Académique Documents

Professionnel Documents

Culture Documents

Sushma Industries Calibration Centre

Transféré par

VAIBHAV INSTRUMENTATIONCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sushma Industries Calibration Centre

Transféré par

VAIBHAV INSTRUMENTATIONDroits d'auteur :

Formats disponibles

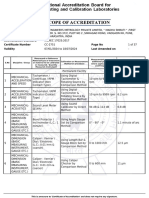

Laboratory Sushma Industries Calibration Centre, Plot No.

18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 1 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. PRESSURE INDICATING DEVICES

1. Pressure (Pneumatic 100 mbar(g) to 0.008 % rdg Using DH Budenberg

and Vacuum) 1000 mbar(g) Pneumatic Dead Weight

Barometers/ Tester Direct

Pressure Transducer/ (-) 950 mbar (g) to 0.01% rdg Comparison for

Transmitters/ (-)15 mbar (g) Pressure Measuring

Dead Weight Testers/ Devices and Cross Float

$

Pressure Calibrators 1 bar (g) to 25 bar (g) 0.008 % rdg Method for Dead Weight

Tester (for Both

Pressure and Effective

Area Determination)

14 mbar (g) to 0.0022 % rdg Using Ruska Piston

1700 mbar (g) Gauge (Pneumatic) And

Manual/Auto Float

2

14 mbar (abs) to [(0.0024) + Pressure Controller.

-6 2 0.5

1700 mbar (abs) (22e p) ] mbar Direct Comparison for

Pressure Measuring

140 mbar to 70bar (g) 0.0022% rdg Devices and Cross Float

Method for Dead Weight

2

140 mbar to 70 bar (abs) [(0.0024) + Tester, (for Both

-6 2 0.5

(22e p) ] mbar Pressure and Effective

Area Determination)

2 -

(-) 950 mbar to [(0.054) +(22e

6 2 0.5

(-) 50 mbar p) ] mbar

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 2 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Pressure (Hydraulic) 6 bar to 60 bar 0.008 % rdg Using DH Budenberg

Pressure Transducer/ 60 bar to 1200 bar 0.008 % rdg Hydraulic Dead Weight

Transmitters/ Tester Direct

Dead weight Testers/ Comparison for

$

Pressure Calibrators Pressure Measuring

Devices And Cross Float

Method for Dead Weight

Tester, (for Both

Pressure and Effective

Area Determination)

3. Calibration of Upto 1200 bar 0.2 bar Using DH Budenberg

Pressure Gauges in Upto 20 mV 0.005 mV Digital Pressure

Units Upto 10 V 0.007 V Calibrator as per DKD

Pressure Upto 20 mA 0.003 mA R6-1 with Precision

Transducers, Calibrator DMP -40/

Pressure CFA225-P- mV/V

$

Transmitters Indicator/Digital

Multimeter

II. MOBILE FORCE MEASURING SYSTEM

$

1. Push Pull Gauges 0.01N to 100 N 0.02 % of reading Using Dead weight

100 N to 22 kN 0.01 % of reading Force Calibration

Machines with Stainless

Steel Newton Weights

As per guidelines

VDI/VDE 2624

Part 2.1 (Dec 2008)

for Push Pull Gauge

III. FORCE PROVING INSTRUMENTS

1. Load Cells/ Force 0.01 N to 100 N 0.02 % of reading Using Dead weight

$

Proving Instruments 100 N to 22 kN 0.01 % of reading Force Calibration

Machines with Stainless

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 3 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Steel Newton Weights

As per IS 4169:2014,

ISO 376 and

ASTM E74 -13a for

Force proving

Instruments of Class

00 and Coarser

2. Load Cells/ Force 20 kN to1000 kN 0.12 % Using Universal Force

$

Proving Instruments Calibration Systems.

