Académique Documents

Professionnel Documents

Culture Documents

Sankalp Hi-Tech Corporation PDF

Transféré par

VAIBHAV INSTRUMENTATIONTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sankalp Hi-Tech Corporation PDF

Transféré par

VAIBHAV INSTRUMENTATIONDroits d'auteur :

Formats disponibles

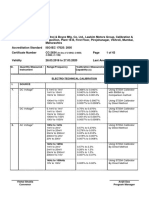

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 1 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

MECHANICAL CALIBRATION

I. DIMENSION (BASIC MEASURING INSTRUMENT, GAUGE ETC.)

$

1. Caliper Using Caliper Checker,

(Vernier, Dial, Digital) & Slip Gauge Set by

L. C. 0.01 mm Upto 1000 mm 16.0 m Comparison Method

2. Depth Gauge / Depth Using Slip Gauge Set,

$

Micrometer & Long Slip Gauge by

ɸ

L.C. : 0.001 mm Up to 300 mm 7.5 m Comparison Method

$

3. Height Gauge Using Caliper Checker,

(Vernier, Dial, Digital) & Slip Gauge Set by

L. C. 0.01 mm Upto 1000 mm 15.0 m Comparison Method

$

4. External Micrometer

(Inclusive of Point, Blade,

Ball, Flange, Groove, Disc ,

'V' anvil type) Using Slip Gauge Set,

L.C. : 0.001 mm Upto 25 mm 1.0 m Mic Check Set

Upto 150 mm 1.5 m & Length Bar Cylinder

Upto 300 mm 4.5 m Master by Comparison

L.C. : 0.01 mm Upto 1000 mm 11.0 m Method

$

5. Thread Pitch Micrometer

L.C.:0.001 mm 0.4mm to 5 mm 5.3 m Using Standard WCP

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 2 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

$

6. Internal Micrometer

( 2 Point )

L.C. : 0.001 / 0.01mm Upto 1000 mm 12.0 m Using Slip Gauge Set

(Extension not more Caliper Checker &

than 400 mm) Accessories by Comparison

Method

$

7. Inside Dial Caliper Using Slip Gauge Set

L.C. : 0.001 mm Upto 1000 mm 12.0 m Caliper Checker &

Accessories by Comparison

Method

$

8. Dial Gauge Plunger

ɸ

L.C.: 0.0005mm Upto 25 mm 2.8 m Using Slip Gauge Set & Dial

ɸ

L.C.: 0.001mm Upto 50 mm 3.5 m Calibration Tester by

Comparison Method

$

9. Dial Gauge Lever Using Dial Calibration

ɸ

L.C.:0.001 mm Upto 2 mm 2.8 m Tester by Comparison

Method

$

10. Bore Dial Gauge

(Transmission

Accuracy Check Only)

L.C. : 0.001 mm Upto 2 mm 2.8 m

Using Dial Calibration

Tester by Comparison

Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 3 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

11. Micrometer Setting 25mm to 100 mm 1.2 m Using Slip Gauge Set &

$

Standard 100mm to 300 mm 3.5 m Electronic Comparator,

300mm to 975 mm 10.5 m Length Bar by

Comparison Method

$

12. V – Block Using Electronic

Symmetricity Upto 150 mm 5.1 m Comparator,

Parallelism 5.1 m Master Cylinder & Master

Squareness 6.5 m Square

13. Dial Thickness Gauge

/ Dial Snap Gauge/

$

Pistol Caliper

L.C. : 0.001 mm Upto 200 mm 1.6 m Using Grade “0” Slip

L.C.: 0.01 mm Upto 200 mm 3.3 m Gauges, by Comparison

L.C. : 0.1 mm Upto 200 mm 58.0 m Method

14. Steel Scale / Taper

$

Scale

ɸ

L.C. : 0.5 mm Up to 2000 mm 150 m Using Scale Calibrator by

Comparison Method

15. Measuring Tape / Pie

$

Tape

ɸ

L.C. : 0.1mm Up to 50 meter 150 L m Using Scale Calibrator by

L is in mm Comparison Method

$

16. Comparator Stand Upto 100 mm 0.8 µm Using Optical Flat

(Flatness of work Upto 300 mm 3.0 µm Using Surface Plate,

Table) Electronic Comparator

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 4 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

