action Research Proposalapi-621535429Pas encore d'évaluation

- Statistics For Communication ResearchDocument48 pagesStatistics For Communication ResearchnadirahPas encore d'évaluation

- Time Team - Derwentcote ForgeDocument64 pagesTime Team - Derwentcote ForgeWessex Archaeology100% (1)

- Introduction PDFDocument7 pagesIntroduction PDFJalal NhediyodathPas encore d'évaluation

- Classification of Research by MethodDocument3 pagesClassification of Research by MethodPutri RamadhaniPas encore d'évaluation

- Laws of UX: Using Psychology to Design Better Products & ServicesD'EverandLaws of UX: Using Psychology to Design Better Products & ServicesÉvaluation : 5 sur 5 étoiles5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneD'EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (52)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessD'EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessPas encore d'évaluation

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tD'EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionD'EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionPas encore d'évaluation

- Waste: One Woman’s Fight Against America’s Dirty SecretD'EverandWaste: One Woman’s Fight Against America’s Dirty SecretÉvaluation : 5 sur 5 étoiles5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchD'EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchÉvaluation : 4 sur 5 étoiles4/5 (10)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableD'EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginablePas encore d'évaluation

- 507 Mechanical Movements: Mechanisms and DevicesD'Everand507 Mechanical Movements: Mechanisms and DevicesÉvaluation : 4 sur 5 étoiles4/5 (28)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsD'EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontD'EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontÉvaluation : 4.5 sur 5 étoiles4.5/5 (18)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesD'EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesPas encore d'évaluation

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsD'EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsPas encore d'évaluation