By Comparison Method

with Precision Load

Cells and Digital Load

Indicator as per

IS 4169:2014,

ISO 376 and

ASTM E74 -13a

IV. UTM, TENSION CREEP AND TORSION TESTING MACHINE

1. Uniaxial and Using Precision Load

Universal Cells and Digital Load

Compression Testing Indicator as per

♣

Machines IS 1828:2005

Compression 0 to 1000 kN 0.12 % (ISO 7500)

Compression & 0 to 20 kN 0.12 %

Tension

2. Verification of Force 0 to 20 kN 0.025 % Using Transfer Standard

♣

Calibration Machine Reference Load Cell

with Precision Calibrator

DMP -40/CFA225-P-

mV/V

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 4 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

V. TORQUE MEASURING DEVICES

1. Torque Wrenches 0.1 Nm to 3000 Nm 0.1 % Using Torque Wrench

Torque Tools Calibration System

Indicating Type I (with Torque Sensors

(A to E) and Digital Torque

Torque Setting Type indicator) As per

II (A to F) and ISO 6789:2017

$

Rotary Torque Tools (Part 1 & 2) for Torque

Tools and ISO 5393,

ISO 6544, ISO 17104

for Rotary Torque Tools

2. Hydraulic Torque 0.5 kNm to 5 kNm 0.11 % Using Hydraulic Torque

$

Wrenches 5 kNm to 80 kNm 0.10 % Wrench Calibrator with

Torque Sensor and

Digital Torque Indicator

as per IS/ISO 6789

3. Torque Measuring 0.1 Nm to 22 kNm 0.01% Using Dead weight

$

Devices 0.001 Nm to 0.1 Nm 0.01% Torque Calibration

System consisting of

Lever Arm and Stainless

steel Newton weights as

per BS:7882:2008/ DIN

51309,ASTM E2428-

15a, DKD-R7 and R8

$

4. Torque Multipliers 0.1 Nm to 22 kNm 1.4 % Using Dead Weight

Torque Calibration

System Along with

Torque Sensor with

Display Unit

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 5 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

5. Torque Measuring 2 kNm to 20 kNm 0.084 % Using Torque Calibration

$

Devices 20 kNm to 100 kNm 0.081 % System with Lever Arm

Along with Force Sensor

and Digital Force

Indicator As per

BS:7882:2008/

DIN 51309 DIN 51309,

ASTM E2428-15a

6. Verification of Torque 0 to 2000 Nm 0.025 % Using Transfer Standard

Calibration Reference Torque

♣

Machines Transducer and

Precision calibrator,

DMP-40/CFA225-P-

mV/V

VI. DIMENSION (PRECISION INSTRUMENTS)

1. Optical Angle Using Optical Encoder &

$

Measuring Device Digital Display Unit

Resolution.: 0.001º Upto 3000º 0.06º By Comparison

2. Angle Measuring Using Optical Encoder &

Device of a Torque Digital Display Unit

$

Angle Wrench By Comparison

Resolution.: 0.001º Upto 3000º 0.06º

$

3. Lever Arm 2.5 m (4+6L) µm Using Portable CMM

L=Arm Length in metre By Comparison

4. Linear Displacement Using Gauge Blocks

Measuring Systems Calibration Stand /

With Display Units Micrometer Head

(Optical/Magnetic/ By Comparison based

LVDT/ Capacitive on ASTM E2309 M-16

$

Probes) Upto 1 m (0.5+L/500) µm

Resolution.: 1 µm “L” in mm

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 6 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