17. Coating Thickness

$

Gauge

ɸ

L.C. : 0.01m Upto 2 mm 5.0 m Using Master Foils

by Comparison Method

18. Ultrasonic Thickness

$

Gauge

ɸ

L.C.:0.01mm Up to 200 mm 58 m Using Slip Gauge Set

by Comparison Method

19. Engineers Square / Upto 600 mm 11.0 m Using Master Square

$

Angle Plate Electronic Comparator by

Comparison Method

$

20. Engineers Parallel 0 to 300 mm 3.8 m Using Electronic

(For Parallelism) Comparator by Comparison

Method

$

21. Straight Edge Upto 5000 mm 3.0 L / 150 m Using Electronic Level &

L is in mm Electronic Comparator by

Comparison Method

22. C.D. / Upto 600 mm 6.5 m Using Single Axis M/c.

$

P.C.D. Gauge Vertical by Comparison

Method

23. Plain Plug Gauge Upto 100 mm 1.2 m Using Slip Gauge Set,

/Setting Plug/ Paddle Upto 300 mm 3.7 m Electronic Comparator &

Gauge / Precision Upto 600 mm 6.8 m Length Bar by Comparison

Balls / Measuring Pins Upto 1000 mm 10.7 m Method

$

/ Width Gauge

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 5 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

24. Snap Gauge / Upto 100 mm 1.0 m Using Slip Gauge Set,

Setting Gauge /

$

Upto 300 mm 3.3 m Long Slip Gauge & Single

Gap Gauge Upto 600 mm 5.5 m Axis Measuring Machine

(C&I Type) vertical by Comparison

Method

$

25. Thread Plug Gauge Upto 100 mm 4.2 m Using FCDM Cylindrical

(W.C.P. /C.P./Setting Upto 200 mm 2.6 m Setting Master/ Measuring

Plug) Wires Single Axis Machine

Major Dia by Comparison Method

Effective Dia

26. Taper Thread Plug Upto 100 mm 6.0 m Using FCDM Cylindrical

$

Gauge Setting Master/ Measuring

(Effective diameter) Wires by Comparison

Method

27. Plain Taper Plug Upto 100 mm 2.6 m Using Single Axis M/c.

$

Gauge (Horizontal) Slip Gauge,

Taper Angle Up to 60º 20 s Sine Bar by

Comparison Method

28. Plain Ring Gauge / 3 to 350 mm 2.5 m Using Single Axis M/c

$

Setting Ring Gauge (Horizontal)

by Comparison Method

29. Plain Taper Ring Upto 100 mm 2.6 m Using Single Axis M/c

$

Gauge (Horizontal) by Comparison

Taper Angle Up to 60º 20 s Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 6 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

$

30. Thread Ring Gauge 3 to 250 mm 3.0 m Using Single Axis M/c

(WCR/CR) (Horizontal) by Comparison

Effective Dia Method

31. Taper Thread Ring 3 to 100 mm 3.0 m Using Single Axis M/c

$

Gauge (Horizontal) by Comparison

( Effective Dia ) Method

32. Feeler Gauge / Upto 1 mm 1.3 m Using Electronic

$

Master Foils Comparator

by Comparison Method

$

33. Test Sives 0.05mm to 50 mm 5.3 m Using Vision Measuring

50mm to 125 mm 38.0 m Machine & Digital Caliper

by Comparison Method

$

34. Radius Gauge 0 to 50 mm 5.3 m Using Vision Measuring

Machine by Comparison

Method

$

35. Standard Wire Gauge 0 to10 mm 5.5 m Using Vision Measuring

Machine by Comparison

Method

$

36. Thread Pitch Gauge Using Vision Measuring

Pitch 0.3 mm to 8.0 mm 5.5 m Machine by Comparison

Flank Angle Upto 90 degree 1.3 min Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 7 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

37. Angle Protractor/

Combination Set / Using Slip Gauge Set,

Digital Protractor / Angle Gauge & Sine Bar

$ 0

Clinometers 0 – 90 - 0 by Comparison Method

L.C. : 0.1 min. 3.5 min

L.C. : 0.1 Deg. / 5 min. 35.0 min

L.C. : 1 Deg

$

38. Spline Plug Gauge 0 to 200 mm 4.0 m Using Single Axis M/c

(Diameter over Pin) (Horizontal) & Cyl. Setting

master & Meas. Pins by

Comparison Method

$

39. Spline Ring Gauge 0 to 200 mm 2.5 m Using Slip Gauge Set,

(Diameter over Pin) Long Slip Gauge & Meas.