5. Extensometer / Elongation/ Length: 1.0 µm Using Calibration

$

LVDT 0 to 50 mm System with Electronic

(a) Resolution: Probe & DRO By

0.1 µm Comparison Based on

Gauge Length: ASTM E-83-16,

0-150 mm ISO: 9513

(b) Resolution: Elongation/ Length : Using Calibration

0.1 µm 0 to 50 mm 2.0 µm System with Micrometer

Gauge Length: Head By Comparison

0-150mm based on ASTM E-83-

16, ISO: 9513

6. Articulated Arm Co- Using Reference Sphere

Ordinate Measuring By Comparison based

Machine (CMM) on ISO 10360-12 &

(a) Probing Size Error 25 mm 1 µm ISO 10360-2

(b) Probing Form 25 mm 1 µm

Error (c)Articulated 25 mm 1.5µm

$

Location Error

(d) Length Measuring 2.5 m (1+L/500) µm Using Gauge Blocks

Accy “L” in mm with Fixture By

Comparison based on

ISO 10360-12 &

ISO 10360-2

7. Articulated Arm 25 mm 1 µm Using Reference Sphere

Co-Ordinate 25 mm 1.5 µm By Comparison based

Measuring Machine on ASME B89.4.22-2004

(CMM)

(a) Effective

Diameter

Performance

(Probing Error)

(b) Single Point

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 7 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

Articulated

Performance

$

(Location Error)

(c) Volumetric 0 to 2.5 m (1+L/500) µm Using Gauge Blocks

$

Performance ‘L’ in metres with Fixture By

Comparison based on

ASME B89.4.22-2004

$

8. Height Gauge Using Caliper Checker /

(Vernier/Dial/ Digital) Gauge Blocks / Long

L.C.: 10 µm Upto 600 mm 11.0 µm Gauge Blocks By

Comparison based on

IS 2921

$

9. External Micrometer Upto 150 mm 1.5 µm Using Gauge Blocks

(Analog/Digital) By Comparison based

L.C.: 1 µm on IS: 2967

$

10. Depth Micrometer Upto 50 mm 7.1 µm Using Gauge Blocks

(Analog/Digital) By Comparison based

L.C.: 10 µm on BS: 6468

$

11. Feeler / Gap Gauge 0 to 2 mm 2.0 µm Using Digital Micrometer

By Comparison

$

12. Calipers Using Caliper Checker /

(Vernier/Dial/Digital ) Gauge Blocks / Long

L.C.: 10 µm Upto 600 mm 9.6 µm Gauge Blocks By

Comparison Based on

IS: 3651 (Part 1, 2 & 3)

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 8 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

VII. ACCELERATION AND SPEED

1. Non-Contact Using Speed Calibration

$

Tachometers System with Reference

L.C.: 0.1 rpm 100 rpm to 10000 rpm 1.1 rpm Non-Contact

10000 rpm to 20000 rpm 1.5 rpm Tachometer and

Servo Controller By

Comparison Based on

SANAS TR 45-01: 2008

2. Speed Calibration of Using Speed Calibration

$

Rotating Transducer System with Servo

L.C.: 0.1 rpm 100 rpm to 10000 rpm 1.5 rpm Controller By

Comparison based on

SANAS TR 45-01 : 2008

3. Travel Speed of 0.01 mm/sec to 0.25 % Using Digital Vernier /

Material Testing 40 mm/sec Gauge Blocks & Timer

$

Machine As per ASTM E2658-15

VIII. WEIGHTS

$

1. Mass-Weights 1 mg 0.0007 mg Using E0 and E1 class

2 mg 0.0007 mg Weights and Balance /

5 mg 0.0007 mg Comparator of

10 mg 0.0007 mg Readability 0.0001mg /

20 mg 0.001 mg 0.001mg/ 0.01mg and

50 mg 0.001 mg 5mg Calibration of

100 mg 0.0017 mg Weights of Class

200 mg 0.002 mg E1 Accuracy and

500 mg 0.0027 mg coarser as per

1g 0.003 mg OIML R-111

2g 0.004 mg

5g 0.005 mg

10 g 0.007 mg

20 g 0.008 mg

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 9 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