Pins by Comparison Method

$

40. Surface Plate 5000 X 5000 mm 1.5(L+W/125) m Using Electronic Level

Where L is in mm

$

41. Bench Centre Upto 500 mm 8.5 m Using Parallel Mandrel &

(Center Alignment) Leaver Dial Gauge

42. Thread Measuring ABCD 1.0 m Using Electronic

$

Prism Comparator by Comparison

Method

43. Thread Measuring 0.17 mm to 7 mm 0.7 m Using Electronic

$

Wires Comparator by Comparison

Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 8 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

44. Cylindrical Setting Upto 100 mm 1.0 µm Using Slip Gauge Set &

Master / Parallel Electronic Comparator

$

Mandrel Sine center by

(Variation in Diameter / Comparison Method

Total Run Out)

45. Electronic Probe with

DRO / Lever Type

$

Probe

L.C.: 0.00001 mm Upto 25 mm 0.4 m Using Slip Gauge Set

L.C.:0.001 mm Upto 25 mm 3.0 m by Comparison Method

46. Caliper Checker / 0 to 1000 mm 5.5 m Using Slip Gauge Set,

Check Master / 0 to 600 mm 3.5 m length Bar & Single Axis

Step Gauge / Machine

Depth Micro checker/ by Comparison Method

Internal Micro

$

Checker

47. Floating Carriage Dia

$

Measuring M/C

L.C. : 0.1 m, 0.2 m, Upto 200 mm 1.7 m Using Cylindrical Master,

1 m Electronic Comparator &

Parallel Mandrels

by Comparison Method

48. Dial Calibration Tester

$

/ Micrometer Head

L.C. : 0.1 m, 0.2 m, Upto 25 mm 0.8 m Using Electronic

1 m Comparator

by Comparison Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 9 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

49. Single Axis Measuring upto 400 mm 0.3 + (3xL) m Using Slip Gauge Set,

M/C / Length L is in Meter length Bar by Comparison

Measuring M/C , Method

Universal Measuring

M/C , Horizontal

$

Metroscope

50. Vertical Single Axis

Measuring Machine /

Electronic Height

$

Gauge 1.5 + (3xL) m Using Slip Gauge Set,

L.C. : 0.1 / 0.5 /1 m 0 to 1000 mm Where L is in Meter length Bar by Comparison

Linearity Method

Squareness

51. Tape & Scale 0 to 1000 mm 6.1 m Using Slip Gauge Set,

$

Calibrator length Bar

52. Video Measuring 0 to 300 mm 3.8 m Using Glass scale

$

Machine (X,Y,

Z Axis) 0 to 300 mm 1.3 m Using Slip Gauge Set &

L.C. : 0.1 / 1 / 5 / 10 Long Slips

m 0 t0 360 degree 14.31 Sec Using Angle Graticule

53. Gauge Block

$

Calibrator

L.C. : 0.01 m 0 to 100 mm 0.07 m Using Gauge Block ‘Grade

“K”

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 10 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

$

54. Linear Glass Scale Upto 300 mm 2.5 m Using Length Measuring

(Graticule / Glass Grid) M/c Vision Measuring

Machine by Comparison

Method

55. Spirit Level / Frame

$

Level

L.C. :0.01 mm / Meter 0 to 400 mm 2.5 m Using Electronics Probe

(Base Length) Level Calibrator by

Comparison Method

$

56. Electronic Level

L.C. : 0.001 mm/Meter 0 to 400 mm 1.1 m Using Electronics Probe

(Base Length) Level Calibrator by

Comparison Method

57. Sine Bar / Sine 0 to 300 mm 5.5 m Using Electronic

$

Centre Comparator

0 to 90 deg 18.7 sec Slip Gauge Set, Angle

Gauge & Single Axis

Machine by Comparison

Method

$

58. Angle Gauges Upto 90 deg 14.0 sec Using Electronic Comp.

Slip Gauge Set, Sine Bar

by Comparison Method

$

59. Angle Graticule 0° to 360° 73.8 sec Using Vision Measuring

( Scale) Machine by Comparison

Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 11 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

60. Cylinder Square / Upto 600 mm 6.1 m Using Master Granite L-

$

Granite Square Square & Electronic

(Squareness) Comparator by

Comparison Method

$

61. Gauge Block 0.5 mm to 25 mm 0.12 m Using Slip Gauges &

Central Length 25mm to 50 mm 0.12 m Slip Gauge Comparator by

Deviation 50mm to 75 mm 0.15 m Comparison Method

Parallelism 75 mm to 100 mm 0.17 m

62. Long Slip Gauges/ Upto 150 mm 0.80 m Using Electronic

$

Length Bars 150 mm to 300 mm 1.50 m Comparator & Length Bar

300 mm to 400 mm 1.80 m by Comparison Method

400 mm to 700 mm 2.60 m

700 mm to 1000 mm 3.60 m

$

63. Optical Flat – Type A Up to 100 mm 0.34 m Using Master Flat &

(Flatness ) Monochromatic Light

64. Optical Parallels – Up to 100 mm 0.7 m Using Master Flat &

$

Type B Monochromatic Light

(Flatness , Parallelism) Source & Two Probe

Comparator

65. Surface Roughness

$

Specimen

Ra Only Ra 8.5 % Using Roughness Tester

66. Surface Roughness

$

Tester Using Surface Roughness

Ra Only Ra 6.5 % Masters

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 12 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

♣

67. Straight Edge Upto 5000 mm 3.0 L / 150 m Using Electronic Level &

L is in mm Electronic Comparator by

Comparison Method

68. Single Axis Measuring upto 400 mm 0.3 + (3xL) m Using Slip Gauge Set,

M/C / Length L is in Meter length Bar by Comparison

Measuring M/C , Method

Universal Measuring

M/C , Horizontal

♣

Metroscope

69. Vertical Single Axis

Measuring Machine /

Electronic Height

♣

Gauge

L.C. : 0.1 / 0.5 /1 m 0 to 1000 mm 1.5 + (3xL) m Using Slip Gauge Set,

Linearity Where L is in Meter length Bar by Comparison

Squareness Method

♣

70. Surface Plate 5000 X 5000 mm 1.5 (L+W/125) m Using Electronic Level

Where L is in mm

71. Tape & Scale 0 to 1000 mm 6.1 m Using Slip Gauge Set,

♣

Calibrator length Bar by Comparison

Method

72. Video Measuring 0 to 300 mm 3.8 m Using Glass scale

♣

Machine

( X , Y , Z Axis) 0 to 300 mm 1.3 m Using Slip Gauge Set &

L.C. : 0.1 / 1 / 5 / 10 Long Slips

m 0 t0 360 degree 14.31 Sec Using Angle Graticule

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 13 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

73. Gauge Block

♣

Calibrator

L.C. : 0.01 m 0 to 100 mm 0.07 m Using Gauge Block ‘Grade

“K”

♣

74. Bench Centre Upto 500 mm 8.5 m Using Parallel Mandrel &

(Center Alignment) Leaver Dial Gauge

II. DIMENSION (PRECISION INSTRUMENTS)

1. Profile Projector/

Tool Makers

Microscope / Optical Linear X,Y Axis 6.3 m Using Glass scale

♣

Microscope 0 - 300 mm

L.C. 0.1 / 1 / 5 / 10 m Angular 1.2 Min Using Angle Graticule

L.C. 1 / 5 min. 0 to 360 deg

Magnification 0.2 % Using Digital Caliper

Upto 100 X

2. 3-D Co Ordinate Using Slip Gauge Set,

♣

Measuring Machine Up to 1000 mm 2.0 + (5xL) m length Bar & Reference

(Linear and L is in Meter sphere by Comparison

Volumetric) Method

MOBILE FACILITY

$

1. Caliper Using Caliper Checker,

(Vernier, Dial, Digital) & Slip Gauge Set by

L. C. 0.01 mm Upto 600 mm 19.0 m Comparison Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 14 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Depth Gauge / Depth

$

Micrometer

L.C. : 0.01 / 0.001 mm Up to 300 mm 9.0 m Using Slip Gauge Set,

& Long Slip Gauge by

Comparison Method

$

3. Height Gauge

(Vernier, Dial, Digital)

L. C. 0.01 mm Upto 600 mm 18.0 m Using Caliper Checker,

& Slip Gauge Set by

Comparison Method

$

4. External Micrometer

(Inclusive of Point,

Blade, Ball, Flange,

Groove, Disc )

L.C. : 0.001 mm Upto 150 mm 1.7 m Using Slip Gauge Set,

L.C.: 0.001 / 0.01 mm Upto 600 mm 7.0 m Mic Check Set

& Long Slips by

Comparison Method

5. Internal Micrometer /

$

Inside Dial Caliper Using Slip Gauge Set,

L.C. : 0.001 / 0.01 / Upto 600 mm 15.0 m & Long Slip Gauge &

0.025 mm(Extension Electronic Comparator by

not more than 400 Comparison Method

mm)

$

6. Dial Gauge Plunger Using Dial Calibration

L.C. : 0.001 / 0.01 mm Upto 50 mm 3.5 m Tester by Comparison

Method

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 15 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

$

7. Dial Gauge Lever

L.C. : 0.001 / 0.01 mm Upto 2 mm 3.5 m Using Dial Calibration

Tester by Comparison

Method

$

8. Bore Dial Gauge

(Transmission

Accuracy Check Only)