50 g 0.01 mg

100 g 0.017mg

200 g 0.033 mg

500 g 0.083 mg

1 kg 0.17 mg

2 kg 0.33 mg

5 kg 2.3 mg Using E2 class weights

10 kg 7.3 mg and balance/ comparator

20 kg 15 mg of readability 0.1mg and

5mg readability

Calibration of weights of

Class F1 accuracy and

coarser as per

OIML R-111

IX. WEIGHING SCALE AND BALANCE

1. Electronic Weighing Maximum Capacity 0.0015 mg Using E2 and F1 Class

♣

Balances Upto 2 g Weights Calibration of

with Readability Maximum Capacity 0.02 mg Electronic Weighing

d=0.001mg, Upto 20 g Balance and

d=0.01 mg, Maximum Capacity 0.035 mg Comparator of Class I

d=0.1mg, d=5 mg Upto 200 g and Coarser

Maximum Capacity 0.2 mg As per OIML R-76-1

Upto 2000 g

♣

2. Weighing Balance Maximum Capacity 35 mg Using Calibration of

Upto 75 kg Electronic Weighing

Balance and

Comparator of Class II

and Coarser As per

OIML R-76-1

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 10 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

X. VOLUME

1. Glassware Like 0.01 ml to 10 ml @27 °C 0.004 ml Using Weighing balance

Pipettes, Burettes, >10 ml to 1000 ml 0.27 ml of 220 g & 2 kg Capacity

Measuring Cylinder, @27 °C and 0.1mg and 0.01 mg

Volumetric Readability and Distilled

$

Flask etc. Water By Gravimetric

Method Based on

IS/ISO 4787

$

2. Micro-Pipette 10 μl to 100 μl 0.11 μl Using Weighing balance

@ 27 °C with Readability

>100 μl to 5000 μl 4 μl 0.001mg/ 0.0001mg and

@ 27 °C Distilled Water

Gravimetric Method

Based on ISO 8655

Part-6

XI. DENSITY AND VISCOSITY

$ 3

1. Density of Liquid 0.1 kg/m to 0.00024 g/cc Using Weighing balance

3

15000 kg/m of 200g capacity and

0.01mg readability with

density determination kit

as per OIML-G14

guideline

$ 3

2. Density of Solids 0.1 kg/m to 0.0012 g/cc Using Weighing balance

3

15000 kg/m of 200g capacity and

0.01mg readability with

density determination kit

as per OIML-G14

guideline

Ram Ashray Avijit Das

Convenor Program Manager

Laboratory Sushma Industries Calibration Centre, Plot No. 18E, Block-A,

1st ‘C’ Main Road, IInd Phase, Peenya Industrial Area, Bengaluru,

Karnataka

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2874 (in lieu of C-0137) Page 11 of 11

Validity 29.09.2018 to 28.09.2020 Last Amended on 26.10.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

XII. DUROMETER

1. Hardness And Shore A & AO 0.58 % rdg Using Dead Weights &

$

Impact Shore D, AM & 0.29 % rdg Durometer Force

IRHD Pocket Meter Measuring System

Based on

ISO18898: 2006,

ASTM D2240-05

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

Ram Ashray Avijit Das

Convenor Program Manager

Vous aimerez peut-être aussi

- Cross Talk Details and RoutingDocument29 pagesCross Talk Details and RoutingRohith RajPas encore d'évaluation

- Runyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechDocument28 pagesRunyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechThe New Vision50% (2)

- Adt672 DatasheetDocument3 pagesAdt672 DatasheetEduardo FelippePas encore d'évaluation

- Sri Gokul Cal Lab.Document4 pagesSri Gokul Cal Lab.VAIBHAV INSTRUMENTATIONPas encore d'évaluation

- CL 221 CertDocument4 pagesCL 221 CertS SHALUPas encore d'évaluation

- CL 222 CertDocument5 pagesCL 222 CertS SHALUPas encore d'évaluation

- MPC-L Very Low Pressure CalibratorDocument2 pagesMPC-L Very Low Pressure CalibratorGery Bisma GentinaPas encore d'évaluation

- VijayDocument1 pageVijayrohanmanimaniPas encore d'évaluation

- Scope Location 1 CC-2101Document12 pagesScope Location 1 CC-2101Ravi Dilawari [Aspire]Pas encore d'évaluation