L.C. : 0.001 / 0.01 mm Upto 2 mm 3.5 m Using Dial Calibration

Tester by Comparison

Method

9. Plain Plug Gauge 0 to 100 mm 1.8 m Using Slip Gauge Set,

/Setting Plug Paddle 100 mm to 300 mm 3.9 m & Long Slip Gauge &

Gauge / Precision 300 mm to 600 mm 7.0 m Electronic Comparator by

Balls / Measuring Pins Comparison Method

$

/ Width Gauge

10. Snap Gauge / 0 to 100 mm 1.3 m Using Slip Gauge Set,

Setting Gauge / 100 mm to 300 mm 3.6 m & Long Slip Gauge by

Gap Gauge (C&I

$

300 mm to 600 mm 7.4 m Comparison Method

Type)

11. Micrometer Setting 25 mm to 100 mm 1.8 m Using Slip Gauge Set,

$

Standard 100 mm to 600 mm 7.0 m & Long Slip Gauge &

Electronic Comparator by

Comparison Method

$

12. Feeler Gauge Upto 2 mm 1.8 m Using Digital Micrometer

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 16 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

13. Dial Thickness Gauge

$

/ Dial Snap Gauge

L.C. : 0.001 mm upto 200 mm 4.0 m Using Slip Gauges bya

Comparison Method

14. Angle Protractor /

$

Combination Set

0

L.C. : 5 minute 0 – 90 - 0 4.0 min of arc Using Angle Gauges by

0

L.C. : 1 Deg. 0 – 90 - 0 35.0 min of arc Comparison Method

II. SPEED AND ACCELERATION

1. Tachometer / RPM Upto 100000 RPM 0.5% Using Indexing Table

$

Meter

( Non Contact Type)

III. ACOUSTICS

$

1. Sound Level Meter 94 dB to 114 dB 0.41 dB Using Sound Level

Calibrator

IV. PRESSURE INDICATING DEVICES

1. Pressure Gauges/ 0 to 10 bar 0.014 bar Using Digital gauge/

Indicator Pneumatic pump

Switch/Transmitters/

Manometers/Transduc 0 to 100 bar 0.32 bar Using Digital Indicator with

er With Indicator/ Test 0 to 700 bar 1.39 bar transducer

$

Gauge

(Pneumatic and 0 to 1000 bar 6.14 bar Using Digital gauge/ water

Hydraulic) based Comparator

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 17 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Vacuum Gauges / (-)0.80 to 0 bar 0.013 bar Using Digital gauge/

Indicator/Transmitter Pneumatic pump

Switch -Analogue &

$

Digital Type

3. Pressure Gauges/ 0 to 10 bar 0.014 bar Using Digital gauge/

Indicator Pneumatic pump

Switch/Transmitters/

Manometers/ 0 to 25 kg/cm² 0.07 kg/cm2 Using Test Gauge/

Transducer With 0 to 100 kg/cm² 0.14 kg/cm2 water based Comparator

♣

Indicator

(Pneumatic and 0 to 700 bar 0.22 bar Using Digital gauge/ water

Hydraulic) 0 to 1000 bar 0.15 bar based Comparator

4. Vacuum Gauges / (-)0.80 to 0 bar 0.013 bar Using Digital gauge/

Indicator/Transmitter Pneumatic pump

Switch -Analogue &

♣

Digital Type

V. TORQUE MEASURING DEVICES

1. Torque Transducer/ 1 Nm to 1000 Nm 0.29 % Using Torque Calibration

Torque Sensor/ Rig and Newtonian Dead

Torque Meter/ Torque Weights:

Tester/Torque

Measuring

Devices/Rotary Torque

$

Sensors

Mohit Kaushik Avijit Das

Convenor Program Manager

Laboratory Sankalp Hi-Tech Corporation, 7/3, "Ramsetu", Ramkrishna Nagar,

Ambad- Satpur Link Road, Ambad, Nashik, Maharashtra

Accreditation Standard ISO/IEC 17025: 2005

Certificate Number CC-2875 Page 18 of 18

Validity 26.10.2018 to 25.10.2020 Last Amended on 19.11.2018

Sl. Quantity Measured / Range/Frequency *Calibration Measurement Remarks

Instrument Capability (±)

2. Torque Wrench / 1 Nm to 1000 Nm 1.31 % Using Digital Torque

Torque Meter/ Digital Tester:

Torque

Wrench/Torque Screw

$

Driver

A. Torque Indicator

Type I (A,B,C,D,E)

B.Torque Setting Type

II

( A,B,C,D,E,F,G)

* Measurement Capability is expressed as an uncertainty () at a confidence probability of 95%

$

Only in Permanent Laboratory

♣

Only for Site Calibration

#

The laboratory is also capable for site calibration however, the uncertainty at site depends on the

prevailing actual environmental conditions and master equipment used.

Φ

Laboratory can also calibrate instruments/devices of coarser resolution / least count within the

accredited range using same reference standard/ master equipment under the scope of accreditation.