- Scope Location 1 CC-2101Document12 pagesScope Location 1 CC-2101Ravi Dilawari [Aspire]Pas encore d'évaluation

- PressureSwitch 20230729124938.190 XDocument1 pagePressureSwitch 20230729124938.190 XDon't MindPas encore d'évaluation

- Sizing CalculationDocument13 pagesSizing CalculationDaniel DuongPas encore d'évaluation

- Scope Location 1 CC-2441Document2 pagesScope Location 1 CC-2441Ravi Dilawari [Aspire]Pas encore d'évaluation

- Digital Pressure Gauge: R&D Instrument ServicesDocument1 pageDigital Pressure Gauge: R&D Instrument ServicesDiptiPas encore d'évaluation

- A O Smith Meter 2 Inch Steel Model C2Document4 pagesA O Smith Meter 2 Inch Steel Model C2RomankoPas encore d'évaluation

- True Value Calibration Services Private Limited: Has Been Assessed and Accredited in Accordance With The StandardDocument19 pagesTrue Value Calibration Services Private Limited: Has Been Assessed and Accredited in Accordance With The StandardMaruthi KPas encore d'évaluation

- 16 Steel Model M16Document4 pages16 Steel Model M16JAIME CIFUENTESPas encore d'évaluation

- VTC ConsolidatedDocument23 pagesVTC ConsolidatedRamKS80Pas encore d'évaluation

- Bouche Laboratories, 1000AD Shaker 10-50kHz PDFDocument2 pagesBouche Laboratories, 1000AD Shaker 10-50kHz PDFLulu Sweet ThingPas encore d'évaluation

- Eja 310 eDocument12 pagesEja 310 efelkawanoPas encore d'évaluation

- Production Control Plan 4111078Document10 pagesProduction Control Plan 4111078Yogesh PatilPas encore d'évaluation

- 16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsDocument4 pages16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsAnnisa RahmadayantiPas encore d'évaluation

- Rotary Torque Sensor - Non-Contact Shaft-to-Shaft: Specifications PerformanceDocument2 pagesRotary Torque Sensor - Non-Contact Shaft-to-Shaft: Specifications PerformanceJoelson MeneghelliPas encore d'évaluation

- Rotary Torque Sensor - Square-Drive With Encoder: Specifications PerformanceDocument2 pagesRotary Torque Sensor - Square-Drive With Encoder: Specifications Performanceomar shadyPas encore d'évaluation

- 2006 Clutch, Brake, Tension Controller CatalogDocument136 pages2006 Clutch, Brake, Tension Controller Catalogvan Dai phamPas encore d'évaluation

- Scope-CC-2231 - Transcal - HYDROMETER SCOPEDocument1 pageScope-CC-2231 - Transcal - HYDROMETER SCOPEAcutePas encore d'évaluation

- Pm-Clinic Service: PMEH102200Document3 pagesPm-Clinic Service: PMEH102200Naughty VongPas encore d'évaluation

- Cda (MS-02-153) R0Document2 pagesCda (MS-02-153) R0herysyam1980Pas encore d'évaluation

- Qa-Pt 11Document2 pagesQa-Pt 11dede_dede_dedePas encore d'évaluation

- List of Other Calibration Certificates Required Apart From QuotationDocument1 pageList of Other Calibration Certificates Required Apart From QuotationQuality JamPas encore d'évaluation

- B One Plus - UkDocument2 pagesB One Plus - Ukcahayu andarupmPas encore d'évaluation

- 03 - Pigsar - Metrological ForumDocument27 pages03 - Pigsar - Metrological ForumShahnoza TorayevaPas encore d'évaluation

- Pm-Tune Up Service: SEPD3076Document5 pagesPm-Tune Up Service: SEPD3076Aulia NafarinPas encore d'évaluation

- 75عDocument3 pages75عFikry FaradinnaPas encore d'évaluation

- 045 Monthly Maintenace MRSDocument1 page045 Monthly Maintenace MRSCHANNE SANTOSHPas encore d'évaluation

- Tesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typeDocument2 pagesTesla meter,Gauss meter、Magnetic flux densimeter、Introduction Handy typesomkiat kongprasiatPas encore d'évaluation

- Counterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11ADocument2 pagesCounterbalance, Standard Guided Poppet Type, Counterclockwise Adjustment SUN Cavity Interchange, T-11AFledson Pereira das ChagasPas encore d'évaluation

- EFM Report GAS COMPRADocument19 pagesEFM Report GAS COMPRAjosecordova2014Pas encore d'évaluation

- Nothlab ChennaiDocument129 pagesNothlab ChennaiVikram BillalPas encore d'évaluation

- PDR1000. - 2019 NDocument4 pagesPDR1000. - 2019 Nalief setiawanPas encore d'évaluation

- 1297 01Document16 pages1297 01ebbasinghPas encore d'évaluation

- ULTRADUR B4300G6 (03p023)Document3 pagesULTRADUR B4300G6 (03p023)ayala castroPas encore d'évaluation

- Kobold - DVH GB FlowDocument8 pagesKobold - DVH GB FlowMS COPPas encore d'évaluation

- PM Clinic 350-8Document6 pagesPM Clinic 350-8Naughty VongPas encore d'évaluation

- LPV63 Test 708-1U-00140 Steering PumpDocument22 pagesLPV63 Test 708-1U-00140 Steering PumpAlonso Inostroza100% (1)

- 054247xyz Re18307-57Document2 pages054247xyz Re18307-57konapla21Pas encore d'évaluation

- Dead Weight TestersDocument5 pagesDead Weight TestersShrikant EkbotePas encore d'évaluation

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirPas encore d'évaluation

- Scope CC 2008 - ERTLDocument59 pagesScope CC 2008 - ERTLAnirban DasPas encore d'évaluation

- LK-067-IDN (Temperature, Mass, & Pressure)Document2 pagesLK-067-IDN (Temperature, Mass, & Pressure)Aries SupiyantoPas encore d'évaluation

- Scope CC 2751Document37 pagesScope CC 2751Vishal ShindePas encore d'évaluation

- Schaevitz Sensors 02560231 000 DatasheetDocument3 pagesSchaevitz Sensors 02560231 000 DatasheetLuca MidaliPas encore d'évaluation

- Ficha Tecnica 3M175Document2 pagesFicha Tecnica 3M175SebastianPas encore d'évaluation

- Scope CC 2559Document183 pagesScope CC 2559HOD Scitpl [Sands]Pas encore d'évaluation

- EJA310E SeriseDocument15 pagesEJA310E Serisecyrano1091Pas encore d'évaluation

- VICKERS Hydraulic Pump VVP SeriesDocument22 pagesVICKERS Hydraulic Pump VVP SeriesPartagon PowPas encore d'évaluation

- HBM P3 Top ClassDocument10 pagesHBM P3 Top ClasslgustavolucaPas encore d'évaluation

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqPas encore d'évaluation

- Enerpac DGR1 CatalogDocument1 pageEnerpac DGR1 CatalogTitanplyPas encore d'évaluation

- 08 ADT 672 Digital Pressure CalibratorDocument3 pages08 ADT 672 Digital Pressure CalibratorphongPas encore d'évaluation

- Mechanical Pressure Switches Tested To PE Directive 97 - 23 - EC (PDFDrive)Document25 pagesMechanical Pressure Switches Tested To PE Directive 97 - 23 - EC (PDFDrive)Tareq AbdellatifPas encore d'évaluation