Mohit Kaushik Avijit Das

Convenor Program Manager

Vous aimerez peut-être aussi

- 24.scope Location 1 CC-2833Document4 pages24.scope Location 1 CC-2833Ravichandran DPas encore d'évaluation

- Reliance 333Document7 pagesReliance 333Ravichandran DPas encore d'évaluation

- Laboratory Calibration Capabilities for Measuring InstrumentsDocument12 pagesLaboratory Calibration Capabilities for Measuring InstrumentsVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory Mikronix Associates Calibration CapabilitiesDocument3 pagesLaboratory Mikronix Associates Calibration CapabilitiesrohanmanimaniPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory Accurate Instruments Calibration CapabilitiesDocument8 pagesLaboratory Accurate Instruments Calibration CapabilitiesRavichandran DPas encore d'évaluation

- G.B.Central Laboratory, TrichyDocument3 pagesG.B.Central Laboratory, TrichyRavichandran DPas encore d'évaluation

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DPas encore d'évaluation

- Khosaca Calibration Lab, Chennai ISO/IEC 17025 certificateDocument4 pagesKhosaca Calibration Lab, Chennai ISO/IEC 17025 certificateRavichandran DPas encore d'évaluation

- Laboratory Calibration Services ISO/IEC 17025:2005Document6 pagesLaboratory Calibration Services ISO/IEC 17025:2005Ravichandran DPas encore d'évaluation

- 3.scope Location 1 CC-2706Document8 pages3.scope Location 1 CC-2706Ravichandran DPas encore d'évaluation

- CMTI ScopeDocument13 pagesCMTI ScopeRavichandran DPas encore d'évaluation

- Using Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651Document13 pagesUsing Gauge Block Set, Length Bar & Caliper Checker by Comparison Method As Per IS 3651rohanmanimaniPas encore d'évaluation

- Accurate Chennai ScopeDocument7 pagesAccurate Chennai ScopeRavichandran DPas encore d'évaluation

- Perfect 684Document4 pagesPerfect 684Ravichandran DPas encore d'évaluation

- Indoshell - C - 0400Document2 pagesIndoshell - C - 0400Ravichandran DPas encore d'évaluation

- ISO 17025 Accredited Laboratory Calibration Certification BMI IndiaDocument2 pagesISO 17025 Accredited Laboratory Calibration Certification BMI IndiarohanmanimaniPas encore d'évaluation

- Measured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksDocument4 pagesMeasured Qty / Instrument Range Calibration Measurement Capability ( ) RemarksRavichandran DPas encore d'évaluation

- FIE Research InstituteDocument8 pagesFIE Research InstituteAcutePas encore d'évaluation

- Sitarc - C - 0135Document7 pagesSitarc - C - 0135Ravichandran DPas encore d'évaluation

- Metrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Document5 pagesMetrology Labortory Tata Motors Limited Jamshedpur Scope 14594876972533Gowtham Raj KPas encore d'évaluation

- Laboratory Calibration Centre AccreditationDocument8 pagesLaboratory Calibration Centre AccreditationRavichandran DPas encore d'évaluation

- Accurate Pune.C0052Document12 pagesAccurate Pune.C0052Ravichandran DPas encore d'évaluation

- Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksDocument3 pagesQuantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) % RemarksrohanmanimaniPas encore d'évaluation

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksDocument8 pagesQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability RemarksrohanmanimaniPas encore d'évaluation

- Perfect 243 - ChennaiDocument11 pagesPerfect 243 - ChennaiRavichandran DPas encore d'évaluation

- Northlab HosurDocument25 pagesNorthlab HosurVikram BillalPas encore d'évaluation

- Scope-CC-2331Document5 pagesScope-CC-2331snsarangi06Pas encore d'évaluation

- Laboratory NameDocument13 pagesLaboratory NameVikram BillalPas encore d'évaluation

- 2658Document7 pages2658rohanmanimaniPas encore d'évaluation

- 5666 01Document18 pages5666 01Laura MarquezPas encore d'évaluation

- ISO/IEC 17025 Calibration Services AccreditationDocument15 pagesISO/IEC 17025 Calibration Services AccreditationDhinagaran APas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJIPas encore d'évaluation

- CL 222 CertDocument5 pagesCL 222 CertS SHALUPas encore d'évaluation

- Scope CC 3131Document6 pagesScope CC 3131Assistant Director KHRIPas encore d'évaluation

- Micrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaDocument1 pageMicrometers - Measurement System Types and Characteristics - Measurement Fundamentals - KEYENCE AmericaTatsPas encore d'évaluation