- (In Lieu of C-0579, C-0766 & C-0767) : TH RDDocument24 pages(In Lieu of C-0579, C-0766 & C-0767) : TH RDVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Questionnaire For Mass GroupDocument3 pagesQuestionnaire For Mass GroupVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument19 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Tempsens Calibration CentreDocument5 pagesTempsens Calibration CentreVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Institute For DesignDocument48 pagesInstitute For DesignVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- ZXX ZXDocument35 pagesZXX ZXVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Perfect CalibrationDocument25 pagesPerfect CalibrationVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Indigo Passenger (S) : Delhi MumbaiDocument2 pagesIndigo Passenger (S) : Delhi MumbaiVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Hi Tech Calibration Services PDFDocument28 pagesHi Tech Calibration Services PDFVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraDocument12 pagesLaboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Automotive Research Association of IndiDocument31 pagesAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDocument14 pagesLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument25 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument20 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Nivel VV-VW Board User Guide enDocument5 pagesNivel VV-VW Board User Guide enHarveyWishtartPas encore d'évaluation

- Toshiba: ® A20SeriesDocument12 pagesToshiba: ® A20SeriesYangPas encore d'évaluation

- 12 Key Principles On Bhava AnalysisDocument28 pages12 Key Principles On Bhava AnalysisDhineshPas encore d'évaluation

- Lafarge Interior Building Solutions BrochureDocument24 pagesLafarge Interior Building Solutions BrochuretwinpixtwinpixPas encore d'évaluation

- LET General Math ReviewerDocument7 pagesLET General Math ReviewerMarco Rhonel Eusebio100% (1)

- Updated Factory Profile of Aleya Apparels LTDDocument25 pagesUpdated Factory Profile of Aleya Apparels LTDJahangir Hosen0% (1)

- BC-6000 Installation Guide V7.0 enDocument111 pagesBC-6000 Installation Guide V7.0 enmentule88Pas encore d'évaluation

- Fully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019Document20 pagesFully Automatic Coffee Machine - Slimissimo - IB - SCOTT UK - 2019lazareviciPas encore d'évaluation

- Contemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceDocument25 pagesContemporary Philippine Arts From The Regions: Quarter 2 - Module 9 Different Contemporary Art Techniques and PerformanceGrace06 Labin100% (7)

- L27/38S Project Guide - Power Plant: Four-Stroke GensetDocument392 pagesL27/38S Project Guide - Power Plant: Four-Stroke GensetAaron Chan100% (1)

- Schneider Pressure Switch XMLDocument2 pagesSchneider Pressure Switch XMLhaoPas encore d'évaluation

- GROSS Mystery of UFOs A PreludeDocument309 pagesGROSS Mystery of UFOs A PreludeTommaso MonteleonePas encore d'évaluation

- Oil Whirl and Whip Instabilities - Within Journal BearingsDocument27 pagesOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirPas encore d'évaluation

- Bulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsDocument6 pagesBulacan Agricultural State College: Lesson Plan in Science 4 Life Cycle of Humans, Animals and PlantsHarmonica PellazarPas encore d'évaluation

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentDocument8 pagesConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Pas encore d'évaluation

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanPas encore d'évaluation

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Document6 pagesWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithPas encore d'évaluation

- Mockery Breed Murder Birds PDFDocument12 pagesMockery Breed Murder Birds PDFLautaro BojanichPas encore d'évaluation

- FYP ProposalDocument11 pagesFYP ProposalArslan SamPas encore d'évaluation

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcPas encore d'évaluation

- Significance of GodboleDocument5 pagesSignificance of GodbolehickeyvPas encore d'évaluation

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- Gemh 108Document20 pagesGemh 108YuvrajPas encore d'évaluation

- 123 09-Printable Menu VORDocument2 pages123 09-Printable Menu VORArmstrong TowerPas encore d'évaluation

- Tugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiDocument4 pagesTugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiFebry SugiantaraPas encore d'évaluation

- Electric ScootorDocument40 pagesElectric Scootor01fe19bme079Pas encore d'évaluation

- Innerwear Industry Pitch PresentationDocument19 pagesInnerwear Industry Pitch PresentationRupeshKumarPas encore d'évaluation

- Eldritch HighDocument39 pagesEldritch Highteam_moPas encore d'évaluation