- 6092 01Document8 pages6092 01Laura MarquezPas encore d'évaluation

- Test CMM 2016 Hand-OutDocument42 pagesTest CMM 2016 Hand-OutHernanda ImawanPas encore d'évaluation

- Flaw Detector Scope Sample PG 4-4150-01Document22 pagesFlaw Detector Scope Sample PG 4-4150-01ebbasinghPas encore d'évaluation

- SCS - ScopeDocument22 pagesSCS - ScopeRakesh TrentiyaPas encore d'évaluation

- AvijitDocument2 pagesAvijitBAlaPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument4 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniPas encore d'évaluation

- Metravi PRO 7273 10A Microohms Meter Catalogue WebDocument3 pagesMetravi PRO 7273 10A Microohms Meter Catalogue WebGaurav kumarPas encore d'évaluation

- UVDocument4 pagesUVJavier CarrizoPas encore d'évaluation

- Mitutoyo Singapur ScopeDocument5 pagesMitutoyo Singapur ScopeADROIT ROHMATTULLOHPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument9 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksSyarif MaulanaPas encore d'évaluation

- Lab Scope of SigmaDocument2 pagesLab Scope of SigmaVivek katariaPas encore d'évaluation

- 4286 04Document18 pages4286 04carlos ricardo herrera castilloPas encore d'évaluation

- Laboratory Alfa Machine Tools ISO/IEC 17025 CalibrationDocument3 pagesLaboratory Alfa Machine Tools ISO/IEC 17025 CalibrationRavichandran DPas encore d'évaluation

- 3467 01Document20 pages3467 01Laura MarquezPas encore d'évaluation

- 3467 01Document19 pages3467 01Sheik Mohamed AliPas encore d'évaluation

- Global Insignia For Technical Services Establishment: This Is To Attest ThatDocument3 pagesGlobal Insignia For Technical Services Establishment: This Is To Attest ThatAlmansoori MPSPas encore d'évaluation

- 41.scope Location 1 CC-2792Document9 pages41.scope Location 1 CC-2792Ravichandran DPas encore d'évaluation

- Scope CC 2751Document37 pagesScope CC 2751Vishal ShindePas encore d'évaluation

- 75عDocument3 pages75عFikry FaradinnaPas encore d'évaluation

- CL 221 CertDocument4 pagesCL 221 CertS SHALUPas encore d'évaluation

- Scope CC 3287Document28 pagesScope CC 3287Indranath MoulickPas encore d'évaluation

- Scope CC 3399Document10 pagesScope CC 3399dheeraj chawlaPas encore d'évaluation

- Position Sensing: Angle and Distance Measurement for EngineersD'EverandPosition Sensing: Angle and Distance Measurement for EngineersPas encore d'évaluation

- Questionnaire for mass, balance and volume calibrationDocument3 pagesQuestionnaire for mass, balance and volume calibrationVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Lab Calibration CertificationDocument24 pagesLab Calibration CertificationVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- ZCZCXZDocument17 pagesZCZCXZVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Institute For DesignDocument48 pagesInstitute For DesignVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- ZCZCXZDocument17 pagesZCZCXZVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument25 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Accurate Engineering Co.Document7 pagesAccurate Engineering Co.VAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument19 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- ZXX ZXDocument35 pagesZXX ZXVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDocument14 pagesLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sushma Industries Calibration CentreDocument11 pagesSushma Industries Calibration CentreVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Institute For DesignDocument48 pagesInstitute For DesignVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Tempsens Calibration CentreDocument5 pagesTempsens Calibration CentreVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Institute For Design of Electrical Measuring InstrumentsDocument48 pagesInstitute For Design of Electrical Measuring InstrumentsVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Godrej & Boyce PDFDocument43 pagesGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory Calibration Centre ISO Accreditation CertificateDocument25 pagesLaboratory Calibration Centre ISO Accreditation CertificateVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sri Gokul Cal Lab.Document4 pagesSri Gokul Cal Lab.VAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Indigo Passenger (S) : Delhi MumbaiDocument2 pagesIndigo Passenger (S) : Delhi MumbaiVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Godrej & Boyce PDFDocument43 pagesGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Automotive Research Association of IndiDocument31 pagesAutomotive Research Association of IndiVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Hi Tech Calibration Services PDFDocument28 pagesHi Tech Calibration Services PDFVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument18 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Godrej & Boyce PDFDocument43 pagesGodrej & Boyce PDFVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Laboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraDocument14 pagesLaboratory: Acme Enterprises, 28 Saraswati, Ayodhya Nagar, Nagpur, MaharashtraVAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Accurate Engineering Co.Document7 pagesAccurate Engineering Co.VAIBHAV INSTRUMENTATIONPas encore d'évaluation

- Metrology Notes 2Document17 pagesMetrology Notes 2Chris MuturiPas encore d'évaluation

- 113 5Document15 pages113 5Eduardo Gutierrez CastroPas encore d'évaluation

- Caleffi: Valvole Di BilanciamentoDocument16 pagesCaleffi: Valvole Di BilanciamentoThomas GregantiPas encore d'évaluation

- Layout ReportDocument1 pageLayout ReportMaheshPas encore d'évaluation

- Measure Precisely with a Vernier Caliper and MicrometerDocument3 pagesMeasure Precisely with a Vernier Caliper and MicrometerEduardo MottaPas encore d'évaluation

- Guide to Measuring Physical Quantities and UnitsDocument23 pagesGuide to Measuring Physical Quantities and UnitsshuganeshPas encore d'évaluation

- Catenary Wire SpecificationDocument21 pagesCatenary Wire Specificationhardeep08Pas encore d'évaluation

- Dimensional Calibration: Masters, Tool and Gauge CalibrationDocument2 pagesDimensional Calibration: Masters, Tool and Gauge CalibrationMohammedPas encore d'évaluation

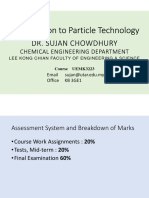

- Introduction To Particle Technology: Dr. Sujan ChowdhuryDocument27 pagesIntroduction To Particle Technology: Dr. Sujan ChowdhuryAh WenPas encore d'évaluation

- Mitutoyo PDFDocument629 pagesMitutoyo PDFcchcristiPas encore d'évaluation

- Installation, Operation and Maintenance Instructions Stainless Steel, Liquid Ring Vacuum PumpsDocument28 pagesInstallation, Operation and Maintenance Instructions Stainless Steel, Liquid Ring Vacuum PumpspinplataPas encore d'évaluation

- RCBS 2013 Catalog and Parts ListDocument37 pagesRCBS 2013 Catalog and Parts ListRendabPas encore d'évaluation

- Zeiss Micura CMMDocument8 pagesZeiss Micura CMMNg Wei LihPas encore d'évaluation

- SSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDocument11 pagesSSPC-PA 2 Procedure For Determining Conformance To Dry Coating Thickness RequirementsDavid Aliaga Sayas100% (1)

- Machinery RepairmanDocument474 pagesMachinery RepairmanAllisen Earls100% (1)

- T208 Measurement Uncertainty Associated in Verification Testing of Indicating Measuring InstrumentsDocument20 pagesT208 Measurement Uncertainty Associated in Verification Testing of Indicating Measuring InstrumentsAlex LesczinskyPas encore d'évaluation

- Calibration error acceptance criteria tableDocument2 pagesCalibration error acceptance criteria tablesajithv7890% (41)

- Experiment 1 Physics FinalDocument8 pagesExperiment 1 Physics FinalBenjo DimaculanganPas encore d'évaluation

- Master List of InstrumentsDocument2 pagesMaster List of InstrumentsAmandeep SinghPas encore d'évaluation

- EXPERIMENT-2: Measurements of Mass, Volume and Density: ObjectivesDocument8 pagesEXPERIMENT-2: Measurements of Mass, Volume and Density: ObjectivesElam KibetPas encore d'évaluation

- Grade 12 General Physics 1Document4 pagesGrade 12 General Physics 1john emerson YabutPas encore d'évaluation

- Pile Load TestDocument8 pagesPile Load TestNgoc Ba NguyenPas encore d'évaluation

- 01 ISA-Skill RequirementDocument1 page01 ISA-Skill RequirementJack LaksmanaPas encore d'évaluation

- Curriculam Vitae: Shiv SinghDocument3 pagesCurriculam Vitae: Shiv SinghSandeepPas encore d'évaluation

- Measurement of Screw ParametersDocument2 pagesMeasurement of Screw Parametersnavneetkpatil8409Pas encore d'évaluation

- D4403 - 05Document10 pagesD4403 - 05Jesus Luis Arce GuillermoPas encore d'évaluation

- Assignment 1-ADocument9 pagesAssignment 1-AHassan YounasPas encore d'évaluation

- Frequently Examined Questions For Physics PracticalDocument2 pagesFrequently Examined Questions For Physics PracticalShuchi HossainPas encore d'évaluation

- Motorcycle Powertrain Diagnosis GuideDocument7 pagesMotorcycle Powertrain Diagnosis GuideNurul Huda Ali0% (1)

- Sub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionDocument3 pagesSub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionJosue FishPas encore d'évaluation